6245

-

6-13-00C

8-18-00D

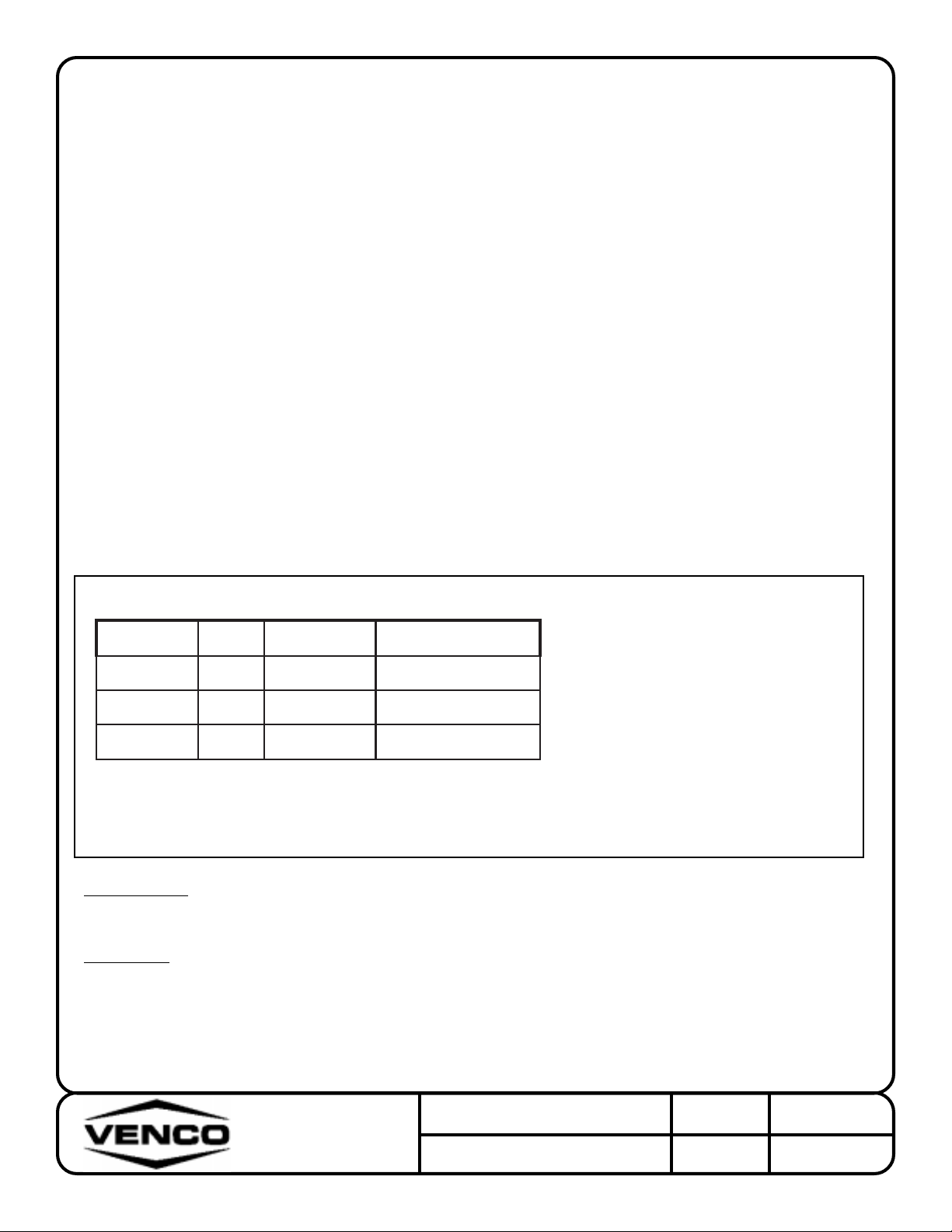

TABLE OF CONTENTS

VP / VC - 6D SUPERCEDES

TITLE DATE SECTION

TABLE OF CONTENTS

VP / VC - 6D MANUAL

PAGE DESCRIPTION REF.NO.

1 GENERALINFORMATION ...................................................... 6246

2 PREPARATION-MOUNTINGHOIST ........................................ 6241

3 UPPERNEST& REARHINGES .............................................. 6248

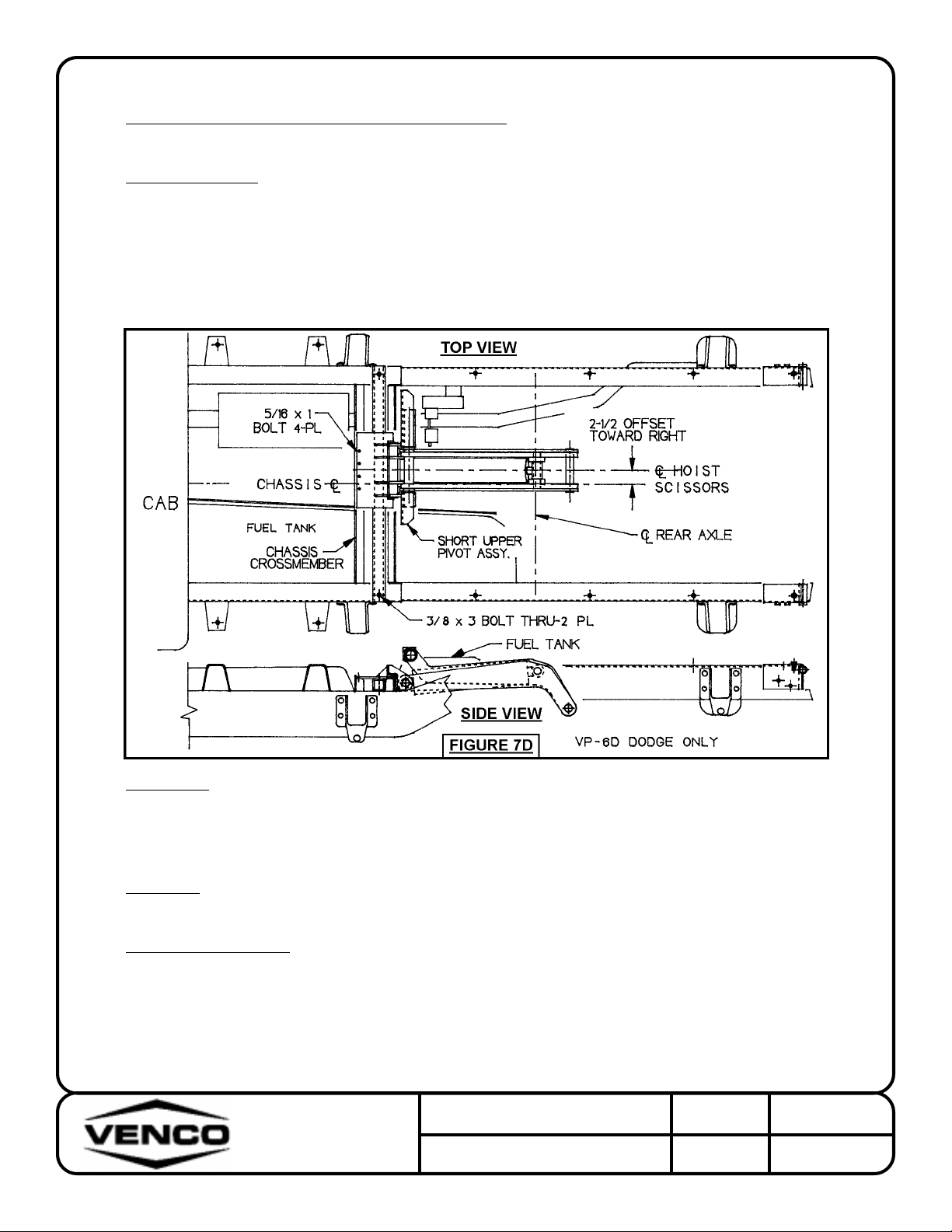

4 HOISTFRAMEONCHASSIS .................................................. 6242

5 LONGITUDINALSUPPORTS-OPTION .................................... 6244

6 HYDRAULICS ......................................................................... 6122

7 EDHOISTPOWERUNIT(BI-ROT) ........................................... 6096

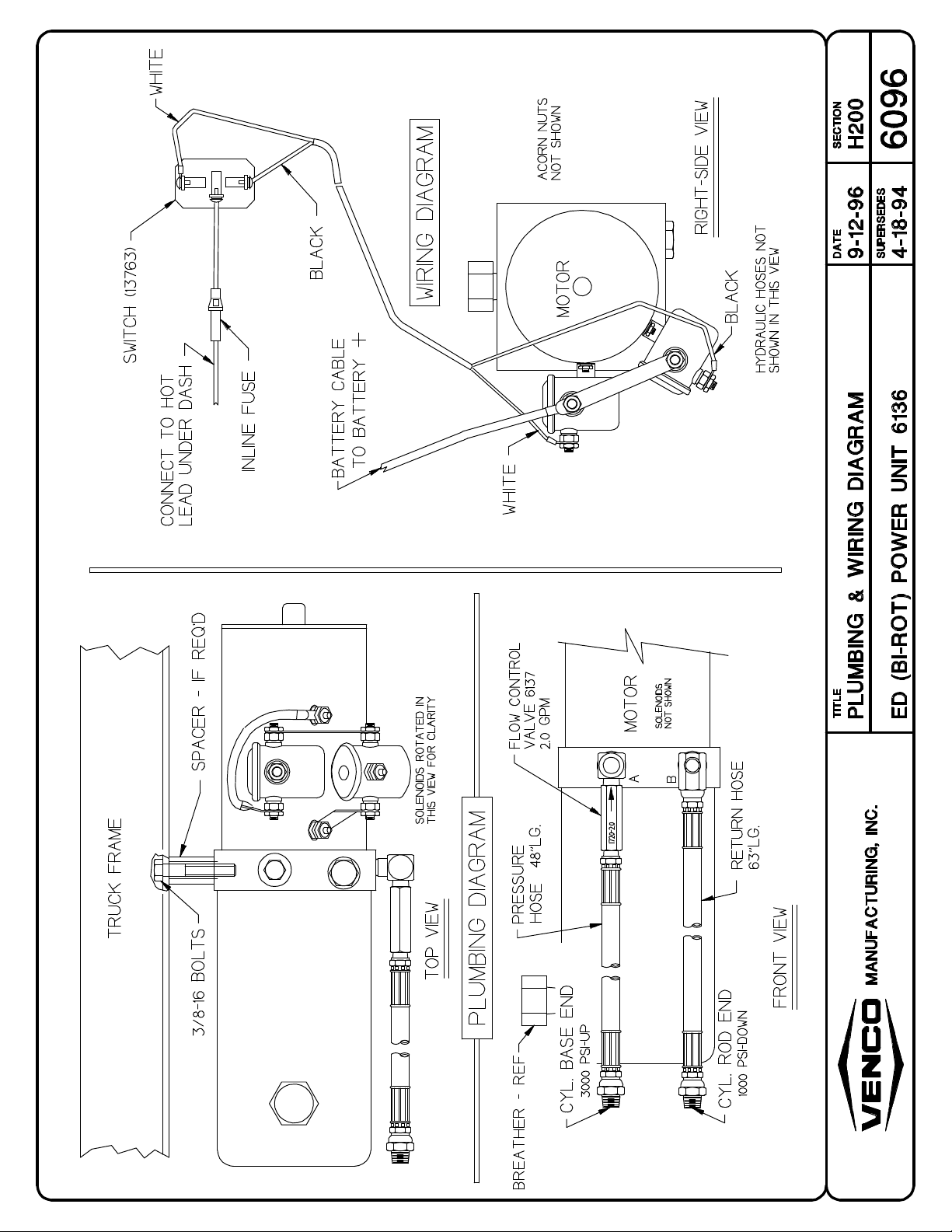

8 6425 ED POWER UNIT PLUMBING & WIRING ......................... 6493

9 6425EDPOWERUNITW/PUSHBUTTONINSTALLATION........ 6500

10 6426 ES POWER UNIT ............................................................ 6506

11 6426 ES POWER UNIT W/ PUSH BUTTON CONTOL ................. 6507

12 RESERVOIRFILLING ............................................................. 416140

13 ESHOISTPOWERUNIT ......................................................... 6133B

14 DASH CONTROL SWITCH ....................................................... 6123

15 DASHCONTROLDRAWING ................................................... 40124

16 UPPERNEST PIVOTS- BODY ............................................... 6243

17 UPPERNEST PIVOTS-UPPER NEST .................................... 6251

18 FUELFILLERTUBE-SUPPORT ............................................. 6252

19 BUMPERBRACKETS ............................................................ 6072

20 LUBRICATION/SERVICECHART ........................................... 40260

21 BUMPER,GREASEFITTINGS,DECALS ................................. 6118

22 CONTRACTORREARHINGE&UPPERPIVOTS ..................... 6250

23 HOISTREPLACEMENTPARTSDRAWING .............................. 6255

24 HOISTREPLACEMENTPARTSLIST ....................................... 6256

25 FENNERESPARTSLIST ....................................................... 40058-2

26 MTEED(BI-ROT)6136POWERUNIT .................................... 6097

27 REPLACEMENT PARTS DWG - ED POWER UNIT .................... 6486

28 REPLACEMENT PARTS LIST - ED POWER UNIT .................... 6487

29 REPLACEMENT PARTS DRAWING ES POWER UNIT .............. 6508

30 REPLACEMENT PARTS LIST ES POWER UNIT ....................... 6509

31 WARRANTYPAGE ................................................................ 12-00073

-PDECALSANDPACKAGEINCLUDES:

12524 CAUTIONSTANDCLEAR 2 PCS.

416052 CAUTIONDECAL 2 PCS.

6066 PLASTICBAG 1 PC.

12-00075 ENVELOPE 1 PC.

MANUFACTURING,INC.