Product Information

10 of 38

IM-PP 724607 1218 ProPress

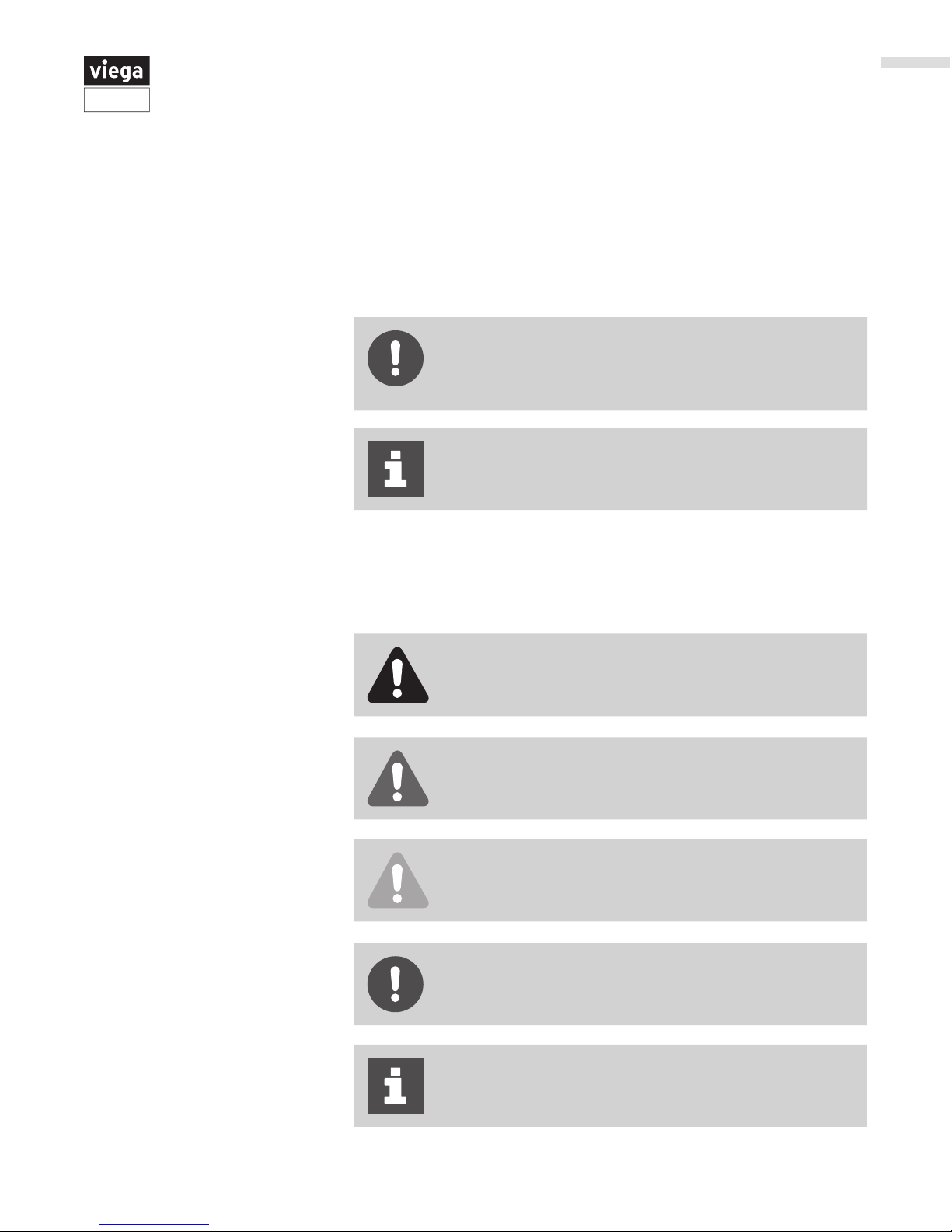

2.4.4 Press Fittings

2.4.4.1 Viega ProPress Fittings

1 Each tting contains an application specic sealing element. A green

dot on a Viega ProPress tting indicates the presence of Smart

Connect technology and an EPDM sealing element.

2 Viega’s distinctive hexagonal pressing pattern bonds tting and tube

and provides the mechanical strength for the connection.

3 Color coded dots indicate the presence of Viega’s unique, patented

Smart Connect technology which helps installers ensure that they

have pressed all connections.

4 Cylindrical guides ensure the proper insertion of the tube and protects

the sealing element.

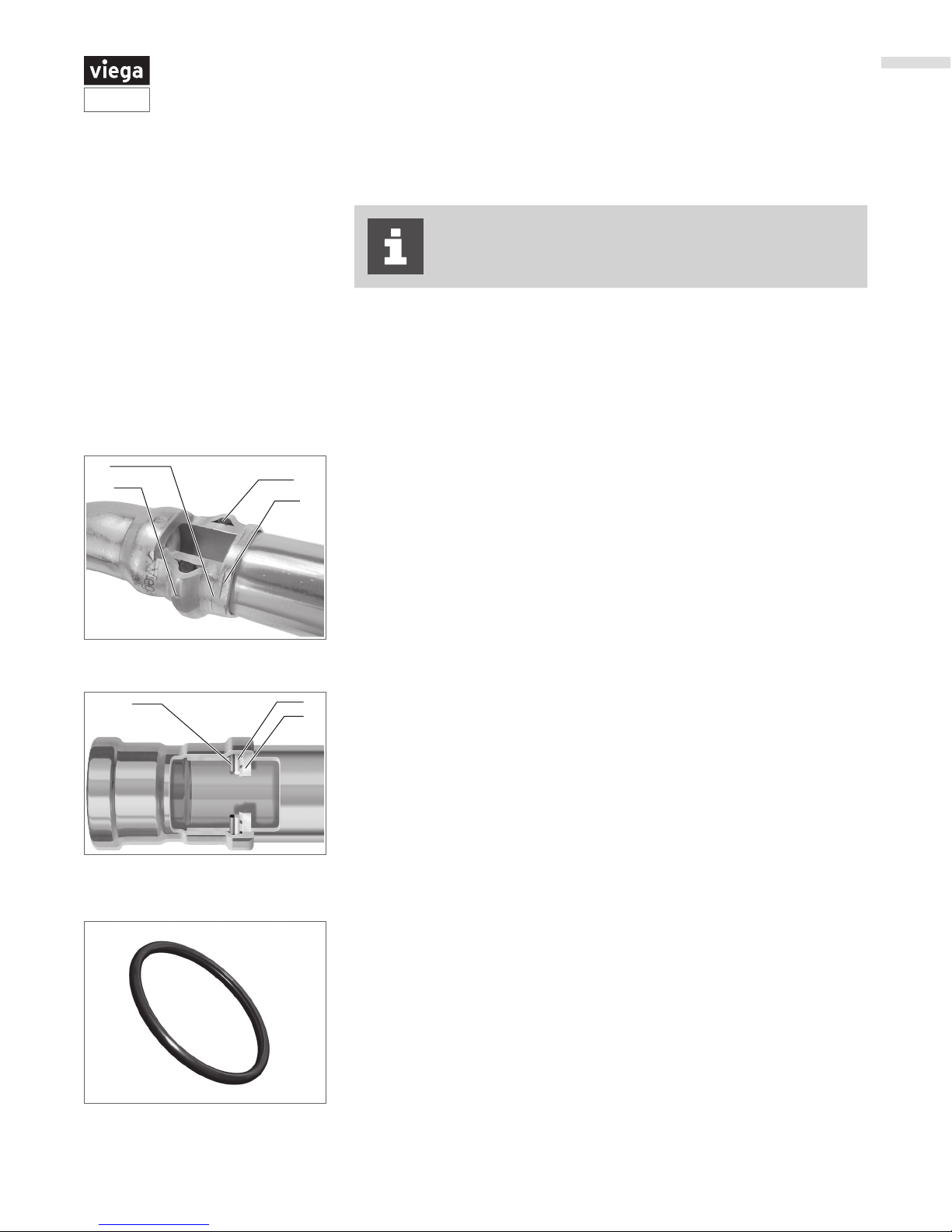

2.4.4.2 Viega ProPress XL-C Fittings

Viega ProPress ttings are manufactured with a high-quality, shiny black

EPDM (Ethylene Propylene Diene Monomer) sealing element installed at

the factory. The molded sealing lips also seal tube surfaces with slightly

uneven surfaces. Sealing elements are inserted into the tting using a H1

food grade lubricant registered with NSF and the USDA, and is approved

for use under FDA 21 CFR.

The EPDM sealing element possesses excellent resistance to aging,

ozone, sunlight, weathering, environmental inuences, and most alkaline

solutions and chemicals used in a broad range of applications.

The operating temperature of the EPDM sealing element is 0° to 250°F

(-18° to 120°C).

2.4.4.3 EPDM Sealing Element

1 The 420 stainless steel grip ring's teeth cut into the tube and lock the

tting securely in place.

2 A PBT (Polybutylene Terephthalate) separator ring protects the sealing

element from damage by creating a positive physical separation during

installation and later during pressing.

3 The EPDM sealing element ensures water-tight or air-tight connections.

ProPress XL-C ttings are designed to be pressed with ProPress XL-C press

rings and V2 actuator to produce a non-detachable, secure connection.

2.4.5 Copper Tubing

Copper and copper alloy ttings are compatible with ½ inch to 1¼ inches soft

copper tubing and ½ inch to 4 inches hard copper tubing types K, L, and M. All

copper tubing that is to be used must comply with ASTM B88 standards.

Copper tubing must be free of surface imperfections,

including metal stamped print lines, before a ProPress

tting is installed.