TABLE OF CONTENTS

Chapter 1 Overview ............................................................................................1

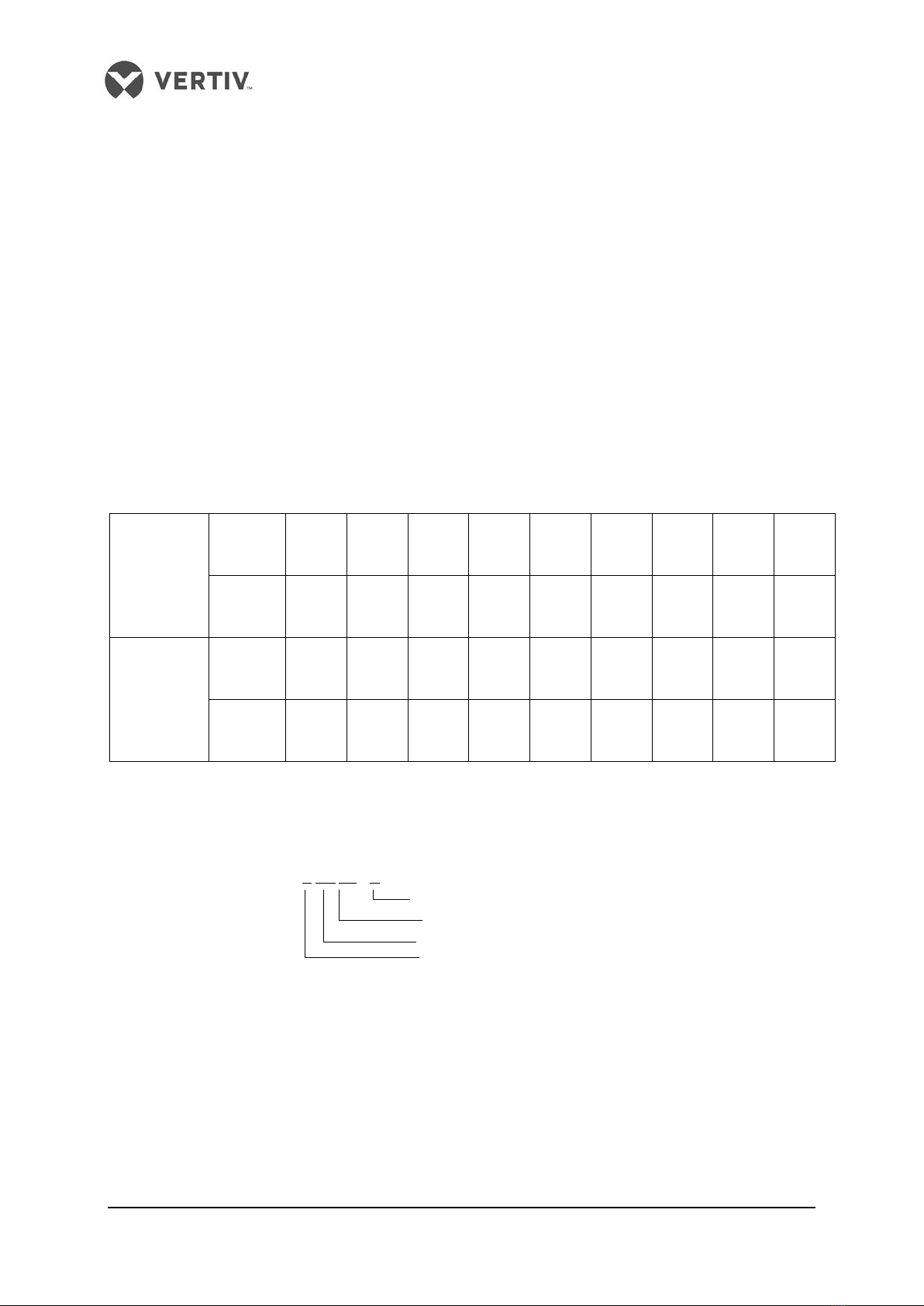

1.1 Classification And Models.....................................................................................................................................1

1.2 Model Description.................................................................................................................................................1

1.3 Main Components .................................................................................................................................................2

1.4 Technical Parameters...........................................................................................................................................3

1.4.1 Mechanical Parameters.............................................................................................................................3

1.4.2 Mounting Base Dimensions.......................................................................................................................4

1.4.3 Parameters of Operating Environment......................................................................................................6

1.4.4 Parameters Of Storage Environment.........................................................................................................6

Chapter 2 Installation ....................................................................................... 7

2.1 Moving, Unpacking And Inspection .....................................................................................................................7

2.2 Installation Notes .................................................................................................................................................8

2.3 Space Requirements ............................................................................................................................................9

2.4 Installation Procedures......................................................................................................................................10

Chapter 3 Application of Fan Speed Controller ...........................................13

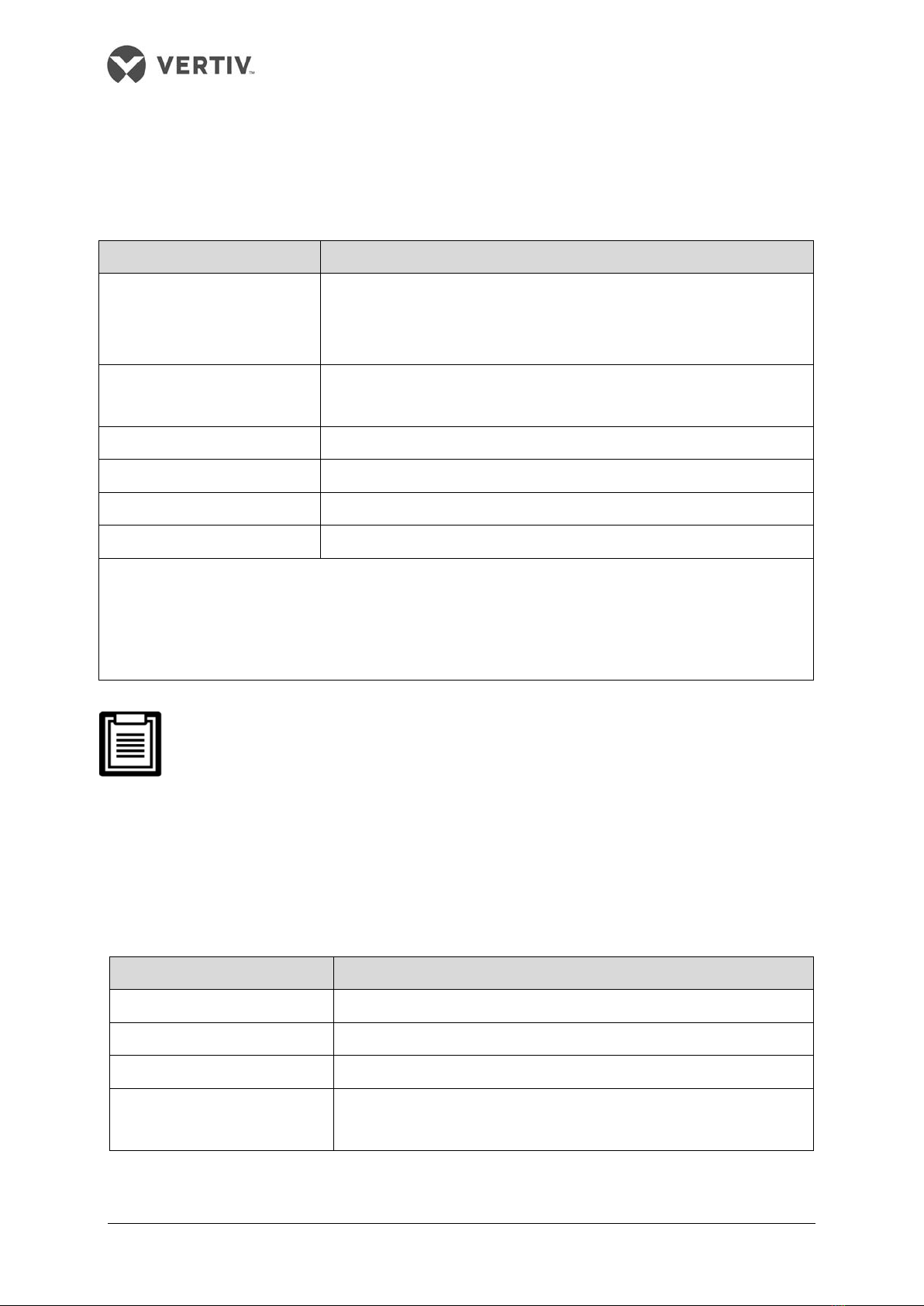

3.1 Wiring Terminals................................................................................................................................................. 13

3.2 HMI .....................................................................................................................................................................14

3.3 Operation Description Of HMI ...........................................................................................................................17

3.3.1 Initial Interface.........................................................................................................................................17

3.3.2 Main Menu Interface................................................................................................................................17

Chapter 4 Maintenance and Troubleshooting ............................................24

4.1 Maintenance .......................................................................................................................................................24

4.2 Troubleshooting.................................................................................................................................................26

Appendix Circuit Diagram...........................................................................28