Instruction manual - English - EN

3MNVCNTW_1811_EN

1 About this manual

Read all the documentation supplied carefully before

installing and using this unit. Keep the manual in a

convenient place for future reference.

1.1 Typographical conventions

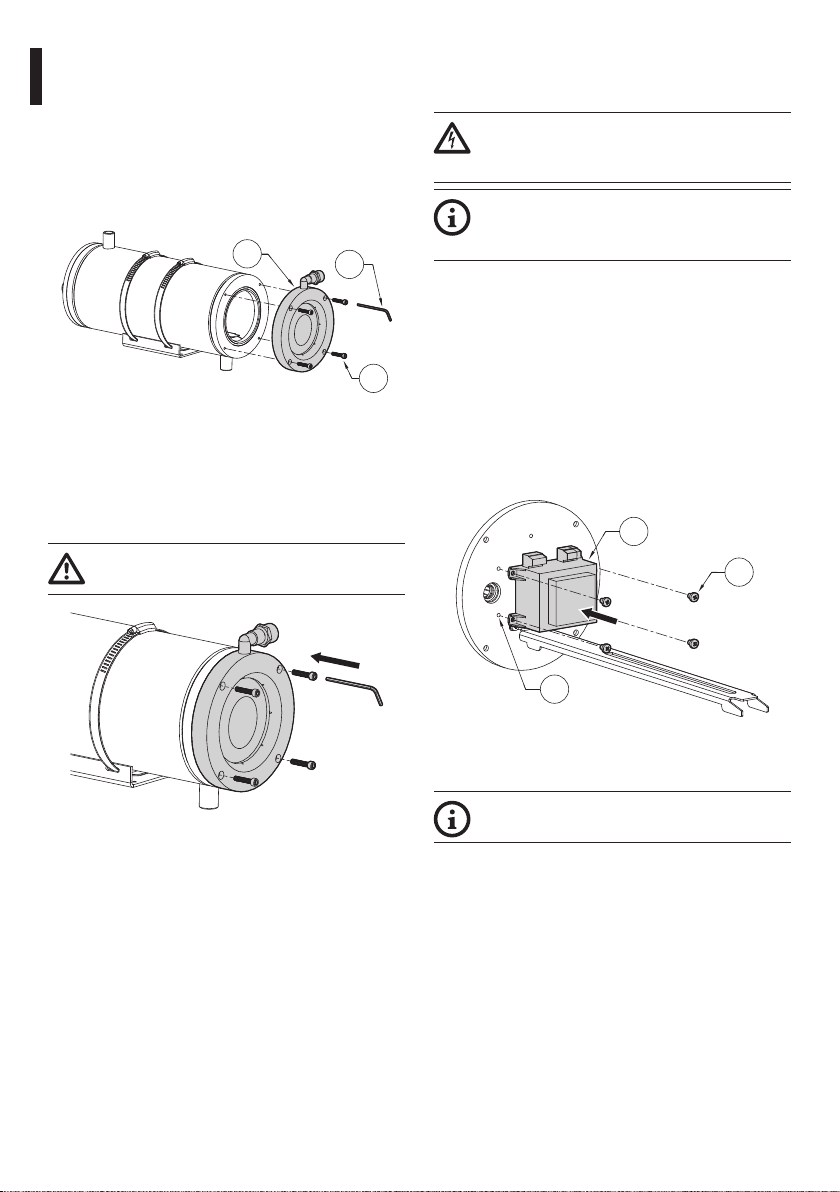

DANGER!

High level hazard.

Risk of electric shock. Disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

CAUTION!

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

Description of system specications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and

information on trademarks

The mentioned names of products or companies are

trademarks or registered trademarks.

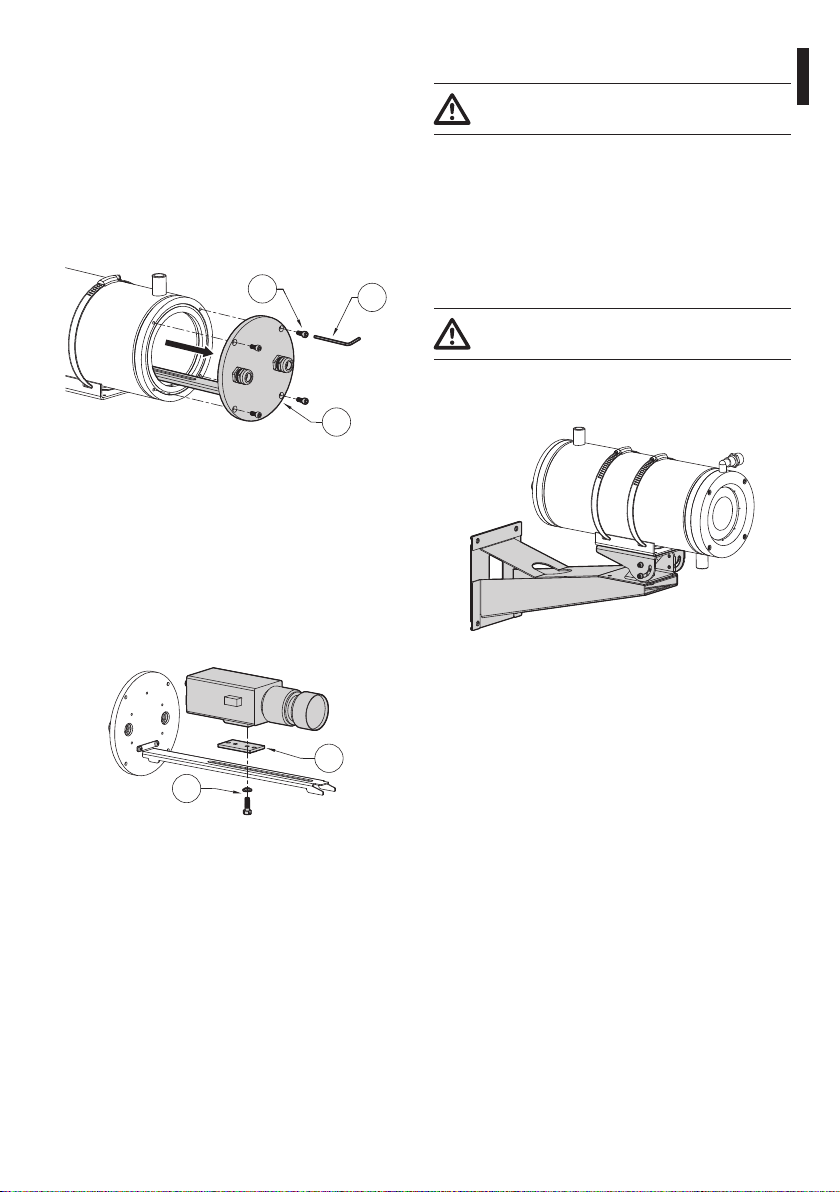

3 Safety rules

CAUTION! Device installation and

maintaining must be performed by

specialist technical sta only.

CAUTION!The electrical system to which the

unit is connected must be equipped with a

10A max automatic bipolar circuit breaker.

The minimum distance between the circuit

breaker contacts must be 3mm (0.1in).

The circuit breaker must be provided

with protection against the fault current

towards the ground (dierential) and the

overcurrent (magnetothermal).

• The manufacturer declines all responsibility

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves the right

to modify its contents without any prior notice.

The documentation contained in this manual has

been collected and veried with great care. The

manufacturer, however, cannot take any liability

for its use. The same thing can be said for any

person or company involved in the creation and

production of this manual.

• Before starting any operation, make sure the

power supply is disconnected.

• Be careful not to use cables that seem worn or old.

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook. Improper use of the appliance

can cause serious hazards, risking the safety of

personnel and of the installation.

• Use only original spare parts. Non-original spare

parts could cause re, electrical discharge or other

hazards.

• Before proceeding with installation, check the

supplied material to make sure it corresponds

to the order specication by examining the

identication labels (4.2 Product marking, page 4).

• Equipment intended for installation in Restricted

Access Location performed by specialist technical

sta.