SAFETY

• The owner of this machine is solely responsible for properly training the operators.

• The owner/operator is solely responsible for the operation of this

machine and prevention of accidents or injuries occurring to him/her-

self, other people, or property.

• Do not allow operation or service by children or untrained personnel.

Local regulations may restrict the age of the operator.

• Before operating this machine, read the operator’s manual and under-

stand its contents.

• If the operator of the machine cannot understand this manual, then it

is the responsibility of this machine’s owner to fully explain the material

within this manual to the operator.

• Learn and understand the use of all controls.

• Know how to stop the power unit and all attachments quickly in the event of an emergency.

It is the responsibility of the owner to be sure that the operators use the proper personal protective equip-

ment while operating the machine. Required personal protective equipment includes, but is not limited to,

the following list.

• Wear a certied ear protection device to prevent loss of hearing.

• Prevent eye injury by wearing safety glasses while operating the machine.

• Closed toe shoes must be worn at all times.

• Long pants must be worn at all times.

• When operating in dusty conditions, it is recommended that a dust mask be worn.

• Inspect machine before operation. Repair or replace any damaged, worn, or missing parts. Be sure

guards and shields are in proper working condition and are secured in place. Make all necessary

adjustments before operating machine.

• Alterations or modications to this machine can reduce safety and could cause damage to the machine.

Do not alter safety devices or operate with shields or covers removed.

• Before each use, verify that all controls function properly and inspect all safety devices. Do not operate

if controls or safety devices are not in proper working condition.

• Check parking brake function before operating. Repair or adjust parking brake if necessary.

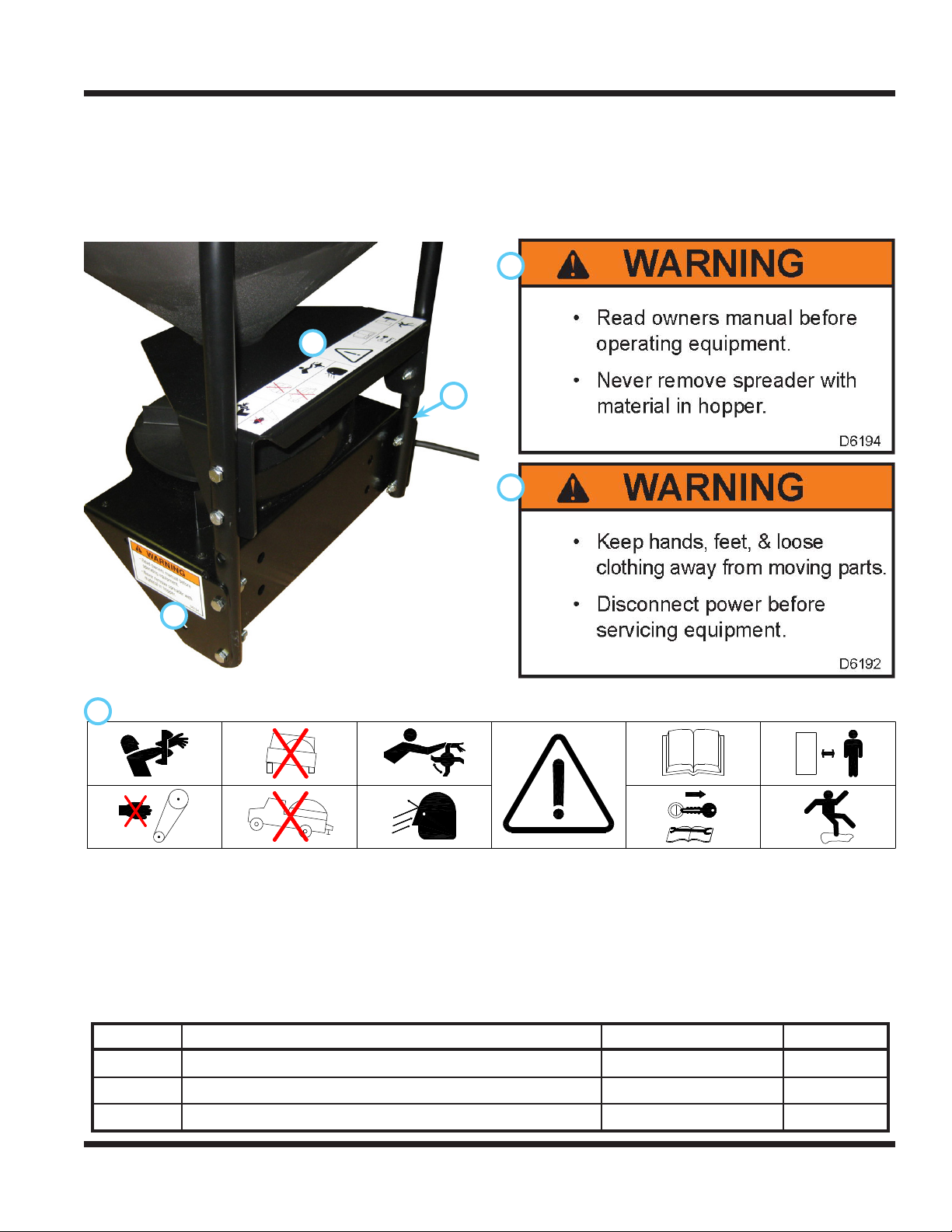

• Observe and follow all safety decals.

• All controls are to be operated from the operator’s seat only.

• Always wear a seat belt if the machine has a roll cage/bar installed.

• Ensure the attachment or accessory is locked or fastened securely to the power unit before operating.

• Ensure that all bystanders are clear of the power unit and attachment before operating. Stop machine if

someone enters your work area.

• Always be alert to what is happening around you, but do not lose focus on the task you are performing.

Always look in the direction the machine is moving.

• Look behind and down before backing up to be sure of a clear path.

• If you hit an object, stop and inspect the machine. Make all necessary repairs before operating machine again.

• Stop operation immediately at any sign of equipment failure. An unusual noise can be a warning of equipment

failure or a sign that maintenance is required. Make all necessary repairs before operating machine again.

• If equipped with a high/low range feature, never shift between high and low range while on a slope.

Always move the machine to level ground and place the selector lever in park before shifting range.