3. CLEANING

Caution: child safety

Cleaning and user maintenance shall not be made by children.

Warning: do not jet wash or steam clean

This the appliance must not be cleaned with a jet wash or steam cleaner.

Warning: switch off and unplug

The unit must be switched off and unplugged from the electrical supply before cleaning.

Stainless steel surfaces will give you many years of trouble-free use as long as you follow a few simple rules. If it appears to mark do

not worry, it is usually not the steel but something deposited on it which has stained.

Wash all surfaces before use:

You should use a damp cloth and a mild detergent or soap, or similar cleaner. Wipe over with a cloth, rinsed well with clean water, to

remove any residue and dry the surfaces with a soft cloth. Clean regularly when in use. Do use soft cloths, nylon or bristle brushes.

Do not use:

Metal scrapers, wire brushes or wire wool pads as they can scratch the steel. Do take care when handling sharp objects as they can

scratch the surface of the stainless steel. Any scratches on stainless steel will blend together over a period of time and become less

noticeable with age. There is no detriment to the corrosion resistance or general performance of the material.

Do not use:

Bleach for cleaning purposes (remember dishwasher powders, sterilising agents and similar products all contain chlorides). If used,

black pit marks, large brown patches or other such effects may appear and permanent damage may be caused. If used inadvertently

rinse immediately with clean water.

Do not splash the unit with bleach when cleaning around the counter:

If you do, rinse the surface immediately with clean water thoroughly.

Do not allow:

Corrosive foodstuffs such as fruit juices, vinegar, mustards, pickles, mayonnaise, etc., to remain on stainless steel for long periods.

Wash and rinse away.

Do not leave:

Steel objects or utensils standing on the stainless steel surfaces for long periods. They can rust and leave marks. After cleaning with

detergent always remove residues with a wet cloth and wipe dry, if left they can have an etching effect on the surface.

Correctly applied the above instructions will result in continuous good looks!

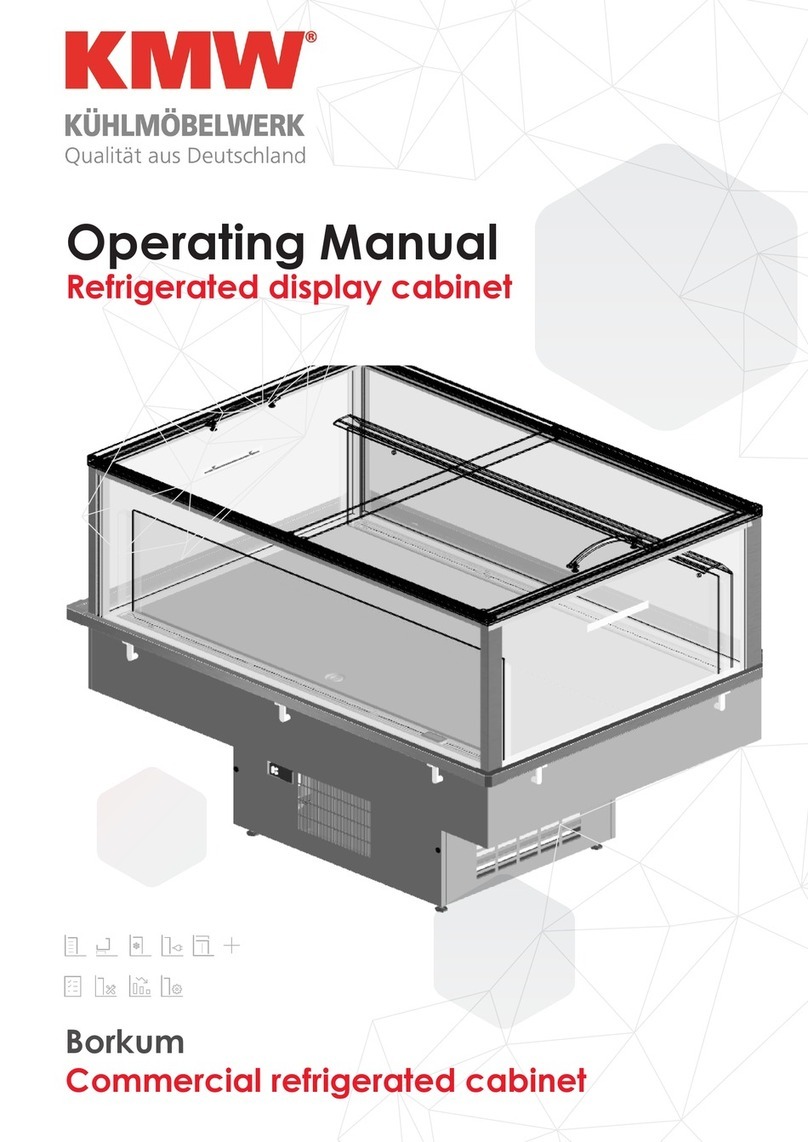

3.1. CLEANING UNDER THE SHELF AND BASE COVERS

Do not do this until the unit has been unplugged and

allowed to cool.

The covers over the shelves and base heating area are designed

to be removable for cleaning.

Removing the Shelf and Base Covers

(a) Each Cover plate can be removed for cleaning and allow

access to clear around the elements.

(b) Please note the covers are not interchangeable and have to

be returned to their original positions.

(c) Carefully lift each Cover panel from the unit and store safely.

Remove the Right hand (from the customer viewpoint) cover

first.

(d) In the event of a spillage the Front Vents can be removed to

allow full access (see below).

(e) Replace once cleaning is complete, ensuring the covers are

returned to their original positions.

Removing the Front Vent

(a) Once the Shelf covers have been removed, lift the Support

Bar up and remove.

(b) Pull the Front Vent assembly towards the back of the unit

and lift clear.

(c) There is now full access to the inside of the shelf to clean as

required.

(d) Once Cleaning is complete, replace the Front Vent by

locating the Tabs at each end into the slots and pushing firmly

forward.

(e) Replace the Support Bar into the Slots at the front and back

of the shelf/base assembly.

Figure 3 - Remove shelf covers

Figure 4 - Front lip removal