1 www.versitron.com

SECTION 1

DESCRIPTION OF EQUIPMENT

1.1 INTRODUCTION

This manual provides general and detailed information on the installation and operation of

Model F22XX FOM II Series RS-530 High-Speed Fiber Optic Modems. Section 1 contains a

general description of the equipment. Section 2 contains installation instructions. Section 3

contains operating instructions. Section 4 provides the theory of operation. Section 5 contains

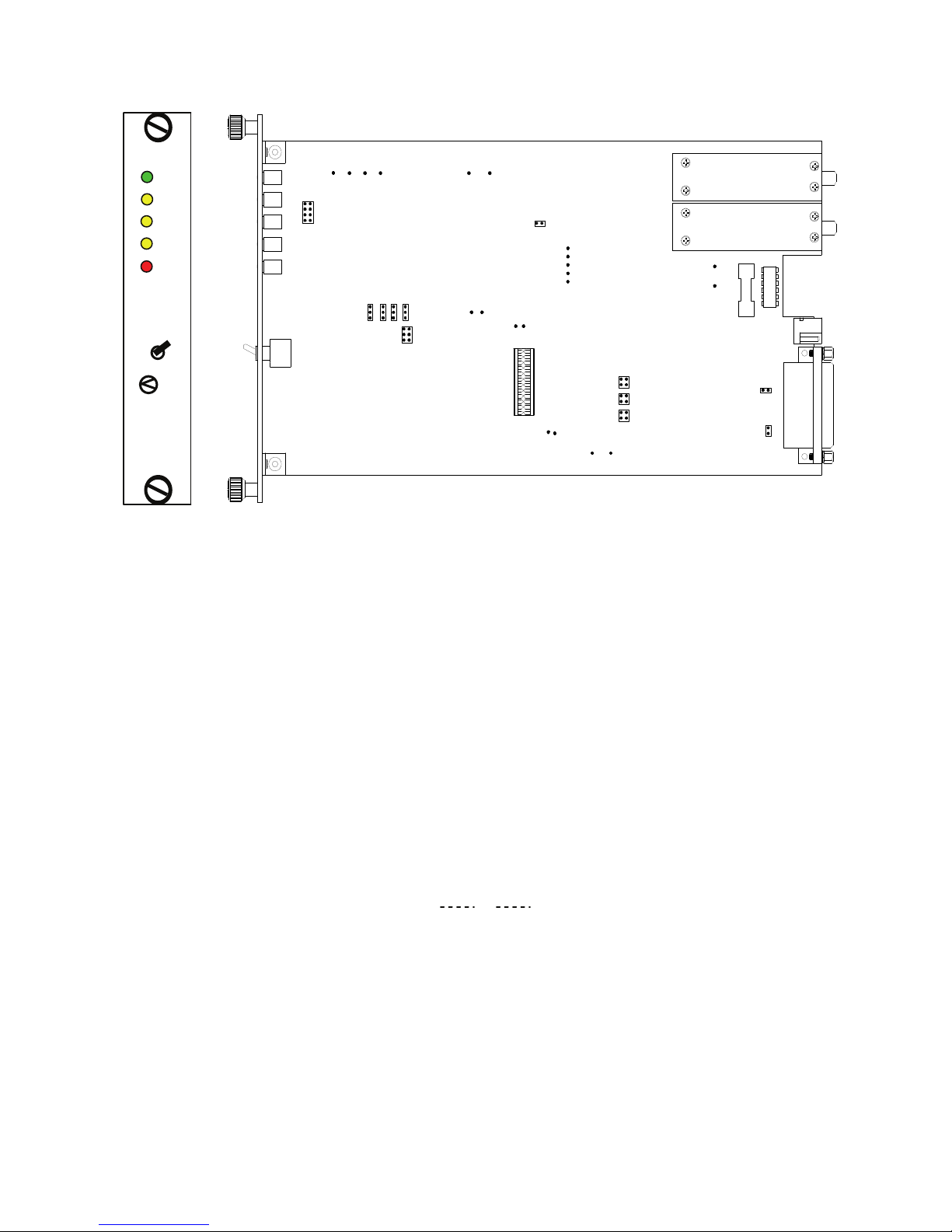

maintenance and troubleshooting information. Figure 1 is an overall view of the F22XX circuit

card assembly.

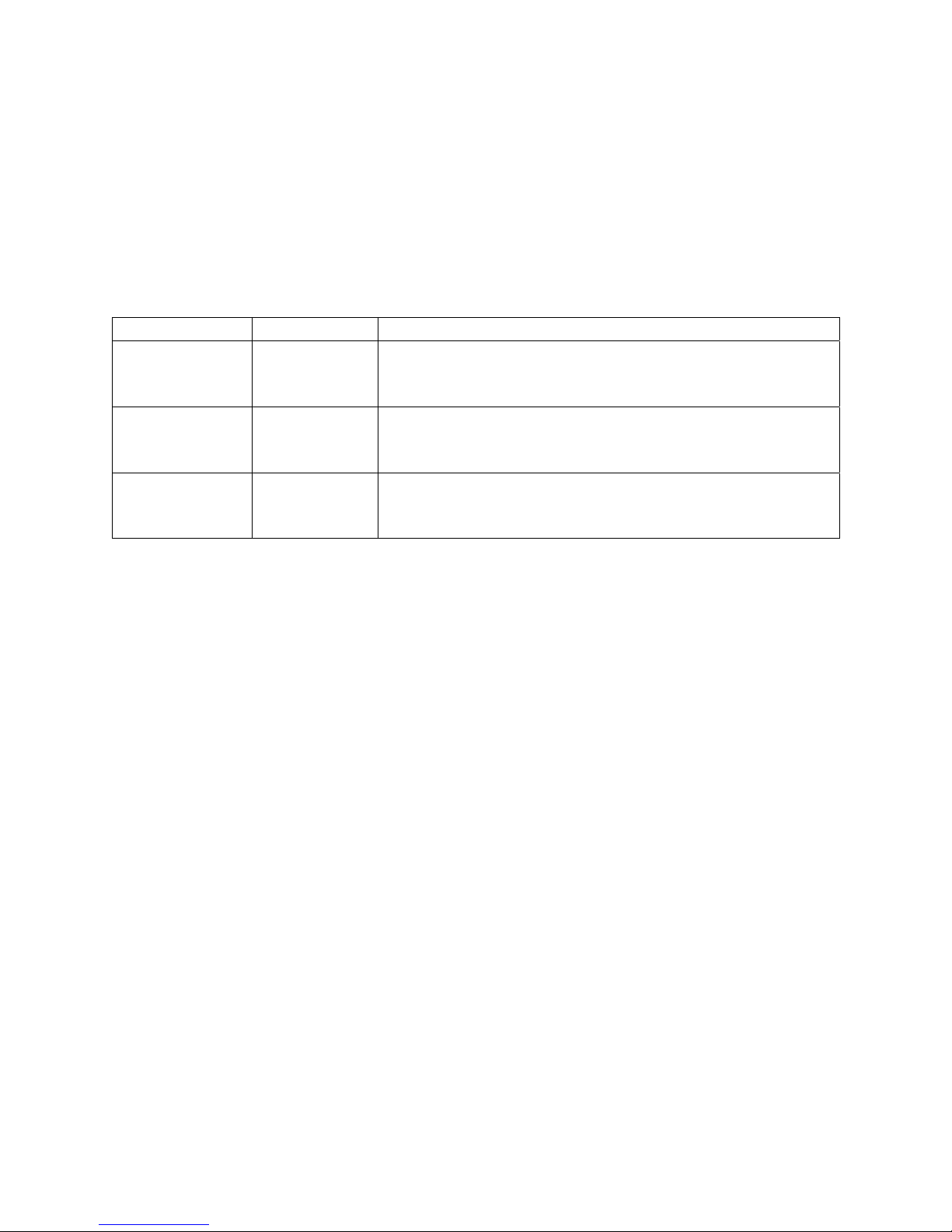

Model Number Part Number Description

F2238 19643-02

RS-530 High-Speed Fiber Optic Modem, duplex,

multimode, 850 nM, ST connectors, 250 Bps – 10 Mbps,

distances to 2 Km*.

F2240 19643-04

RS-530 High-Speed Fiber Optic Modem, duplex,

multimode, 1300 nM, ST connectors, 250 Bps – 10 Mbps,

distances to 6 Km*.

F2245 19643-05

RS-530 High-Speed Fiber Optic Modem, duplex, single

mode, 1300 nM, ST connectors, 250 Bps – 10 Mbps,

distances to 15 Km*.

* Note: Multimode tests performed @ 100 Kbps on 62.5/125 µM fiber optic cable.

Single mode tests performed @ 100 Kbps on 10/125 µM fiber optic cable.

1.2 DESCRIPTION OF EQUIPMENT

1.2.1 Functional Characteristics

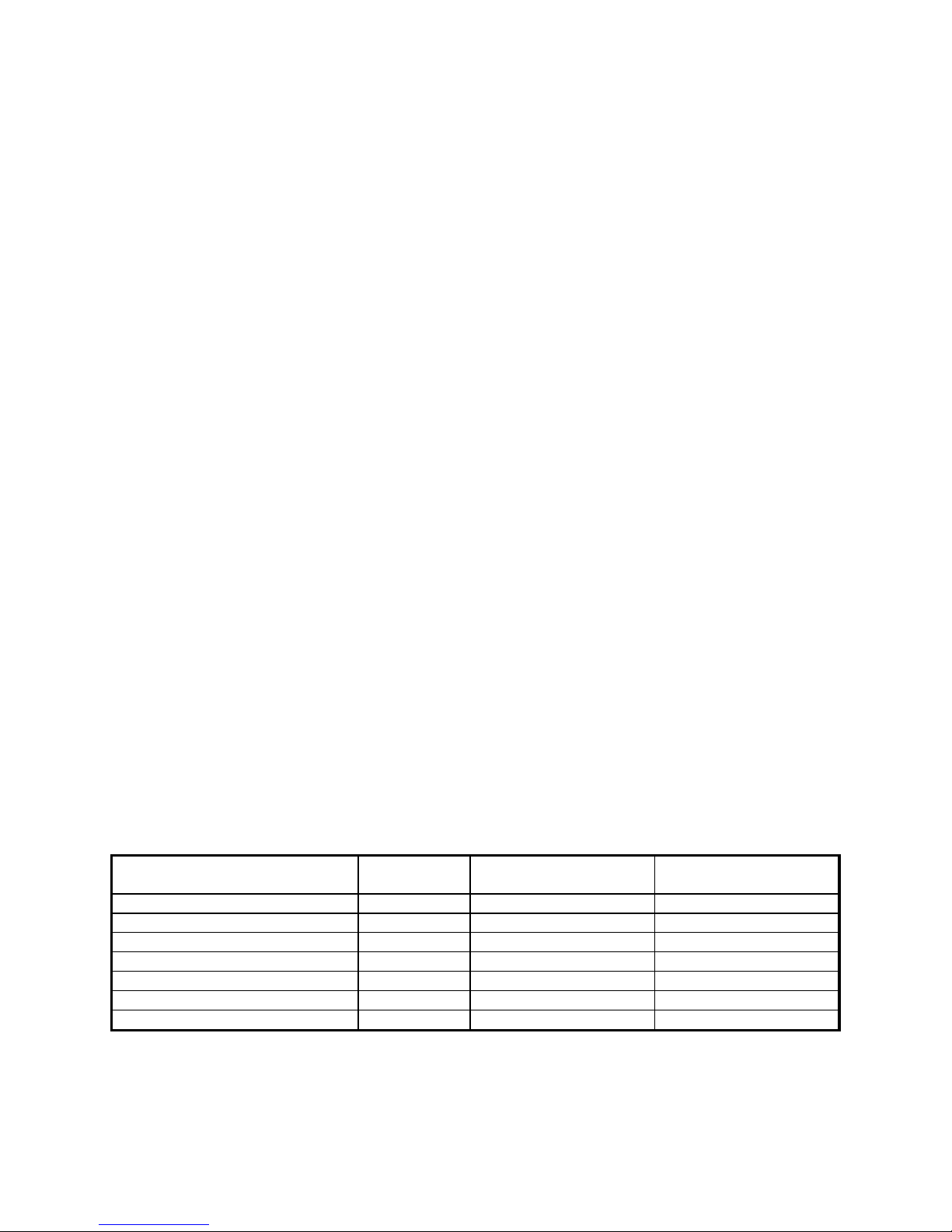

Model F22XX modems are high-speed modems that allow the full duplex transmission of

data, clock and a control signal (data terminal ready (DTR), data set ready/data carrier detect

(DSR/DCD)) over fiber optic cable. Figure 2 shows the modem link configuration. The fiber

circuit consists of two modems connected by two fiber optic strands with data rates and electrical

signal characteristics that conform to EIA RS-530 and MIL-STD-188-114 balanced/unbalanced

standards. The modems provide synchronous or asynchronous data transmission at speeds up to

10 Mbps. The link is fully transparent in both directions and is data agile. Model F2238 modems

are installed with 850 nM multimode optics and operate at distances of up to 2 Km (1.25

mi./6,600 ft.) on multimode fiber cable. Model F2240 modems installed with 1300 nM

multimode optics operate at distances of up to 6 Km (3.7 mi./19,680 ft.) on multimode fiber

cable. Model F2245 modems installed with 1300 nM single mode optics operate at distances of

up to 15 Km (9.3 mi./49,100 ft.) on single mode fiber cable. Basically, model F22XX modems

operate as two channel multiplexers/modems. For high-speed synchronous operation the first

channel is used for data and the second for transmit clock. Both channels may be used for data

in low-speed, asynchronous operation at less than 100 Kbps.