4 308791

Operation

WARNING

Never exceed 20 psi (1.4 bar) static air pressure to

the cup. Exceeding the maximum working pressure

of the cup or any other system component could

cause component rupture, which could result in

serious injury and property damage.

WARNING

Pressure Relief Procedure

To reduce the risk of serious injury, including splash-

ing in the eyes or on the skin, always follow this

procedure after you stop spraying, when checking or

servicing any part of the spray system, before dis-

connecting the gun, air regulator, or pressure cup

and when removing a pressure cup for refilling or

cleaning.

1. Turn off the air supply to the gun.

2. Trigger the gun into a grounded metal waste

container to relieve fluid pressure.

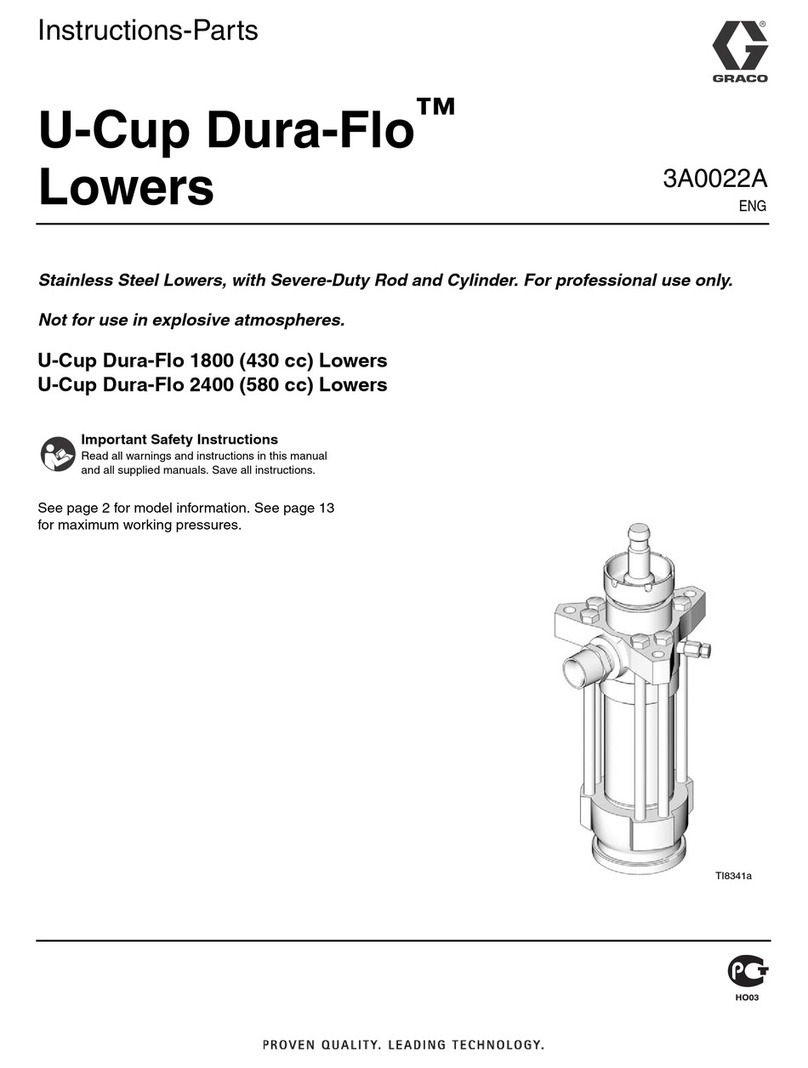

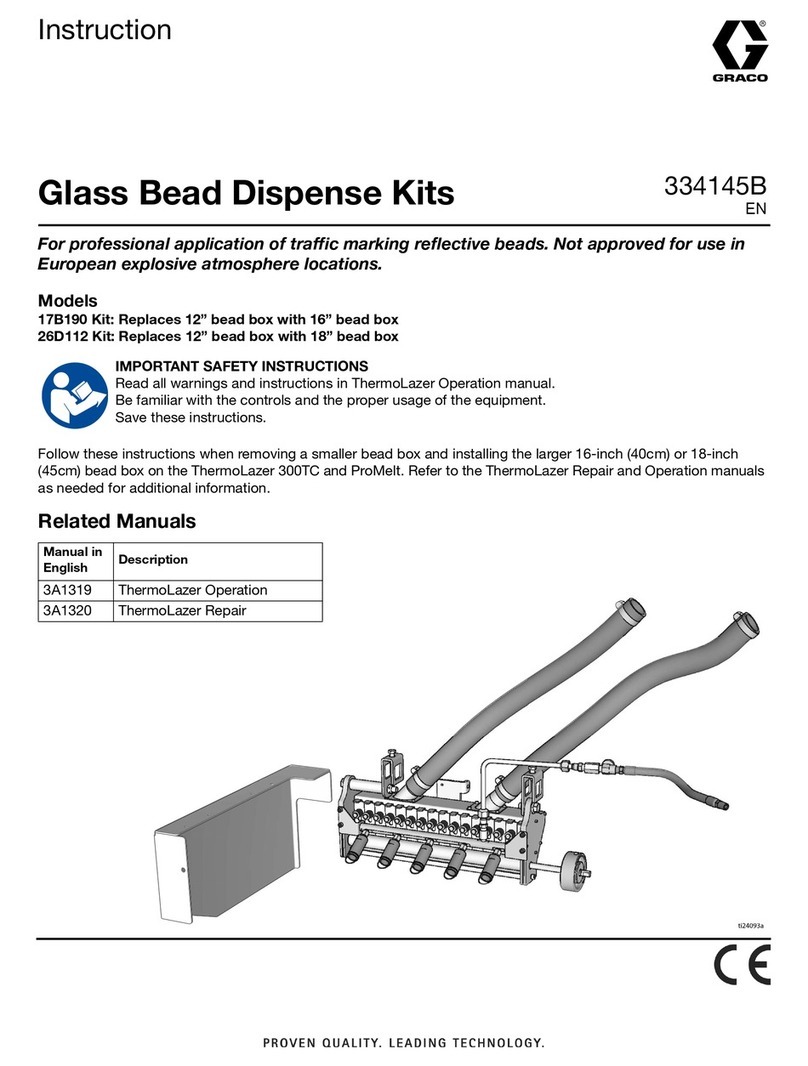

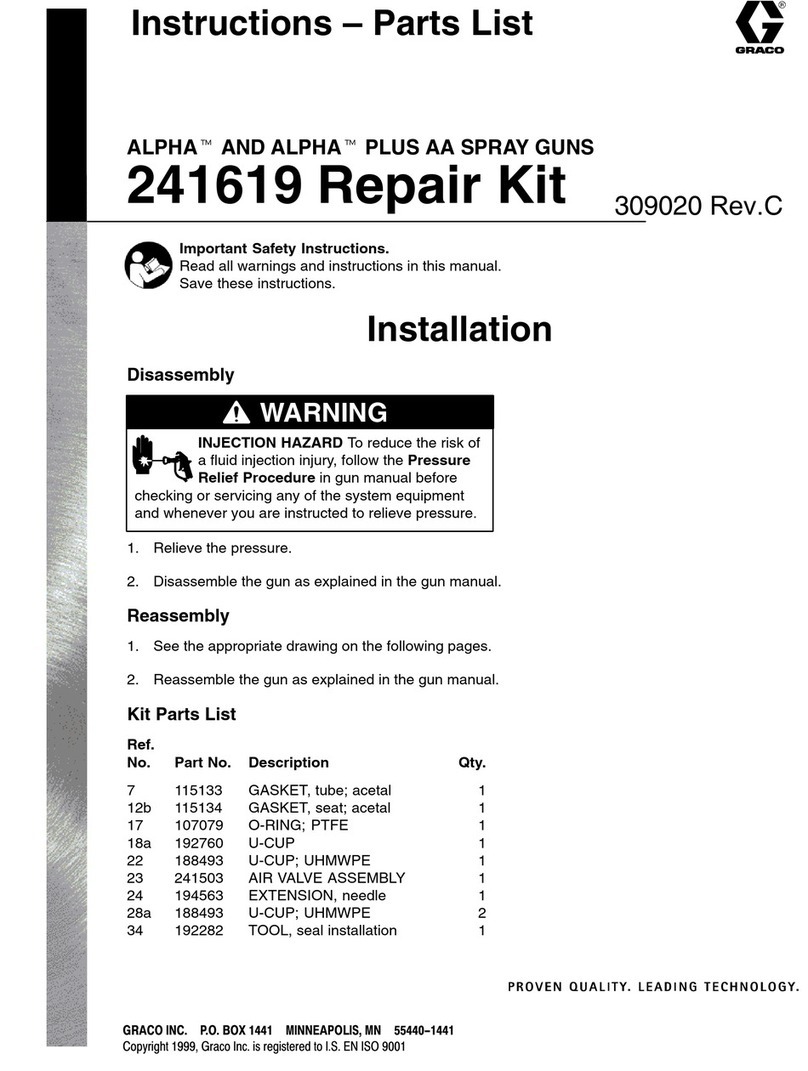

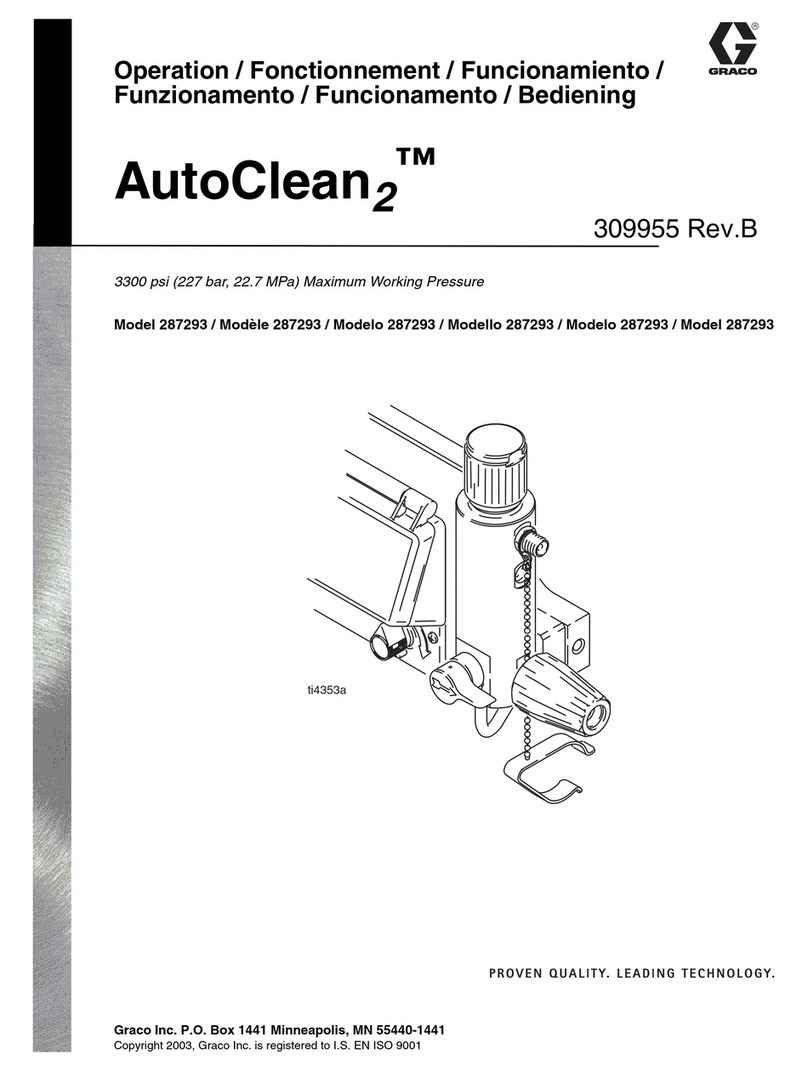

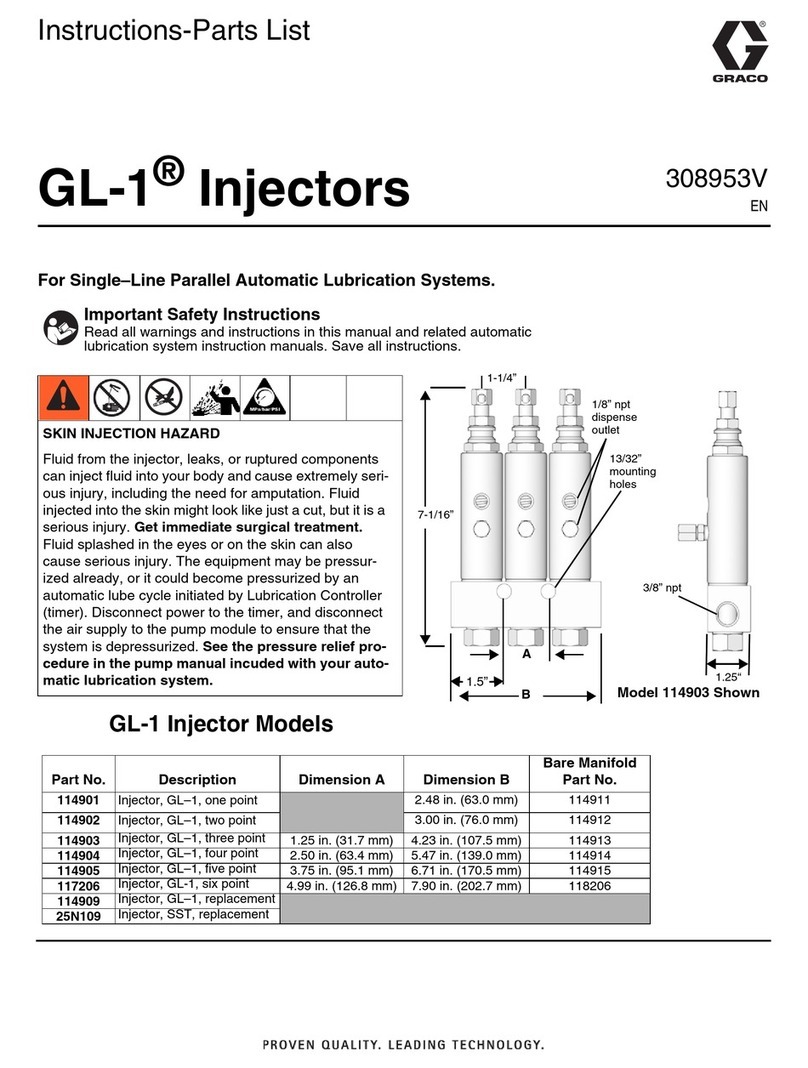

3. Place the cup on a table and slowly release the

clamp (A) to bleed-off any residual pressure in

the cup. See Fig. 4. Be sure to push the clamp

lever fully to the clamped position before turning

on the air supply to the gun again.

Setting the Cup Air Pressure

1. Pull up the cup regulator adjustment knob lock-ring

(L); this allows the knob (K) to turn. See Fig. 4.

2. Set the cup pressure at zero by turning the

adjustment knob (K) fully counterclockwise.

3. Slowly turn the adjustment knob (K) clockwise to

increase the air pressure to the cup.

4. Push the adjustment knob lock-ring (L) down to

lock the cup pressure setting.

Setting the Gun Air Pressure

NOTE: Installing the gun air inlet regulator adds a

pressure drop that could limit the air cap pressure.

Set the gun air pressure regulator for the minimum

pressure needed to atomize your fluid. See your gun

manual for recommended settings.

A

Fig. 4

L

K

M

7611A

Spraying Tips

The regulator is not self relieving so if the regulated air

pressure setting is causing excessive fluid flow, follow

these steps.

1. Pull up the cup regulator adjustment knob lock-ring

(L). See Fig. 4.

2. Turn the adjustment knob (K) counterclockwise.

3. Trigger the gun into a grounded metal waste

container until cup pressure is lowered.

4. Turn the adjustment knob (K) clockwise until you

obtain the desired lower pressure setting.

5. Push down the adjustment knob lock-ring (L).

CAUTION

Do not restrict the fluid flow by continuously spraying

with the gun’s fluid adjustment knob (M) turned in

(clockwise) as this will cause excessive abrasive

wear on the fluid needle and trigger/air valve shaft.

To restrict the fluid flow, lower the cup pressure or use

a smaller size needle/nozzle set and air cap combina-

tion.

If the cup pressure must be below 1.0 psi (0.07 bar) to

achieve the desired fluid flow, a smaller needle/nozzle

size is recommended.