v1.0

Owner’s Manual

Vessel Operations - 8 Viking Sport Cruiser 61FY

••••••••••••••••••••••••••••••••••••••••••••••••••••••

←

Aft engine room

checks, cont.

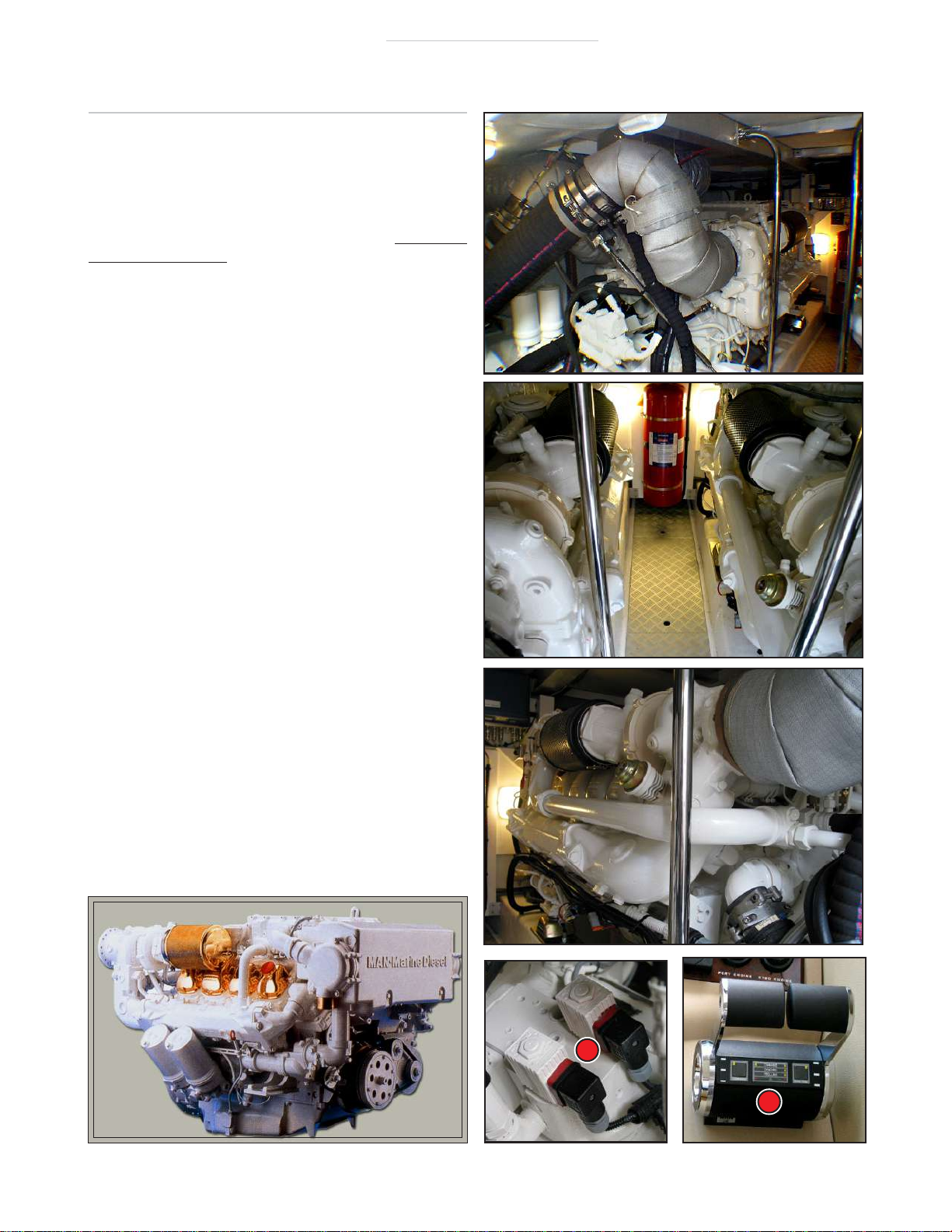

Keep the engine room clean,

this makes it easier to see

leaks, which indicate a prob-

lem that must be addressed.

There should be no oil on the

outside of or under the en-

gines. Use a funnel when top-

ping up the oil level. Do not

overfill. Keep the level a little

below the FULL mark. Overfill-

ing can damage the engine.

Check for leaks on all fittings

that have hose clamp attach-

ments, at the base of oil fil-

ters C, on the outside of the

Separ fuel filters, lids of raw

water strainers etc. Check the

outside of the engine air filters

M, look for oil on the outside

of them. This will indicate that

the filter must be replaced.

At least monthly open and

close the engine raw water in-

let valves V. On a long voy-

age, every two hours slow

down, don ear muffs and look

into the engine room for ob-

vious signs of leaks, fumes,

odor, smoke or a different or

excessive noise.

See propulsion chapter for

more information.

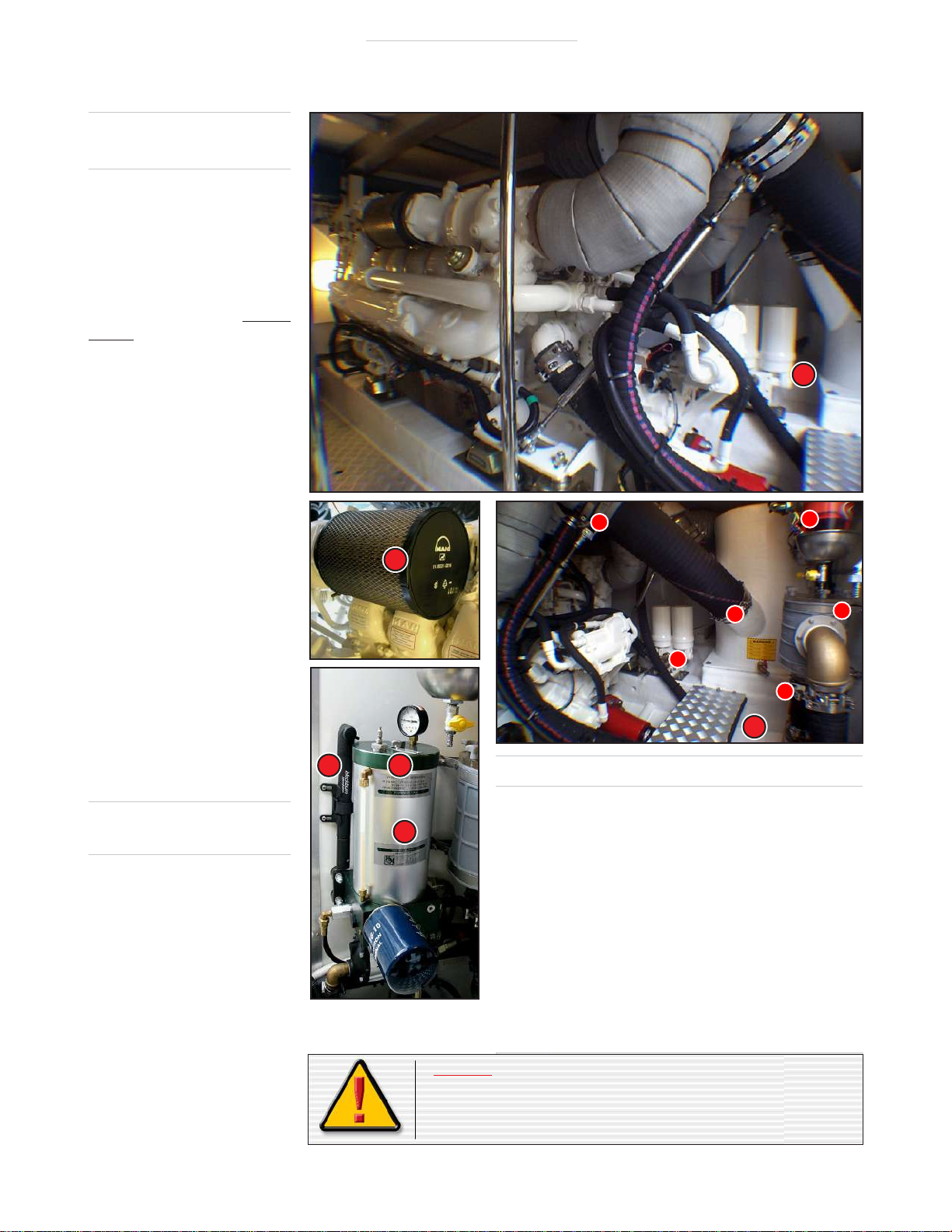

Power steering

reservoir, R

Check oil level in sight tube L.

Check for oil and air leaks. Air

pressure should be between 20

and 30 psi. If lower than 20 psi

use hand pump Hto increase

pressure to 30 psi. See the

Subsystems chapter for more

information.

Filter

C

C

C

C

C

C

Check

for

black

marks

here

Engine water lift mufflers

Water lift mufflers are installed on all Viking boats. They

result in a very quiet running vessel, allowing normal

conversation when underway.

Inspect the white fibreglass for black marks, which may

indicate exhaust gas leakage caused by a loose hose

clamp.

This must be attended to

as deadly carbon mon-

oxide gas can seep through the vessel.

Use a SHORT 5-inch ratchet and the correct size socket

to see if the bolt in the clamp is loose. DO NOT USE

EXCESSIVE PRESSURE – the fibreglass piping can be

deformed resulting in a serious exhaust gas leak.

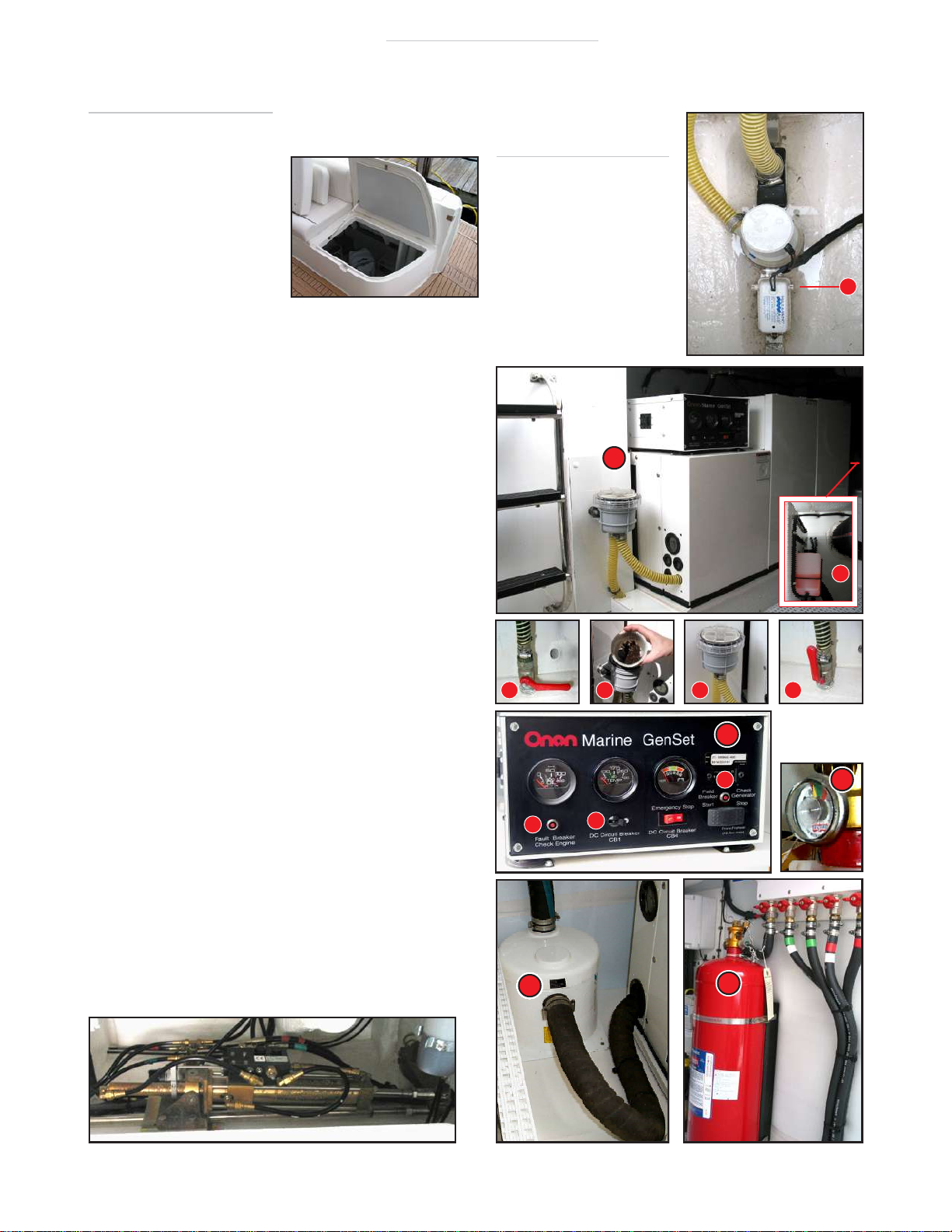

Warning:- Do not store loose or flammable materials,

equipment, or gear in the engine room. Objects must be

prevented from falling on the engines. Do not obstruct

entrance to engine room.

C

H

L

M

R

V→

↵