INSTRUCTION FOR USE ENGLISH

1

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................................ 2

GUIDE PURPOSE AND CONTENTS .............................................................................................................................................2

HOW TO KEEP THIS INSTRUCTION FOR USE ..........................................................................................................................2

DECLARATION OF CONFORMITY .............................................................................................................................................2

ACCESSORIES AND MAINTENANCE .........................................................................................................................................2

CHANGE AND IMPROVEMENT...................................................................................................................................................2

SCOPE OF APPLICATION .............................................................................................................................................................2

MACHINE IDENTIFICATION DATA ............................................................................................................................................2

TRANSPORT AND UNPACKING ..................................................................................................................................................3

SAFETY ............................................................................................................................................................ 3

VISIBLE SYMBOLS ON MACHINE ..............................................................................................................................................3

SYMBOLS THAT APPEAR ON THE INSTRUCTION FOR USE ................................................................................................3

GENERAL SAFETY INSTRUCTION .............................................................................................................................................4

MACHINE DESCRIPTION............................................................................................................................ 6

MACHINE STRUCTURE ................................................................................................................................................................6

CONTROL PANEL ..........................................................................................................................................................................8

WORKING MODE DESCRIPTION ................................................................................................................................................9

ACCESSORIES .............................................................................................................................................................................. 10

TECHNICAL DATA ...................................................................................................................................................................... 11

WIRING DIAGRAM ...................................................................................................................................................................... 12

OPERATING GUIDE .................................................................................................................................... 13

BATTERY CHECK/SETTING ON A NEW MACHINE .............................................................................................................. 13

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET /GEL/ AGM/ DIS/EXI/FUL/OPT/ENE(TPPL))......... 14

BEFORE MACHINE START-UP .................................................................................................................................................. 15

STARTING AND STOPPING THE MACHINE ........................................................................................................................... 16

PARKING BRAKE ......................................................................................................................................................................... 17

MACHINE OPERATION ............................................................................................................................................................... 17

HOPPER DUMPING ...................................................................................................................................................................... 18

SIDE BROOM INSTALLATION................................................................................................................................................... 18

WATER SPRAY FLOW SETTING ............................................................................................................................................... 19

AFTER USING THE MACHINE ................................................................................................................................................... 19

PUSHING/TOWING THE MACHINE .......................................................................................................................................... 19

MACHINE STORAGE DURING LONG INACTIVITY ............................................................................................................... 20

FIRST PERIOD OF USE ................................................................................................................................................................ 20

MAINTENANCE ........................................................................................................................................... 20

SCHEDULED MAINTENANCE TABLE ..................................................................................................................................... 20

BATTERY CHARGING ................................................................................................................................................................ 21

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT ............................................................................................................ 22

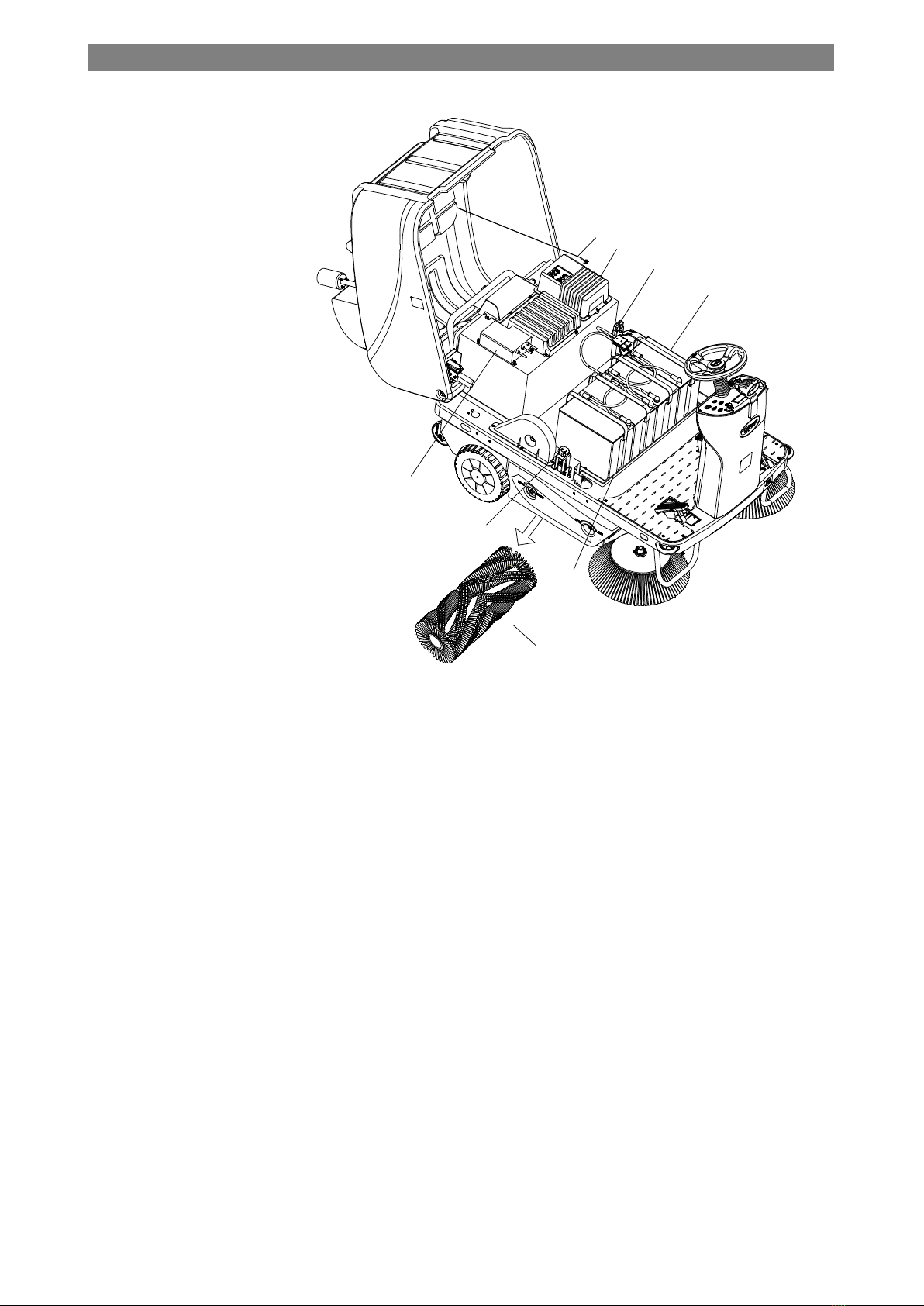

MAIN BROOM REPLACEMENT ................................................................................................................................................. 23

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT .............................................................................................................. 24

DUST FILTER CLEANING AND INTEGRITY CHECK ............................................................................................................. 25

BLADE HEIGHT AND OPERATION CHECK ............................................................................................................................ 26

WHEEL CHAIN CHECK AND ADJUSTMENT .......................................................................................................................... 27

TROUBLESHOOTING ................................................................................................................................. 27

ERROR CODE OF DISPLAY app: detail ................................................................................................... 28

SCRAPPING ................................................................................................................................................... 28