The Model SS240 will NOT eventually compensate and correct for any errors

during the set-up or filling operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly recommended that

personnel responsible for the equipment’s operation, both assembly and

disassembly, go through these procedures together in order to be properly

trained and to make sure that no misunderstandings exist.

In the event you should require technical assistance, please contact your local

authorized Distributor.

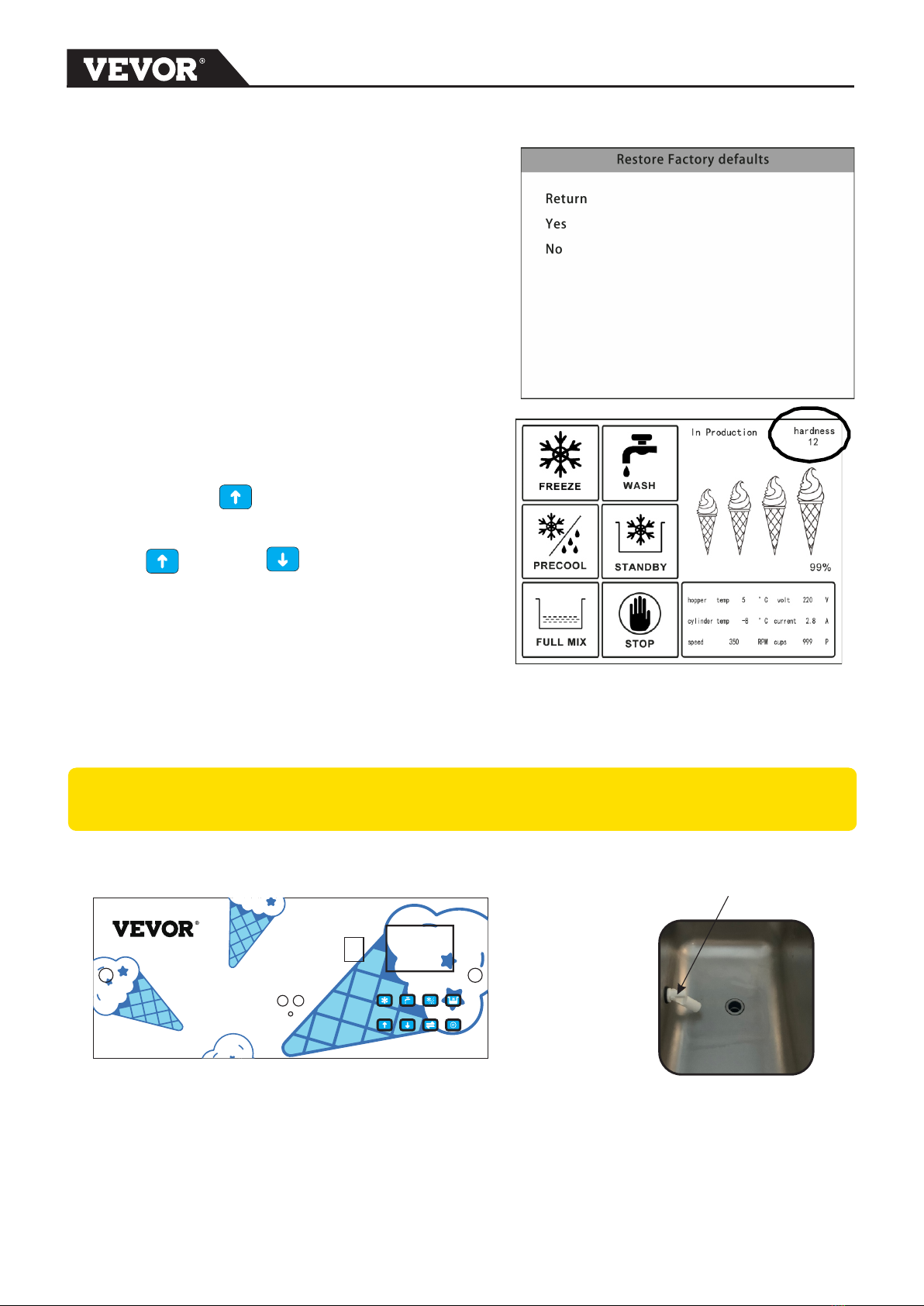

MIX INFORMATION

The Hygeian ice cream mix is required to be used for frozen production. Mix can

vary

considerably from one manufacturer to another. Differences in the type of

ingredients,

quality, and quantity all have a different bearing on the finished frozen product. A

change

in machine performance that cannot be explained by a technical problem may be

related

to mix. Mix does not improve with age. Old mix or mix that has been stored at too

high

temperature can result in a finished product that is less than satisfactory from the

appearance and taste standpoint.

We are concerned about the safety of the operator when he or she comes in

contact with the freezer and its parts. We have gone to extreme efforts to design

and manufacture built-in safety features to protect both you and service

technician.

IMPORTANT- Failure to adhere to the following safety precautions may

result in severe personal injury. Failure to comply with these warnings may

damage the accessories and raise your operation cost.

1. DO NOT operate the freezer without reading this operator’s manual. Failure

to follow this instruction may result in equipment damage, poor freezer

performance, health hazards, or personal injury.

2. DO NOT operate the freezer unless it is properly grounded. Failure to follow

this instruction may result in electrocution.

3. DO NOT allow untrained personnel to operate this machine. Failure to follow

this instruction may result in severe personal injury to fingers or hands from

hazardous moving parts.

4. DO NOT attempt any repairs unless the main power supply to the freezer has

been cut off. Failure to follow this instruction may result in electrocution. Contact

your local authorized Distributor for service.

5. DO NOT operate the freezer unless all service panels and access doors are

restrained with screws. Failure to follow this instruction may result in severe

personal injury from hazardous moving parts.

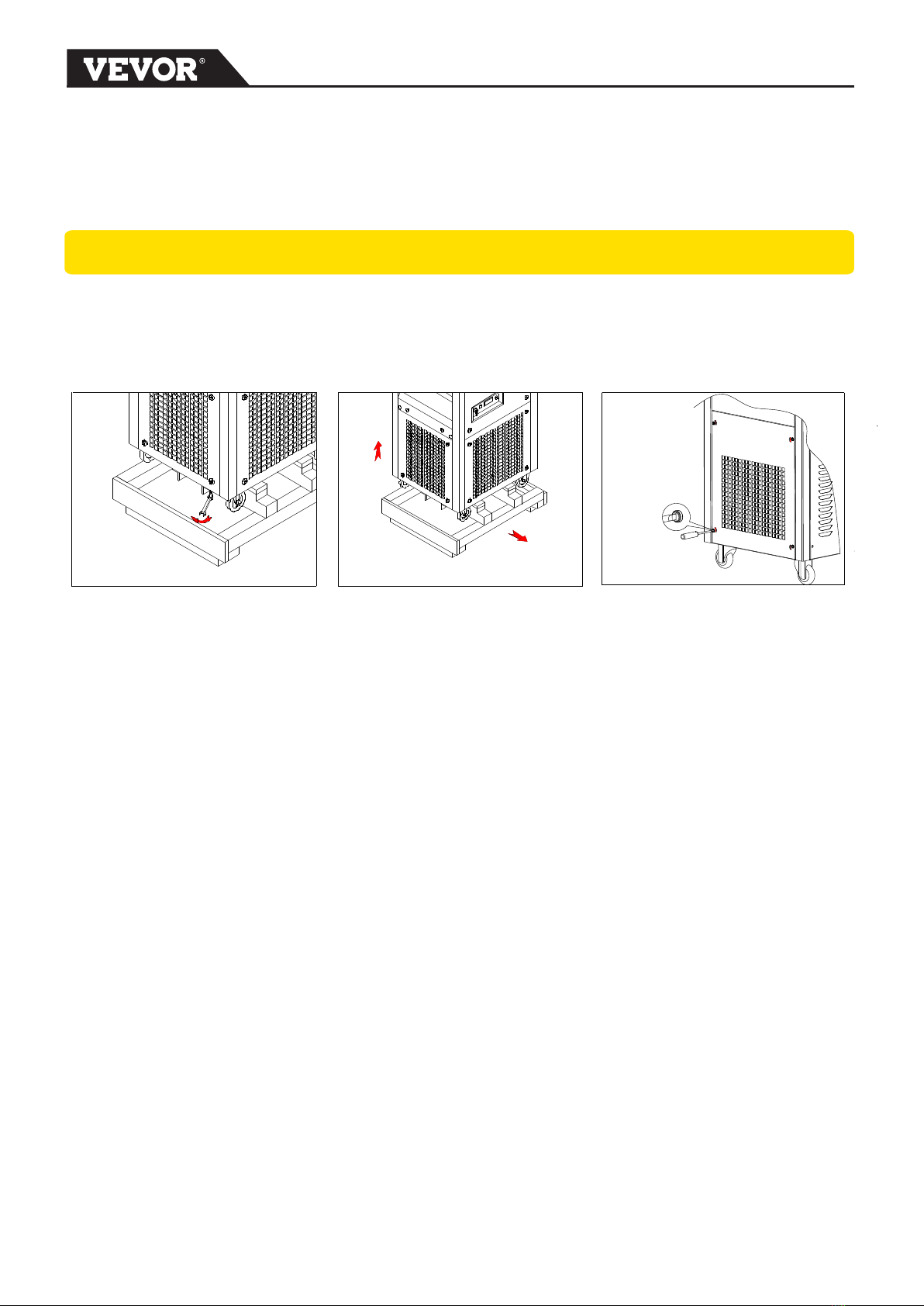

6. DO NOT obstruct air intake and discharge openings: minimum of 200mm of

clearance around both sides.

7. DO NOT remove the door, beater and blades, or drive shaft unless all control

switches are in the OFF position. 3