B-4

SAFETY

General Safety Procedures

for Ventrac Tractors, Attachments, & Accessories

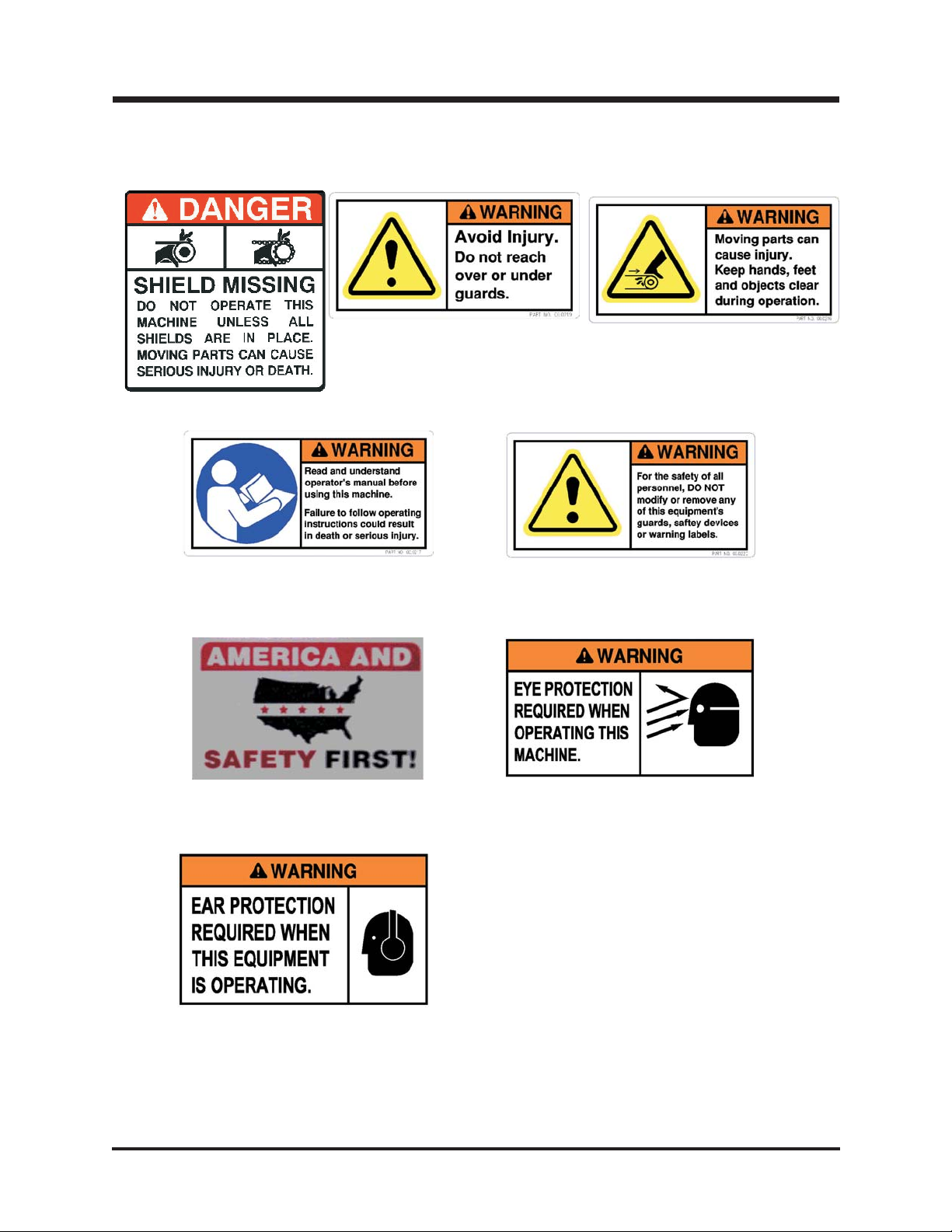

Read and understand the operator’s manual before operating this equipment.

Observe and follow all safety decals.

DO NOT let children or any untrained person operate the tractor or attachment. Make sure

that all operators of this equipment are thoroughly trained in using it safely.

Never allow additional riders on the tractor or attachments.

DO NOT operate tractor or attachments if you are under the influence of alcohol,

drugs, medication that may impair judgment or cause drowsiness, or if you are not feeling

well.

Operate all controls from the operator’s seat only.

Before operating equipment, make sure all shields are in place and fastened.

Ensure the attachment or accessory is locked or fastened securely to the tractor before

operating. See tractor manual for locking procedure.

Ensure that all bystanders are clear of the tractor and attachment before operating. Be

especially careful and observant if other people are present. Never assume that bystanders

will remain where you last saw them.

Always look in the direction the tractor is moving.

Never direct the discharge of any attachment in the direction of people, animals, buildings,

vehicles, or objects of value.

Immediately stop at any sign of equipment failure and correct the problem before continuing

to operate. An unusual noise can be a warning of equipment failure.

Before adjusting, cleaning, lubricating, or changing parts on the tractor or attachment,

engage the parking brake, lower the attachment to the ground, stop the engine, and remove

the ignition key.

To prevent the risk of uncontrolled equipment movement on tractors equipped with 2 speed

axles, always shift the transaxle range with the tractor stationary on level ground and with the

parking brake engaged.

If equipment is to be left unattended, stop the engine, remove the key, and make sure the

parking brake is engaged.