Sirijus 20, 30 Sirijus 20, 30

Sirijus 20, 30 (13.05) V1 LT Sirijus 20, 30 (13.05) V1 LT

5.2. CHIMNEY AND FLUE

When connecting the boiler to the chimney with metal pipes, they should be made of

metal sheet with the thickness at least 2 mm.

A chimney and a flue must comply with construction codes and regulations.

A hole of the chimney, depending on the type of the boiler, must be no less than

diameter of the flue connection, specified in the Technical Data Table (see Section 2).

When connecting the boiler to a separate chimney, no other devices can be connected

to it. The chimney draft, depending on the type of the boiler, is specified in the Technical Data

Table (see Section 2).

It is highly important for the chimney to be erected above the highest point of the roof.

The chimney must be provided with a cleaning opening. The chimney and the flue

should be cleaned before the start of the heating season and then every 3 months.

It is recommended to install a stainless steel liner in the chimney against damaging

effects of condensation moisture and exhaust gases.

The flue, connecting the boiler to the chimney, should be as short as possible and rise in

the direction of the chimney. The recommended maximum length of the horizontal flue is up to

1.5m.

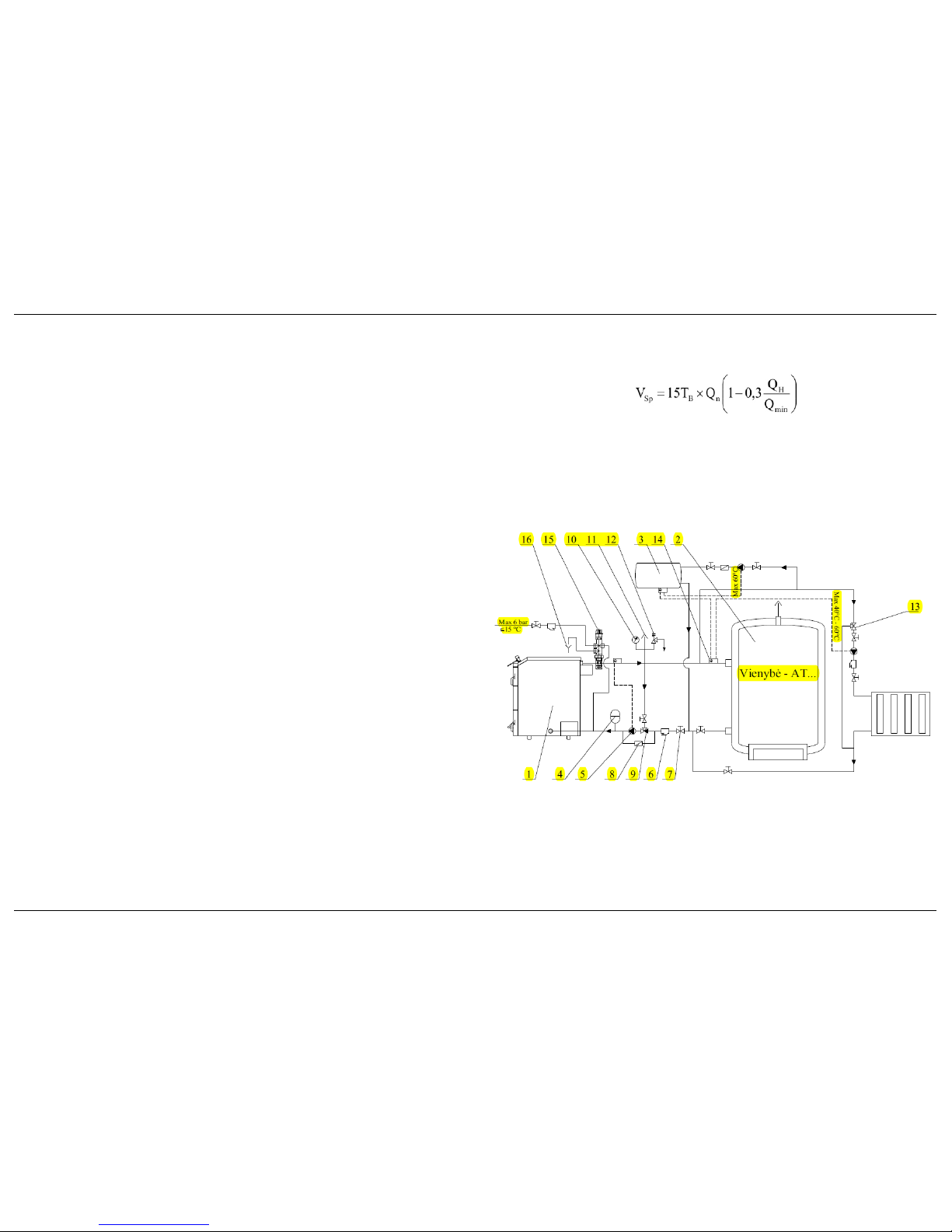

5.3. CONNECTION TO THE HEATING SYSTEM

Requirements for connection to the heating system:

- The boiler must be connected to the heating system according the project

developed by heat technology specialists, either, the works may be carried out independently by a

highly qualified, well-experienced plumber - welder, who has got well familiarized with the boiler

design and with this description.

- The boiler can be connected to the heating system (incl. an expansion tank),

with the operating pressure no higher than 1.5 bar.

- If the system pipes are equipped with valves that switch off the boiler from the

heating system, they should be fully opened. To avoid an accident due to negligence, after

opening the valves, please, remove their handles.

- The system must be equipped with a safety valve, which maintains the

maximum operating pressure of 1.5 bar in the heating system.

- To avoid condensation, which can shorten the life span of the boiler by several

times, the heating system must be installed in such a way so that the temperature of the return

heat carrier (water) is at least 60°C. Such a temperature of the heat carrier (water) is too high for

heating a living space, therefore, a minor heating circuit of heating system should be installed. For

the purpose, the system should be equipped with a three-way or four-way valve or a thermostat.

- The system must be equipped with a recycling pump, mounted in the return

water line to ensure a better circulation of the heat carrier and a more even distribution of

temperature in the boiler. If the circulation water pump is fitted in the water supply line, there is

generated a direct water flow in the boiler, whereby the water poorly distributed and mixed in the

boiler, especially in the upper front part of the boiler. There may emerge a significant temperature

difference between the water in the upper front part and at the outlet of the boiler. The

temperature controller and the thermometer are mounted on the top front of the boiler, thus, when

the recycling pump is in the wrong place, it can result in inaccurate adjustment of the air damper

position, while the boiler will not work in the optimal mode.

In order to fill the chamber1 with a fuel during combustion, open the chimney valve 3 and

close a secondary air supply valve 17. Hang off the chain 11 from the primary air suction valve 8;

the valve, as well as the bottom door 16 must be closed. Then, carefully semi-open the top door,

wait 2-3 seconds, and carefully open the top door. The smoke should not enter the room. If the

room gets smoked, it means that any of the valves may be still closed, or the primary air suction

valve is still opened. After loading a fuel to the chamber, hook the chain 11 to the primary air

suction valve 8 for the normal fuel burning monitoring process. Open the secondary air supply

valves 17.

When the burning is in progress, ashes cover the firegrating, therefore burning intensity

decreases, and boiler output capacity drops, as well. For this reason, the fuel must be shaken and

raked. You must rake through the slots in the inner door. Take the ashes away in time. Strewn

ash heap hinders primary air access to the combustion zone.

When in use, the boiler should operate within 100-80% limits of its rated output capacity.

To ensure such operating conditions, if there is a need, heat accumulators (accumulation tanks)

should be employed.

When firing the wood, you can load the chamber fully and set the fire. Mixed fuel

provides the longest duration of burning in the combustion chamber, for instance, wood, coal, and

sawdust. Good results can be obtained when burning a mixture of coal 60% and sawdust 40%

(according to weight).

NOTICE! When firing coal, only a half the chamber can be stocked, while firing

other kinds of fuel, you can load the chamber fully provided that the fuel does not fall off

over the top door.

NOTICE! Firing household waste in the boiler is strictly prohibited. In particular, all

types of plastics waste. The boiler is not intended for that. Firing this type of waste not only sots

the boiler and the chimney walls, but also discharges, along with the smoke, a lot of emissions to

the environment. Save the nature - and your health!

Try to use as a dry fuel as possible. This will improve the efficiency of the boiler,

increase its power output. Keep in mind that a part of the heat, generated during combustion, is

consumed for evaporation of the water contained in the fuel; so, the more water is in the fuel, the

more heat is consumed for it –and the less of it remains for space heating.

To extend the chamber burning process, use high-calorific fuel. Also, note that the

chamber burning duration depends on the loaded volume of firewood, as well as on its weight.

From time to time, if necessary, clean the boiler and the chimney. Be sure to clean

the boiler from soot and tar at the end of the heating season. Otherwise, water and various acids,

accumulated in the resin, can cause damage to the walls of the boiler.

At the end of the heating season, do not leave the system dewatered, since the boiler

will start to rust from the inside.

6.4. CLEANING

The ash accumulated under or over the firegrating, can hinder air access to the

combustion chamber. Therefore, before each heating, we recommend to clean the ash from the

ash box and the firegrating. Do not collect the ash to combustible vessels - plastic containers,

cardboard boxes, and so on. We recommend to use a metal container for the ash. Do not pour

out the ashes in recycle bins or other combustible places because of possible fire hazard. Wait for

it to cool down completely. You can use the ash as fertilizer as well.

To ensure the efficient operation of the boiler, clean the accumulated ashes and soot

from inner surfaces of the boiler. Cleaning frequency depends on the thickness of the

accumulated ashes and soot layer, which, in turn, is subject to the nature of the heating. A

regularly used boiler should be cleaned 2-3 times a month.

NOTICE! Do not clean the boiler during its heating.