4 • VibrationVIEW Quick Start Guide

Setting Up The Hardware

VR9500 | Connecting the Unit

Set up the computer in the conventional configuration with power cables,

mouse, keyboard, and monitor.

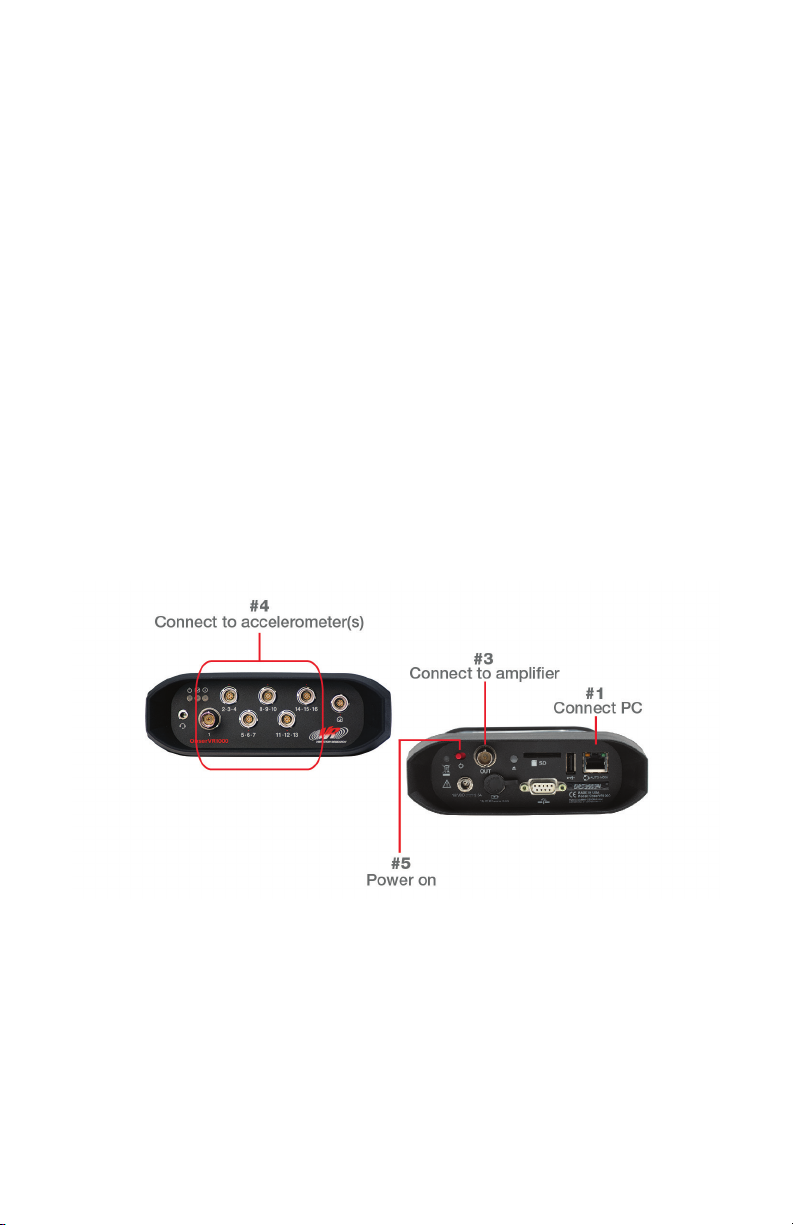

To connect one VR9500 unit:

1. Connect the VR9500 network port to the dedicated network card on

the computer using an Ethernet cable (included).

2. Connect the power cord to the VR9500. The power input will

automatically switch for voltage 90VAC to 250VAC and 50/60 Hertz.

3. Connect the shaker amplifier’s input to the Drive output connector on

the rear panel of the VR9500.

4. Connect an accelerometer to channel 1 on the front panel. Other

accelerometers can be connected to channels 2, 3, and 4.

5. Turn on the VR9500.

Video: Setting Up Your System

Scan this QR code with your smart device camera.

vibrationresearch.com/resources/setting-up-your-vr9500-control-system