ELECTRICAL SAFETY-TO PREVENT SERIOUS INJURY AND

● The power supply environment of this product must have a good grounding

device, must use a three-core plug, and with a well-grounded three-hole

socket to ensure good grounding of this product.

● Three-phase power supply air compressor, must use three-phase five-core

wire, with good grounding, after the cable is connected, start to check whether

the motor rotation direction is consistent with the direction of the arrow of the

main engine, if the opposite direction of the arrow, please switch the two live

wires, the wire diameter of the cable is different due to the different power and

choose different, Refer to the three phase cable diameter selection table in

Chapter 2 of this manual for specific wire diameter selection.

● Before powering this product, please make sure that the power supply you

provide can meet the input power information marked near the power input

port of this product.

● Do not share the socket with other electrical appliances, in case the voltage

is unstable sometimes, resulting in damage to the product.

● When maintaining/repairing or cleaning the product, please be sure to

unplug the power cord to ensure that the product is completely powered off

before operation.

● Regularly check whether the power cord and power plug are damaged, and

make sure that the power cord is not squeezed by other items.

DO NOT let comfort or familiarity with product (gained from repeated use)

replace strict adherence to the product safety rules. If you use this product

unsafely or incorrectly, you can suffer serious personal injury.

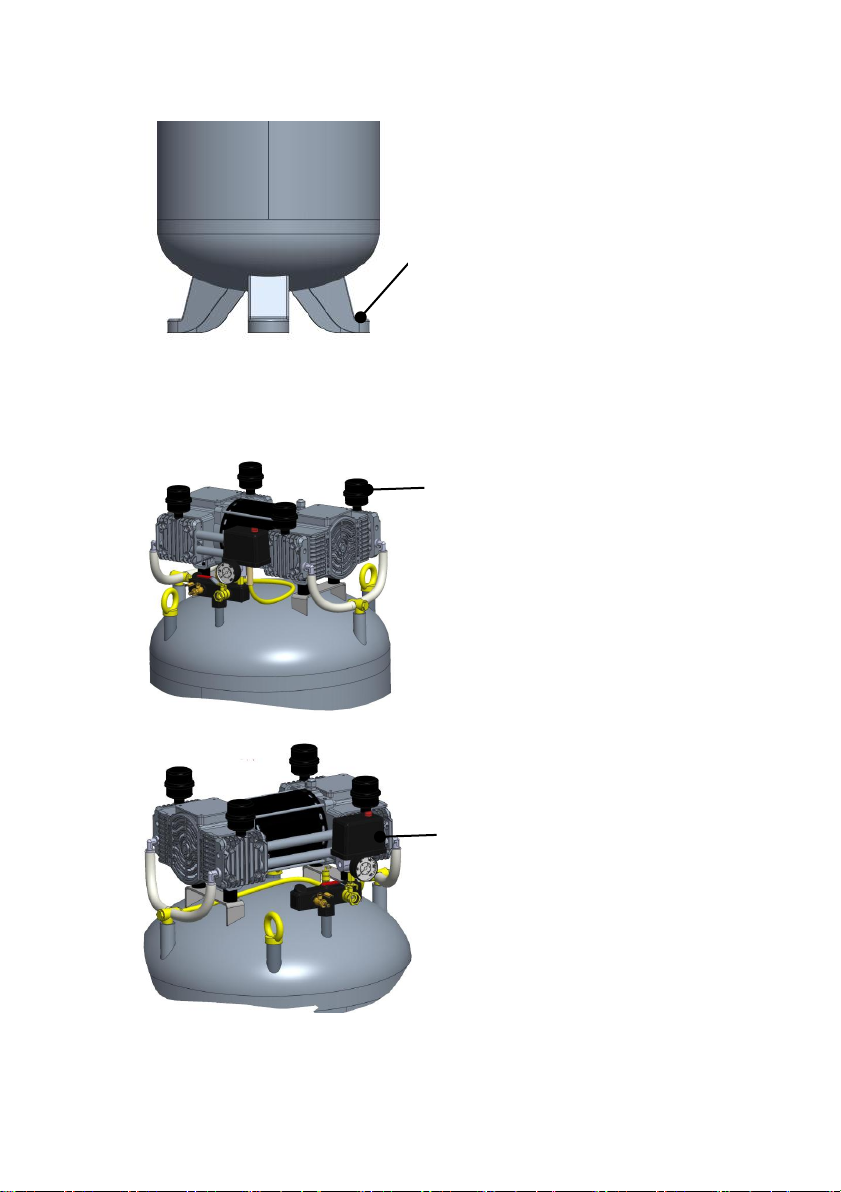

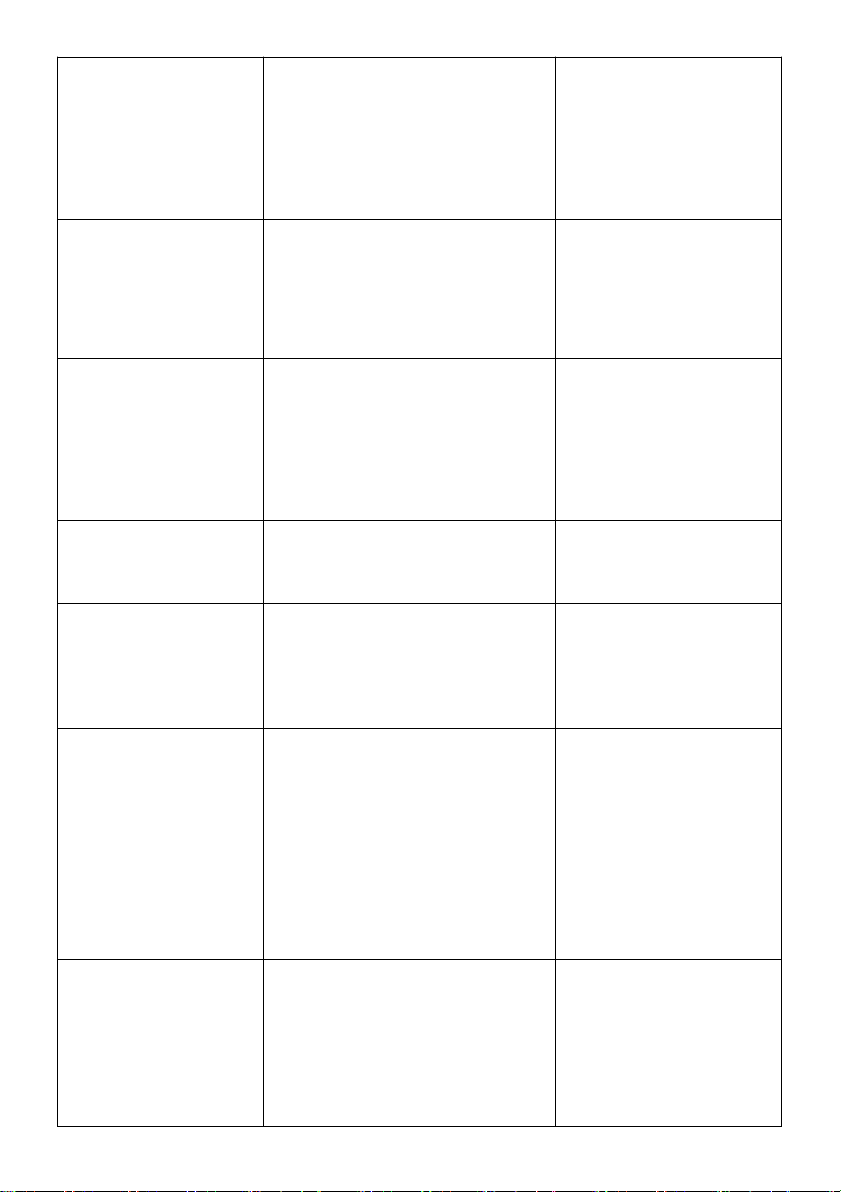

Preparation

Before beginning assembIy of product. make sure aII parts are present.

Compare parts with package contents Iist and hardware contents Iist.

If any part is missing or damaged. do not attempt to assembIe the product.