UG:020 Page 4

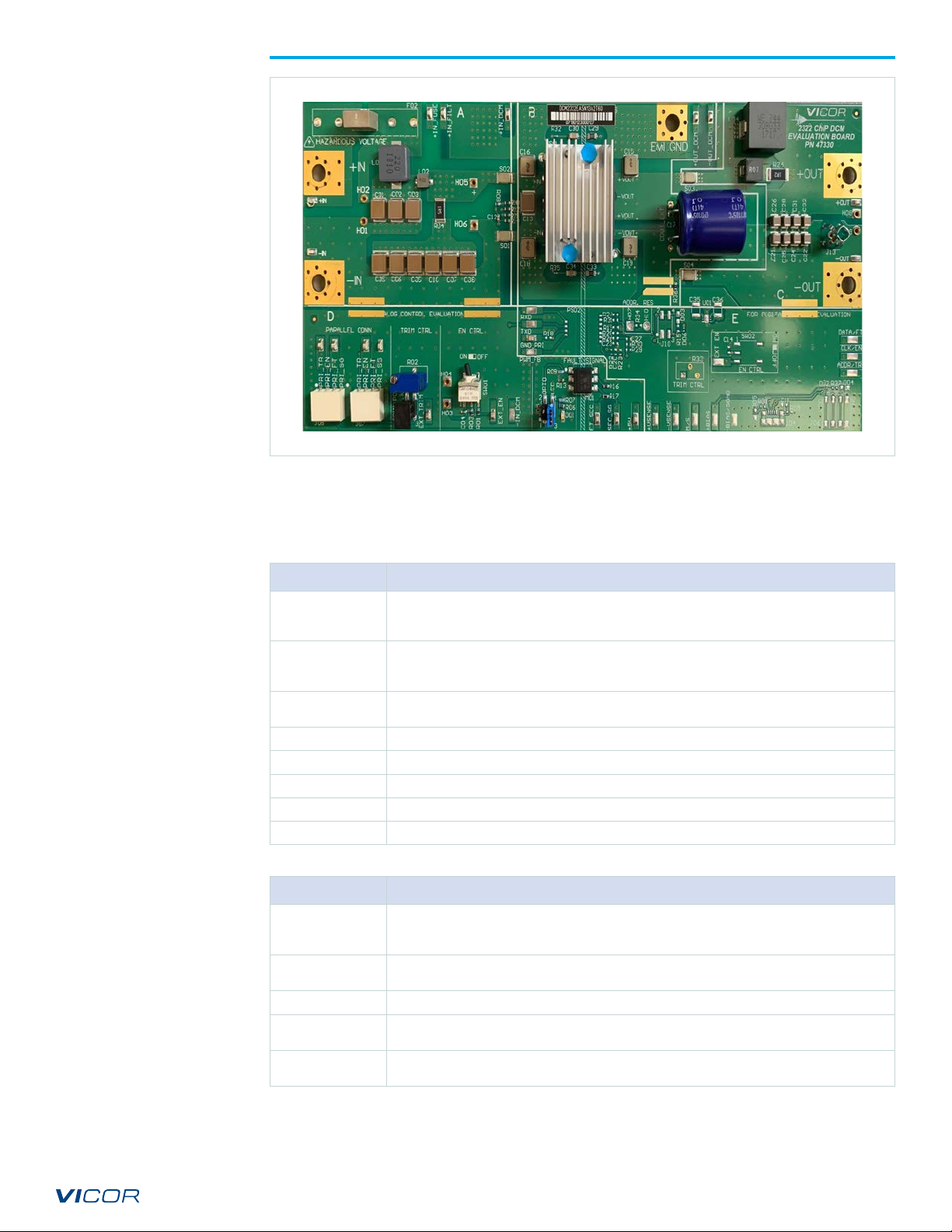

Board Description

The following section provides a detailed description of the evaluation board components, test

points and sockets.

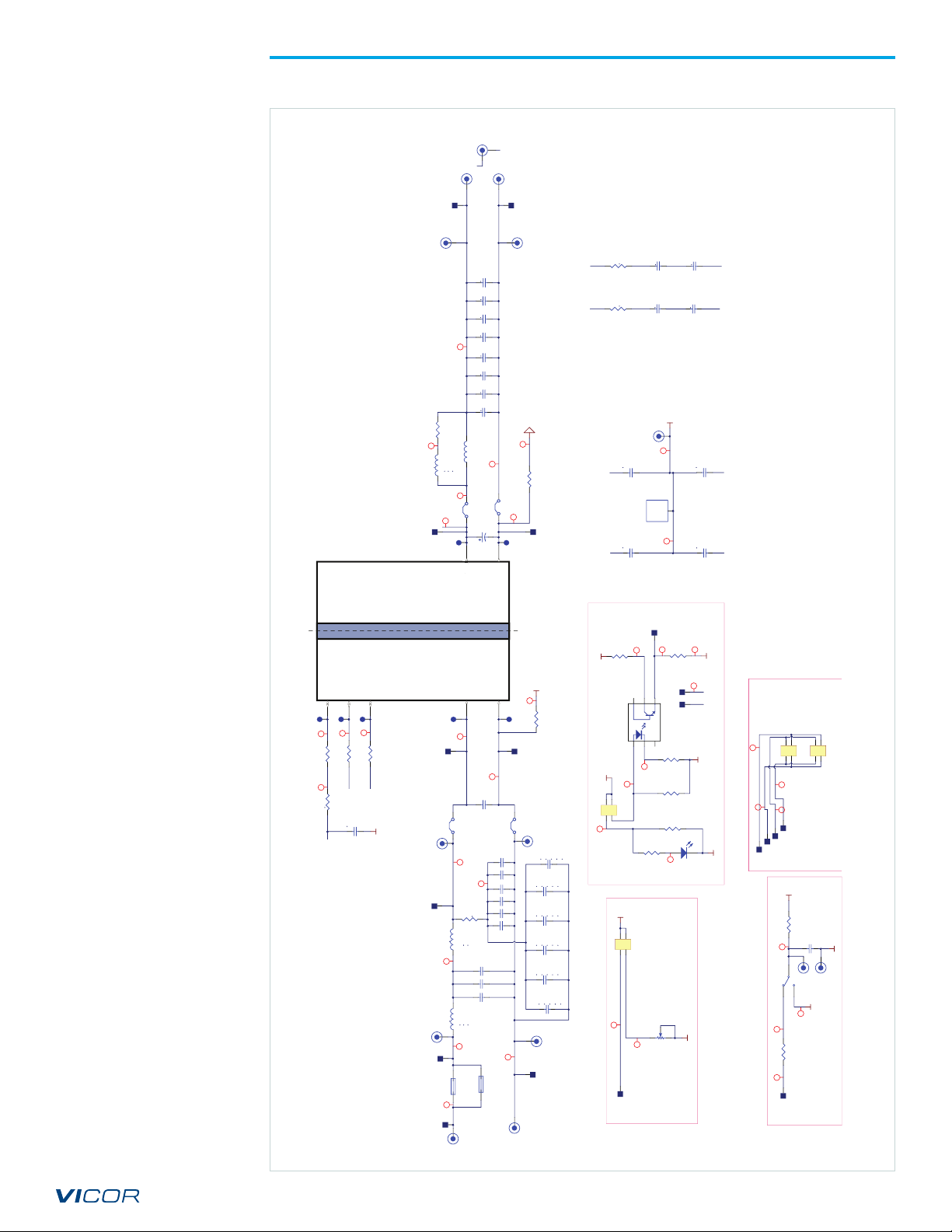

General Components

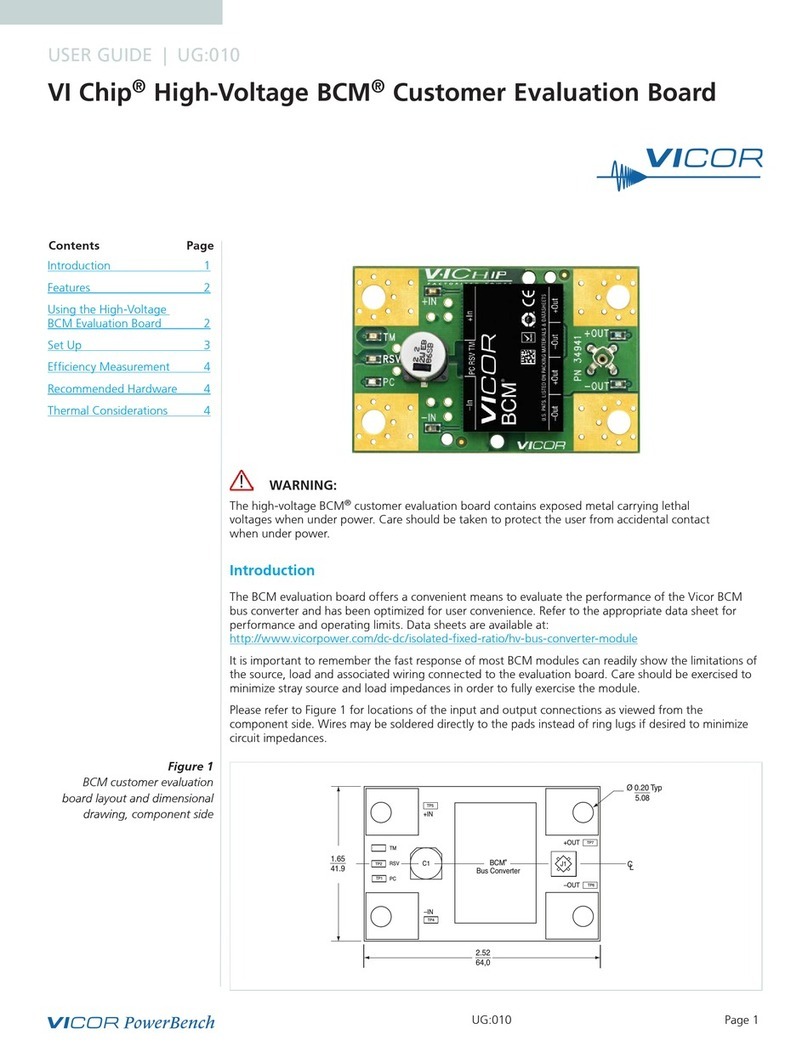

1. DCM (PS01).

2. Input lugs: Sized for #10 hardware. Use these for making connection to the input source.

This board does not contain reverse polarity protection. Check for proper polarity before

applying the power.

3. Input fuse (F01 & F02): Appropriately rated for the DCM model on the board.

4. Input filter: Ceramic input capacitors (C01 – C03, C05 – C10), filtering inductor (L01, L02) and

damping resistor (R04) provide input filtering. Sockets (H01 – H02) can be used for easy

installation of aluminum-electrolytic input capacitors. This board also adds H05 – H06 for

additional input bypassing.

5. Enable / Disable switch (SW01): When actuator is in top position towards “ON” text on the

board, the ENABLE pin will be open and the DCM will be enabled. When actuator is in bottom

position towards “OFF” text on the board, the ENABLE pin will be connected to PRI_SG and

the DCM will be disabled. When switch SW01 is ON, an external voltage source can control the

ENABLE state.

6. Header-jumper for trim control (J03): Provides the option to enable the trim function to set the

DCM programmed trim value via either the on board trim rheostat or an external voltage source:

a. Using potentiometer (R02)

b. Using external voltage source.

7. Output lugs: Sized for #10 hardware. Use these lugs to connect the output directly to the load.

8. Output oscilloscope probe Jack (J13): Used for making accurate scope measurements of the

output voltage (e.g. ripple). The jack is directly compatible with many common passive voltage

probes models. Remove the grounding lead and insulating barrel of the probe and insert the

probe tip and barrel directly into the jack, ensuring that the probe tip seats in the center socket

of the jack. To avoid the risk of an inadvertent short circuit, do not attempt to install while power

is applied.

9. Output filter: Filtering inductor (L04) and damping network (L03, R24), and ceramic output

capacitors (C21 – C22, C24 – 26, C28, C31 – C32) provide output filtering. Sockets H08 – H09 can

be used for easy installation of aluminum-electrolytic output capacitors.

10. Dual paralleling wire-to-board connectors (J07 and J08): Used for bussing control signals

and their reference (ENABLE, TRIM, FAULT and PRI_SG) across board assemblies during parallel

operation. The connector style provides simple “strip and insert” use with 18 – 24AWG solid wires.

Once inserted, a spring loaded barb retains each wire with no need for soldering. To release the

wire, insert a thin bladed tool (AVX 06-9276-7001-01-000 or similar) into the slot above each

wire entry point.