Contents 3

DB 534 02. 02

Contents ........................................................................................................................................................Page

1. Details about the machine.....................................................................................................................5

1.1 Range of application ...................................................................................................................5

1.2 Manufacturer...............................................................................................................................5

1.3 Conformity declaration................................................................................................................5

1.4 On requesting after sales service and parts ...............................................................................5

1.5 Type plate....................................................................................................................................5

1.6 Technical data.............................................................................................................................6

1.6.1 Operational data ............................................................................................................6

1.6.2 Hydraulic connections....................................................................................................6

1.6.3 Details about noise level................................................................................................6

1.7 Designated use of the machine...................................................................................................7

2. Safety.......................................................................................................................................................8

2.1 Danger when not adhering to the safety advice..........................................................................8

2.2 Qualification of operator..............................................................................................................8

2.3 Identification of advice in this instruction manual........................................................................8

2.3.1 General danger symbol .................................................................................................8

2.3.2 Attention symbol ............................................................................................................8

2.3.3 Hint symbol....................................................................................................................8

2.3.4 "Attention" pictographs and "advice" pictographs on the machine................................9

2.4 Safety conscious operation.......................................................................................................13

2.5 Safety advice for the operator...................................................................................................13

2.5.1 General safety and accident prevention advice...........................................................13

2.5.2 General safety and accident prevention advice for mounted implements...................14

2.5.3 General safety and accident prevention advice when operating with PTO shafts......14

2.5.4 General safety and accident prevention advice for the hydraulic system ...................14

2.6 General safety and accident prevention advice for maint-enance, repair and cleaning...........16

3. Description of product.........................................................................................................................17

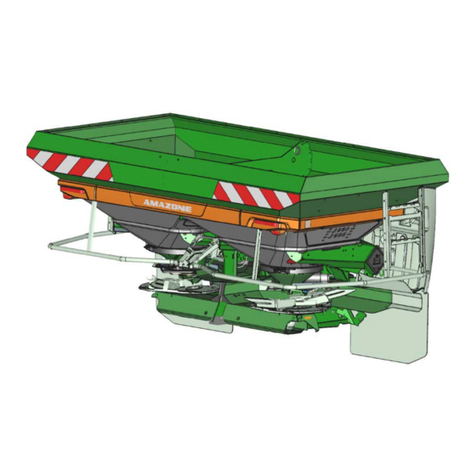

3.1 Function.....................................................................................................................................18

4. On receipt of the machine ...................................................................................................................19

4.1 Function control.........................................................................................................................19

4.2 PTO shaft drive .........................................................................................................................20

4.3 Fitting the PTO shaft.................................................................................................................20

4.4 Hydraulic drive...........................................................................................................................22

5. Mounting and dismounting .................................................................................................................23

5.1 Mounting....................................................................................................................................24

5.1.1 E+S with PTO shaft .....................................................................................................24

5.1.2 E+S with hydraulic motor.............................................................................................25

5.2 Dismounting ..............................................................................................................................25

5.3 Initial fitting and matching up of the PTO shaft.........................................................................26

6. Transport on public roads...................................................................................................................27