UG:307 vicorpower.com Applications Engineering: 800 927.9474 Page 7

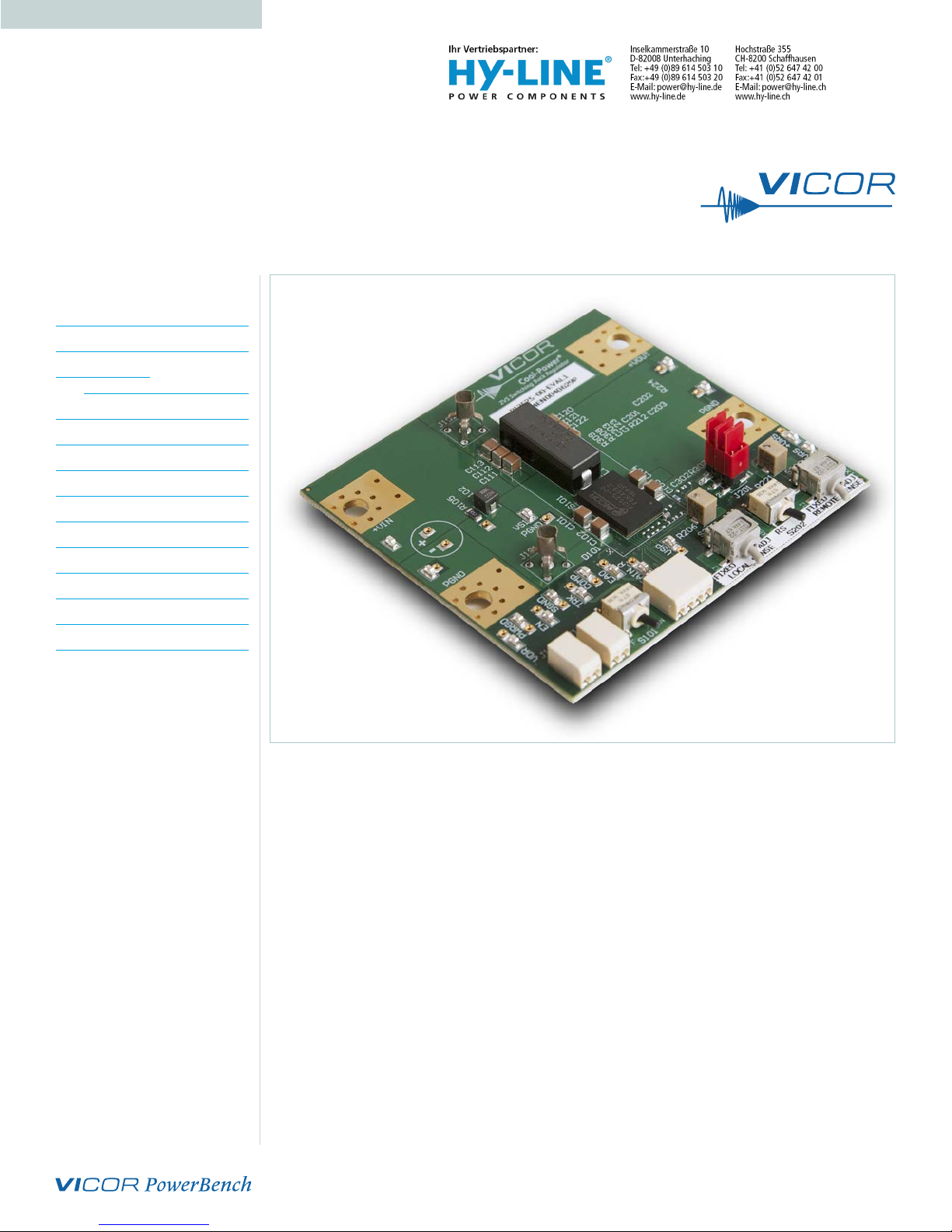

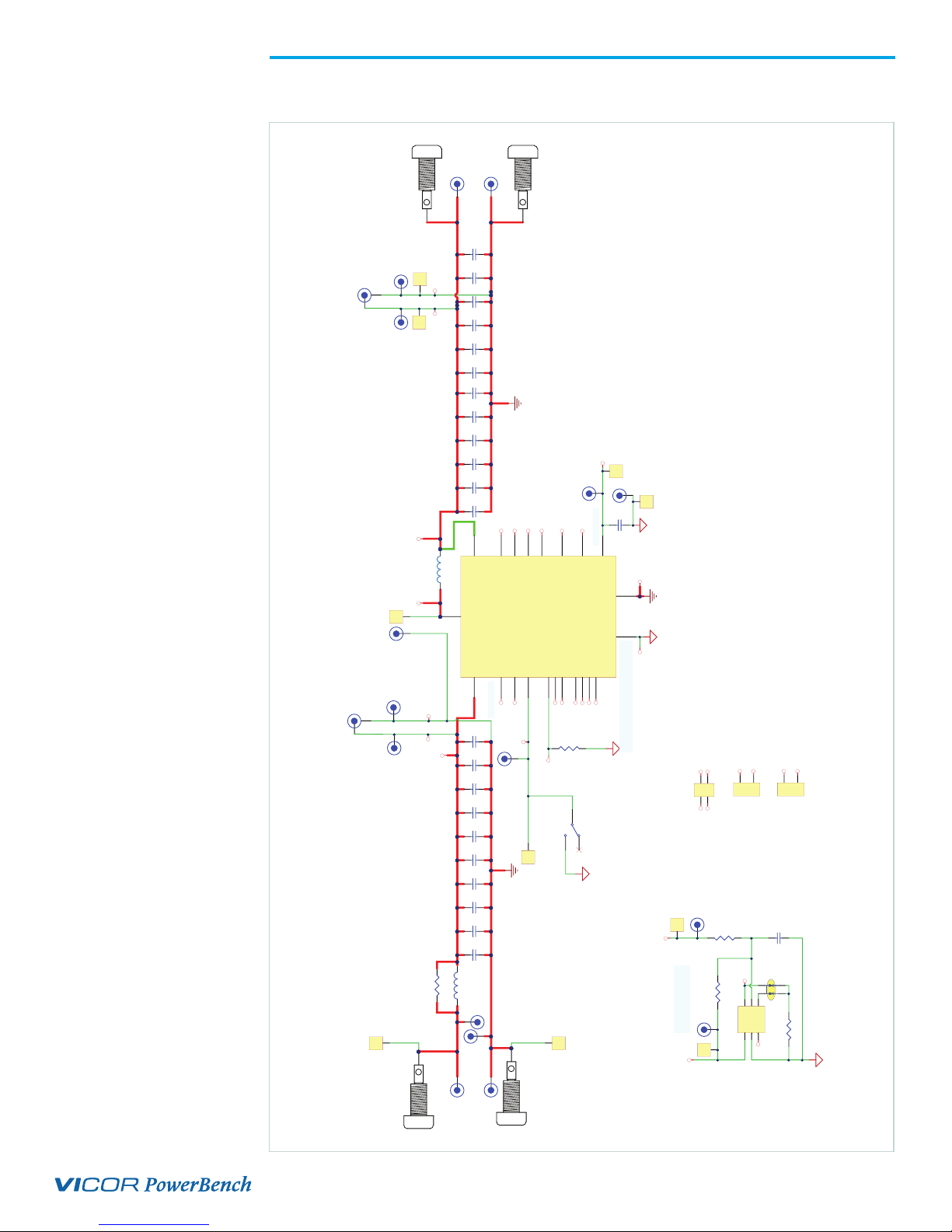

6. Loop compensation mode selection (S202): Used to select one of the following:

Local Sense (LS): default. Single ended feedback loop using the internal to the regulator

operational transconductance amplifier. +VOUT Lug is the local sensed location. +VOUT lug is

connected to the Error Amplifier Inverting Input (EAIN) through a voltage divider network.

Remote Sense (RS): Non-isolated remote sensing option using the internal to the regulator

independent differential amplifier which outputs (VDIFF) is in turn connected to the

transconductance amplifier input (EAIN) pin. Remote sensing is achieved using +VRS and –VRS

test points. Resistors R223 and R224 are 100Ωcatch resistor placed to prevent an open loop

condition if accidentally switched to this mode.

7. Trim mode selection (S201 or S203): Switch (S201) and trim potentiometer (R206) are associated

with local sense loop while switch (S203) and trim potentiometer (R221) are associated with remote

sense selection. Both Switches (S201 and S203) provide the following trim modes:

Fixed Trim (FIXED): default. Fixed resistor divider is used to set regulator output to the nominal

datasheet output voltage.

Adjustable Trim (ADJ): selection allows the use of trim potentiometer (R206 or R221) to

exercise the full output voltage range. Turn counterclockwise to increase the output voltage

and clockwise to decrease the output voltage. The trim potentiometer at either lowest or

highest point can only exercise the voltage range defined in the datasheet as valid operational

range within tolerance limits. If preferred, through-hole receptacles are available to bypass the

potentiometer with external leaded resistor.

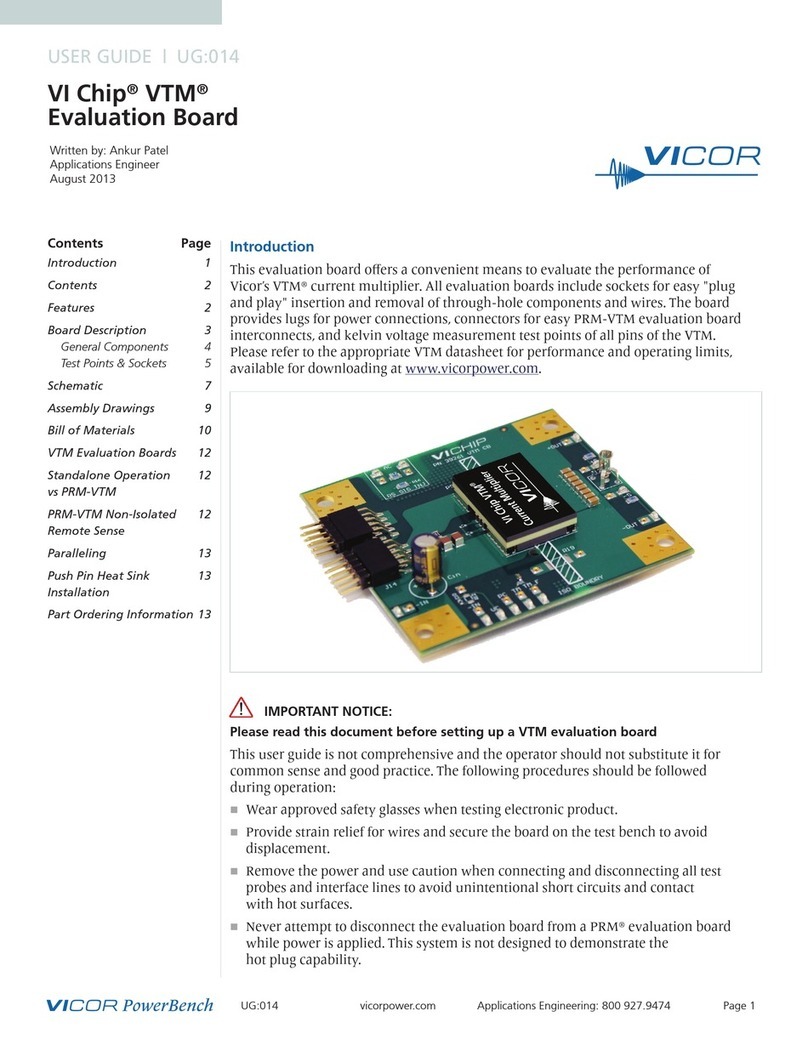

8. Header-jumper (J201): Default setting is all three jumper sockets populated. This header provides

the following function:

Pin 1 and pin 2 can be used to inject the isolated signal of a network analyzer through

(R211= 49.9Ω) used for bode plot measurement in order to evaluate the stability in

local sense mode.

Pin 3 and pin 4 are used to short the Lighting (LGH)/Constant Current (CC) Sense Input to

SGND. LGH header pin 4 is used for lighting and constant current type applications. When not

in use the constant current mode (CC mode), the LGH pin should be connected to SGND. Refer

to the product datasheet for availability of this pin function.

Pin 5 and pin 6 can be used to inject the isolated signal of a network analyzer through

(R214 = 49.9Ω) used for bode plot measurement in order to evaluate the stability in remote

sense mode.

9. Soft-start capacitor (C123): Capacitor connected to regulator TRK pin and SGND. The soft-start

time is set with an internal 47nF capacitor to roughly 0.94ms. C123 can be added to further stretch

the soft-start ramp CTRK = (tTRK_DESIRED x 50E-6) – 47E-9 where ITRK = 50µA.

10. Internal operational transconductance amplifier compensation network (C201, R212, C203, C202):

this network provides flexibility during loop compensation design to adjust the compensation.

For the purpose of this evaluation board C201 in series to the internal R(ZI) of 5kΩis used.

The maximum mid-band gain that can be achieved when using the internal R(ZI) is roughly

(20•log(R(ZI)•gm•VREF/VOUT_SET). With a reference voltage of 0.99V and output voltage of 5V max

midband gain is ~14dB. R212 + R(ZI) and C203 in series can be used to further increase the mid-

band gain. C202 can be used to lower the high frequency pole if desired. The high frequency pole

is set internally to ~1.7Mhz using a C(HF) = 56pF.

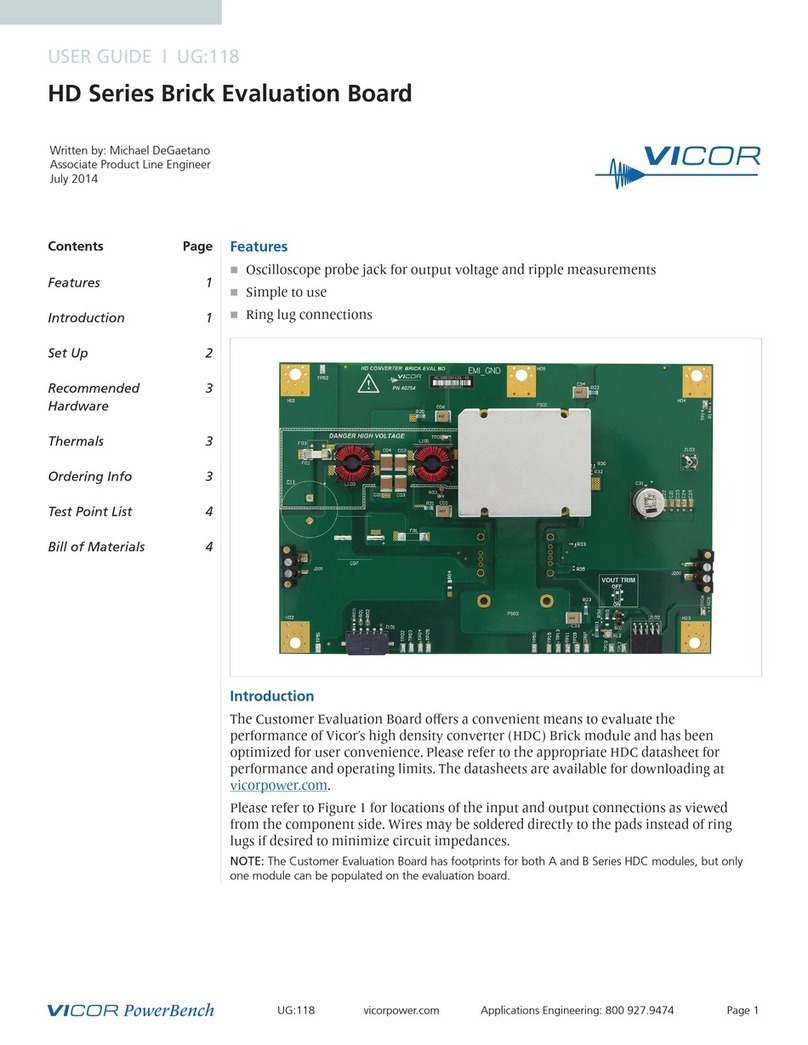

11. Output lugs: Sized for #10 hardware. Use these lugs to connect the output directly to the load.

12. Output oscilloscope probe Jack (J102): Used for making accurate scope measurements of the

output voltage (e.g. ripple). The jack is directly compatible with many common passive voltage

probes models. Remove the grounding lead and insulating barrel of the probe and insert the probe

tip and barrel directly into the jack, ensuring that the probe tip sits in the center socket of the jack.

To avoid the risk of an inadvertent short circuit, do not attempt to install while power is applied.

This Johnson Jack is kelvin connected to C113 positive pin.

13. Output filter: 12x 47µF output ceramic capacitors 1210 (C111- C122). Is used to achieve <1.5% of

VOUT peak to peak ripple.