The following provides more detail on each of the above steps.

1. Establish communication with the sensor.

The sensor broadcasts UDP packets. By using a network monitoring tool, such as Wireshark, you can capture and observe the

packets as they are generated by the sensor. See Appendix for the UDP packet format. The default source IP address for the

sensor is 192.168.3.043, and the destination IP address is 192.168.3.255. To change these IP addresses, see page 11.

2. Create an internal calibration table either from the calibration data included in-stream from the sensor or from the included

db.xml data file.

This table must be built and stored internal to the point-cloud processing software. The easiest and most reliable way to build the

calibration table is by reading the calibration data directly from the UDP data packets. A MatLab example of reading and building

such a table can be found in Appendix D and on the CD included with the sensor named CALTABLEBUILD.m.

Alternatively, the calibration data can be found in the included db.xml file found on the CD included with the sensor. A description of the

calibration data is shown in the following table.

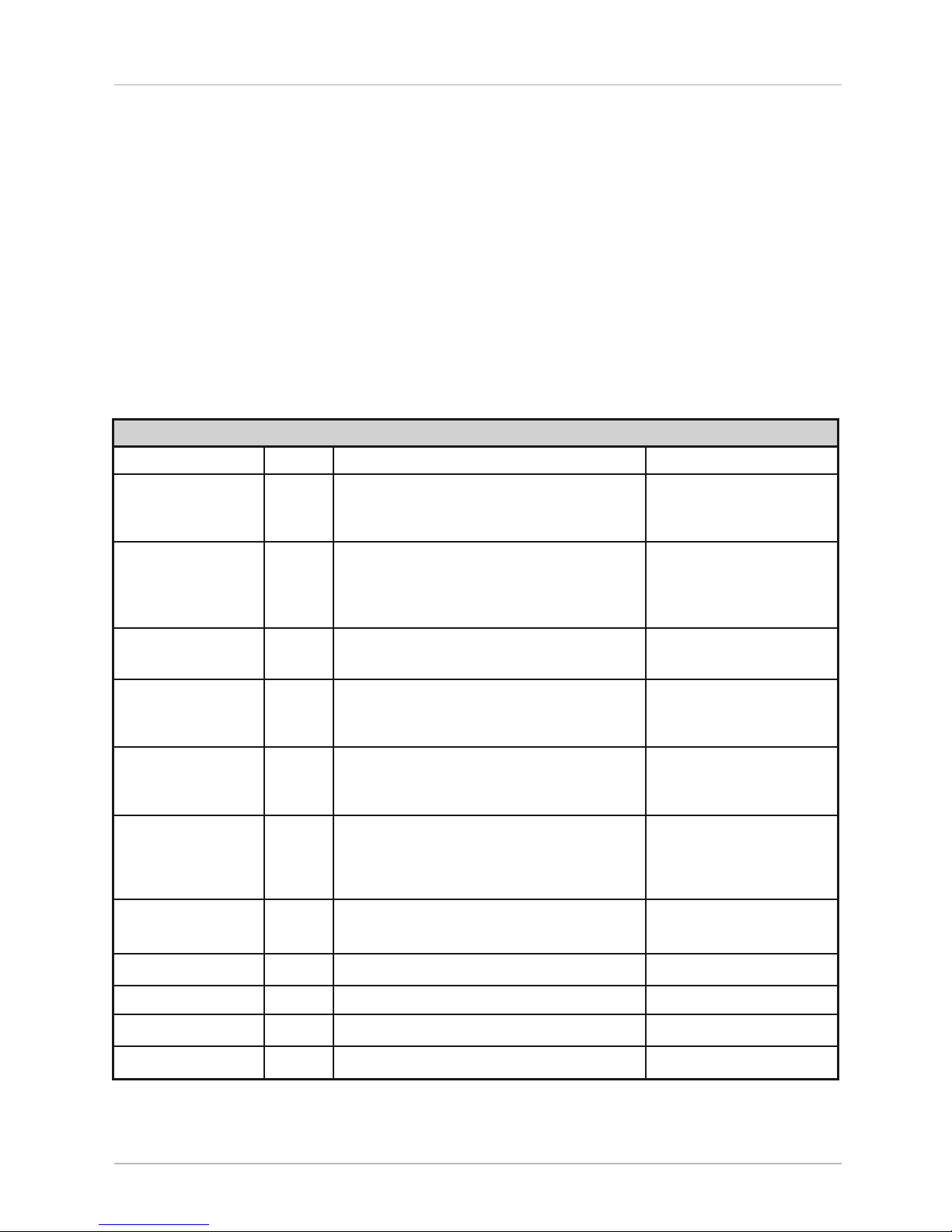

db.xml Cal brat on Parameters

Parameter Unit Description Values

rotCorrection degree The rotational correction angle for each laser, Positive factors rotate to the left.

as viewed from the back of the unit. Negative values rotate to

the right.

vertCorrection degree The vertical correction angle for each laser, Positive values have the laser

as viewed from the back of the unit. pointing up.

Negative values have the laser

pointing down.

distCorrection cm Far distance correction of each laser distance Add directly to the distance value

due to minor laser parts’ variances. read in the packet.

distCorrectionX cm Close distance correction in X of each laser due to

minor laser parts variances interpolated with far

distance correction then applied to measurement in X.

distCorrectionY cm Close distance correction in Y of each laser due to

minor laser parts variances interpolated with far

distance correction then applied to measurement in Y.

vertOffsetCorrection cm The height of each laser as measured from One fixed value for all upper

the bottom of the base. block lasers.

Another fixed value for all lower

block lasers.

horizOffsetCorrection cm The horizontal offset of each laser Fixed positive or negative value

as viewed from the back of the laser. for all lasers.

Maximum Intensity Value from 0 to 255. Usually 255.

Minimum Intensity Value from 0 to 255. Usually 0.

Focal Distance Maximum intensity distance.

Focal Slope The control intensity amount.

The calibration table, once assembled, contains 64 instances of the calibration values shown in the table above to interpret the packet data to

calculate each point’s position in 3D space. Use the first 32 points for the upper block and the second 32 points for the lower block. The

rotational info found in the packet header is used to determine the packets position with respect to the 360° horizontal field of view.

[ 7 ]

HDL-64E S2 and S2.1 User’s Manual