11

Ele tri al & Gas Requirements

10

Electrical Requirements

Che k your national and lo al odes

regarding this unit. This range requires

120VAC/60 Hz; 4 ft. (121.9 m), 3-wire ord

with grounded 3-prong plug atta hed to

unit. See “Ele tri al Conne tion” se tion for

grounding instru tions. Must be fused

seperately from any other ir uit.

Gas Connection

The gas supply (servi e) line must be the

same size or greater than the inlet line of the

applian e. This range uses a 1/2” (1.3 m) ID

NPT (S h40) inlet. Sealant on all pipe joints

must be resistive to LP gas.

The ran e is desi ned specifically for

natural as or liquid propane (LP) as.

Before be innin installation verify that

the model is compatible with the intended

as supply.

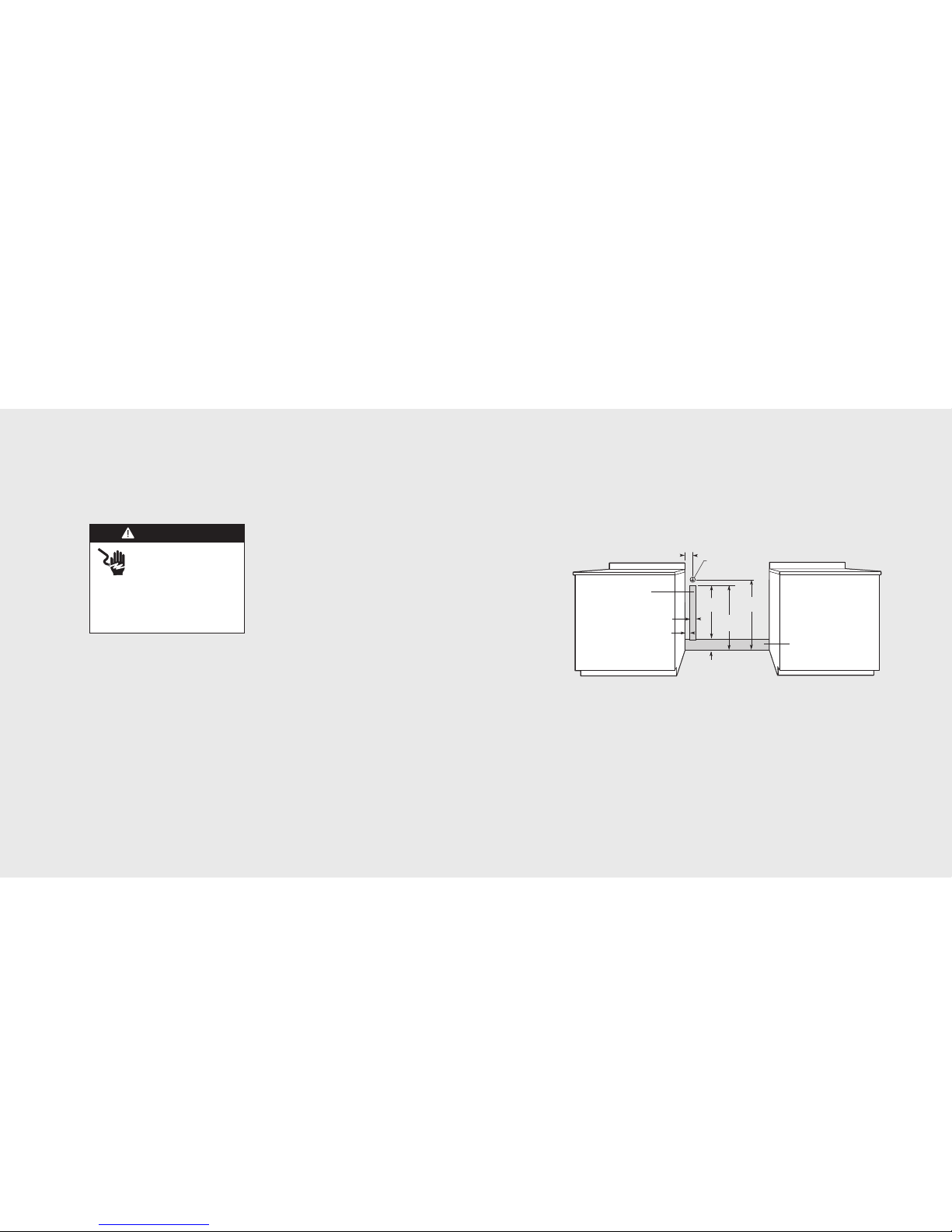

Manual shut-off valve:

This installer-supplied valve must be installed

in the gas servi e line before the applian e

in the gas stream and in a lo ation where it

an be rea hed qui kly in the event of

an emergen y. Any opeing behind the range

shall be sealed.

In Massachusetts: A “T” handle type

manual valve must be installed in the gas

supply line to the applian e.

IMPORTANT: Any conversion required

must be performed by your dealer or a

qualified licensed plumber or as service

company. Please provide the servi e person

with this manual before work begins.

Pressure Re ulator:

• All heavy-duty, ommer ial type ooking

equipment must have a pressure regulator

on the in oming servi e line for safe and

effi ient operation, sin e servi e pressure

may flu tuate with lo al demand. External

regulators are not required on this range

sin e a regulator is built into ea h unit at

the fa tory. Under no ondition bypass

this built-in regulator.

• Manifold pressure should be he ked with

a manometer, natural gas requires 5.0”

W.C.P. and LP gas requires 10.0” W.C.P.

In oming line pressure upstream from the

regulator must be 1” W.C.P. higher than

the manifold pressure in order to he k

the regulator. The regulator used on this

range an withstand a maximum input

pressure of 1/2” PSI (14.0” W.C.P.). If the

line pressure is in ex ess of that amount, a

step down regulator will be required.

• The applian e must be dis onne ted from

the gas supply piping system during any

pressure testing of that system.

ELECTRICAL SHOCK

HAZARD

To void the risk of electric l

shock, person l injury or de th;

verify electric l power is turned off t the

bre ker box nd g s supply is turned off

until the r nge is inst lled nd re dy to

oper te, inst ll tion by n uthorized

inst ller only.

Flexible Connections:

If the unit is to be installed with flexible

ouplings and/or qui k-dis onne t fittings,

the installer must use a heavy-duty AGA

design- ertified flexible onne tor of at least

1/2” (1.3 m) ID NPT (with suitable strain

reliefs) in omplian e with ANSI Z21.41

and Z21.69.

In Canada: CAN 1-6, 10-88 metal

onne tors for gas applian es and CAN

1-6.9 M79 qui k dis onne t devi es for use

with gas fuel.

In Massachusetts: This applian e must be

installed with a 36” (3-foot) long flexible

gas onne tor.

Ele tri al & Gas Requirements