Product Installation

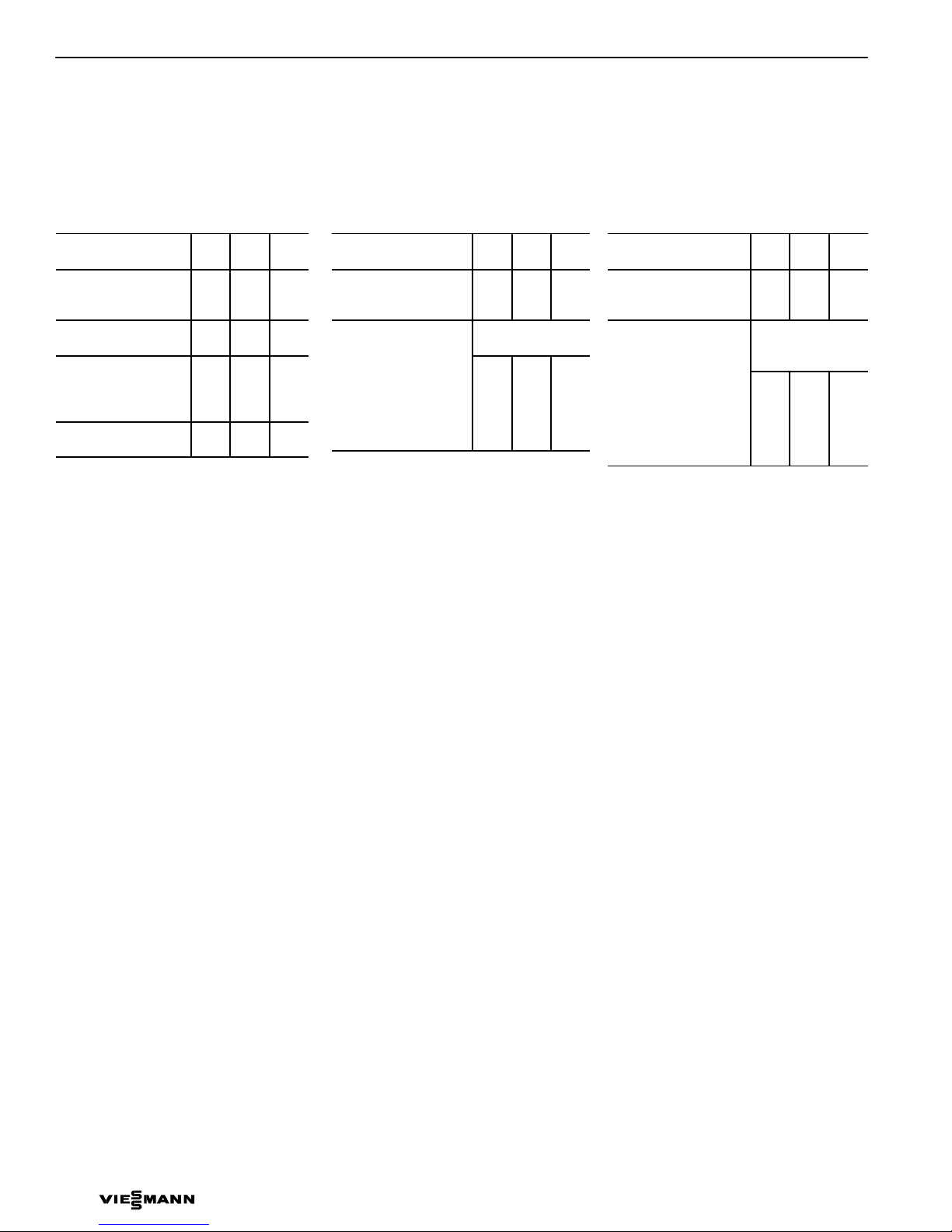

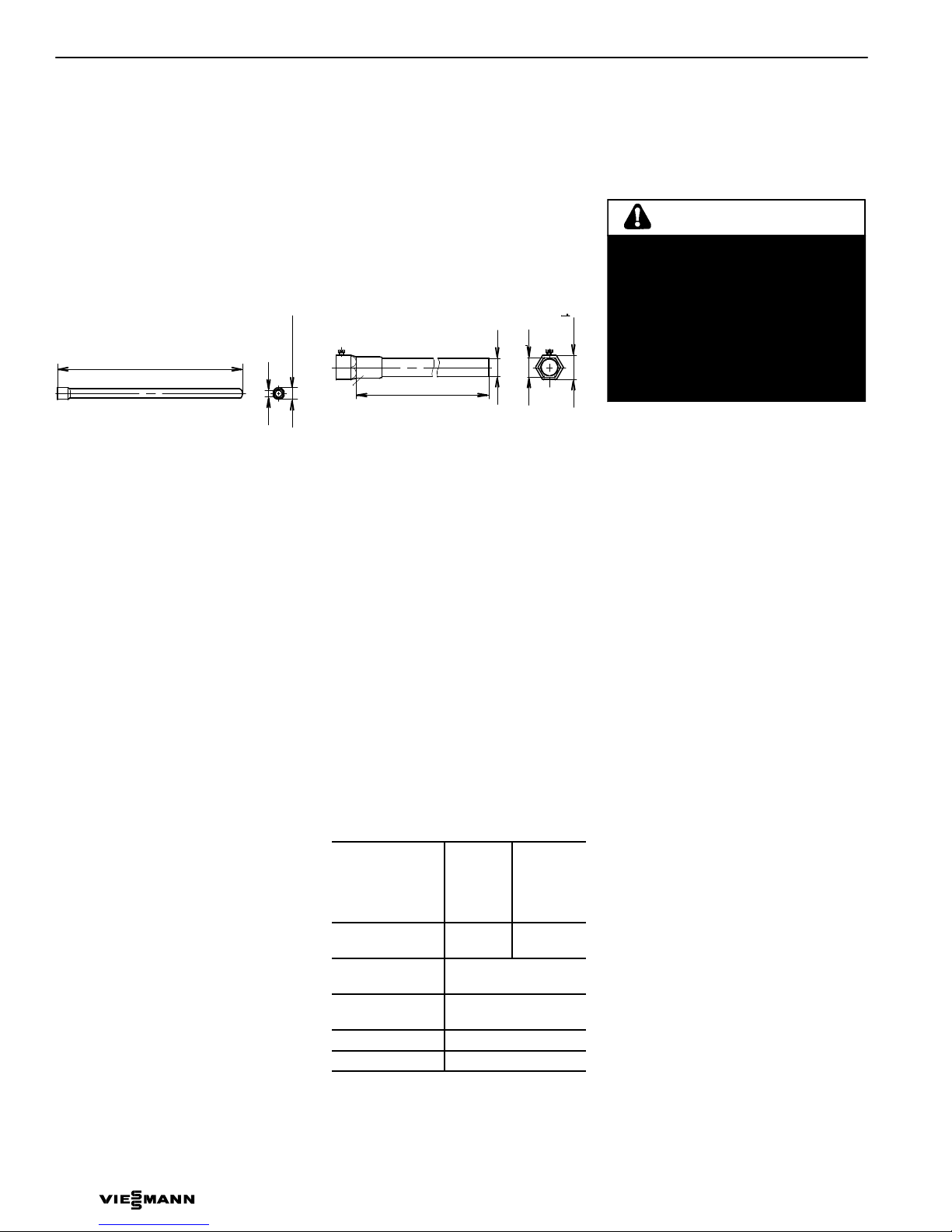

7”/175 mm

Ø ¼”/7 mmØ

1

/

”

/

9 mm

15”/ 80 mm

Ø ½”/15 mm

Ø ¾”/19.2 mm

Ø 1”/24 mm

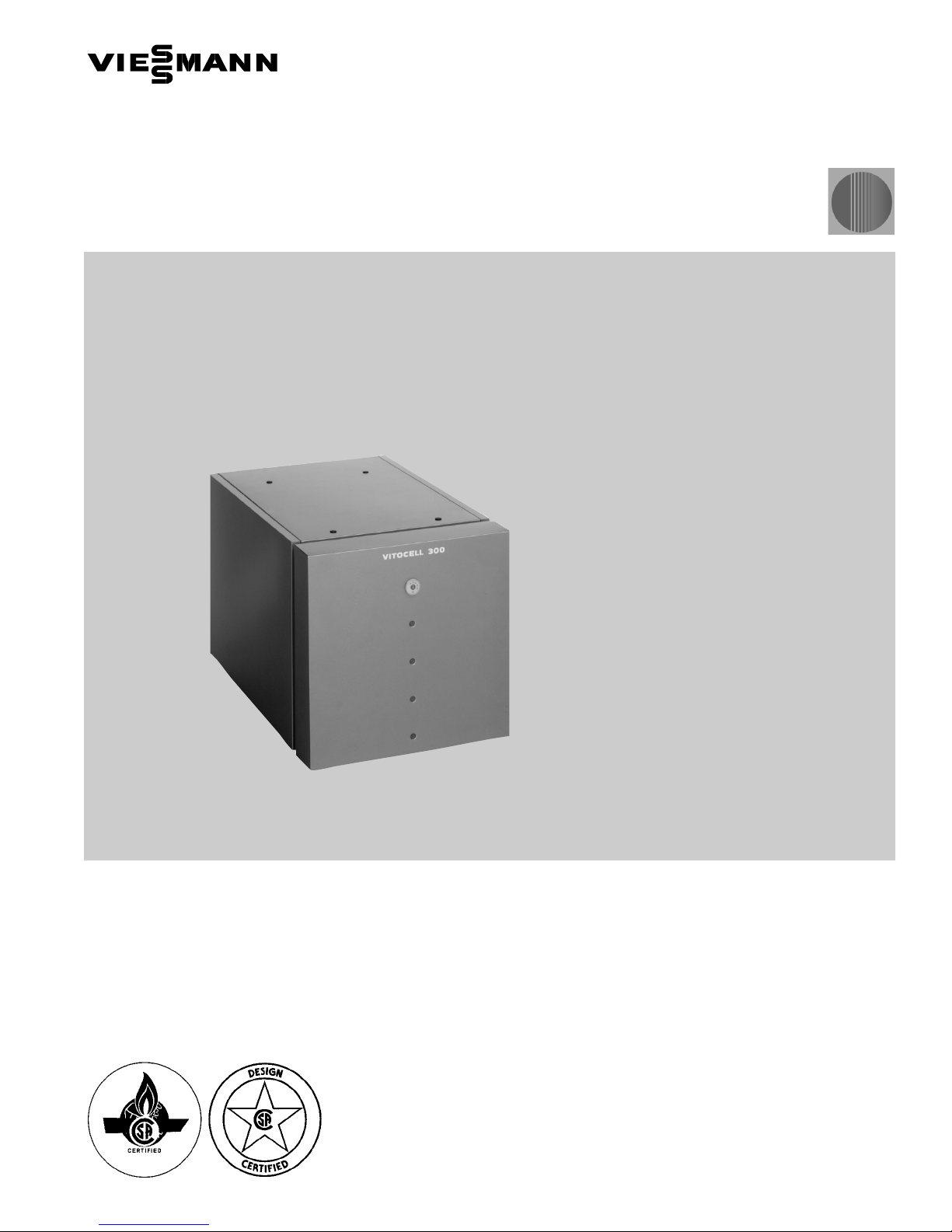

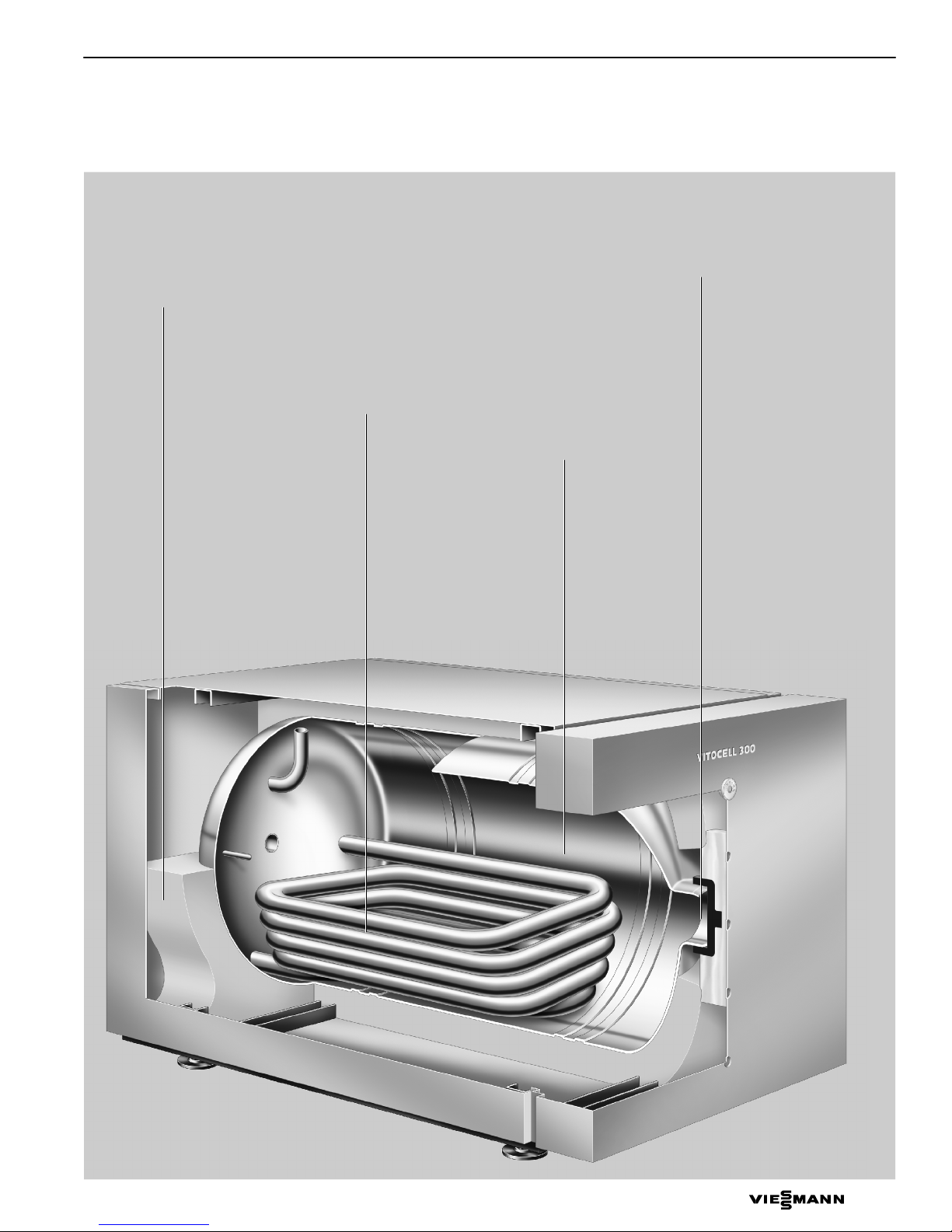

10 VITOCELL 300-H

Sensor Well

Vitocell 300-H,

ith 42 and 53 USG / 160 and 200 ltr

capacity

The sensor well is welded into the DHW

tank.

Vitocell 300-H,

ith 92 and 119 USG / 350 and 450 ltr

capacity

Heating ater supply temperatures

over 230°F / 110°C

For these operating conditions, an approved

high limit safety aquastat must be installed

to limit the domestic hot water temperature

to 20 °F / 95°C in the tank.

Vitocell-H domestic hot ater tank

positioned under the boiler

Please note that only the boiler/tank

combinations stated in the Price List are

possible. In the case of the 92 USG / 50 ltr

capacity Vitocell 00-H , the boiler can only

be positioned on the DHW tank so that it is

flush at the front.

Recirculation tapping

The recirculation tapping on the Vitocell-H

00 is also the opening for mounting the

temperature and pressure relief valve.

If this opening is utilized for recirculation,

extend the stainless steel nipple on the tank

with a brass tee of the same size as the

stainless steel nipple ∅to accommodate

both connections; see installation

instructions.

Temperature and pressure

relief valve

A temperature and pressure relief valve

(T&P relief valve) is supplied with the tank.

The heating contractor must install the valve

on each tank in a method meeting code

requirements. If local codes require a

different relief valve, substitute the

manufacturer’s supplied valve. The tank is

approved for 100 psig where a CRN is

required. Maximum operating pressure is

150 psig.

The T&P relief valve supplied with the tank

is ASME pressure steam rated for 998 MBH

and CSA temperature steam rated for

200 MBH. It is tested under ANSI Z21.22

code for Relief Valves and Automatic Gas

Shut-off Devices for Hot Water Supply

Systems.

For steam applications, a field supplied 1”

T&P valve must be utilized.

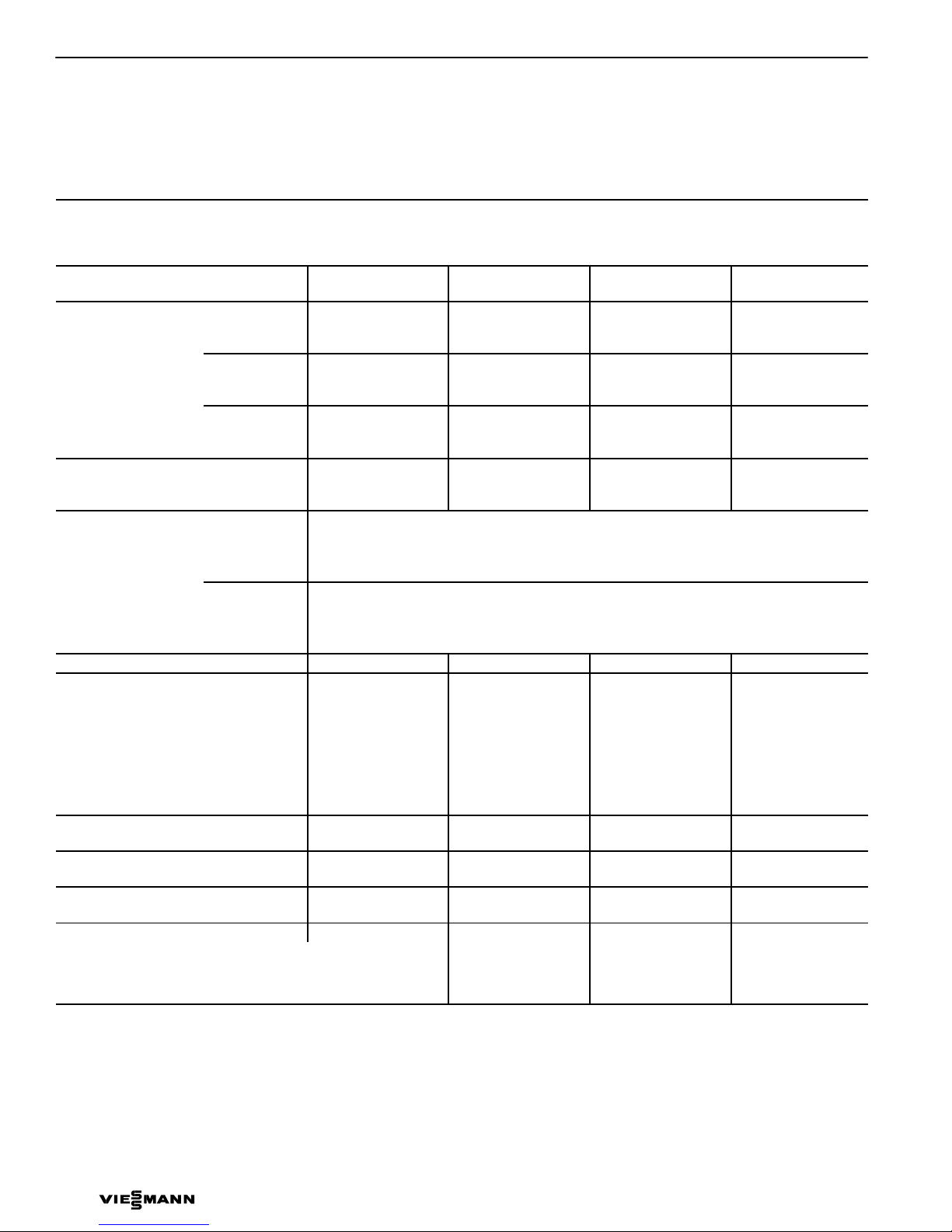

Watts Model

40XL-8

100 psig

(Canada

here

CRN is

required)

150 psig

(US and

Canada)

ASME pressure

steam rating

998 MBH 14 8 MBH

CSA temperature

steam rating

205 MBH

Relief

temperature

210ºF (99ºC)

Inlet thread

¾” male

Outlet thread

¾” female

Warranty excerpt

Our warranty for domestic hot water tanks

states that the water heated should be of

drinking water quality and that any water

treatment equipment in use must function

correctly.

If the product has been improperly installed

or misapplied by the installer, contractor or

final user, Viessmann accepts no

responsibility for damage howsoever caused

and reserves the right to withdraw the

product warranty. In order to qualify for

product warranty, strict adherence to the

installation and service manuals must be

observed. In the event that Viessmann

non-approved components are utilized,

Viessmann reserves the right to withdraw all

expressed or implied warranties without

written notice.

The water to be heated with the Vitocell

must be drinking (potable) water quality. If

the tank is used to heat other media, the

warranty will be null and void. Damage

resulting from excessive pressure or

temperature is clearly not the responsibility

of Viessmann.

The amount of chloride and sulfate

acceptable to the tank is limited. In areas

where high concentrations of chloride and

sulfate are present in drinking water, please

consult Viessmann for directions.

For full warranty details, please read the

product warranty card.

Backflo preventers

Where backflow preventers are required, a

domestic water expansion tank installation

is recommended in the cold water inlet

piping before the cold water enters the

Vitocell. For the backflow device, observe

local plumbing codes and regulations.

To ensure optimum, safe operation,

the supplied stainless steel ell must

be installed. The ell diameter is

large enough to accommodate a ide

variety of sensing bulbs.

Al ays use spring clip to ensure

proper contact of capillary bulb

against the stainless steel ell for

proper sensing/heat transfer!

WARNING