Southwest Graphic Whizard PT320 CC User manual

PT320 CC

Business card cutter

SET UP/OPERATOR’S MANUAL

755 Griffith Court, Burlington, Ontario, CANADA Tel +905-633-7663 Fax +905-637-4419

WWW.GRAPHICWHIZARD.COM

1

Table of Contents

Chapter 1 Safety........................................................................................4

1 Safety Precautions .........................................................................4

1-1 Safety Precautions....................................................................4

1-2 Warning Labels.........................................................................5

2 Safety Devices................................................................................5

2-1 Operational Safety Guidelines...................................................6

Chapter 2 General......................................................................................7

1 Outline of mechanism .....................................................................7

1-1 Purpose ...................................................................................7

1-2 Main technical parameters ........................................................7

1-3 Accessories ..............................................................................7

1-4 Machines Diagram....................................................................8

Chapter 3 Set-up, operation and maintenance .............................................9

1 Set-up............................................................................................9

1-1 Set-up Guide............................................................................9

1-2 Set-up Guidelines ...................................................................10

2 Operation .....................................................................................11

2-1 Cutting ..................................................................................11

2-2 Operation Panel......................................................................12

2-3 Datum Selection.....................................................................13

2-4 Cutting mode.........................................................................14

24 UP - 12" x 18" QUICK SET-UP….………………………………………………………………………..14

2-5 Set-up of the Cutting Parameters.............................................30

2-6 Job Guidelines........................................................................34

2-7 Longitudinal Knife Assembly Replacement................................36

2-8 Paper Weight Adjustment........................................................37

3 Troubleshooting............................................................................38

2

3-1 Safety cover fails....................................................................38

3-2 Paper Jamming ......................................................................38

3-3 Long Blade Jam......................................................................39

3-4 Cut Mark■not detected..........................................................39

3-5 Cut Mark Sensor failed............................................................40

3-6 Paper Size..............................................................................40

3-7 Paper Feeding........................................................................41

4 Aftercare......................................................................................42

4-1 Maintenance

4-2 Machine Parts Lifespan ...........................................................42

5 System troubleshooting analysis .........................................42

3

Chapter 1 Safety

This manual is designed to help you operate and maintain the PT320 CC

machine. Please read, understand and keep this manual in a convenient place

for easy access.

DO NOT operate the machine until you have read and understand the

instructions in this manual.

Graphic Whizard Inc. shall not be held liable for incidental consequential

damages resulting from: improper or inadequate maintenance by the

customer; unauthorized modifications or misuse; or operation outside of the

environment specified for the machine.

Graphic Whizard Inc. is committed to continually improving the design and

performance of our product line. Please note: The design and specifications

of this machine are subject to change without notice and without our legal

obligation.

All rights are reserved. No part of this manual may be photocopied, reproduced

or translated to another language without the prior written consent of Graphic

Whizard Inc.

1 Safety Precautions

1-1 Safety Precautions

To prevent any accidents, please follow the precautions below strictly.

(1) Have the ground-wire of the power supply well grounded.

(2) Ensure that any loose hair or clothing are tied back and away from moving

parts of the machine when operating.

(3) Do not touch any electric components of the machine and ensure electrical

components stay dry and out of contact.

(4) Always turn the machine off when not in use.

(5) In case of any issue with the machine, turn off the main power.

4

(6) Please contact your dealer or Graphic Whizard with any questions or

concerns and before attempting to service machines.

1-2 Warning Label

Operators are required to pay special attention to the places fitted with

the warning labels during operation.

Description of the warn labels

2 Safety devices

To prevent accidents and possible injury to the machine and operator

safety measures have been put in place. Please ensure the Operator is aware of

all safety features and possible hazards on the machine.

2-1 Operational Safety Guidelines

Both fixing and lock covers are set to prevent any tools and clothes from

being rolled into the machine.

A. This warning indicates a pinch point.

Please exercise caution and ensure you are

well clear of nay moving parts

B. This warning indicates a chance of

electric shock. Please do not tamper with

or attempt to repair any electrical machine

components.

C. The machine uses an extremely sharp

cutting blade- do not attempt to touch

anywhere near working parts while it is

running and exercise caution when near

the blades.

5

Never run the machine if either of the covers are open or damaged. Once

the lock cover is opened, the machine will stop moving right away.

2-1-2 Lock cover, fixing cover

⒈Upper cover ⒉Switch for lock cover

⒊Left-side cover

⒋Right-side cover

⒌Front cover

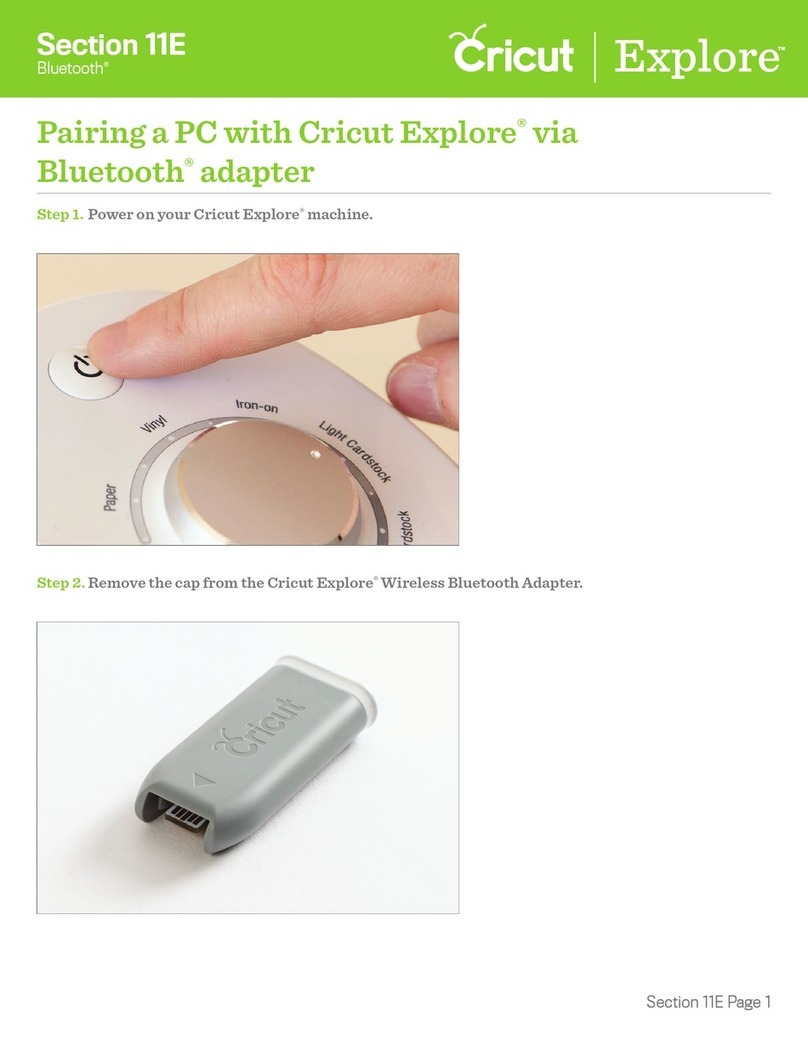

Fig.1-1Front

Fig. 1-2 Top Fig. 1-3 Back

Safety Labels

⒍Take care- pinch point ⒎Take care of sharp cutter edge

⒏Take care of sharp cutter edge ⒐Take care of sharp cutter edge

⒑Take care of electric shock

6

Chapter 2 General

1 Outline of mechanism

1-1 Purpose

A quick and simple card cutting machine to expertly cut finished cards from a

12” by 18” stock.

1-2 Main technical parameters

Cutting Longitudinal: cutting by a roller;

horizontal: cutting by a lateral guillotine blade

Feeding Automatic soft friction feeding

Paper size A3(297×420mm) 11” x 17”,SRA3(320×450mm) 12” x 18”

Paper thickness

0.20mm(180g/m²)--- ~0.35mm(350g/m²)

Cutting speed 250 business cards in under 2 minutes

Cutting size Longitudinal:( 89, 85,90,95)mm

Horizontal:(45;50;54;90;95;127)mm;40-250mm,customize)

Mechanical

dimension 550mm×350mm×240mm (L x W x H)

Operating

environment -15

℃

~+40

℃

humidity 35%~70%

Weight About 21Kg, 46 lbs

Power supply AC 90~260V,50/60HZ,0.5A

1-3 Accessories

No

Item

Quantity

Remark

1 Operating instructions 1 (This manual)

2 Business card catcher 1 For collecting name cards

3 Cross Screwdriver 1 For machine adjustments

7

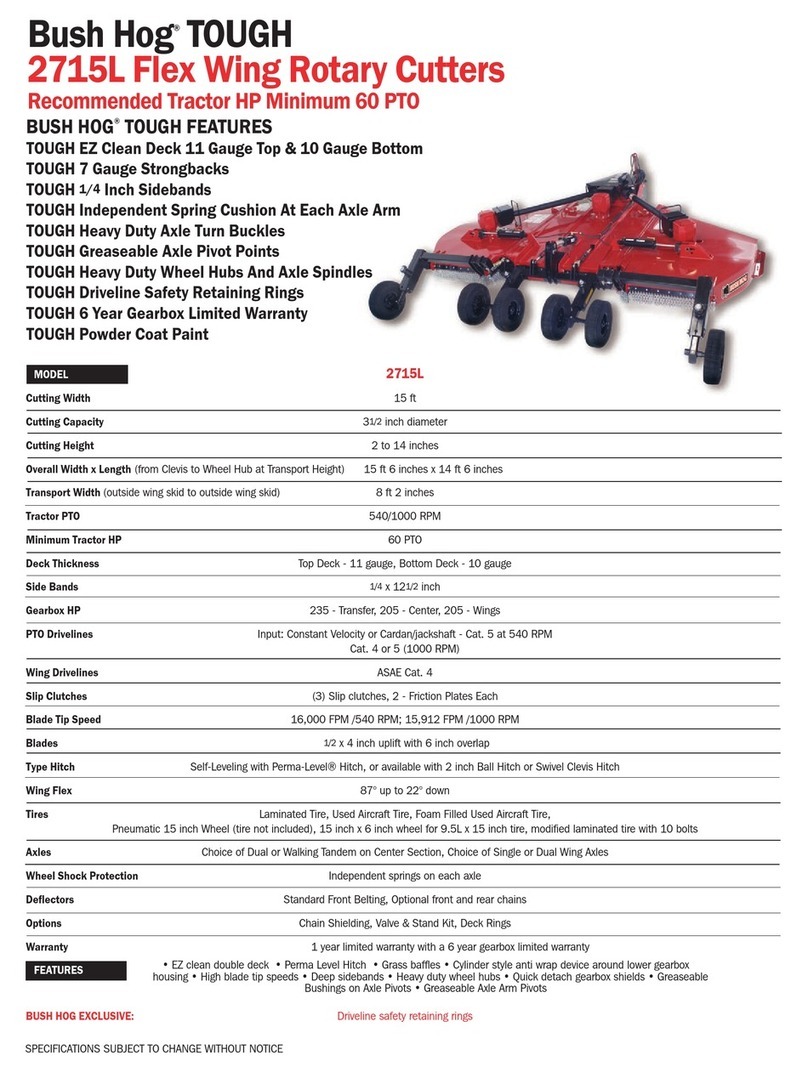

1-4 Machine Diagram

1 Left side cover 2 Right side cover

3 Operation panel 4 Upper cover

5 Paper feed tray 6 Feeding wheel

7 Power switch 8 Frontal cover

9 Power cord 10 Lock nut

11 Paper weight adjustment needle 12 Paper weight adjustment needle

13 Left paper guide plate 14 Right paper guide plate

15 Paper feed wheel 16 Horizontal knife

17 Cut wheel 18 Static prevention

19 Business card catcher 20 Waste collection

8

1

Setting 320CC Parameters

The 320 Card Cutter is capable of cutting 24 business cards from 12X18 sheet stock. To produce the

cleanest cuts, some adjustments may be required. Let’s start by defining the menu options.

When the 320CC is powered on and ready, the screen will display the current settings. Here’s a

breakdown of the selected settings in the image below.

0024 –this displays the number of cards the cutter will cut from a sheet of 12X18

SRA3 –although this is a European size definition, the 320CC has been set up to accept 12X18 sheets.

The actual measurements for this setting is 12.59 X 17.71, which is well within the capabilities of the

320CC.

3.50X2.00* - defines the size of the cut cards

in –the current measurement value.

Now, this can be changed according to your needs. There are 4 buttons above the display that let you

make changes to the current cut options.

Mode Changeover –allows the user to change the cut size of the business card. See appendix for all

available options

Set Parameter –allows the user to make changes to the parameters with is a subscribed mode.

Start (+) –starts the cut process. The + is used to change parameter settings.

Stop (-) –stops the cut process. The –is used to change parameter settings.

2

Now we will take a look at the Set Parameter options. Press the Set Parameter button to navigate

through the options.

Note: though many of the parameters are adjustable, the selected mode will program the default

parameters. Some changes should not be required.

Cut Pieces –this is defined by the Mode. In this instance the 320CC is set to cut 24 pieces. This number

increases in increments of 24.

Datum selection: frontal end or mark █–this sets the datum type. In this instance, the 320CC will use

the frontal end. Mark █will read the registration mark.

3

Language –set to English

Mark █posit comp: +0.000 in –registration mark compensation. When setting the 320CC to cut for the

first time, set the compensation to 0.000 and make changes only if needed. Changes to this parameter

will only be reflected when the Datum is set to Mark █.

First cut comp: +0.000 in –first cut compensation. When setting the 320CC to cut for the first time, set

the compensation for 0.000 and make changes only if needed. This permits the user to adjust the

position of the first cut.

Card length comp: +0.000 in –card length compensation. Use this to adjust the size of the card length.

When setting the 320CC to cut for the first time, set the compensation for 0.000 and make changes only

if needed. This adjusts the length of the card f you are cutting standard business cards (3.5 X 2).

4

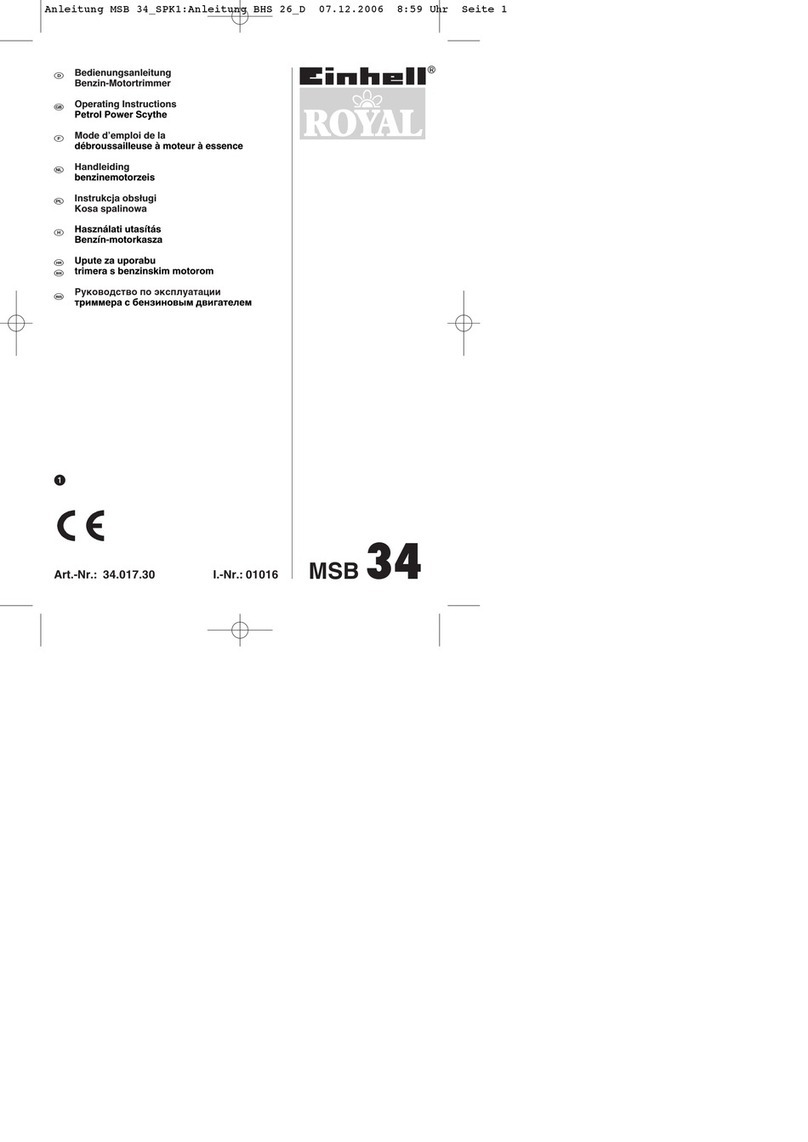

Gutter cut comp: +0.000 in –gutter cut compensation. Use this to adjust the size of the gutter cut

between cards. When setting the 320CC to cut for the first time, set the compensation for 0.000 and

make changes only if needed.

Sub-accumulated cards: 2265 –current subtotal of cards cut per current job. This parameter can be

cleared by pressing the (-) stop button.

Accumulated card 0000NNNN (where N = number) –life counter of total number of cards cut. This

number cannot be cleared.

5

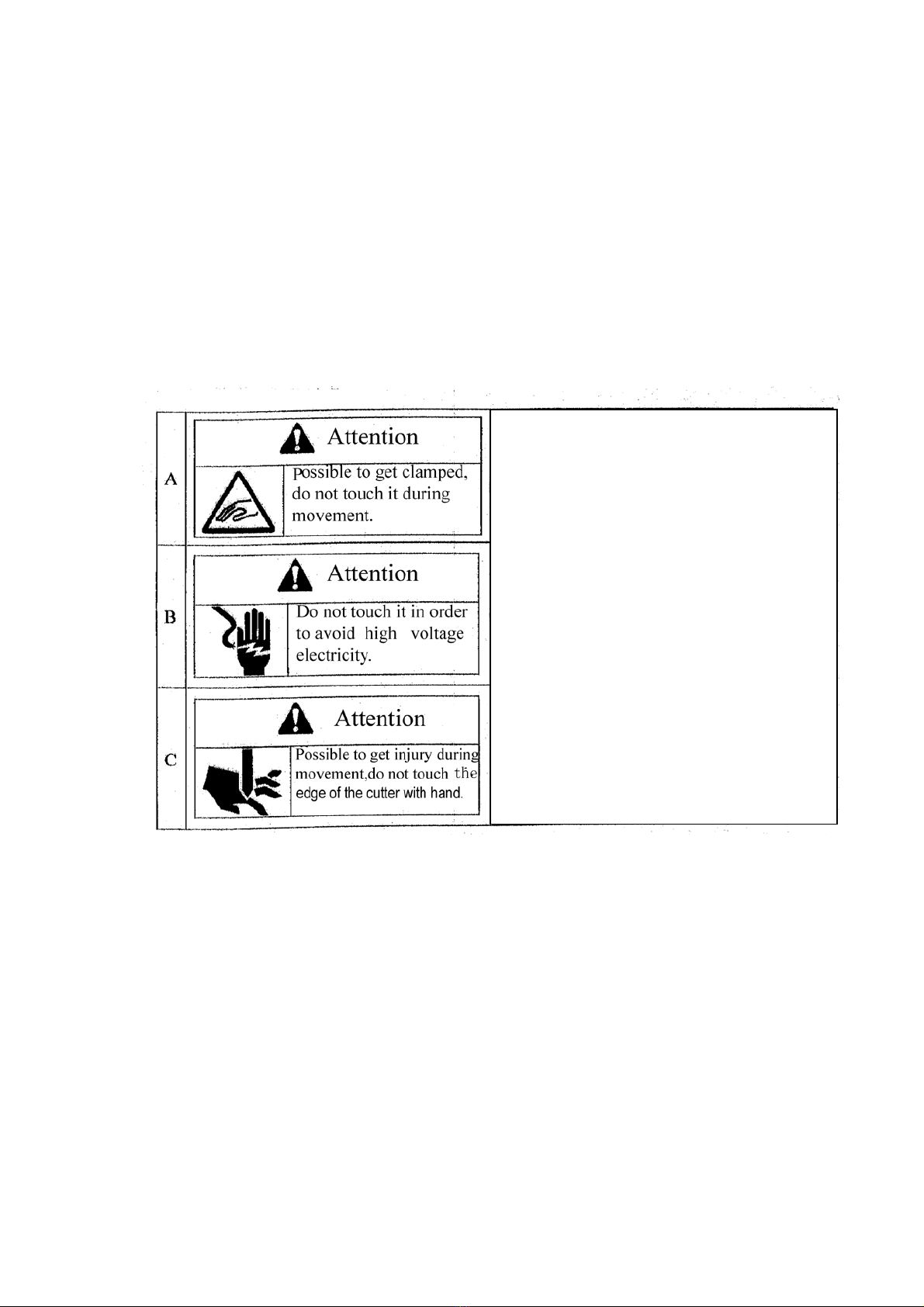

Slitting width –displays the current slitting width. This parameter is set based on the mode selected.

This can be adjusted however, the default is set based on the selected mode. Note: the slitters are fixed

and cannot be changed. Though the data can change the slit cut will remain at 3.5. Any change to this

parameter will not be reflected in the cut. This parameter is for information only.

Sheet size: A3 or SRA3 –displays the current sheet size. Note: though the option is defined as SRA3, the

320CC has been set up for North American parameters. This parameter is for information only. Changes

to this parameter will not be reflected in the cut.

Column number of card –displays the number of columns under the selected mode. 1 –4 columns can

be set. The default selection is set based on the selected mode. This parameter is for information only.

Changes to this parameter will not be reflected in the cut.

6

Factory setting loaded –loads the factory settings. Do not change this setting.

Unit –allows the user to set the unit of measurement: inch or mm

Making adjustments for cut accuracy

Though digital and offset printing creates near-perfect templates, there will be instances where some

minor adjustments are required. Please use the following to create the best cut for your business cards.

Paper alignment (slitter cut)

The slitters are fixed in the 320CC and should not require adjusting. Before making any electronic

adjustments, ensure your cut material is properly centred in the 320CC feed table. As depicted in the

image below, the paper position is adjustable. Simply move the left and right tabs to align the paper.

Once the template is centred, you can make adjustments to the gutter cut. Run a test cut to check the

alignment of the business card and adjust the following as needed.

7

Registration mark variance

Permits the user to adjust the cutter to compensate for the registration mark position. Run the first cut

and check the alignment of the image. Make adjustments according to the outcome. A negative number

will shorten the cut; a positive number will lengthen the cut.

First cut variances

The first cut can be adjusted. Note, the numbers below show centre, maximum, and minimum variance

of the first cut from the leading edge. This parameter is not used with the registration mark.

First cut at 0.000 = 0.3410 inches

First cut at +0.078 = 0.4335 inches

First cut at -0.078 = 0.2940 inches

Card length

To adjust the length of the card, increase or decrease the card length parameter as needed. Note, there

is no adjustment for card width.

Gutter cut

The gutter cut compensation changes the size of the gutter as the cards are cut. This parameter

compensates for image shifting.

8

Demonstration in Images

The following details setting the parameters for Graphic Whizard 3.5X2 business cards on 12X18 stock.

We start by selecting the Mode (if not already selected). For the GW business cards, we select 3.50 X

2.00 24 up SRA3. Run test cuts to centre the stock on the slitters. Once that is complete, check the

image alignment for first cut and gutters.

Start with all parameters are set to zero. The image below shows the first cut of GW business cards with

first cut and gutter set to zero.

The above image shows the results of the first cut with parameters set to zero.

A close-up shot shows only 7 cards were cut. The 8th card ended up as waste. To fix this, we

will have to adjust the gutter.

Because we lost a row of cards as waste, we know we have to decrease the size of the gutter. We set

the gutter to -0.011 and ran another test.

This image shows the gutter variance. The first set of cards was cut with the gutter set to zero. The

second set was cut with the gutter set to -0.011 and the third shows the gutter set to -0.015. We use the

green line as the benchmark. -0.011 is near-perfect but -0.015 starts shifting the image in the opposite

direction, making the cut size too small.

Chapter 3 Set-up, operation and maintenance

1 Set-up

1-1 Set-up Guide

(1)Take the machine out of the package.

(2)Place it on a safe, solid, fixed and stable working table.

(3)Insert the business card catcher on the back of the machine, then place it

flatly.

Insert it completely and ensure contact with the magnetic switch.

(4)Make the ground-wire is grounded securely in order to eliminate the static

electricity.

electric shock may occur.

(5)Please make sure of the power switch is properly connected.

9

1-2 Set-up Guidelines

Please use this machine under the following conditions:

●Horizontally fixed

●Well ventilated place

●Leave a proper workspace around the machine.

●As this machine is made with a precise mechanism and electronic elements,

ensure the machine is clear of the following:

●Direct sunshine

●Mists

●Moisture/ wetness

●In an area with frequent temperature changes

●Areas which may be consistently vibrating.

●Please do not use any other plugs in the socket unless used specially for the

machine.

●Use a static-electricity preventing cover and a humidifier for any place in

which there may be electro-static buildup

●Do not place the machine on a table smaller than itself.

10

2 Operation

2-1 Cutting

Rate cutting test upon the flow below in the initial use.

(xx)=85,89,90,95

Have the machine placed

turn on the power switch

press [start] key to let it idly move once,

place the printing test used paper on

the paper feed desk

Paper selection: A3

Cutting mode selection

(xx)

×50

mm

(xx)

×54

mm

(xx)

×95

mm

Adjust the left-right positions of the paper feed desk

cut the test paper

End of test

Adjust the cutting size

Accurately cut without

error

(xx)

×90

mm

(xx)

×127

mm

customise

mm

Detected with

paper mark ■

Detected with

front-end of paper

(xx)

×45

mm

11

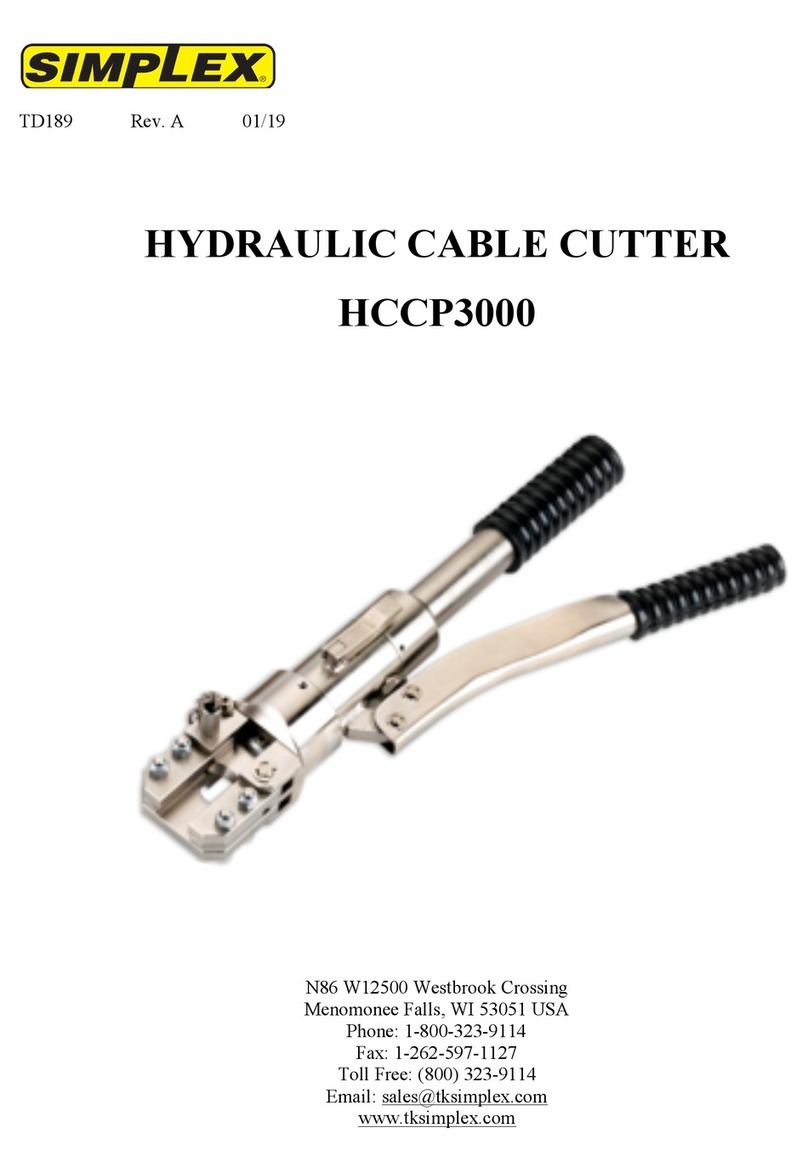

2-2 Operation panel

(1) Back of the panel

●Mode changeover key: Standby, changeover to the cutting mode, return

to standby state after setting parameters.

●Parameter setting key: used to adjust the cutting size and set the cutting

paper number

●Start (+) key: start cutting when in the standby state; increase the value in

the cutting size adjustment

●Stop(-) key: stop cutting during a job; decrease the value in the cutting

size adjustment

●LCD screen: display the cutting mode and counting

(2) LCD display

After the power is turned on, the machine starts initialization and then

goes into the standby state. The said state means the machine has finished

initializing but not entered into the cutting mode (the machine is stopped),

the LCD in the standby state will display:

LCD

screen

Mode changeover

Parameter set

Key

Start (+)key

Stop(-) key

12

Table of contents