8/ 30

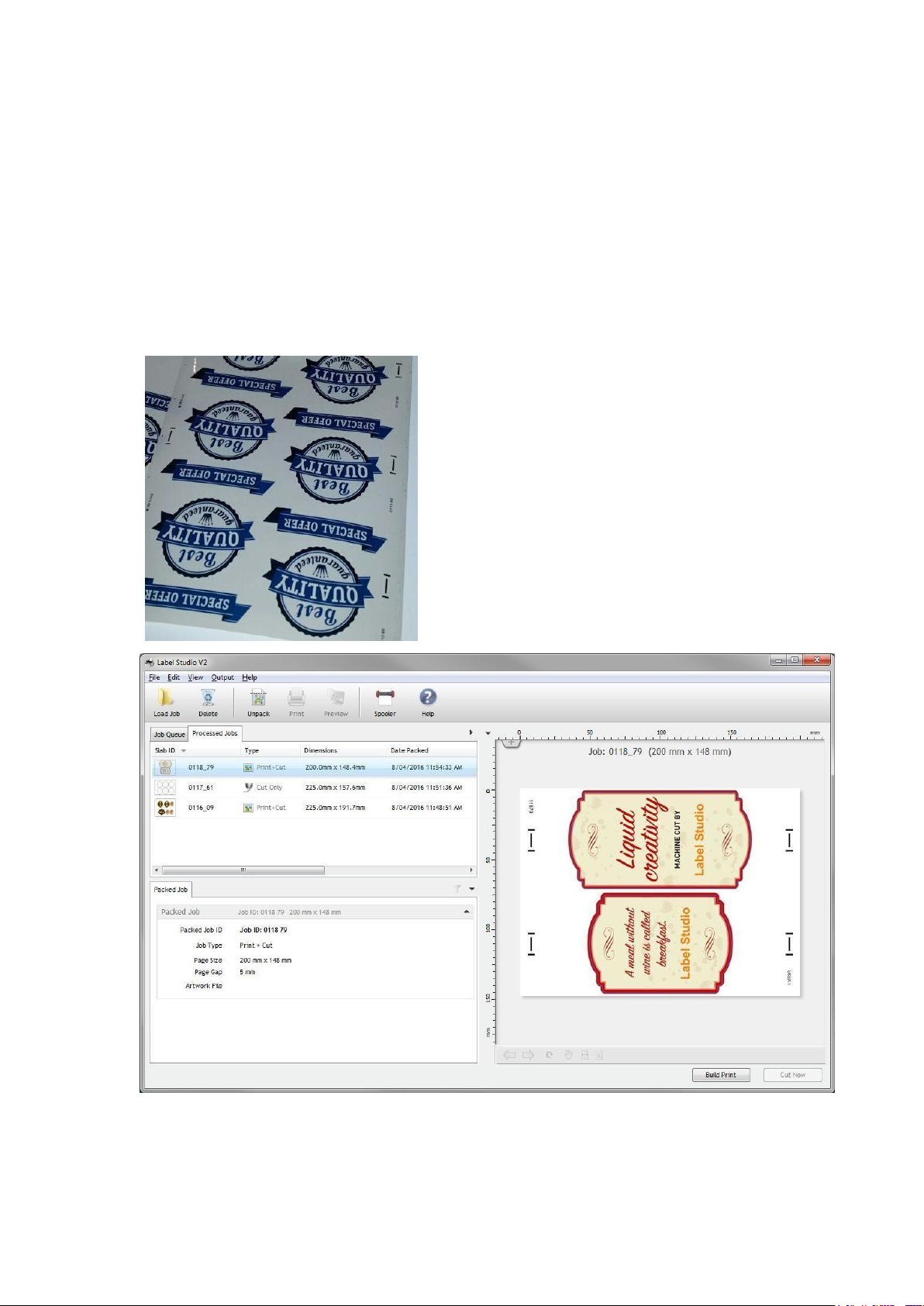

When you select the cutting color, you have the option to also allow this color to print, or by

default, the selected cutting color will not be printed. You can visually inspect the selected

cutting contours by changing the view mode to either “Show Overlay”, “Show Print” or

“Show Cut”.

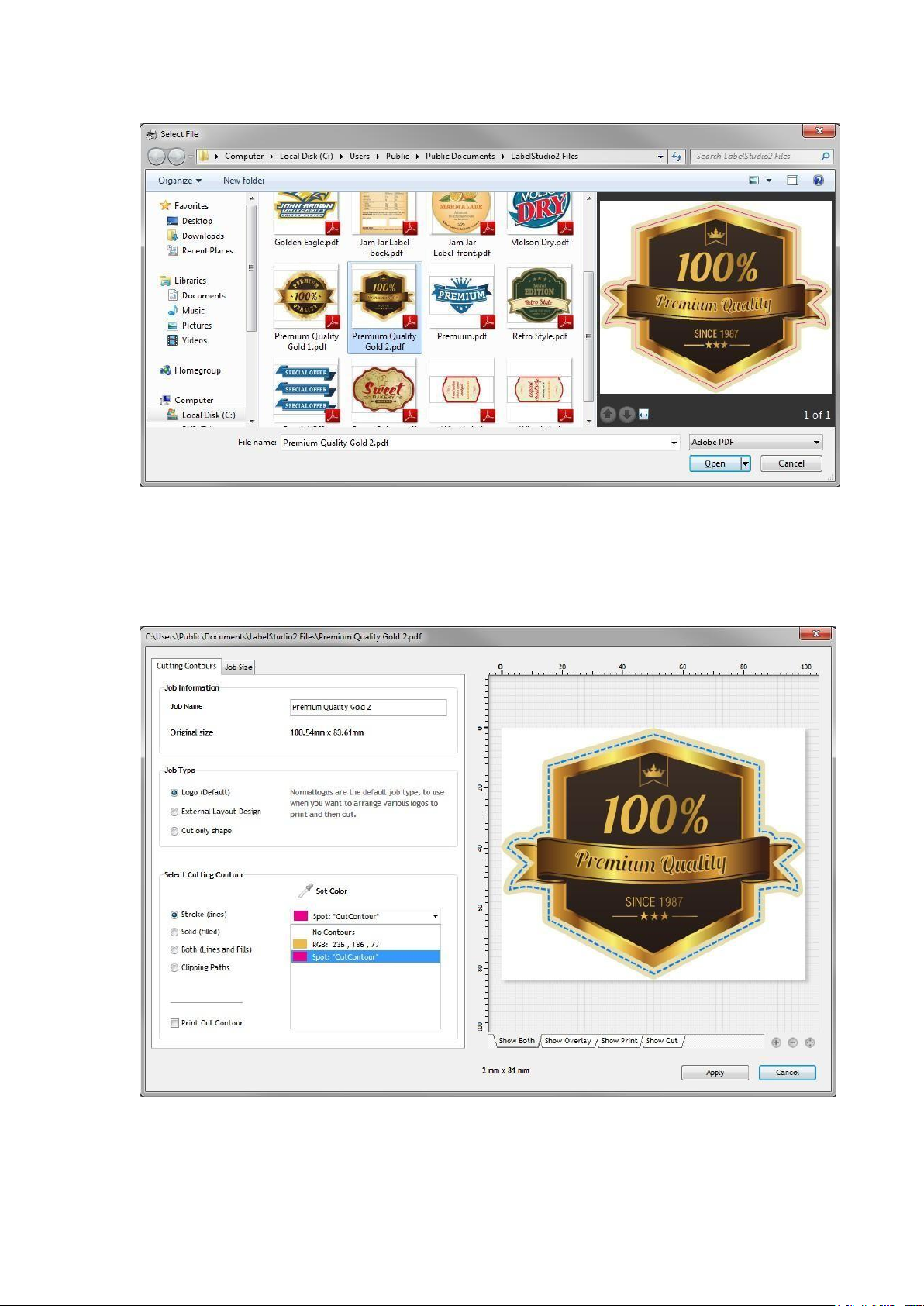

Creating a job layout

After you have loaded the required artwork jobs, you can now build a job layout to be print

and cut. The first thing you should do is specify the page options to match the size you

wish to print.

Paper Width: Total size of printed artwork. This should be slightly less than the maximum

printing size of your printer.

Edge Margin: How much gap to allow from the left and right edge of the paper, before

placing the alignment marks.

Vertical spacing: This setting is the amount of gap to add between each row of logos.

The page layout is designed so that when you print multiple copies of the layout, they

should be printed with no gaps between them (on the printer), as the exact gap spacing

required is already built into the page layout, using the vertical spacing setting. This allows

you to create a single layout that can be repeated as many times as you wish, joining

together seamlessly to fill your roll with the final print.

Horizontal spacing: The amount of gap to allow when positioning logos adjacently in

the horizontal direction.

Auto Center: When this setting is selected, the page is treated as a series of columns, so

if you had 2 logos on the same row, each would be cantered on either the left or right half

of the available layout. This setting is useful for multi row printing, where you want top and

bottom logos to be cantered to each other.

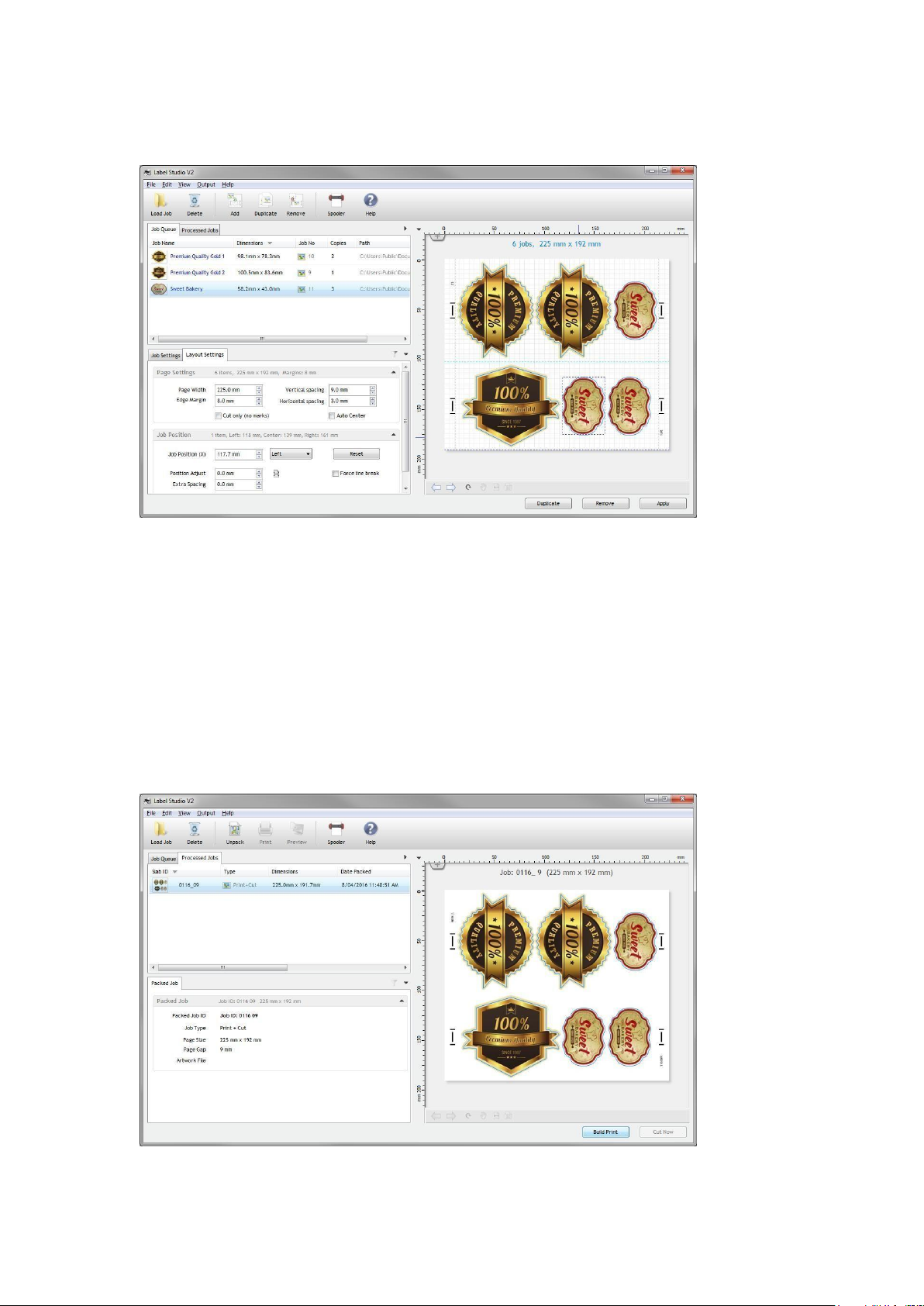

Adding Jobs to the Layout

With the selected jobs selected, click on “Add” to place the selected jobs into the current

layout.

The buttons at the bottom of the screen will change, depending upon the selection,