83 - Corrosion Protection

Viking Sport Cruiser 61FY

Owner’s Manual

v1.0

••••••••••••••••••••••••••••••••••••••••••••••••••••••

Electrolytic corrosion

Stray currents are present at most marinas, and near other boats.

A particularly strong source is shore power cords lying in the wa-

ter –they cause severe corrosion, and are a safety hazard. At the

docks themselves there are often metal reinforcing rods in con-

crete that lie in the water. These conduct stray currents that can

cause a boat’s zincs to erode quickly. Stray current corrosion is

also caused by DC or AC current leaks from other boats around

you. Aluminum is particularly susceptible to this –just look at

some outdrives at a marina!

In the lazarette the two 15 kVA isolation transformers have a rated

input of 100 amps @ 240 volts. Shore power coming aboard is

isolated through the transformer windings from any direct contact

with outside grounds. ONLY red, black and green are brought into

the transformer. In effect, 240 volts AC ONLY goes into the pri-

mary winding of each transformer. 120 volt power is produced by

the transformer. This isolation protects against stray currents and

electrolytic corrosion that destroys underwater fittings.

In effect, the vessel has its own CLOSED CIRCUIT electrical sys-

tem which also protects crew and passengers from potentially

lethal electricity flowing through them to a shore ground.

The engines and generator have their own internal zinc anodes for

protection of their metal parts, these MUST be maintained ac-

cording to manufacturers’recommendations.

Stainless steel corrosion

All metals except gold, silver, titanium, and platinum corrode –

some much more than others. Despite its name, stainless steel

is also subject to corrosion because it is a ferrous alloy. 18/8

stainless, for example, is 67% iron, with 22% chromium and 11%

of other metals added to make it more resistant to corrosion. The

three types of stainless steels common in the marine industry

are 302 or 18-8, used for screws; 304, used for stamped parts;

and 316 or CF-8M, used for tubing, etc.

Though high up on the noble chart (-30 mV for resistance to cor-

rosion), stainless steel WILL rust quickly in its natural state, par-

ticularly in the warm moist climate of Florida. For stainless to be

corrosion RESISTANT it must be highly polished, plated, or electro-

polished in a number of ways during production. Unpolished stain-

less steel has iron or iron oxide sitting on the surface of the metal,

but polishing brings the chromium to the surface. The more shine,

the more resistance to corrosion.

If stainless is scratched, or cut and not polished at the edges,

corrosion will result. Thus, if a screw driver bit slips on top of a

screw, it will rust. And a hole drilled in stainless steel will corrode

inside the hole unless protected by a watertight sealer.

When washing the vessel, never let water dry on the stainless.

To

avoid unsightly water spotting dry off stainless with a chamois.

Stanchions and rails must be kept clean, use a wax such as

Collinites 850 cleaner/wax to further protect them.

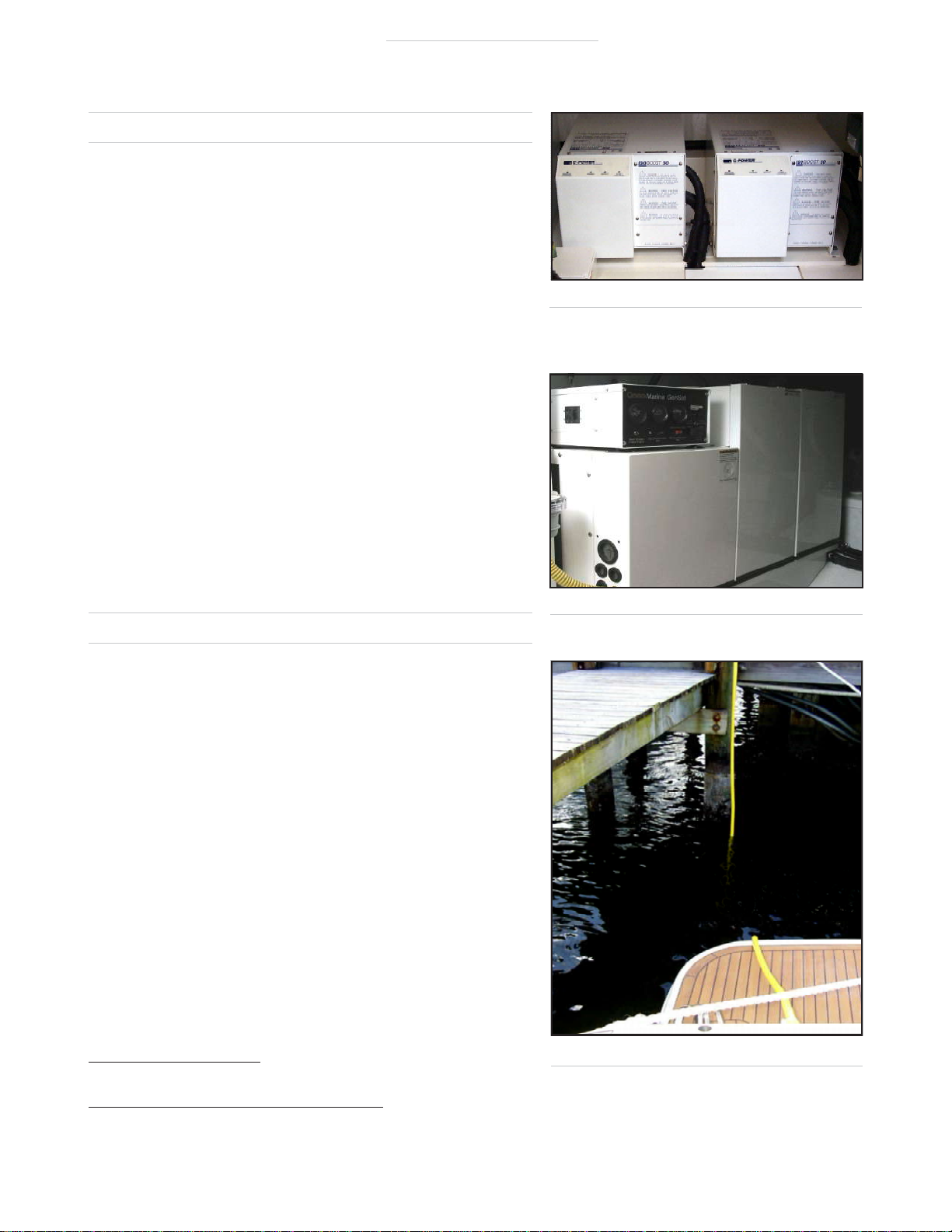

A corrosion and safety hazard

A shore power cord in the water is a hazard to

anyone in the water. The flow of AC current

inside the cable will also make the vessel more

susceptible to corrosion.

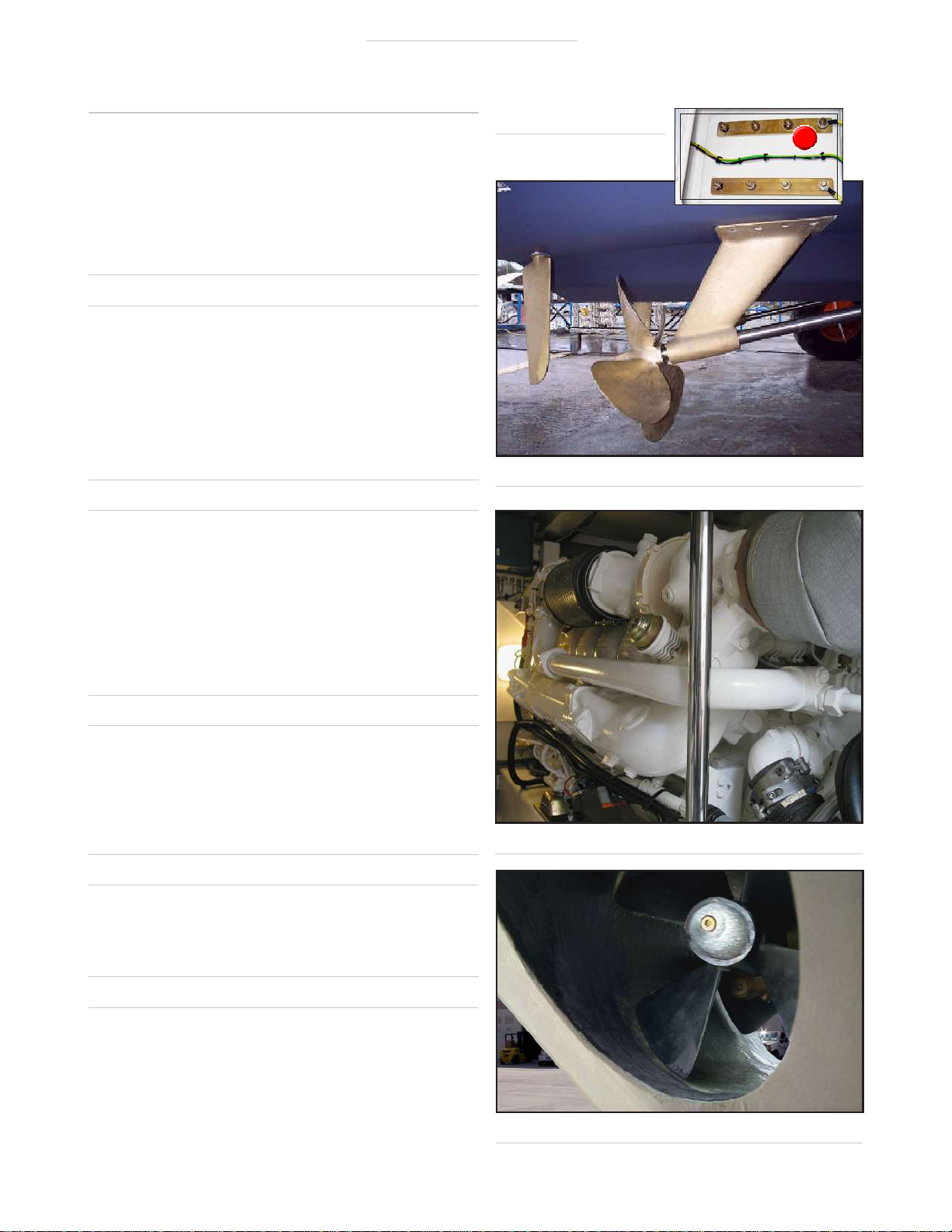

Isolation transformers

Isolation transformers effectively give the vessel

a ‘closed circuit”electrical system that is safe,

and will not leak current and cause corrosion.

Onan generator

Internal zinc anodes must be changed on schedule.

(optional model shown)