4

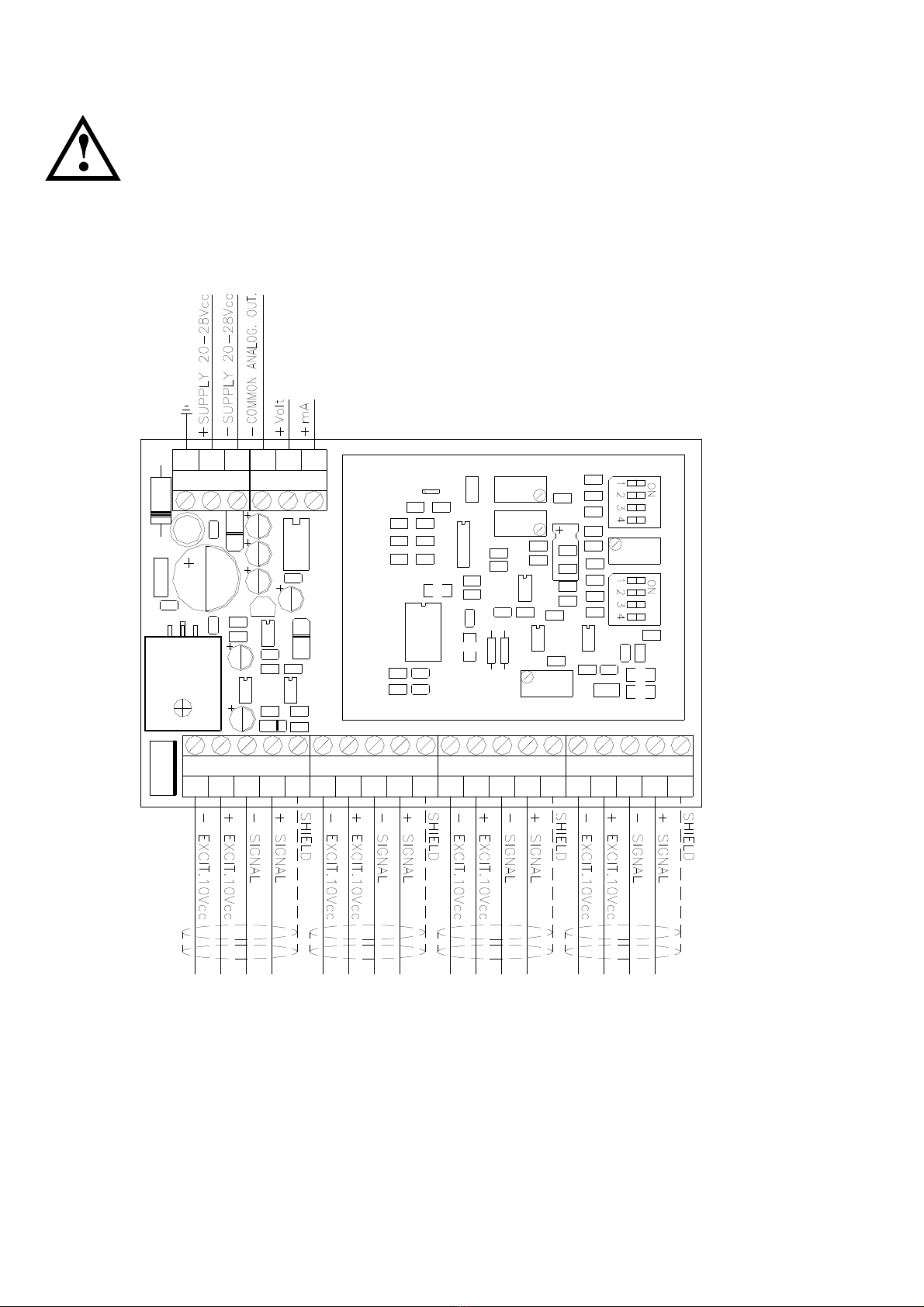

AWT20L TRANSMITTER

DIMENSIONS:base114 mm ,depth93 mm, high 60 mm.

MOUNTING: instrument formounting back panel orin junction box.

BOXCONTAINER (in resin ): forDINoromega bar.

TECHNICALFEATURES:

POWER from20 to28Vdc

PRECISION 0,25 %

REPEATIBILITY 0,01 %

POWERCONSUMPTION 6VA

PROTECTIONDEGREE IP50

CAPACITY6load cellsin parallel 350 Ohm

LOAD CELL CONNECTION 4-wirestechnique

LOAD CELL SUPPLY 10 Vdc+/ -3%

MEASURINGRANGE from3,5to24 mV

COARSE ZERO by4dip-switches, 70%range

FINEZERO bytrimmer10%range

COARSE FULL SCALE by4dip-switches

FINEFULL SCALE bytrimmer,10%range

OPERATINGTEMPERATURERANGE -10 to+50 °C

STORAGETEMPERATURERANGE -20 to+70 °C

THERMICSTABILITY 0,01 %of range for10°C

TIMEOFTHERMICSTABILIZATION 10 minutes

ANALOGOUTPUT :

AWT20L isprovided withthe following outputs:

0-10 Vdc(terminals22-23 )

0-20 mA, 4-20 mA(terminals21 -23 )

Tomodifythe outputfollow the proceduresatchapterANALOG OUTPUTMODIFY. In thestandard

version inorder toincrease theinputfield upto35 mVenter in parallela49,9K resistance;see

ANALOGUEOUTPUTMODIFICATIONsection forfurther details.

NOTE:

Thereisalsoanotherversion of the AWT20L transmitterwhichhasan output voltage of +/-5Vcc.

USE:

Normallyused witha12 bit analog / digital boardsinstalled on programmable logic(PLC )