Attaching

1. Adjust the height of the rotor assembly until the indicator is located in the attaching zone^.

2. Drive the tractor slowly forward into the hitch arms on the power rake. Align the lift arms of the

tractor with the power rake hitch arms by raising or lowering the front hitch and complete the en-

gagement.

3. Once completely engaged, close the front hitch locking lever.*

4. Engage the parking brake* and shut off engine.

5. Place the attachment belt over the outside groove of the PTO drive pulley on the tractor. Ensure

the belt is properly seated in each pulley.

6. Engage the PTO spring tension lever.*

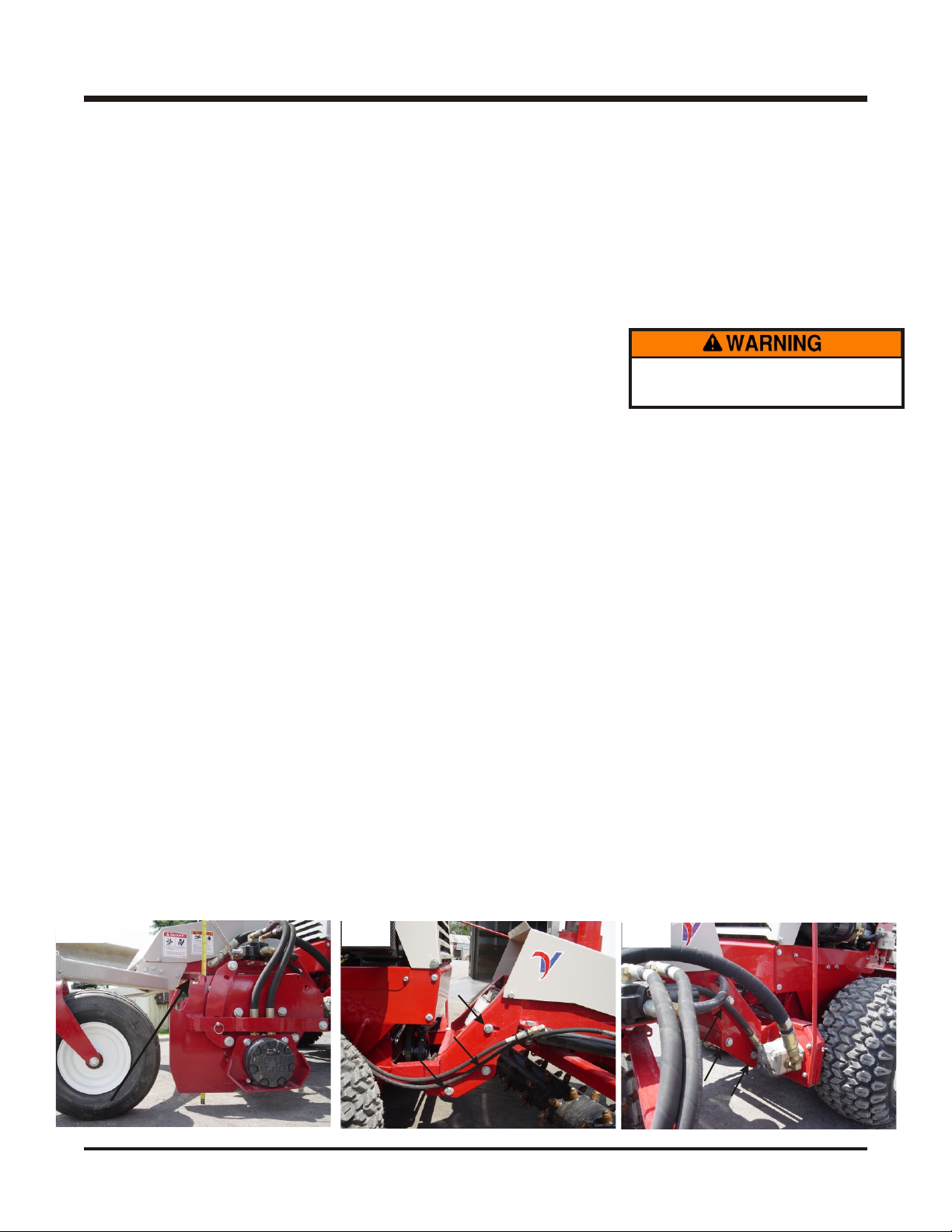

7. Wipe the quick couplers clean, and connect to the tractor. If equipped, connect the hoses and quick

couplers so the red indicators are paired together and the yellow indicators are paired together.

Detaching

1. Adjust the height of the rotor assembly until the indicator is located in the attaching zone^.

2. Park the tractor on a level surface and set the parking brake.*

3. Lower the power rake to the ground.

4. Shut off tractor engine.

5. Disengage the PTO spring tension lever.*

6. Remove the attachment belt from the PTO drive pulley of the tractor.

7. Disconnect the hydraulic quick couplers from the tractor.

8. Disengage the hitch locking lever.*

9. Restart tractor and slowly back away from the power rake.

*Refer to tractor manual for operation of controls.

^ Attaching zone is set for the standard lift arm height of Ventrac 4000 series tractors. Variables

such as tire size, tire inflation, and attempting to attach on an uneven surface will affect the proper

location of the attaching zone. The purpose of the attaching zone is to remove all the attachment

weight from the tractor hitch before removing from the tractor. This is done by lowering the rotor to

the ground and allowing it to carry the weight of the power rake. This will ensure a quick and easy

hitch alignment when reattaching to the tractor.

Operating Techniques & Tips:

Using low range on the tractor during operation of the power rake is recommended in most conditions.

Operator must be sitting on the tractor seat before the PTO can be engaged. The recommended

tractor engine speed during operation is 2,800-3,600 RPM. Adjust the engine RPM and tractor ground

speed to get the desired finish.

Before raking, clear the area of large rocks, wood, and leftover construction materials.

The rake can be used to “rough in” the area prior to finishing. This is done by setting the rake depth

and pushing dirt into low areas and up to buildings, trees, and other obstructions.

The rotor reverse feature allows you to pull material away from buildings, trees, and obstructions,

eliminating most hand raking.

If the rotor becomes plugged with sticks and debris, or becomes wrapped with string or wire, reversing

the rotor will make quick work of cleaning it out.

OPERATION

C-1