flowscreen

Operating Instructions

Copyright © Version 1.0 5 / 24

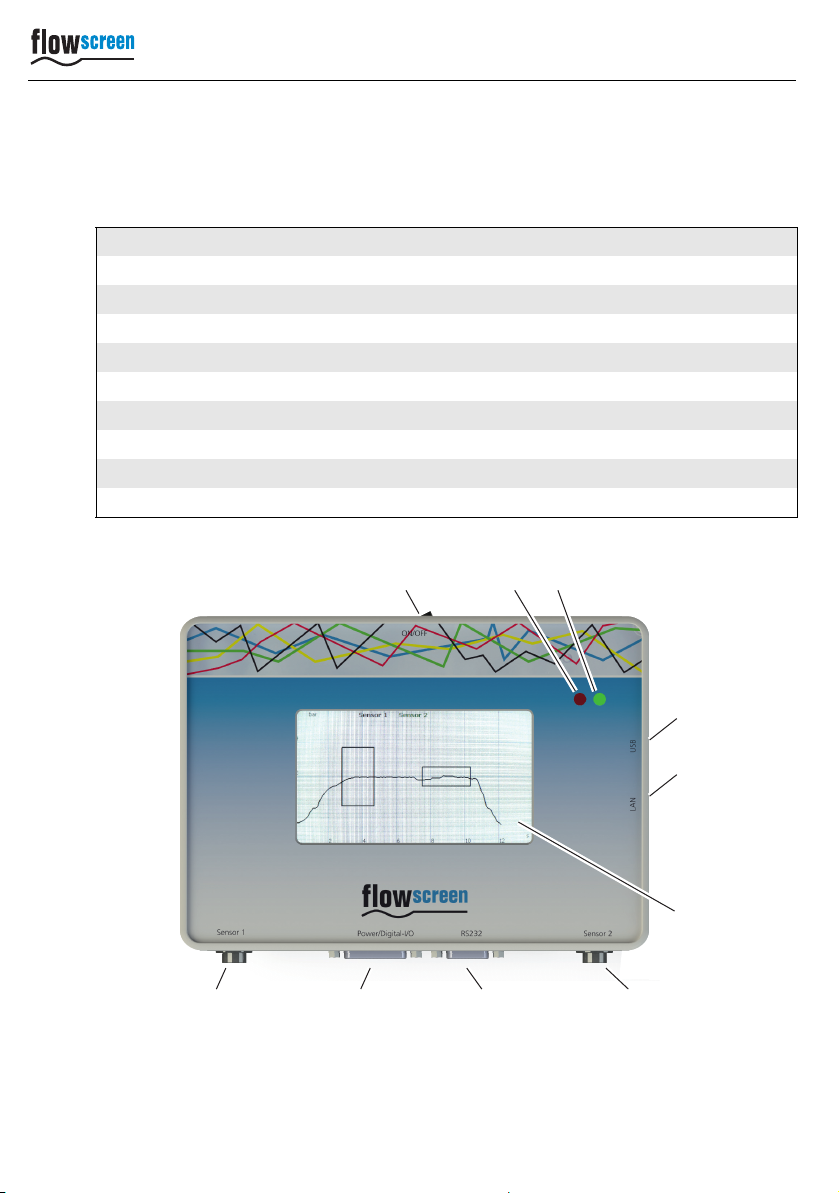

1.1 Function description

The flowscreen analysis system is designed and produced for the monitoring of dosing

processes. Up to two pressure sensors can be attached. The pressure values determined

from the measurement signals are shown on a graphic display.

The start of a measurement can be set either at pressure build-up or after creating a start

signal. The raw data from the attached sensors are defined using the calibration function.

The display can be adapted for the current application in the view for the axes of pressure

and time.

A fault message is indicated via a LED if the determined limits for pressure increase,

pressure gradient during dosing and pressure reduction are exceeded. An error tolerance

number can be set for each attached sensor.

1.2 General information on the menu guide / operation

The flowscreen analysis system is operated via a touch screen using the stylus provided.

The operating menu is largely self-explanatory. System states are depicted via symbols

and plain text.

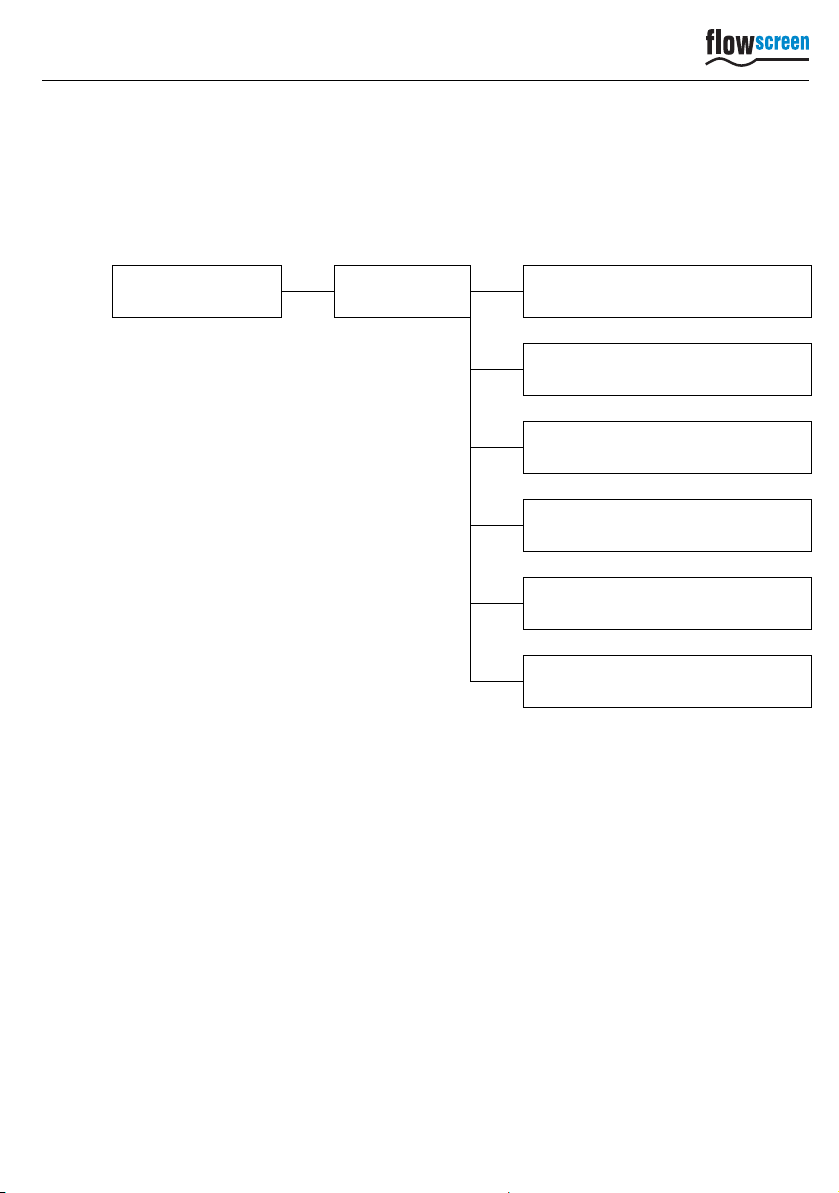

1.3 Description of software operation

In order to ease legibility, details on using the software interface that are considered too

basic are not described.

If for example, a certain button must be pressed, the generally understandable

information is not mentioned, with the necessary action and logical result described in

brief.

Example

Long form Short form

Click the "Save" button, the XY window is opened. <Save> ►XY opens