TM

CURRENT MONITORING INSTALLATION GUIDE

Solid-Core Current Switch, Adjustable Trip Point

With Command Relay, 120 VAC/DC Status Output

Installer’s Specifications

Amperage Range 1-135 A continuous

Sensor Power Induced from monitored current

Insulation Class 600 VAC RMS

Frequency Range 50/60 Hz

Temperature Range -15° to 60°C (5°to 140°F)

Humidity Range 10-90% RH non-condensing

Hysteresis 10% of setpoint, typical

Terminal Block Maximum WIre Size 14 AWG

Terminal Block Torque (nominal) 4 in-lbs (0.45 N-m)

Status Output N.O. 0.2 A@120 VAC/DC

Relay Coil 24 VAC/DC, 10 mA

Relay Contact Resistive: 10 A@250 VAC, 30 VDC; Inductive: 5 A@250 VAC, 30 VDC

Agency Approvals UL508 E150462

Do not use the LED status indicators as evidence of applied voltage.

The product design provides for basic insulation only.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

DANGER

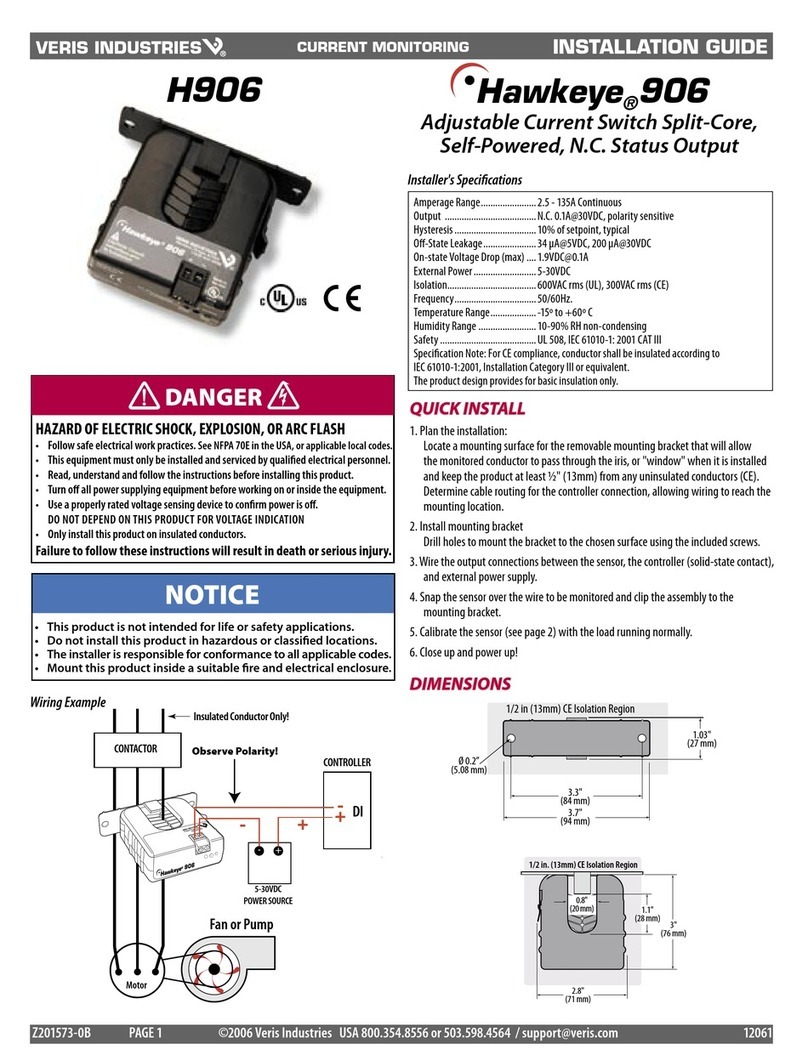

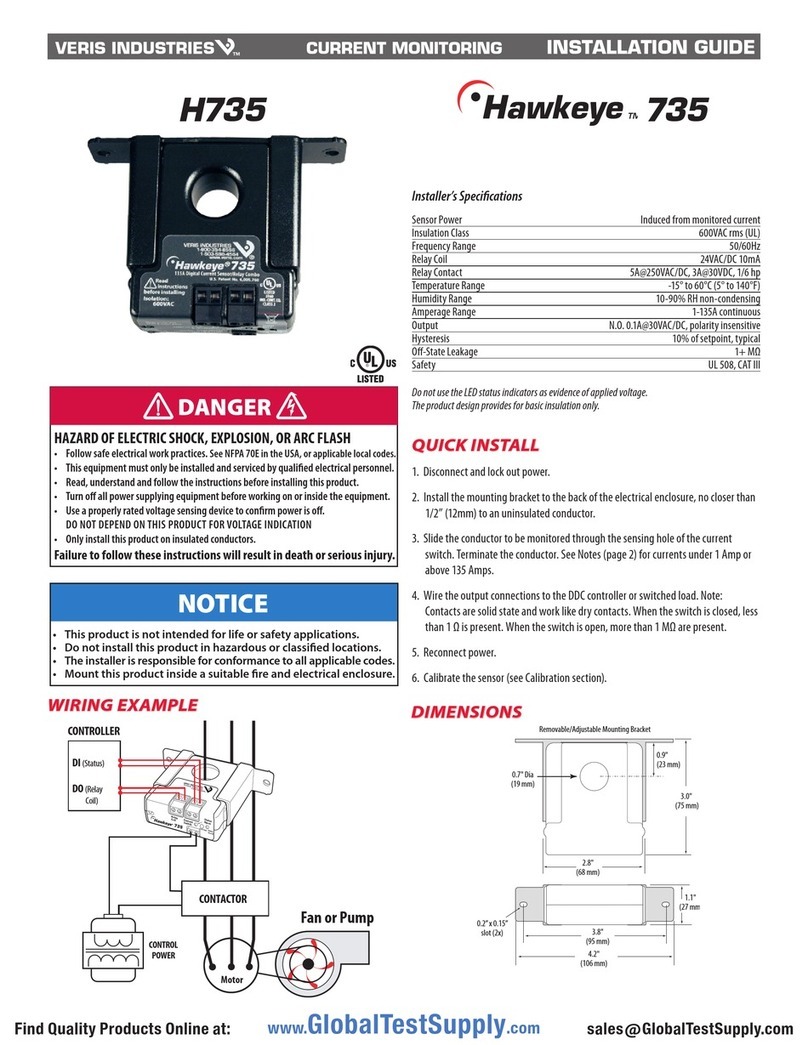

Fan or Pump

CONTROLLER

DI

(Status)

DO

(Relay

Coil)

Motor

CONTACTOR

CONTROL

POWER

WIRING EXAMPLE

H739 TM 739

DIMENSIONS

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

INSTALLATION

Disconnect and lock out power to the enclosure containing the

conductor to be monitored.

1. Locate a mounting surface for the removable mounting bracket that will allow

the monitored conductor to pass through the center window when it is installed

and that will keep the device at least 1/2” from any uninsulated conductors.

Determine cable routing for the controller connection, allowing wiring to reach

the mounting location.

2. Route the conductor through the sensor’s center window and slip the assembly

into the mounting bracket. Terminate the conductor. See Notes (page 2) for

currents under 1 Amp or above 135 Amps.

3. Wire the output connections to the DDC controller or switched load (solid state

contact).

4. Secure enclosure and reconnect power.

5. Calibrate the sensor (see Calibration section).

0.2”x 0.15”

slot (2x)

1.1"

(27 mm)

2.8"

(68 mm)

0.7"

(19 mm)

0.9"

(23 mm)

3.0"

(75 mm)

Removable/Adjustable Mounting Bracket

3.8"

(95 mm)

4.2"

(106 mm)

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com