1

LIEBERT®BATTERY INTERFACE BOX™: UPSBIBX, UPSBIBN AND

UPSBIBR

Product Specification/Installation Sheet—Liebert EXL™, Liebert EXL™S1, Liebert NX™225-600

and Liebert NXL™

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation of your Liebert Battery Interface Box. The Liebert Battery Interface Box can be

used with the Liebert NXL, Liebert NX 225-600, Liebert EXL and Liebert EXL S1 systems. Read this document thoroughly before working with the DC system. Retain

this manual for use by installing personnel.

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J of the FCC rules. These limits provide reasonable protection against harmful

interference in a commercial environment. This unit generates, uses and radiates radio frequency energy and, if not installed and used in accordance with this

instruction manual, may cause harmful interference to radio communications. Operation of this unit in a residential area may cause harmful interference that the user

must correct at his own expense.

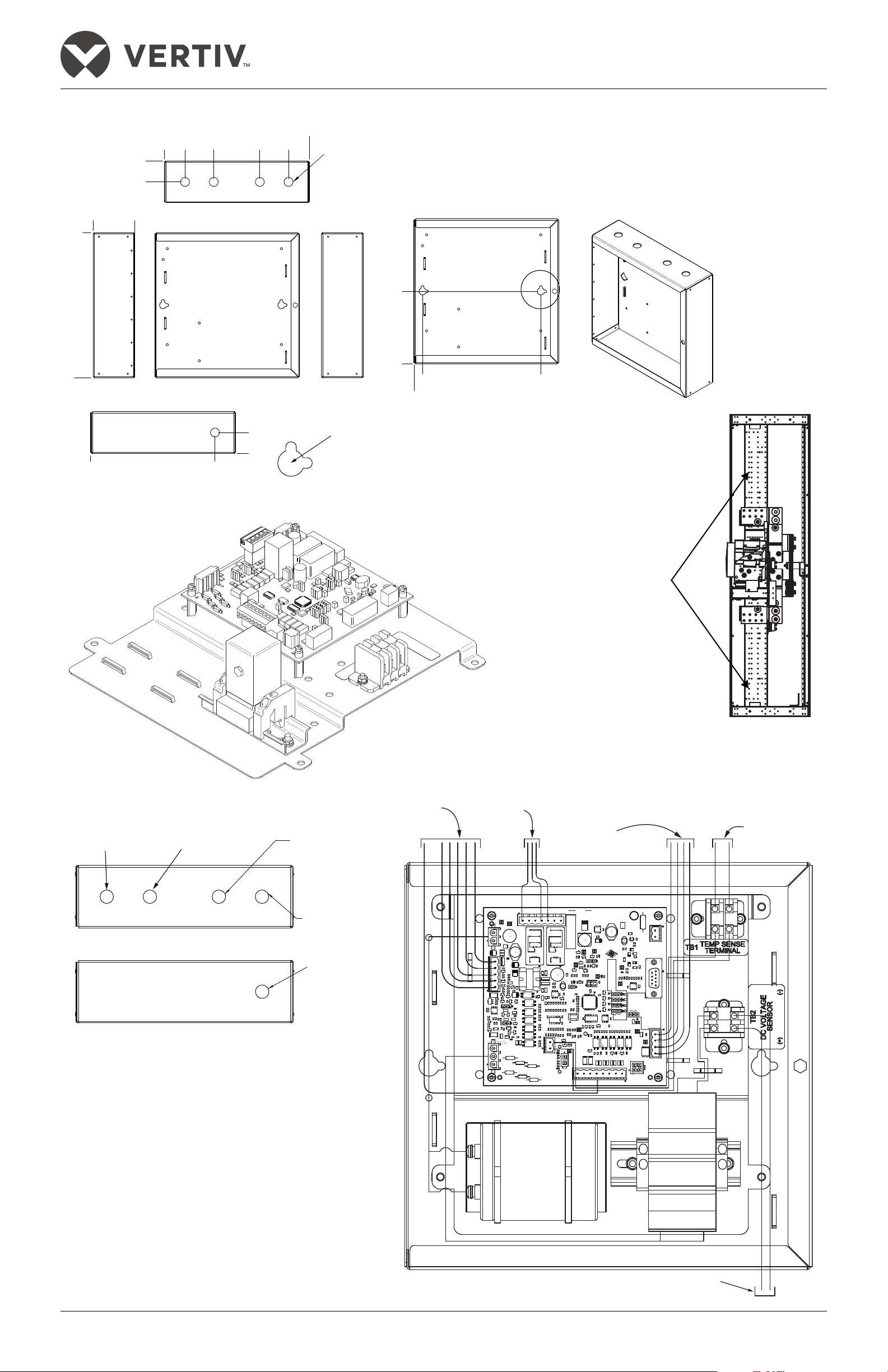

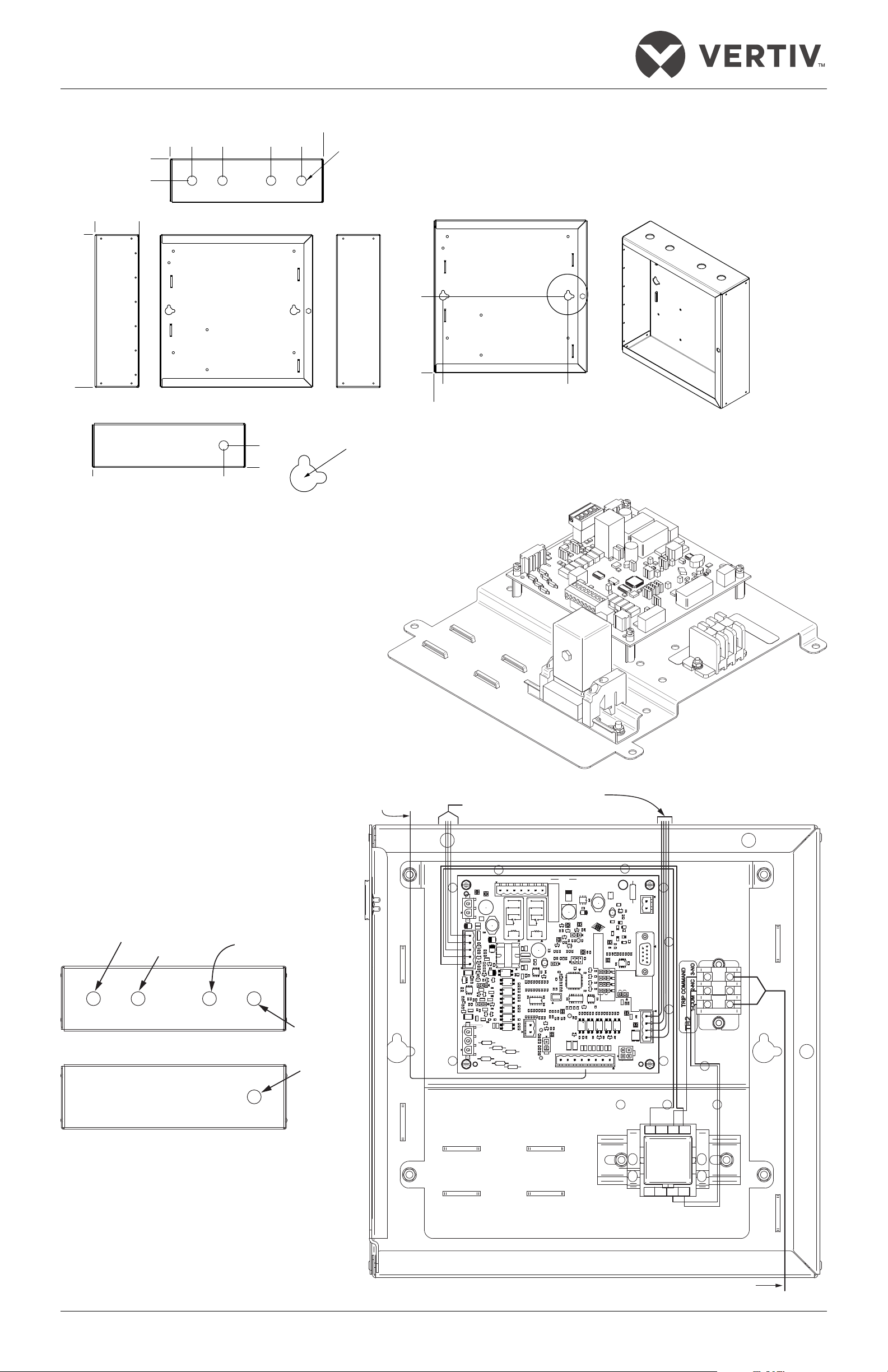

PLACEMENT AND CABLE ENTRY

The Liebert Battery Interface Box should be installed near the DC disconnect. The location should allow access to the box and allow the front door to be opened for

service. Access to the Battery Interface Board (BIB), fuse disconnects and terminal blocks are behind the front door. See Figure 1 for cable entry layout.

UPSBIBX—Separately mounted assembly to interface with a battery breaker, either stand-alone or as part of a battery cabinet.

UPSBIBN—Variation of the UPSBIBX that includes a mounting plate, hardware and wire harness, allowing installation on a Vertiv-supplied MBD and BIS using a

Square D type NW-DC breaker.

UPSBIBR—Separately mounted assembly to interface with a Samsung lithium-ion battery.

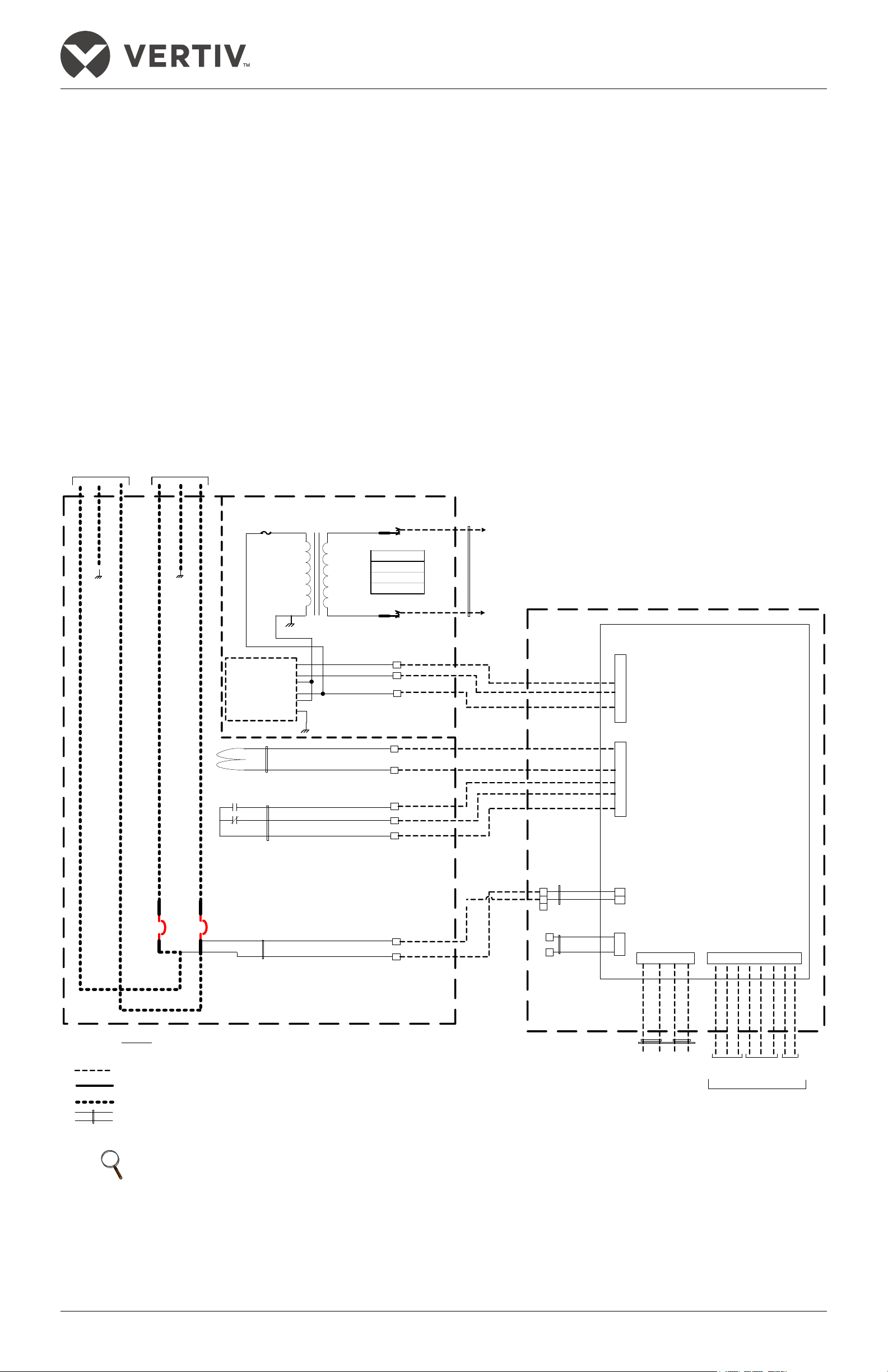

CONTROL CONNECTION

Each Liebert Battery Interface Box contains a Battery Interface Board (BIB). When multiple BIB’s are used, DC systems must have their Battery Interface Board controls

connected in series. The CAN cables must be two twisted pair. Vertiv recommends Belden 9156 or the equivalent; however, the wire size is dependent on the length of

the cable run..

NOTICE

Risk of improper installation. Can cause equipment damage.

During system commissioning, Vertiv Services will set the jumpers on the External Interface Board in the UPS and the BIB. If another DC source is added to the system

after commissioning, it is imperative that Vertiv Services reset the jumpers on the EIB and the BIB.

WARNING

Risk of electric shock. Can cause personal injury or death.

The DC terminal voltage connected to this equipment will exceed 400VDC and is potentially lethal. Be constantly aware that the DC system contains

high DC as well as AC voltages. Check for voltage with AC and DC voltmeters before making contact.

Special safety precautions are required for procedures involving handling, installing and maintaining the DC system. Only properly trained and

qualified personnel wearing appropriate personal protective equipment should be involved in installing the Liebert Battery Interface Box or preparing

the system for installation.

Special care must be taken when working with the batteries associated with this equipment. Observe all DC safety precautions before working on or

near the DC system.

The following precautions must be observed when working on this equipment:

• Remove watches, rings and other metal objects.

• Use tools with insulated handles.

• Wear rubber gloves and boots.

• Do not lay tools or metal parts on top of batteries.

• Disconnect charging source prior to connecting or disconnecting DC terminals.

• Determine whether the DC source is grounded. If it is grounded, remove source of ground.

Contact with any part of a grounded DC source can result in electrical shock. The likelihood of such shock will be reduced if such grounds are

removed during installation and maintenance.

AVERTISSEMENT

Risque de décharge électrique pouvant causer des blessures graves, voire mortelles.

La tension c.c. à la borne de cet équipement dépasse 400 V c.c. et est potentiellement mortelle. Soyez toujours conscient du fait que le système c.c.

contient des tensions c.c. et c.a. élevées. Vérifiez les tensions avec des voltmètres c.a. et c.c. avant d’établir tout contact.

Des précautions de sécurité spéciales sont requises pour les procédures associées à la manutention, à l’installation et à l'entretien du système c.c.

Seuls des employés qualifiés et dûment formés portant l’équipement de protection personnel approprié peuvent se charger d'installer le boîtier

d’interface pour batterie Liebert ou de préparer le système pour l’installation.

Des précautions particulières doivent être prises lors de travaux touchant les batteries associées à cet équipement. Observez toutes les précautions

de sécurité appropriées lorsque vous travaillez sur à proximité d’une source c.c.

Lorsque vous travaillez avec cet équipement, prenez les précautions suivantes :

• Retirez montre, bagues et tout autre objet métallique.

• Utilisez des outils dont le manche est isolé.

• Portez des gants et des bottes de caoutchouc.

• Ne posez aucun outil ni pièce métallique sur le dessus d’une batterie.

• Déconnectez la source de chargement avant de brancher ou de débrancher les bornes c.c.

• Vérifiez si la source c.c. est mise à la terre. Le cas échéant, éliminez la cause de la mise à la terre.

Le contact avec toute partie d'une source c.c. mise à la terre peut provoquer une décharge électrique. Pour réduire de tels risques d’accident,

débranchez les prises de terre avant de procéder à l’installation ou à l’entretien.

NOTE

Care must be taken to route control cables away from high-voltage cables and busbars.Use recommended knockouts for installing all

cables and use provided tie point to secure, see Figure 2.