Vision tools 09V0002B User manual

Technical Manual

VoE-IOBox Rev. 2.0

Article-No.: 09V0002B

Version: 5.2

© Vision Tools Bildanalyse Systeme GmbH

Heinrich-Hertz-Straße 7

68753 Waghäusel

Germany

Tel.: +49 7254 –9351 0

Fax: +49 7254 –9351 200

www.vision-tools.com

Revision date:

July 2021

Version:

5.2

Version change:

Log

Table of contents

Technisches Handbuch

Version 5.2

1

1 Table of contents

1Table of contents.....................................................................1

2General .....................................................................................2

2.1 Abbreviations.................................................................................................. 2

2.2 Information on the manual.............................................................................. 2

2.3 Documents enclosed...................................................................................... 2

2.4 Safety information........................................................................................... 2

2.5 Limitation of liability ........................................................................................ 4

2.6 Copyright law.................................................................................................. 4

2.7 Guarantee and Liability................................................................................... 4

3Safety........................................................................................5

3.1 Appropriate use .............................................................................................. 5

3.2 Foreseeable misuse ....................................................................................... 6

4Technical data..........................................................................7

4.1 Dimensions (mm)............................................................................................ 8

4.2 Plug Position................................................................................................... 9

4.3 Status LEDs.................................................................................................... 9

4.4 Pin Assignment............................................................................................. 10

4.5 Delivery status.............................................................................................. 11

4.6 Settings......................................................................................................... 12

4.6.1 Log................................................................................................................ 12

4.6.2 Bootloader .................................................................................................... 22

4.6.3 Calibration of analogue measurement ......................................................... 22

4.6.4 Change the IP address................................................................................. 23

4.6.5 Update firmware ........................................................................................... 25

4.6.6 Setting the IP address of the network adapter............................................. 26

4.6.7 Dim lights...................................................................................................... 28

5Commissioning......................................................................29

5.1 Assembly...................................................................................................... 29

6Disposal..................................................................................30

7Notes.......................................................................................31

8Attachment.............................................................................32

8.1 Manufacturer's Declaration........................................................................... 33

General

Technisches Handbuch

Version 5.2

2

2 General

2.1 Abbreviations

The abbreviations used are explained below:

V60 = Image analysis program from the VisionTools company

PPE = personal protective equipment

I/O = Input/Output

VoE = Vision over Ethernet

GND = Ground

EMC = Electromagnetic compatibility

2.2 Information on the manual

This technical manual contains important instructions for working with the product named on

the cover sheet. The prerequisite for workplace safety is the observance of all safety and

handling instructions specified in this manual. The local accident prevention regulations and

national health and safety regulations must be observed in addition to the instructions in this

manual. All information and instructions are to be carefully read before use. The manual is a

product component and must be kept accessible to the plant operator at all times.

2.3 Documents enclosed

Manufacturer's declaration

2.4 Safety information

In this manual, icons (acc. to EN ISO 7010) are used to highlight correct text passages and

relevant sections. If the product is sold in a non-EU country, the warning symbols may need

to be amended, if necessary.

The signal word describes the severity of the impending risks:

Danger! Imminent dangerous situation which will result in serious bodily injury or death.

Warning! Potentially dangerous situation which could result in serious bodily injury or

death.

Caution! Potentially dangerous situation which could result in minor bodily injury or

death. Also warning of damage to property.

Note! For application instructions and other important information.

General

Technisches Handbuch

Version 5.2

3

Note

General information

Follow the instructions

In accordance with DIN EN ISO 7010

General warning sign

In accordance with DIN EN ISO 7010

Warning of electrical voltage

In accordance with DIN EN ISO 7010

Warning of oxidising substances

In accordance with DIN EN ISO 7010

General

Technisches Handbuch

Version 5.2

4

2.5 Limitation of liability

All information and statements in this manual are compiled in consideration of valid standards

and regulations, as well as state of the art technological knowledge.

The manufacturer accepts no liability for damages due to:

Failure to observe this manual

Inappropriate use

Using non-trained personnel

Undertaking unauthorized modifications

Using impermissible replacement parts

Additionally, the obligations, the General Terms and Conditions and delivery conditions of the

manufacturer, and the statutory regulations valid at the time the contract was concluded will

apply.

2.6 Copyright law

Copyright law to this operating manual belongs to the company VisionTools Bildanalyse

Systeme GmbH. This manual is intended only for the operator and the operator’s personnel.

It includes regulations and information that may not be

duplicated,

distributed, or

transmitted in any other manner, either in whole or in part.

Duplicating the manual within a company for the purposes of training by the operator is

excepted. Violations may have criminal consequences.

2.7 Guarantee and Liability

Our General Terms and Conditions apply. Claims for a guarantee or for liability in case of

personal injury or property damage are excluded if they are due to one or more of the

following causes.

Inappropriate use of the assembly

Inappropriate installation, commissioning, operation, and maintenance of the device or

system

Failure to follow the information in the manual regarding transportation, storage,

installation, commissioning, operation, limit values, maintenance of assemblies

Unauthorized modifications to the assemblies

Unauthorized modifications to the programmes

Lack of monitoring of components subject to wear

Catastrophic incidents due to foreign objects and force majeure

Liability for subsequent damages is excluded

Safety

Technisches Handbuch

Version 5.2

5

3 Safety

3.1 Appropriate use

The VoE IOBox provides an interface between industrial process technology and the

personal computer (PC).

It is intended for use on a PC, which is equipped with an Ethernet interface. The PC is

subject to EC Directive 89/336/EEC and must meet the EMC protection requirements.

Products that meet these requirements bear the CE mark.

The data between the VoE IOBox and the PC is exchanged via a shielded CAT6 cable with

an X-Cross connector on the side of the module. The cable is connected to the X1 socket.

The module has 6 inputs and 4 outputs for processing digital 24 V signals.

For operation of the inputs and outputs, an external 24 V supply voltage is required. The

terminals are divided into two groups with the GND potential. The inputs E1.0-E1.7 and the

outputs A1.0-A1.7 have a common GND potential as well as the inputs E2.0-E2.7 and the

outputs A2.0-A2.7.

The use of the VoE IOBox in combination with external clamping or relay boards requires

professional installation in a closed control cabinet.

Therefore check the shielding capacity of the PC housing and cable shield before using the

equipment.

Any other use or use beyond the scope of this document is deemed contrary to the

designated use. The manufacturer shall not be liable for any resulting damages.

The intended use requires compliance with all instructions in the technical manual.

Limits of use

When using the VoE IOBox, in a plant, the interference resistance and emissions of the plant

can also change. Increased emission or decreased interference resistance could means that

the conformity of the system is no longer ensured.

The VoE IOBox must remain in its original packaging until use.

Do not remove the identification numbers (serial number) of the VoE IOBox. To do so

will result in loss of the warranty.

Safety

Technisches Handbuch

Version 5.2

6

3.2 Foreseeable misuse

Any other use besides that determined in Appropriate use this chapter or any use extending

beyond this is not appropriate!

The operator will bear sole responsibility

for any damages that may result from such use.

the company VisionTools accepts no liability.

In case of changes or unauthorized modifications to the system, any liability or guarantee

from VisionTools Bildanalyse Systeme GmbH will cease to exist.

The electromagnetic behaviour of the system can be impaired by additions or changes of any

kind.

Therefore, make no changes or additions to the system without consulting with the company

VisionTools Bildanalyse Systeme GmbH and receiving written approval to do so.

Danger!

Dangers may occur following improper use.

Technical data

Technisches Handbuch

Version 5.2

7

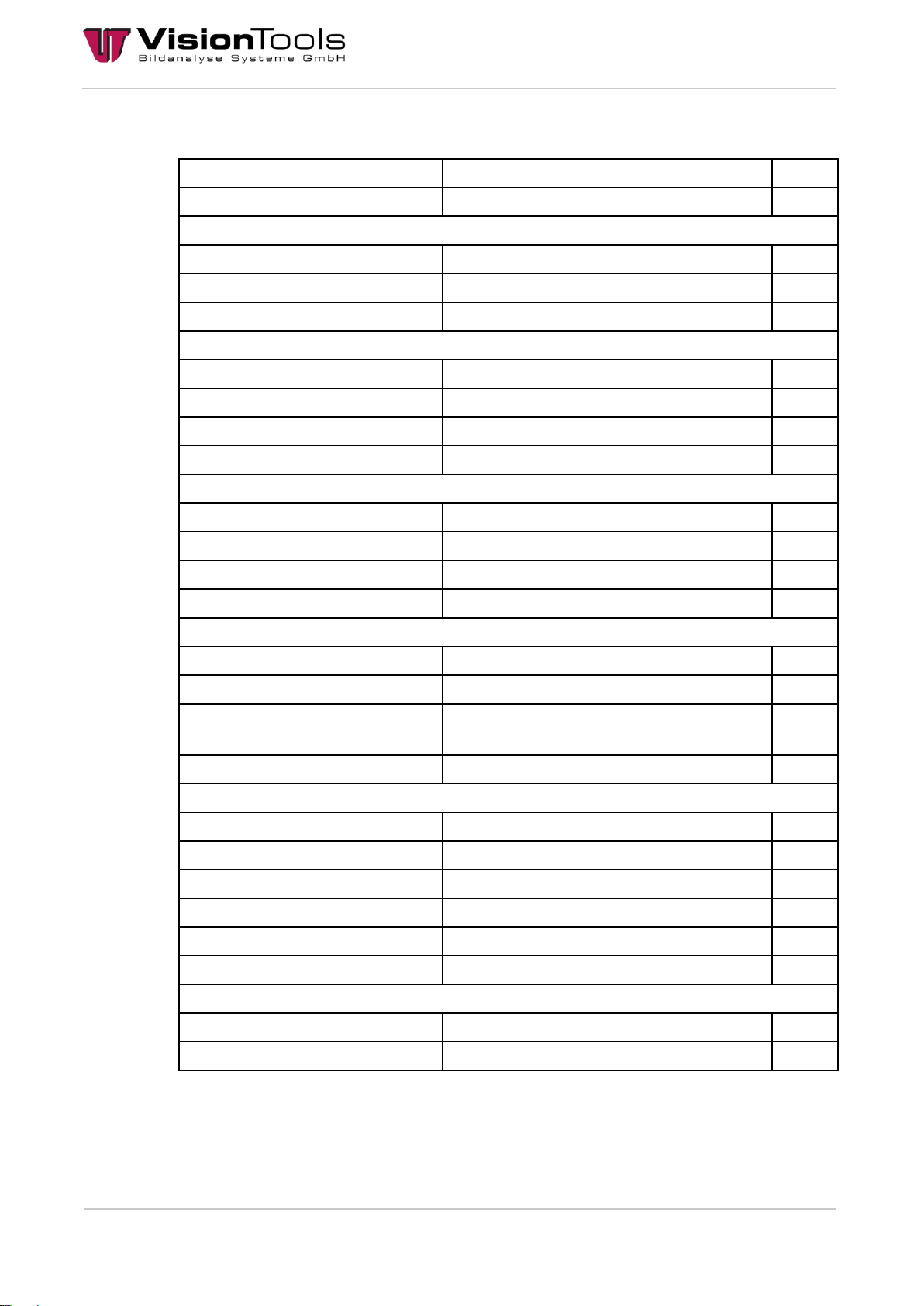

4 Technical data

Housing

Aluminium diecast (IP65)

Unit

Dimension (LxBxH)

130x140x76 (without plug)

mm

Temperature limit

Operating temperature

0 to 60

°C

Storage temperature

-15 to 70

°C

Humidity

30 –99 whitout condensation

%

Electrical limits

PoE voltage

max. 56

V

PoE current

max. 1.2

A

X2 voltage

max. 30

V

X2 current

max. 12

A

Inputs (IN)

Type

positive switching

Voltage

max. 30

V

Current

5

mA

Connection type

M12 Male-Connector 4pos. A-Coded

Outputs (OUT 24)

Type

positive switching

Voltage

24

V

Current

max. 4 / in total max. 12

(depending on the power supply)

A

Connection type

M12 Female-Connector 4pos. A-Coded

Outputs (OUT PW)

Type

push-pull

Voltage

24

V

Current

max. 200

mA

Frequency

1.5

kHz

min. pulse width (duty factor 1%)

6.7

µs

Connection type

M12 Female-Connector 4pos. A-Coded

Interface

Type

Ethernet 10

MBit/s

Connection type

M12 Female-Connector 8pos. X-Coded

Technical data

Technisches Handbuch

Version 5.2

8

Power X2

Type

Power supply

Voltage

max. 30

V

Current

max. 12

A

Connection type

M12 Male-Connector 4pos. T-Coded

Current drain without load

(idle)

approx. 0.1

A

Power consumption without load

approx. 2.4

W

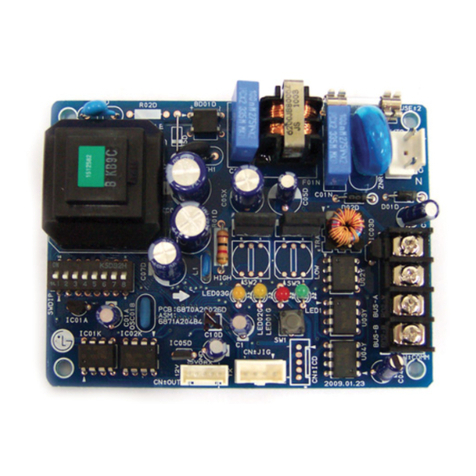

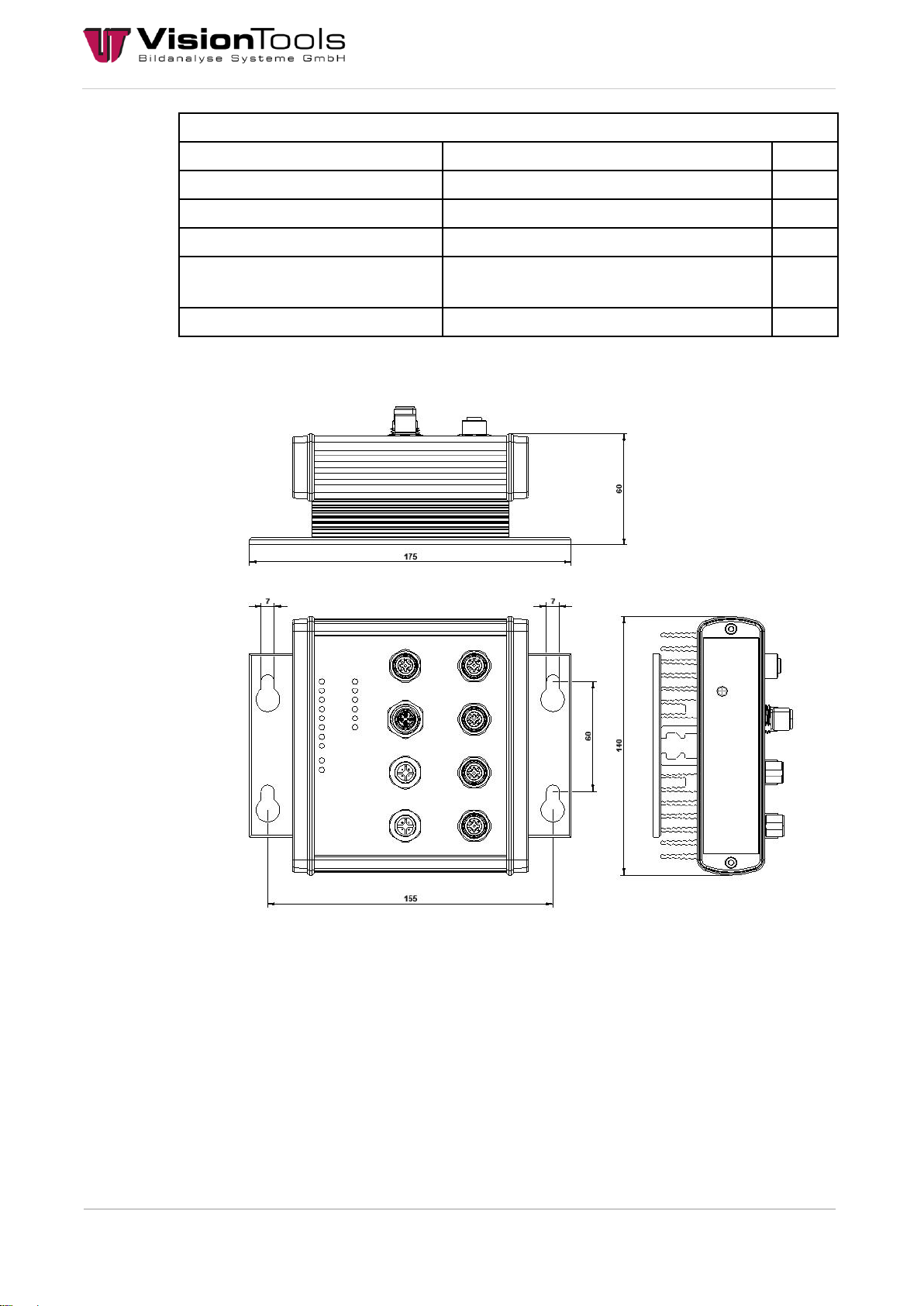

4.1 Dimensions (mm)

Technical data

Technisches Handbuch

Version 5.2

9

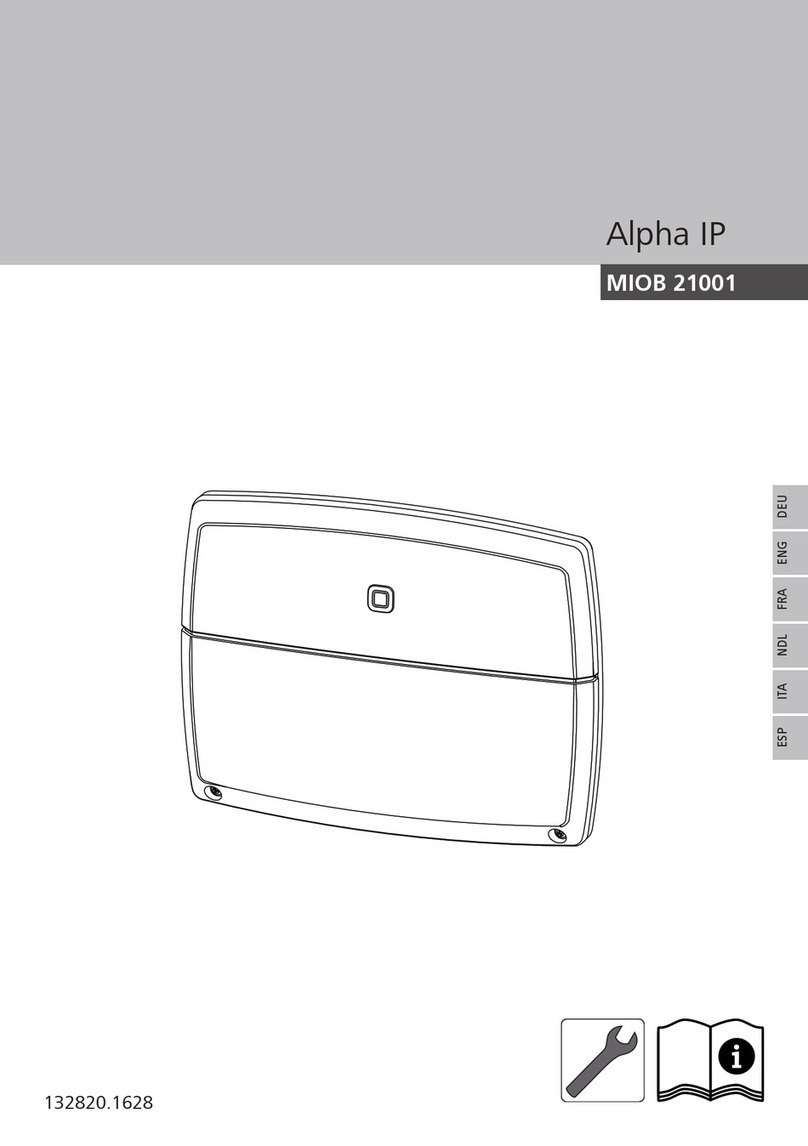

4.2 Plug Position

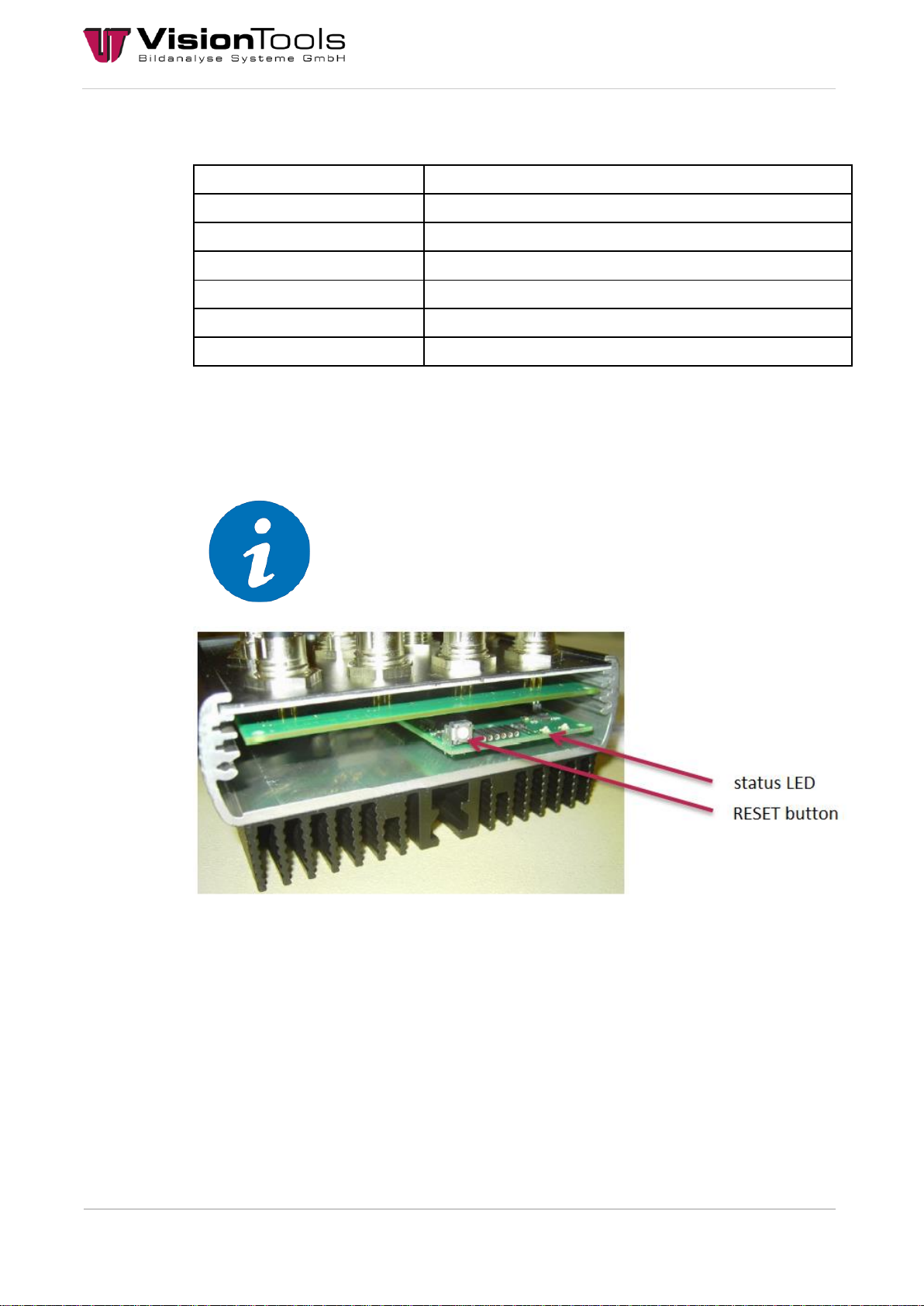

4.3 Status LEDs

LED label

Meaning

LINK

The VoE-IOBox is connected and supplied with power.

DATA

Data transmission takes place, or data packages are

transmitted.

O1.24 –O4.24

Outputs 1, 2, 3 or 4 are switched.

O1.PW –O4.PW

Outputs 1, 2, 3, or 4 were switched via the PWM duty factor [%].

IN1 –IN6

Inputs 1, 2, 3, 4, 5 or 6 are switched.

PoE

The power supply is via PoE.

24V

The power supply is via 24V.

Technical data

Technisches Handbuch

Version 5.2

10

4.4 Pin Assignment

X1 Ethernet

X5 Output

M12 Female-Connector 8pos.

X-Coded

PIN

Signal

1

MX0+

2

MX0-

3

MX1+

4

MX1-

5

MX3+

6

MX3-

7

MX2-

8

MX2+

M12 Female-Connector 4pos.

A-Coded

PIN

Signal

1

24V

2

GND

3

GND

4

PWM

X2 Power 24V

X6 Output

M12 Male-Connector 4pos.

T-Coded

PIN

Signal

1

24V

2

GND

3

GND

4

24V

M12 Female-Connector 4pos.

A-Coded

PIN

Signal

1

24V

2

GND

3

GND

4

PWM

X3 Input

X7 Output

M12 Male-Connector 4pos.

A-Coded

PIN

Signal

1

INB/24V

2

INC

3

GND

4

INA

M12 Female-Connector 4pos.

A-Coded

PIN

Signal

1

24V

2

GND

3

GND

4

PWM

X4 Input

X8 Output

M12 Male-Connector 4pos.

A-Coded

PIN

Signal

1

INB/24V

2

INC

3

GND

4

INA

M12 Female-Connector 4pos.

A-Coded

PIN

Signal

1

24V

2

GND

3

GND

4

PWM

Technical data

Technisches Handbuch

Version 5.2

11

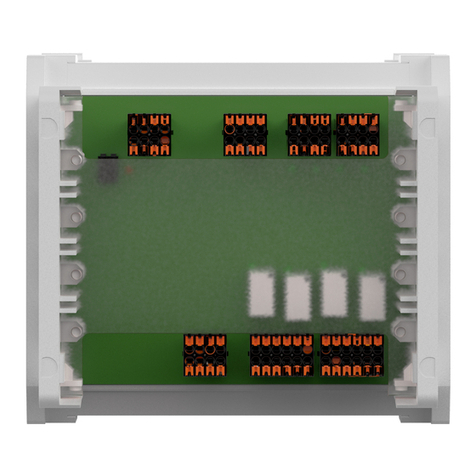

4.5 Delivery status

MAC

individual

IP address

192.168.0.254

Subnetwork mask

255.255.255.0

Gateway

192.168.0.1

DNS1

192.168.0.1

DNS2

0.0.0.0

TCP/IP Port

9760

To return the device to the delivery status, the RESET button must be pressed until the LED

on the left of the RESET button begins flashing.

Then adjust the IP address in the "TCP/IP-Client - Init" object (see chapter Change the IP

address) and briefly switch the box off.

NOTE!

Only the power supply may be connected for resetting.

The video "How to reset the VoE IO-Box.mp4" serves as an additional

help.

Technical data

Technisches Handbuch

Version 5.2

12

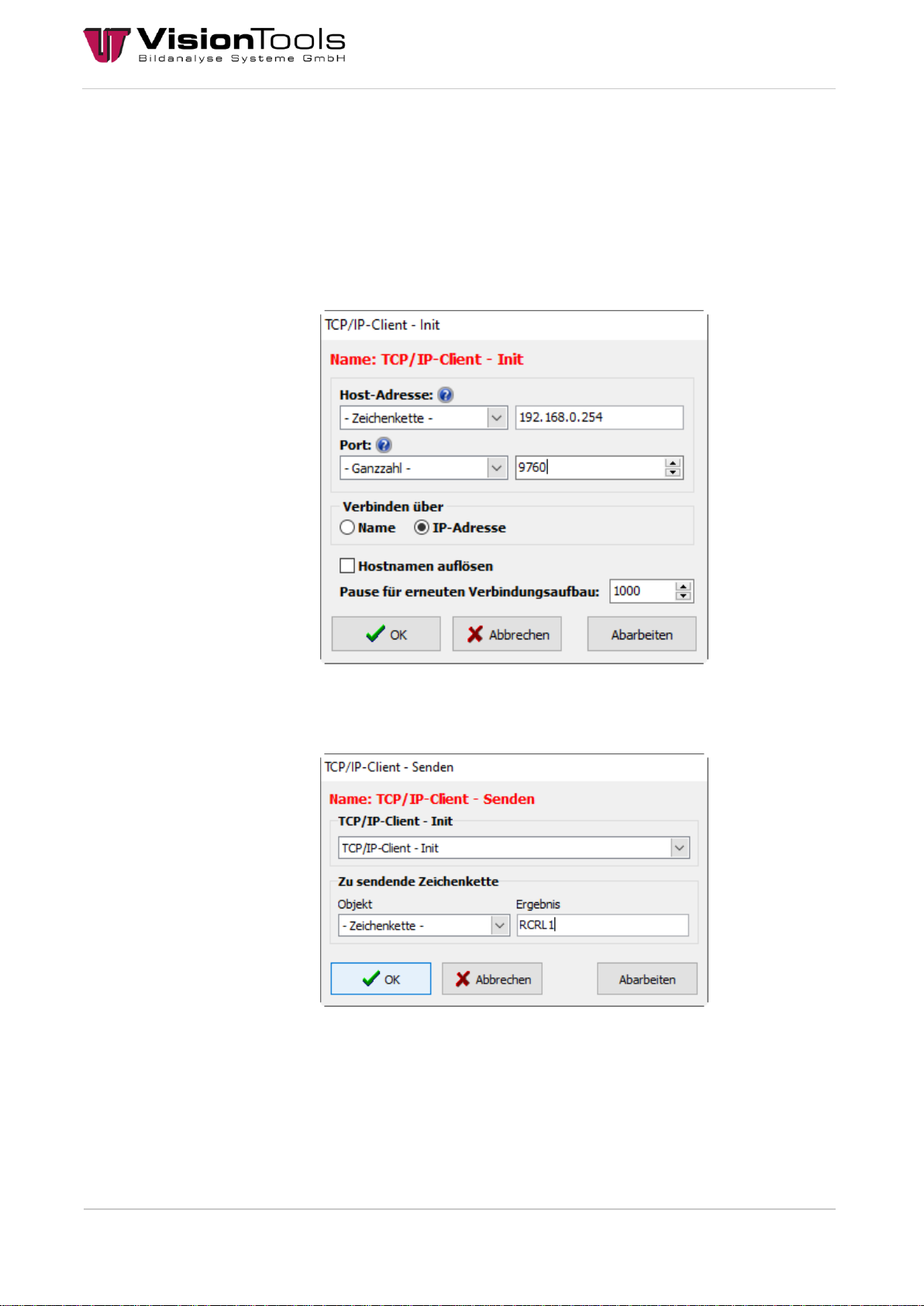

4.6 Settings

4.6.1 Log

The commands are sent and received to the VoE-IOBox via "TCP-IP". The correct IP address

as well as the correct port must be entered.

All commands are sent in plain text (ASCII). Values begin with an angle bracket and end with

an angle bracket. Values are sent as decimal values in plain text (ASCII). If a command is not

understood or is wrong, the module sends "ENR<X>".

1. Example (read out limit values of the outputs):

Command to read: RCRL1 (1 to 4 are the outputs of the VoE-IOBox)

2. Example (read error):

Command to read: ERR (Result 99 = over-current)

Technical data

Technisches Handbuch

Version 5.2

13

Configure CIP/RCIP IP addresses

Write:

CIP<IPAddr,Mask,Gateway,DNS1,DNS2,HostName>

Answer: none

_CIP<IPAddr,Mask,Gateway,DNS1,DNS2,HostName>

Answer: „ACK“

E.g. CIP<192.168.0.10,255.255.255.0,192.168.0.1,0.0.0.0,VOE_HOST>

Read:

RCIP

Answer: CIP<MACAddr,IPAddr,Mask,Gateway,DNS1,DNS2,HostName>

E.g.: CIP<00:04:A3:D0:00:00,192.168.0.10,255.255.255.0,192.168.0.1,0.0.0.0,VOE_HOST>

RVER Returns the program version

Read:

RVER

Answer: VER<vX.XX.XX>

UPL Upload Mode

Send:

UPL

Answer: UPL<vX.XX.XX>

The controller is set to upload mode for 4 seconds. See Bootloader.

TEST starts and stops the test run.

Send:

TEST

Answer: TEST<1>

Answer: TEST<0>

The controller is set to test mode.

CADC Calibration of the analogue measurement

Send:

CADC

Answer: RVER<vX.XX.XX>

See Calibration of analogue measurement.

Technical data

Technisches Handbuch

Version 5.2

14

SPA memory parameter

Send:

SPA

Answer: SPA

Transmitted parameters such as CFIx<>, CFOx<>, TMRx<> and CRL<> are not immediately

permanently stored in the EEPROM of the VoE-IOBox. Only with the command SPA are the

parameters stored permanently and are then still available after a restart.

EXCEPTION CIP<> is stored immediately.

CFI/RCFI Setting the inputs IN1...6

Write:

CFI1<PORT,EVENT,MODE,Debounce time>

Answer: none

_CFI1<PORT,EVENT,MODE,Debounce time>

Answer: „ACK“

CFI1<0..4,0..4,0..1,0..999>

Specifies the output to be switched.

0 = not assigned to any output, 1 = OUT1, 2 = OUT2, 3 =

OUT3, 4 = OUT4

CFI1<0..4,0..4,0..1,0..999>

0 = Input static. Output remains on as long as the input is

present.

1 = positive edge.

Output switches on with rising edge for the time programmed

with TMR1<...>.

2 = negative edge.

Output switches on with falling edge for the time programmed

with TMR1<...>.

3 = positive edge.

Output switches on/off with rising edge (impulse relay).

4 = negative edge.

Output switches on/off with falling edge (impulse relay).

CFI1<0..4,0..4,0..1,0..999>

0 = polling input.

1 = push input.

If the input state changes, INP1<0> or INP1<1> is transmitted.

CFI1<0..4,0..4,0..1,0..999>

0..999 ms debouncing for IN1.

CFI2<x,x,x,xxx>

see CFI1<x,x,x,xxx>

CFI3<x,x,x,xxx>

see CFI1<x,x,x,xxx>

CFI4<x,x,x,xxx>

see CFI1<x,x,x,xxx>

CFI5<x,x,x,xxx>

see CFI1<x,x,x,xxx>

CFI6<x,x,x,xxx>

see CFI1<x,x,x,xxx>

Technical data

Technisches Handbuch

Version 5.2

15

Read:

RCFI1

Answer: CFI1<0..4,0..4,0..1,0..999>

RCFI2

Answer: CFI2<0..4,0..4,0..1,0..999>

RCFI3

Answer: CFI3<0..4,0..4,0..1,0..999>

RCFI4

Answer: CFI4<0..4,0..4,0..1,0..999>

RCFI5

Answer: CFI5<0..4,0..4,0..1,0..999>

RCFI6

Answer: CFI6<0..4,0..4,0..1,0..999>

RINP Reads the inputs IN1...6

RINP1

Answer: INP1<0..1>

RINP2

Answer: INP2<0..1>

RINP3

Answer: INP3<0..1>

RINP4

Answer: INP4<0..1>

RINP5

Answer: INP5<0..1>

RINP6

Answer: INP6<0..1>

CFO/RCFO Sets the outputs OUT1...4

Write:

CFO1<MODE,Delay>

Answer: none

_CFO1<MODE,Delay >

Answer; „ACK“

CFO1<0..1,0..9999>

0 = OUT1.24 = Switch, OUT1.PW = PWM (pulse width modulation)

1 = OUT1.24 = PWM, OUT1.PW = off

CFO1<0..1,0..9999>

0..9999 ms Switch-on delay OUT1.

CFO2<x,xxxx>

see CFO1<x,xxxx>

CFO3<x,xxxx>

see CFO1<x,xxxx>

CFO4<x,xxxx>

see CFO1<x,xxxx>

Read:

RCFO1

Answer: CFO1<0..1,0..9999>

RCFO2

Answer: CFO2<0..1,0..9999>

RCFO3

Answer: CFO3<0..1,0..9999>

RCFO4

Answer: CFO4<0..1,0..9999>

Technical data

Technisches Handbuch

Version 5.2

16

OUT/ROUT Switches the outputs OUT1…4

Write:

OUTx<STATUS>

Answer: none

_OUTx<STATUS>

Answer: „ACK“

OUT1<0..1>

0 = Switches OUT1 off

with CFO1<0,xxxx> Output OUT1.24 is switched off and the PWM signal

at output OUT1.PWM is stopped.

with CFO1<1,xxxx> the PWM signal is stopped at Output OUT1.24.

1 = Switches OUT1 on

with CFO1<0,xxxx> Output OUT1.24 is switched on and the PWM signal

at Output OUT1.PWM is output.

with CFO1<1,xxxx> the PWM signal is output at Output OUT1.24.

OUT2<x>

see OUT1<x>

OUT3<x>

see OUT1<x>

OUT4<x>

see OUT1<x>

Read:

ROUT1

Answer: OUT1<0..1>

ROUT2

Answer: OUT2<0..1>

ROUT3

Answer: OUT3<0..1>

ROUT4

Answer: OUT4<0..1>

OUTP Switches the outputs OUT1...4 with PWM value

Write:

OUTPx<STATUS,PWM>

Answer: none

_OUTPx<STATUS,PWM>

Answer: „ACK“

OUTP1<0..1,0..100>

0 = Switches OUT1 off

with CFO1<0,xxxx> Output OUT1.24 is switched off and the PWM

signal at output OUT1.PWM is stopped.

with CFO1<1,xxxx> the PWM signal is stopped at Output OUT1.24.

1 = Switches OUT1 on

with CFO1<0,xxxx> Output OUT1.24 is switched on and the PWM

signal at Output OUT1.PWM is output.

with CFO1<1,xxxx> the PWM signal is output at Output OUT1.24.

OUTP1<0..1,0..100>

0..100% Brightness for OUT1.

Technical data

Technisches Handbuch

Version 5.2

17

OUTP2<x,xxx>

see OUTP1<x,xxx>

OUTP3<x,xxx>

see OUTP1<x,xxx>

OUTP4<x,xxx>

see OUTP1<x,xxx>

OUT0 Simultaneous switching of the outputs OUT1…4

Write:

OUT0<OUT1,OUT2,OUT3,OUT4>

Answer: none

_OUT0< OUT1,OUT2,OUT3,OUT4>

Answer: „ACK“

OUT0<0.X.1,0.X.1,0.X.1,0.X.1>

0 = Switches OUTx off

with CFO1<0,xxxx> Output OUT1.24 is switched off and

the PWM signal at output OUT1.PWM is stopped.

with CFO1<1,xxxx> the PWM signal is stopped at Output

OUT1.24.

1 = Switches OUTx on

with CFO1<0,xxxx> Output OUT1.24 is switched on and

the PWM signal at Output OUT1.PWM is output.

with CFO1<1,xxxx> the PWM signal is output at Output

OUT1.24.

X = no change at OUTx

OUTP0 Simultaneous switching of outputs OUT1...4 with PWM value

Write:

OUTP0<OUT1,PWM1,OUT2,PWM2,OUT3,PWM3,OUT4,PWM4>

Answer: none

_OUTP0<OUT1,PWM1,OUT2,PWM2,OUT3,PWM3,OUT4,PWM4>

Answer: „ACK“

OUTP0<0.X.1,0..100,..

..,0.X.1,0..100>

0 = Switches OUTx off

with CFO1<0,xxxx> Output OUT1.24 is switched off and the PWM

signal at output OUT1.PWM is stopped.

with CFO1<1,xxxx> the PWM signal is stopped at Output OUT1.24.

1 = Switches OUTx on

with CFO1<0,xxxx> Output OUT1.24 is switched on and the PWM

signal at Output OUT1.PWM is output.

with CFO1<1,xxxx> the PWM signal is output at Output OUT1.24.

X = no change at OUTx

OUTP0<0.X.1,0..100,..

..,0.X.1,0..100>

0..100% Brightness for OUTx.

Technical data

Technisches Handbuch

Version 5.2

18

PSS/RPSS Switches the outputs PSS1…2 on

Write:

PSS1<STATUS>

Answer: none

_PSS1<STATUS>

Answer: „ACK“

PSS1<0..1>

0 = Switches PSS1 off

1 = Switches PSS1 on

Switches at X3.1 24Volt on/off. Used to supply voltage to a connected

sensor with max. 200mA.

PSS2<x>

see PSS1<x>

Switches at X4.1 24Volt on/off. Used to supply voltage to a connected

sensor with max. 200mA.

Read:

RPSS1

Answer: PSS1<0..1>

RPSS2

Answer: PSS2<0..1>

TRG Software trigger for Outputs OUT1…4

Write:

TRG1<TIME>

Answer: none

_TRG1<TIME>

Answer: „ACK“

TRG1<0…9999>

0..9999 ms Duty cycle for OUT1

with CFO1<0,xxxx> Output OUT1.24 is switched on and the PWM signal

at Output OUT1.PWM is output. After the time has elapsed, both outputs

are switched off.

with CFO1<1,xxxx> the PWM signal is output at Output OUT1.24. After

the time has elapsed, the output is switched off.

TRG2<xxxx>

see TRG1<xxxx>

TRG3<xxxx>

see TRG1<xxxx>

TRG4<xxxx>

see TRG1<xxxx>

If TRG1..4 is sent with empty brackets "<>", the time of TMR1..4 is taken.

Table of contents

Other Vision tools Control Unit manuals