Water Hookup

WATER SUPPLY

Observe and follow all local building codes when installing

this appliance.

This ice machine must be connected to a potable cold

water supply line. delivering water pressure between a

minimum of 20 psi and a maximum of 120 psi.

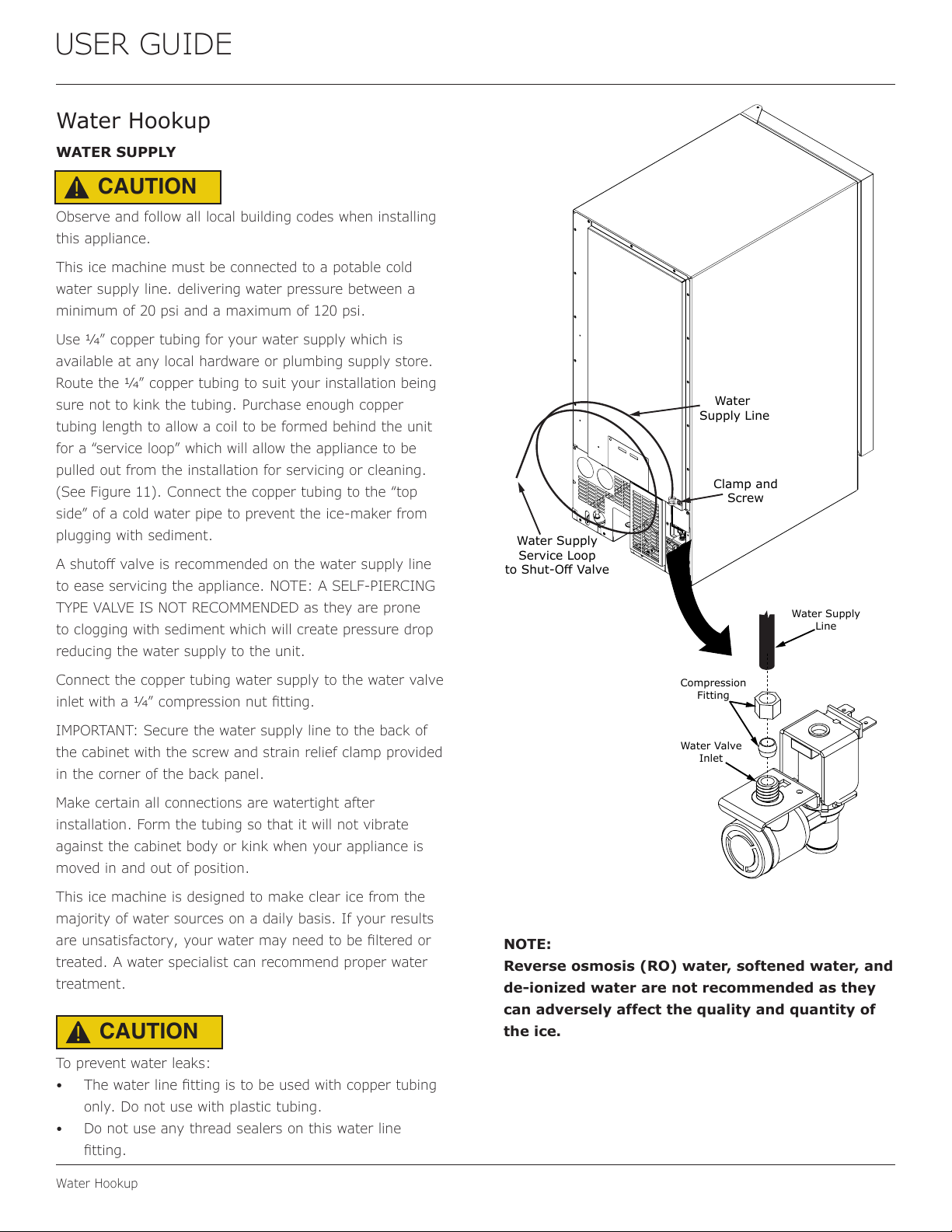

Use 1⁄4” copper tubing for your water supply which is

available at any local hardware or plumbing supply store.

Route the 1⁄4” copper tubing to suit your installation being

sure not to kink the tubing. Purchase enough copper

tubing length to allow a coil to be formed behind the unit

for a “service loop” which will allow the appliance to be

pulled out from the installation for servicing or cleaning.

(See Figure 11). Connect the copper tubing to the “top

side” of a cold water pipe to prevent the ice-maker from

plugging with sediment.

A shuto valve is recommended on the water supply line

to ease servicing the appliance. NOTE: A SELF-PIERCING

TYPE VALVE IS NOT RECOMMENDED as they are prone

to clogging with sediment which will create pressure drop

reducing the water supply to the unit.

Connect the copper tubing water supply to the water valve

inlet with a 1⁄4” compression nut tting.

IMPORTANT: Secure the water supply line to the back of

the cabinet with the screw and strain relief clamp provided

in the corner of the back panel.

Make certain all connections are watertight after

installation. Form the tubing so that it will not vibrate

against the cabinet body or kink when your appliance is

moved in and out of position.

This ice machine is designed to make clear ice from the

majority of water sources on a daily basis. If your results

are unsatisfactory, your water may need to be ltered or

treated. A water specialist can recommend proper water

treatment.

To prevent water leaks:

•The water line tting is to be used with copper tubing

only. Do not use with plastic tubing.

• Do not use any thread sealers on this water line

tting.

NOTE:

Reverse osmosis (RO) water, softened water, and

de-ionized water are not recommended as they

can adversely affect the quality and quantity of

the ice.

CAUTION

!

CAUTION

!

Water

Supply Line

Clamp and

Screw

Water Supply

Service Loop

Water Valve

Inlet

Compression

Fitting

Line

10