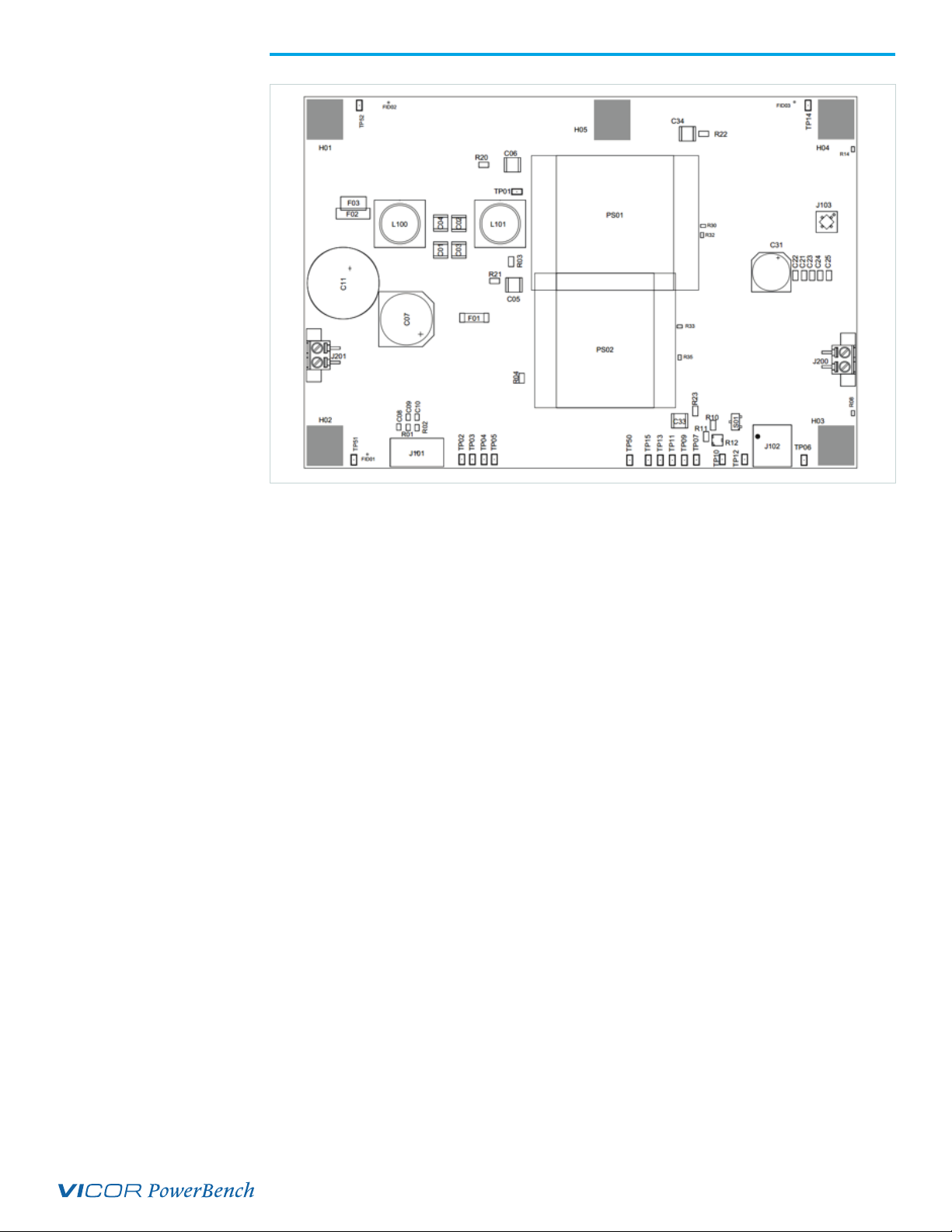

UG:118 vicorpower.com Applications Engineering: 800 927.9474 Page 3

GND

The GND terminal of the Customer Evaluation Board is provided for basic conducted EMI

testing of the HDC, during which it should be connected to earth ground.

Output Voltage Measurement Jack (J103)

This connector is provided to make accurate measurements of the output voltage of the

HDC. Many types of scope probes may be directly connected to this point if the probe is

equipped with a removable plastic sheath. To avoid creating ground loops when making

measurements of the output or input voltage, these measurements should be made

separately.

Input Current Measurement

A current probe can be passed around the +IN lead connected to the HDC.

Note: The input filter consists of capacitors C01, C02, C03, C04 and common-mode inductors L100 and

L101 on the Customer Evaluation Board. This filter is downstream of input current measurements.

Efficiency Measurement

As the HDC can deliver and consume large currents, the eect of the PCB must be

considered when making an eciency measurement. Be certain to accurately measure

the voltage directly at the HDC using the appropriate pair of contact points located at the

corners of the HDC.

Recommended Hardware:

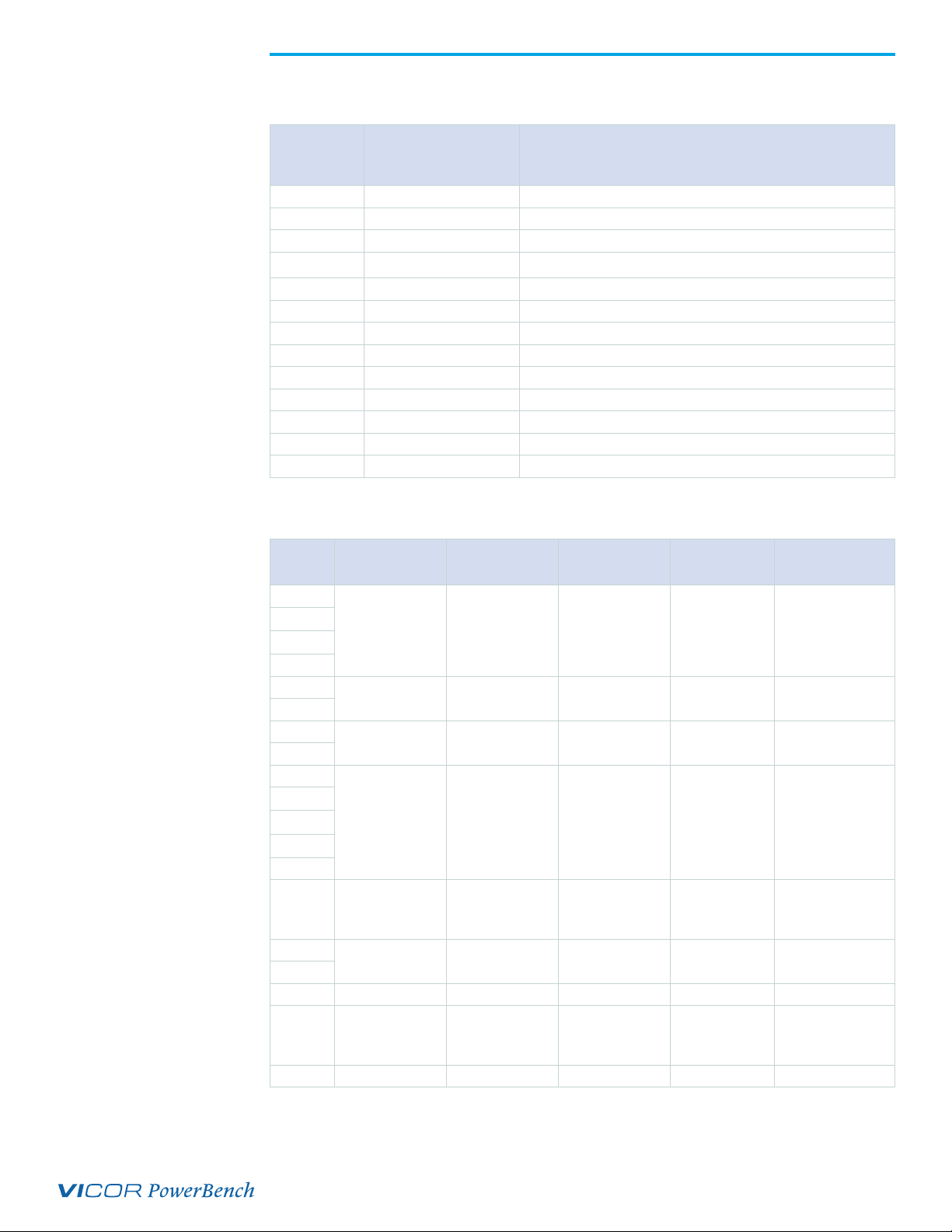

Qty Description Manufacturer P/N

5 # 10-32 lock washer

Kit # 410625 # 10-32 screw

5 # 10-32 hex nut

Kit # 41062 is included with the Customer Evaluation Board.

Thermals

For most lab environments a fan blowing across the evaluation board is recommended.

For additional thermal information regarding the HDC refer to the datasheet or contact

Vicor Applications Engineering for assistance (800) 927-9474.

NOTE: The HDC Customer Evaluation Board can operate between -20 to 100°C.

Caution

The HDC Customer Evaluation Board can comfortably operate at surface temperatures

which may pose a thermal hazard to the operator. Be careful not to touch any exposed

surface. HDCs may operate at potentially dangerous voltages and pose and energy

hazard. The Customer Evaluation Board is not intended for use in end item equipment.

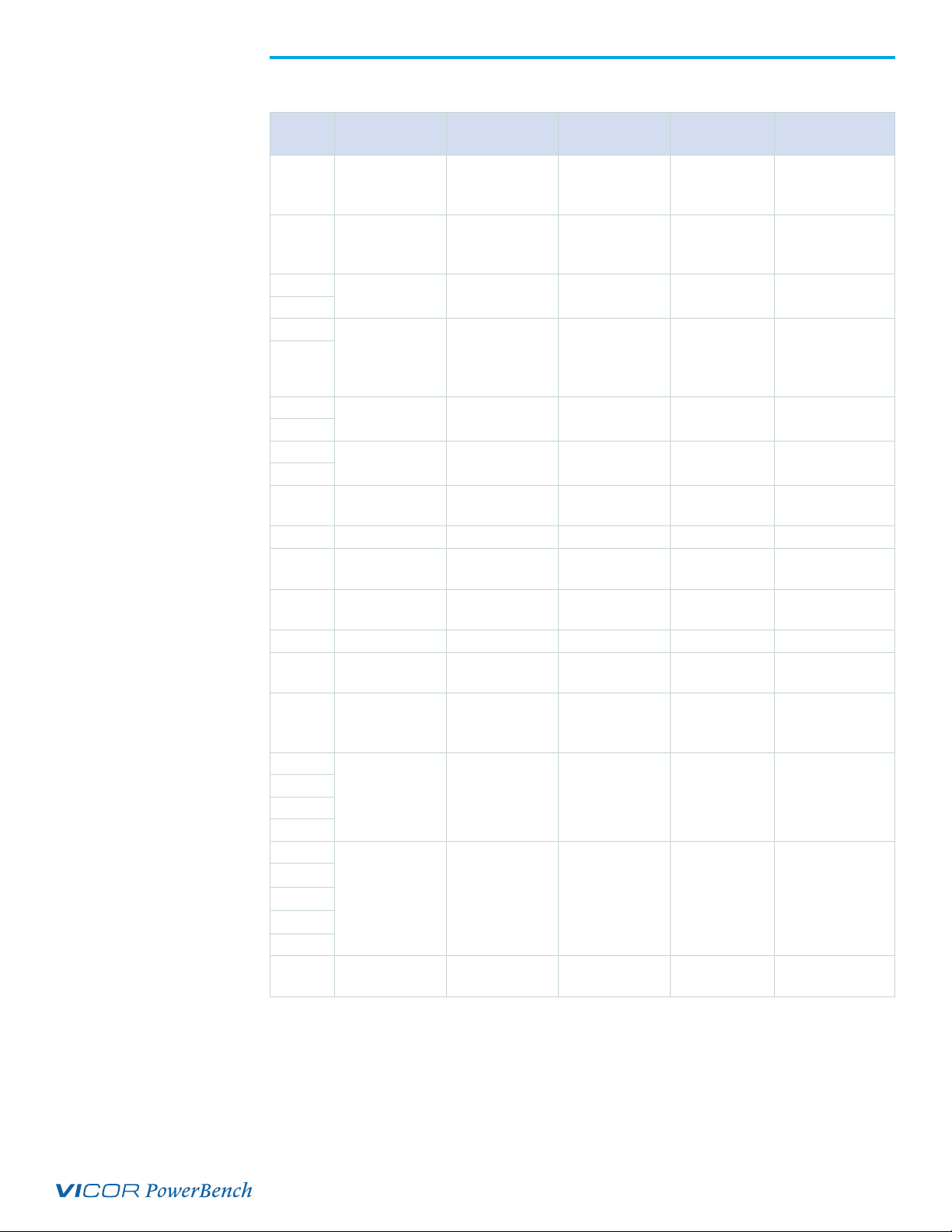

Ordering Information

The Customer Evaluation Board is specified by replacing the “–00” sux with “–CB” to

the appropriate HDCC model number.

See: http://www.vicorpower.com/dc-dc-converters-board-mount/hd-brick-dc-dc-

converters for model number listings.