UG:014 Page 5

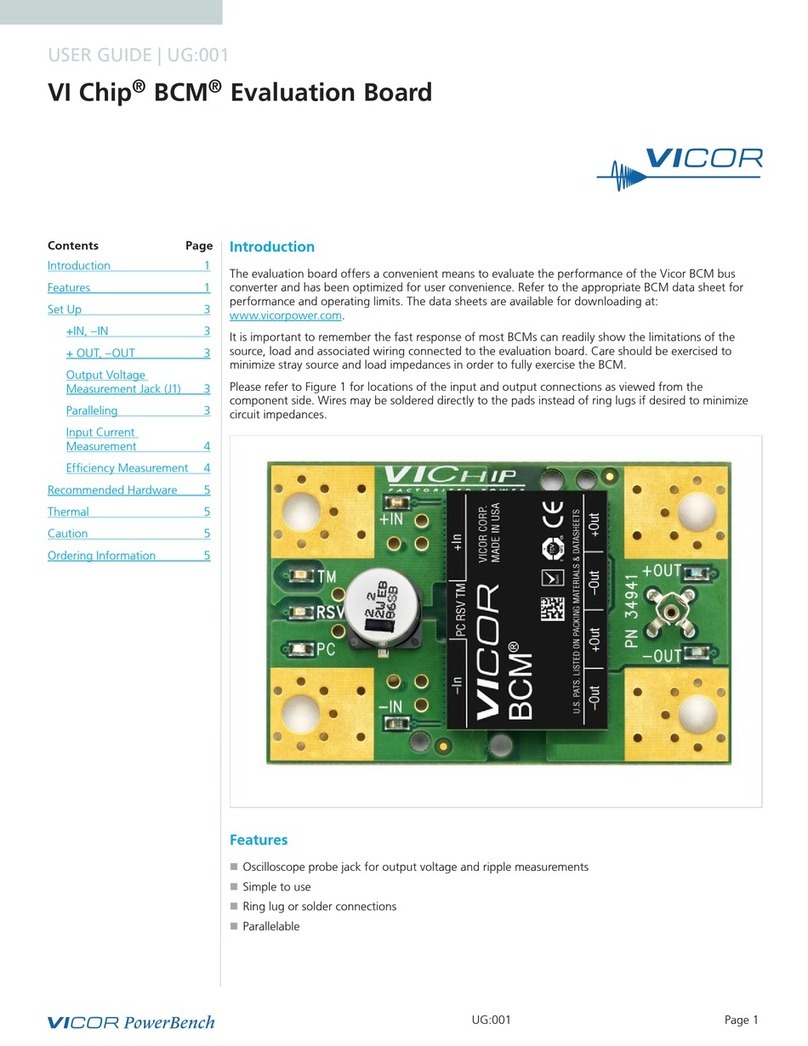

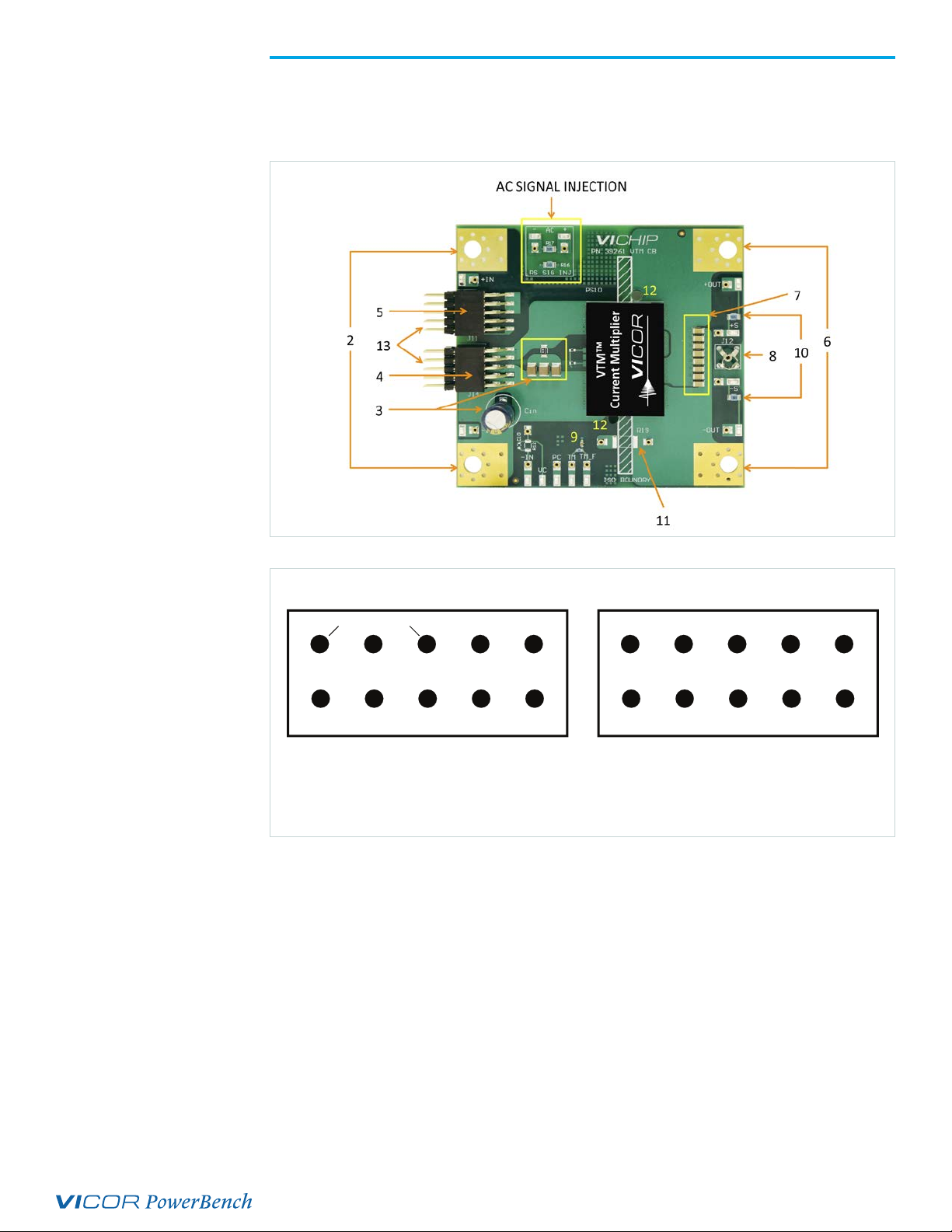

Test Points and Sockets Description

Each test-point socket accepts 0.015 – 0.025 inch diameter leads of solid wires and through-hole

components for use with external circuitry and test equipment. All test points are aligned on the board’s

edge for easy access, measurement and external circuitry connections. Each point is labeled and is

accompanied by an additional adjacent socket.

Reference

Designator

Functional

Name Functional Description

TP20

TP21

+IN

–IN

Input voltage test points provide Kelvin connection to input pins of the VTM™.

Use these test points for measuring the input voltage of the VTM to avoid error

due to interconnect losses.

H20

H21

+IN

–IN Sockets for +IN and –IN test points. Kelvin connected to the VTM input pins.

TP17

TP22

+OUT

–OUT

Output voltage test points provide Kelvin connection to output pins of the

VTM. Use these test points for measuring the output voltage of the VTM to

avoid error due to interconnect losses.

H17

H22

+OUT

–OUT

Sockets for +OUT and –OUT test points. Kelvin connected to the VTM

output pins.

TP12 VC

VC test point provides Kelvin connection to VC pin of the VTM. Can be used

to apply and measure the VC signal with reference to –IN signal. VC is used to

enable the VTM. Apply 14V to VC to enable the VTM, when not using PRM.

H12 VC Socket for VC test point. Kelvin connected to VC pin of the VTM. Aligned with

–IN socket for placing through hole resistor from VC to –IN.

TP10 PC

PC test point provides Kelvin connection to PC pin of the VTM. Can be used

to measure the PC signal with reference to –IN signal. PC can be used to

disable the VTM in the presence of input power. Connecting PC to –IN will

disable the VTM.

H10 PC Socket for PC test point. Kelvin connected to PC pin of the VTM.

TP11 TM TM test point provides Kelvin connection to TM pin of the VTM. Can be used

to measure and monitor the TM signal with reference to –IN signal.

H11 TM Socket for TM test point. Kelvin connected to TM signal of the VTM

TP16 FILTERED

TM

Provides the low noise measurement of TM signal. Output of the TM RC filter

can be measured using this testpoint with reference to –IN.

H15 FILTERED

TM Socket for TP16 test point.

TP13 –IN –IN test point provides Kelvin connection to –IN pin of the VTM. All signals on

input side of the VTM are measured with reference to –IN signal of the VTM.

H13 –IN Socket for –IN test point.

TP15

TP14

+S

–S

Output sense test points provide connection to the output pins of VTM

through local-sense resistors. Routed to connector J11 for use in

differential non-isolated remote-sense circuitry for remote-sense operation of

VTM and PRM™.

H15

H14

+S

–S Sockets for +S and –S test points.

TP18

TP19 AC SIG INJ

Can be used to inject the isolated signal of network analyzer for bode plot

measurement to measure the stability in remote-sense operation using VTM

and PRM

H18

H19 AC SIG INJ Sockets for AC +/– test points.

TP30 IM

IM test point provides the Kelvin connection to IM pin. Can be used to measure

the IM signal of the half VTM. IM can be used to monitor the output current of

the VTM. Available on half-VTM boards only.

H27 IM Socket for IM test point.

Table 1

Test points and

sockets description