SERVICE MANUAL

NON HWS SOFTENERS

ORION 500 –6000 Standard Softeners

TABLE OF CONTENTS

1HEALTH AND SAFETY RECOMMENDATIONS.................................................................4

1.1 CHEMICALS...................................................................................................................................... 4

1.2 ELECTRICITY ................................................................................................................................... 4

1.3 EMERGENCY SHUTDOWN ............................................................................................................. 4

1.4 AIR AND WATER PRESSURE ......................................................................................................... 4

1.5 ION EXCHANGE RESINS................................................................................................................. 4

2TECHNICAL SPECIFICATIONS .........................................................................................5

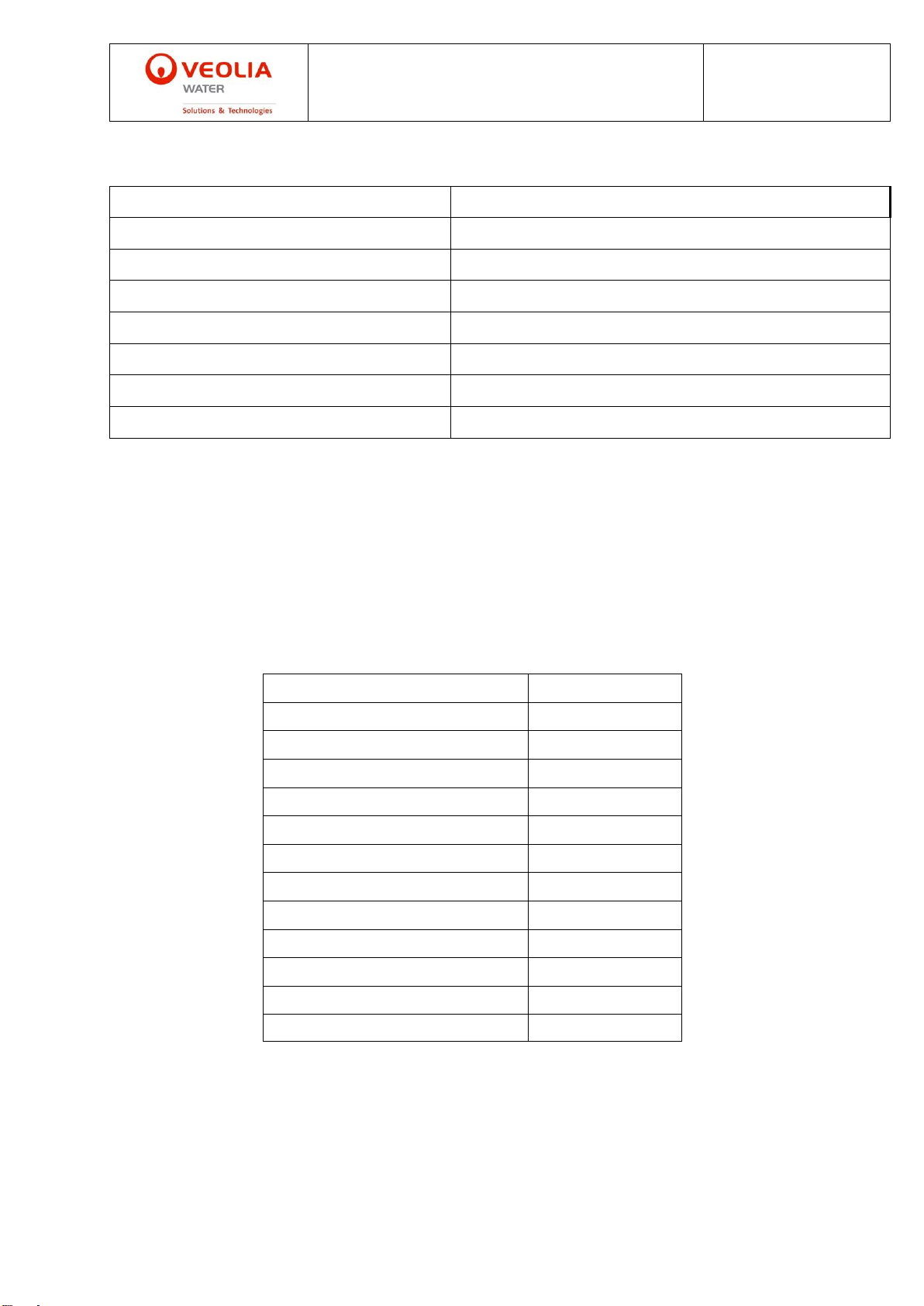

2.1 CAPACITY DATA –SOFTENER OPTION (BES).............................................................................. 5

2.2 CAPACITY DATA –CARBOSOFT OPTION (CBES) ........................................................................ 6

2.3 OPERATING PARAMETERS............................................................................................................ 7

2.4 FEEDWATER LIMITS........................................................................................................................ 8

2.5 SALT SPECIFICATIONS................................................................................................................... 8

3SOFTENER MAIN COMPONENTS.....................................................................................9

3.1 VESSELS .......................................................................................................................................... 9

3.2 SOFTENING RESIN.......................................................................................................................... 9

3.3 GRANULAR ACTIVATED CARBON................................................................................................. 9

3.4 CONTROL VALVES.......................................................................................................................... 9

3.5 CONTROLLER .................................................................................................................................. 9

3.6 SALT STORAGE / BRINE SYSTEM................................................................................................. 9

4PROCESS AND EQUIPMENT DESCRIPTION .................................................................10

4.1 THE SOFTENING PROCESS......................................................................................................... 10

4.2 RESIN REGENERATION................................................................................................................ 10

4.2.1 BACKWASHING........................................................................................................................ 10

4.2.2 BRINING.................................................................................................................................. 11

4.2.3 SLOW OR DISPLACEMENT RINSE.............................................................................................. 11

4.2.4 FAST OR FINAL RINSE ............................................................................................................. 11

4.2.5 MANUAL INITIATION ................................................................................................................. 11

4.2.6 POSITION OF THE SIATA 132 VALVE DURING SERVICE AND REGENERATION STAGES ................. 12

4.2.7 PNEUMATIC CONNECTIONS TO THE SIATA 132 MULTIPORT VALVES.......................................... 13

4.2.8 POSITION OF THE SIATA 250 VALVE DURING SERVICE AND REGENERATION STAGES ................. 14

4.2.9 PNEUMATIC CONNECTIONS TO THE SIATA 250 MULTIPORT VALVES.......................................... 17

5INSTALLATION.................................................................................................................18

5.1 INITIAL CHECKS............................................................................................................................. 18

5.2 DRAIN CONNECTION .................................................................................................................... 18

5.3 SALT STORAGE TANKS, SALT SATURATORS........................................................................... 19

5.4 LOW LEVEL SALT ALARM SWITCHES......................................................................................... 19

6COMMISSIONING AND OPERATING PROCEDURES.....................................................20

6.1 FILLING THE VESSELS ................................................................................................................. 20

6.2 MEDIA REQUIRED FOR EACH SOFTENER................................................................................. 20

6.3 EQUIPMENT REQUIRED ............................................................................................................... 20

6.4 FILLING THE VESSELS WITH GAC .............................................................................................. 20

6.4.1 INITIAL BACKWASHING THE GAC.............................................................................................. 21

6.4.2 GAC COMMISSIONING BACKWASH FLOW RATES....................................................................... 22

6.5 FILLING THE VESSELS WITH SOFTENING RESIN..................................................................... 22

6.5.1 CARBOSOFT UNITS.................................................................................................................. 22

6.5.2 STANDARD SOFTENER............................................................................................................. 23

6.5.3 REFIT VALVES......................................................................................................................... 23

6.6 RINSING THE MEDIA..................................................................................................................... 24