GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

ALL OTHER FANS IN SERIES

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

LOW VOLTAGE WIRING

24v

FIRST FAN IN SERIES

LOW VOLTAGE WIRING

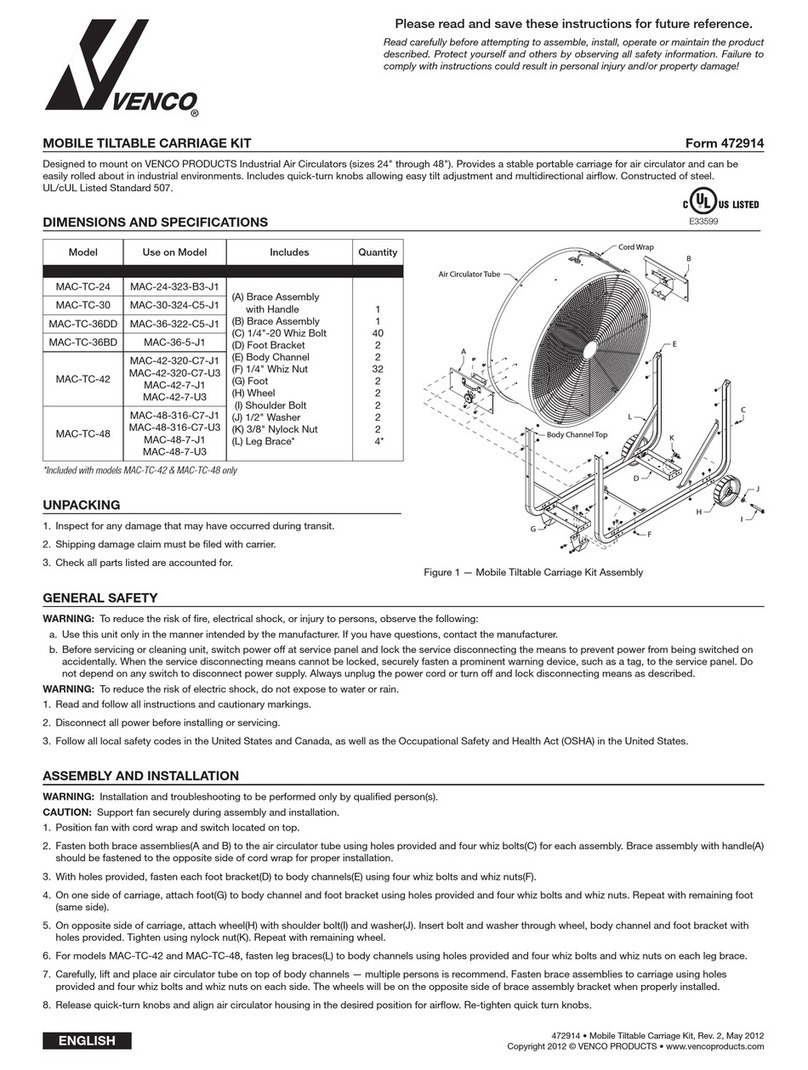

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

EF

FIRST FAN IN DAISY-CHAIN

MANUAL PAGES 36-37

NO VFD WIRING MODIFICATIONS REQUIRED

VERIFY VFD WIRING MATCHES

MODIFY DIP SWITCH BANKS 2 AND 3

AS SHOWN

STEP #10 - FAN NETWORKING

ALL REMAINING FANS IN DAISY-CHAIN

MANUAL PAGES 38-39

REMOVE WHITE/BROWN 24V WIRE AND CAP

VERIFY VFD WIRING MATCHES

MODIFY DIP SWITCH BANKS 2 AND 3

AS SHOWN

IMPORTANT: DO NOT REMOVE BROWN GND WIRE

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

ALL OTHER FANS IN SERIES

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

LOW VOLTAGE WIRING

24v

FIRST FAN IN SERIES

LOW VOLTAGE WIRING

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

DIPSWITCH BANK 2 SETTINGS DIPSWITCH BANK 3 SETTINGS

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1 ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

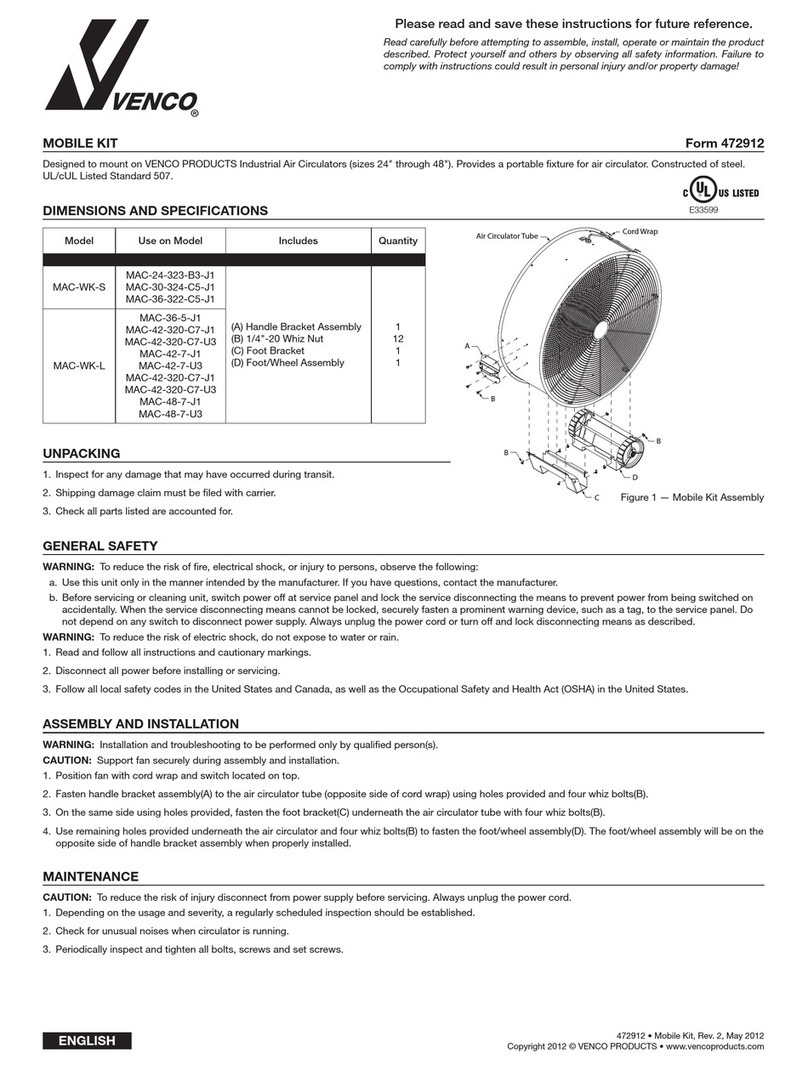

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

Fan

Number

Modbus

Address

Position

1

Position

2

Position

3

Position

4

Position

5

Position

6, 7, 8

N/A 1 Reserved for HVLS Fan Control

Do Not

Modify

1 2 On Off Off Off Off

2 3 Off On Off Off Off

3 4 On On Off Off Off

4 5 Off Off On Off Off

5 6 On Off On Off Off

6 7 Off On On Off Off

7 8 On On On Off Off

8 9 Off Off Off On Off

9 10 On Off Off On Off

10 11 Off On Off On Off

IMPORTANT: DO NOT MODIFY POSITIONS 6, 7, AND 8 ON

DIPSWITCH BANK 3. DEFAULT SETTINGS ARE ON, OFF, OFF

(UP, DOWN, DOWN)

Position

1

Position

2

Position

3

OFF ON ON

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1 ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

Position

1

Position

2

Position

3

OFF OFF OFF

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1

ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1 ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

Overhead Ceiling Fans8