ANHUI WILLIAM CNC TECHNOLOGY

Chapter 1 Safety Matter

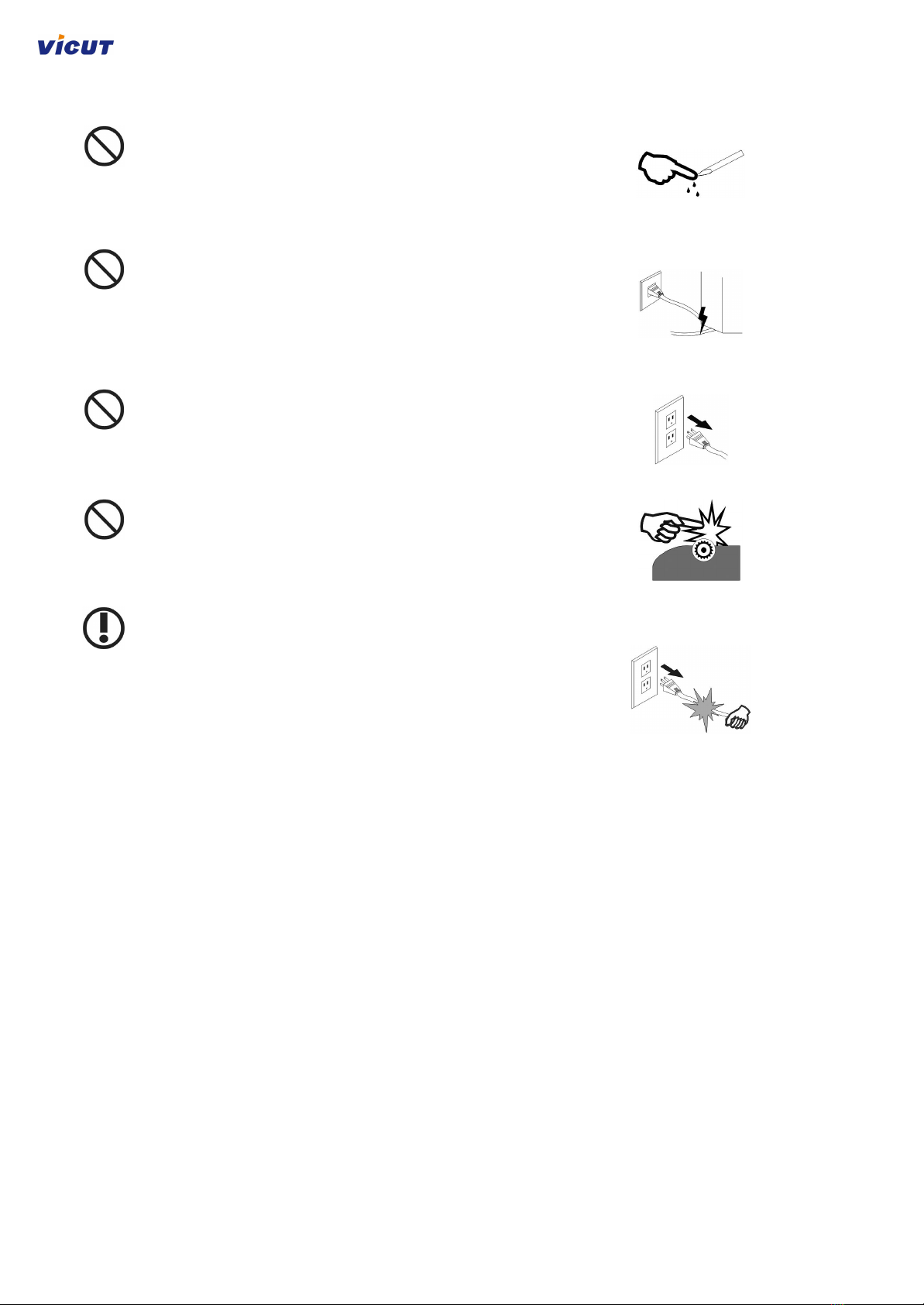

1-1 Safety matter needing attention

1. The operator should obey the following 4 basic safety operation principles

(1) The machine should be operated or maintained only by trained technician.

(2) Read the user manual in detail and understand its contents.

(3) For check convenience, put the user manual near the machine.

(4) The people including operator and maintenance technician should know location of E-

stop device and realize its function and operation methods.

2. Safety precaution before or after turning on the machine

Firstly confirm that whether all switches are OFF, and machine has been correctly

ground.

AC electric power source

The electric power source used on this machine is 1, 3 wires, 110V-220V~. Rated current of

the main power switching device 20A. Such switching device should be in compliance with its

safety relevant standards.

3. Safety precaution during handling and installation

To increase the machine working efficiency, the installation environment should be well

ventilated with good air quality. The surrounding temperature should be lower than 40C,

and prevention of rain and direct sunlight is required.

Safety precautions during handling and installation are as follows:

(1) Make sure that the foundation is strong enough to support the machine.

(2) Lifting operation is only allowed one person.

(3) When lifting the machine, nobody is allowed to be under or near the machine.

(4) Helmet is required during handling, installation or cleaning.

(5) If it’s necessary to climb on the machine, please use safe and secure ladder or

platform.

(6) Adopt proper device for heavy parts lifting.

(7) Confirm that whether the lifting wire rope is strong enough to lift the machine or

components.

(8) Please turn off the power before handling or installation. If power is required, let

others know the location of E-stop device in advance.

(9) Please wear leather gloves or other similar protective equipment during handling.