I N D E X

.....................................................................page 3

.....................................................................................page 5

....................................page 6

...............................................................................page 8

.........................................page 8

.................................................................................page 9

................................................page 10

.................page 11

.............................................................page 13

................................................................................page 13

.....................................page 13

.............................................................................................page 14

........................................................................................page 15

...........................................................................................page 20

...................................................................................page 20

.............................................................................page 21

........................page 22

.................................................................page 22

................................................................................page 20

...............................................................................page 23

....................................................................page 23

....................................page 23

...................................................................................................page 26

........................................................................page 26

................................................................................page 27

.................................................................................page 28

..............................................................................page 30

...................................................................page 30

....................................................................page 31

...........................................................................................page 32

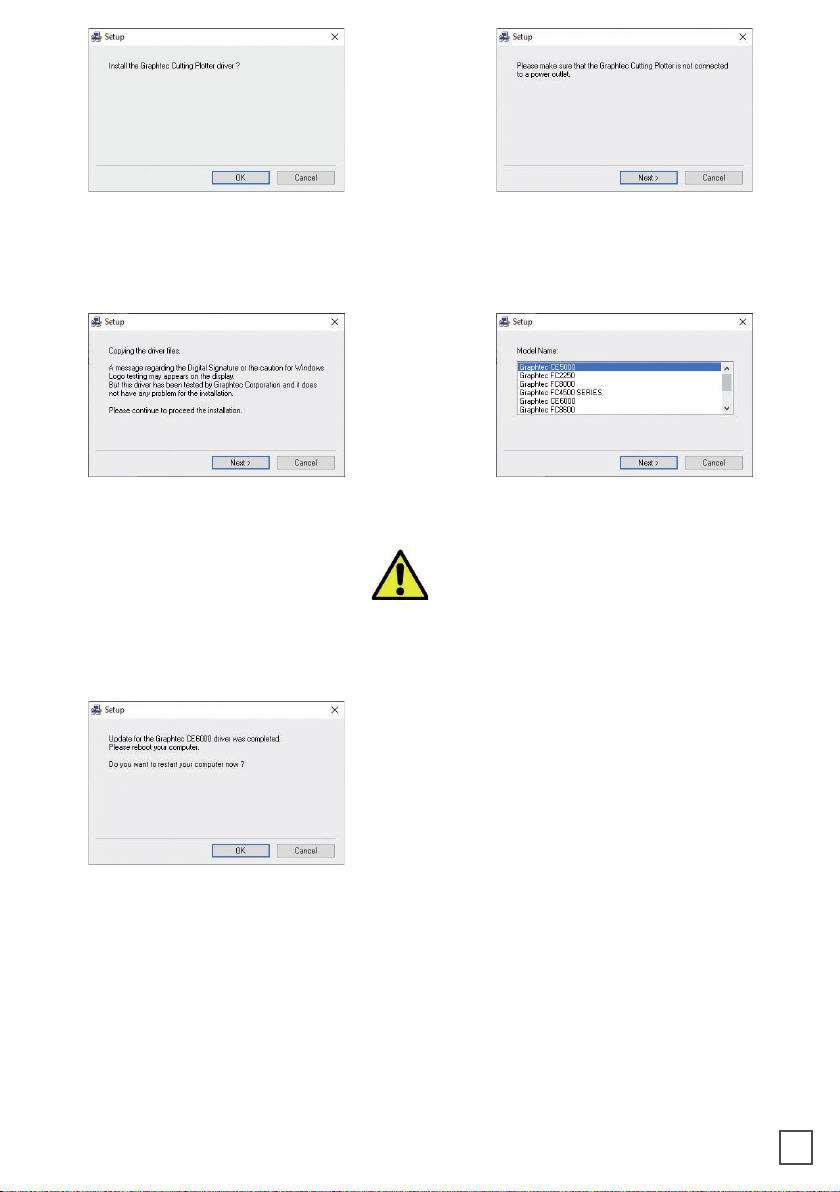

How to install the cutting plotter

System requirements

How to load and operate with the lamination module

How to adjust the clutch

How to load the laminated media into the plotter

How to run the cut test

How to load the matrix remover core holder

How to load the rewinder core holder and set the slitter module

How to add or remove blade holder

Metal guides alignment

Remove unwanted waste from the edge of the roll

VIRGO CUTTING MANAGER

User interface

Advanced options

Error Messages

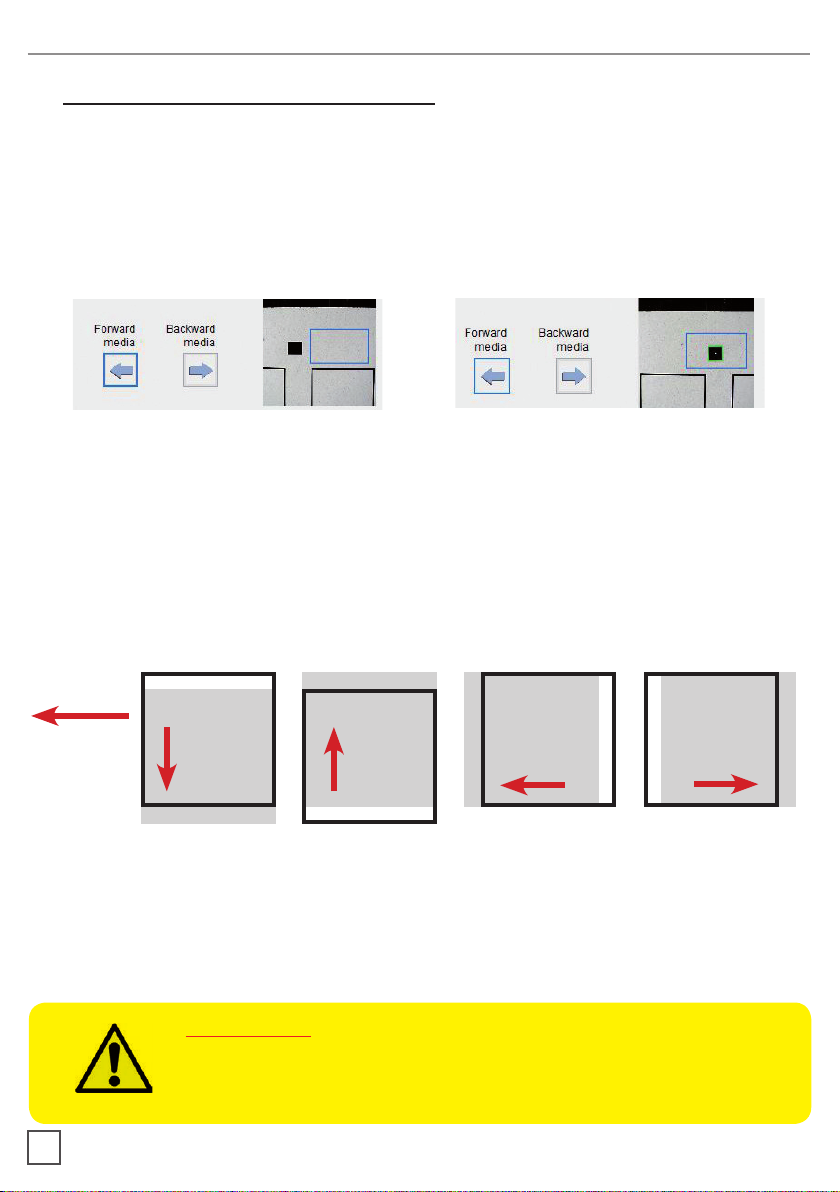

Black-mark detection

Black-mark position in the media

How to cut blank labels

How to update software

How to restore plotter settings

When and how to reduce the plotter feeding speed

Media path

Ultrasonic sensor calibration

Modules speed rotation

Graphtech mantenaice

How to replace the knife

How to replace the slitter blade

How to replace the cutting mat

Troubleshooting

2