COMBI VENDOR • 3532 | 1

INTRODUCTION

This manual contains instructions, service and installation guidelines for the 3W

COMBI Vendor. Please read this manual thoroughly and follow instructions. The

initial set-up of a vending machine is a very important step of insuring that the

equipment operates in a trouble-free manner.

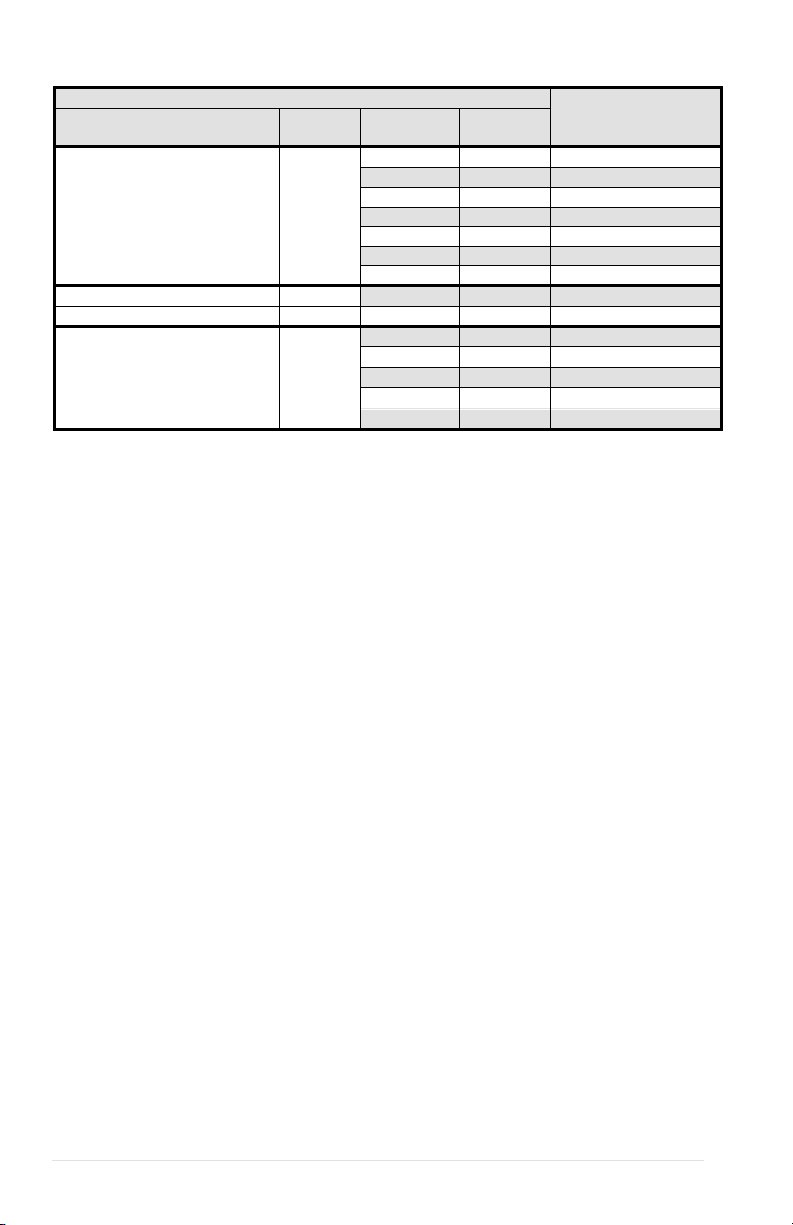

The 3W COMBI Vendor can be factory configured to have two

temperature compartments (top and bottom) in a single

vending machine separated by moveable air deflectors and

insulating barrier. The vending machine has an air duct that

runs up and down on the back inner wall of the cabinet. Each

compartment can have 3 moveable trays and a total of 6 trays

for the entire vending machine. The vending machine will

maintain 2°C (36°F) in the Top compartment and down to -

24°C (-12°F) in the bottom compartment at an ambient range

of 4.4°C-32°C (40°F-90°F). The temperature setting for both

compartments are set by the controller (program).

TOP

BOTTOM

The top compartment has a heater system to maintain constant temperature

across varying ambient temperatures. This consists of a heater, temperature

sensor, air circulating blower and relays

The bottom compartment has a temperature sensor and an insulated

refrigeration system. Cool air is drawn from the refrigeration system’s evaporator

coils through the air duct and is deflected into the bottom zone by a moveable air

deflector. There are openings in the bottom trays to allow air to circulate around

the products.

All programming of the pricing, vend functions and features are also done at the

controller. Changes can be made without any additional accessories or remote

parts. Selections can be priced individually from $00.00 to $655.35 in five cent

increments (US currency). Cash accountability records, total cash transactions,

total vend cycles performed by the vendor, information for individual selections,

complete rows or total machine can be compiled and used for inventory and

ordering records. Electrical malfunctions are recorded and displayed when the

vending machine is placed in the Service Mode. Non-functional motors or

selections are indicated. Each selection has an individual motor. Functional

selections will continue to operate if other motors become nonfunctional.

The vending sequence is "first-in, first-out" for each selection, permitting stock

rotation to maintain fresh products in the vending area.

Each 3W COMBI Vendor has the capability of supporting a "satellite" vending

machine, such as a direct wire CB300-SAT, or a USD satellite such as a CF-

1000. The satellite vendor utilizes the 3W COMBI Vendor’s existing controller,

coin mechanism, bill validator and keypad to perform the vend functions they

require. For details on the satellite vendor, refer to the Service Manual pertaining

to the specific vendor for installation instructions.