Intertronic IDMHDV-130 User manual

For assistance and enquiries, please contact one of our

technical specialists:

01865 842842

sales@intertronics.co.uk

INTERTRONICS

12A Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

England

OX5 1JD

www.intertronics.co.uk

Version 1.0

July 2017

IDMHDV-130

Handheld Diaphragm Valve

User Manual

www.intertronics.co.uk/idmhdv-130

Station Field Industrial Estate

Banbury Road, Kidlington

Oxfordshire, England OX5 1JD

t 01865 842842

e orders@intertronics.co.uk

www.intertronics.co.uk

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Thank you for purchasing the IDMHDV-130 Handheld Diaphragm Valve.

For optimum performance and results, please read this manual carefully. Ensure that all operators and

personnel are adequately trained for use with this product.

This document is based on information available and correct at the time of publication. The statements,

technical information and recommendations contained herein are based on knowledge we believe to be

reliable but they are not to be construed in any manner as warrantees expressed or implied. The user

shall determine the suitability of the product for his intended use and the user assumes all risk and

liability whatsoever in connection therewith.

Allen® is a registered trademark of the Apex Tool Group, LLC.

For any queries regarding this product, please contact Intertronics directly.

[blank page]

9

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Troubleshooting

Problem

Possible Cause

Corrective Action

Valve does

not cycle

•Air pressure to air section is

too low

•Stroke adjustment bolt is

bottomed out

•Material has cured in the

valve

•Valve was assembled w/o

lubricating the O-ring seals

•Increase air pressure to

between 50-80 psi

•Back out stroke adjustment bolt

by turning it counter-clockwise

•Disassemble and clean valve

•Disassemble valve, lubricate

seals and re-assemble

Material

leaks from

valve tip

•Diaphragm is worn

•Air bubble trapped in fluid

body or in dispense needle

•Replace diaphragm

•Flip valve upside down and cycle

until air bubbles are removed

Valve leaks

from mid-

section

•Diaphragm is worn or

damaged

•O-Ring is worn or damaged

•Replace diaphragm

•Replace O-ring

Valve does

not

dispense

anything

•Fluid pressure is too low

•Material has cured in fluid

section

•Stroke adjustment bolt is set

too low

•Increase fluid pressure

•Disassemble and clean valve

•Back out stroke adjustment bolt

by turning it counter-clockwise

Air bubbles

in fluid

•Valve not properly purged

•Problem with fluid delivery

system

•Stroke adjustment set back

too far

•Flip valve upside down and cycle

until air bubbles are removed

•Diagnose and repair

•Turn down stroke adjustment

Dispense

rate too

fast

•Fluid pressure set too high

•Stroke adjust set too high

•Dispense tip gauge too large

•Decrease fluid pressure

•Turn stroke adjust clockwise

•Replace dispense tip with

smaller size

Dispense

rate too

slow

•Fluid pressure set too low

•Stroke adjust set too low

•Dispense tip gauge too small

•Increase fluid pressure

•Turn stroke adjust counter-

clockwise

•Replace dispense tip with larger

size

Table of Contents

Theory of Operation ..................................................................... 2

Air Section............................................................................... 2

Fluid Section............................................................................ 2

Safety......................................................................................... 2

Set Up ........................................................................................ 3

Diagram #IDMHDV-130 ............................................................. 4-5

Operation.................................................................................... 6

Routine Cleaning and Disassembly ................................................. 6

General Assembly ........................................................................ 7

Troubleshooting ........................................................................... 8

Note: Throughout this manual, numbers denoted in brackets refer to the

corresponding parts labelled in Diagram #IDMHDV-130

8

1

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Theory of Operation

The IDMHDV-130 is an all-plastic handheld dispense valve that uses a unique rigid

diaphragm design to act as a front closing valve to accurately dispense small dots and

fine beads. This valve is designed for handheld applications, to take the place of

traditional syringe dispensing or other manually applied fluids. The all-plastic

construction allows adhesives such as cyanoacrylates and anaerobic materials to be

dispensed through the valve along with a variety of other low to medium viscosity

fluids. Applications can include potting and the dispensing of dots and beads.

The IDMHDV-130 body comprises:

1) Air section (aluminium top portion)

2) Fluid section (acetal body with PTFE diaphragm and polyethylene luer

adapter)

Air Section

The air section is an aluminium body with a simple piston/cylinder combination using

air to open the valve and a spring to close. A stroke adjustment bolt in the upper air

body controls how far the piston and needle assembly can retract, thus regulating the

rate of fluid flow along with a lock nut to hold it in place.

Note: Upon delivery, the stroke adjustment bolt is fully closed.

Fluid Section

The fluid section is made up of acetal with a rigid PTFE diaphragm connected to the

air piston. Fluid dispenses as the point of the diaphragm is lifted out of the fluid section

orifice then stops as it moves back into place. The stroke adjustment bolt of the air

cylinder regulates the distance that the diaphragm tip can lift out of the fluid section

orifice thus controlling rate of fluid flow. An M3 female thread is available in the fluid

section to hold a grounding wire in place to remove any ESD charge.

Wetted parts on the IDMHDV-130 include:

•Acetal (ESD Safe)

•PTFE

•Polyethylene

Safety

Due to material contents being under pressure, eye protection is recommended for

operators. Refer to the SDS for the material being dispensed for other precautions.

6) Remove the cylinder cap (7) and stroke adjustment assembly (8, 9) from the

air cylinder (6) to remove the spring (12).

7) Insert a flat head screwdriver into the slot of the piston (5) to hold it in place

then spin the diaphragm (2) counter-clockwise to unthread it from the piston.

8) Slide the cylinder end cap (4) off the piston.

9) Push the threaded end of the piston (5) into the air cylinder (6) to slide it

through the back and remove.

10) Remove the 007 Nitrile O-ring (15) from the air cylinder and the 116 Nitrile

O-ring (13) from the piston (5).

11) Clean all of the wetted parts thoroughly with an appropriate solvent.

Replace components with spares provided in the spare parts kit, if necessary.

General Assembly

All O-rings must be lubricated with a small amount of silicone grease.

1) Thread the lock nut (9) onto the stroke adjustment (8) with knurled side first.

2) Thread the stroke adjustment (8) into the cylinder cap (7).

3) Mount the 116 Nitrile O-ring (13) onto the piston (5).

4) Apply a small amount of silicone grease to the inside of the air cylinder (6)

then drop in the piston (5).

5) Mount the 007 Nitrile O-ring onto the end of the piston (5) and slide it down

into the groove of the air cylinder (6).

6) Place the cylinder end cap (4) onto the piston (5), lip side first and slide up

to the air cylinder (6)

7) Using a square head screwdriver, hold the piston (5) in place and thread the

diaphragm (2) on tightly.

8) If the diaphragm (2) does not square up with the air cylinder (6) use the

square head screwdriver to turn the piston until it is aligned.

9) Place the 016 FFKM O-ring (14) into the groove of the fluid body (1).

10) Place the air cap & diaphragm assembly on top of the fluid body (1) and

assemble with four machine screws (11) using a 3/32” Allen key to tighten

them down evenly.

11) Thread the plastic luer adapter (4) into the bottom of the fluid section (3)

and tighten using a spanner.

Note: Be sure not to over-tighten the luer adapter (4).

2

7

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Operation

1) Set up the valve as outlined in the Setup procedures (page 3).

2) Regulate the air pressure operating the valve between 50-80psi.

3) Making sure that the valve is not aimed toward anyone, cycle the valve several

times. When the valve is cycling, the piston (5) can be heard hitting the stroke

adjustment bolt (8). If the valve is not cycling properly, refer to the

Troubleshooting section (page 8).

4) When the fluid delivery system is connected to the valve, pressurise the

material to be dispensed.

5) Once again, cycle the valve open to purge. Fluid should begin to dispense from

the tip of the valve. Elevate the valve with the tip pointing up in the air, then

hold a purge cup underneath the tip and cycle the valve to open until all air is

removed.

6) Check fluid connection for leaks. If the valve is leaking or dripping, refer to the

Troubleshooting section (page 8).

7) Adjust the material pressure until the desired fluid flow is achieved.

8) Turn the stroke adjustment bolt (8) until the desired flow rate is achieved.

Turning the adjustment clockwise will decrease the material flow rate and

counter-clockwise will increase the material flow rate. If the stroke is turned all

the way down, it will stop fluid flow entirely.

9) Once the stroke is set, tighten the lock nut (9) against the cylinder cap.

Note: refer to the Troubleshooting section (page 8) for any problems.

Routine Cleaning and Disassembly

Cleaning and rebuilding the valve will be required from time to time. A spare parts kit

(IDMHDV-130-SP) is available with all the normal wear parts included (1 x Diaphragm

(IDMHDV-130-114-9539), 1 x Nitrile O-Ring (IDMHDV-130-VLV-116B), 1 x FFKM O-Ring

(IDMHDV-130-VLV-016K), 1x Nitrile O-Ring (IDMHDV-130-VLV-007B) and 1 x Plastic

Luer adapter (IDMHDV-130-V300-UV)). Contact Intertronics to order.

1) Flush the valve thoroughly with an appropriate solvent before disassembly.

(Refer to SDS of fluid for suggested solvent).

2) Remove fluid pressure from the system, and then remove all fluid delivery

fittings, hoses, etc. from the valve. Remove operating air pressure from the

valve.

3) Using a spanner, unthread and remove the luer adapter (10) from the fluid body

(1).

4) Using a 3/32” Allen® key, evenly remove the four machine screws (11) from

the cylinder cap (7).

5) Pull the fluid body (1) apart from the upper assembly and remove the 016 FFKM

O-ring (14).

Set Up

To actuate the air section the IDMHDV-130 requires a dispensing controller, such as

the FISDC100 Automatic liquid dispenser. Contact Intertronics for more information.

The valve should be operated with clean, dry air between 50-80psi. One #10-32

threaded air port is located on the air section of the valve to open the valve when air

is applied. A spring is then used to return the valve to the closed position. A quick

connect air fitting is typically supplied with the IDMHDV-130 to fit 5/32” tubing.

Fluid is supplied to the IDMHDV-130 through the 1/8” NPT port located on the acetal

fluid section of the valve.

6

3

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Diagram #IDMHDV-130

Note: Throughout this manual, numbers denoted in brackets refer to the

corresponding parts labelled in Diagram IDMHDV-130

Item

Description

Part Number

Qty

1

Fluid Section, Wand

IDMHDV-130-214-12039

1

2

Diaphragm*

IDMHDV-130-114-9539

1

3

Expansion Insert

IDMHDV-130-95110A112

1

4

Cylinder End Cap

IDMHDV-130-214-11936

1

5

Piston

IDMHDV-130-214-10420

1

6

Air Cylinder

IDMHDV-130-214-11937

1

7

Cylinder Cap

IDMHDV-130-214-11964

1

8

Stroke Adjustment

IDMHDV-130-214-11981

1

9

Lock Nut

IDMHDV-130-214-11996

1

10

Nitrile O-Ring

IDMHDV-130-VLV-007B

1

11

Socket Head Cap Screw

IDMHDV-130-SH5-40x1.625

4

12

Spring

IDMHDV-130-01511

1

13

Nitrile O-Ring*

IDMHDV-130-VLV-116B

1

14

FFKM O-Ring*

IDMHDV-130-VLV-016K

1

15

Nitrile O-Ring*

IDMHDV-130-VLV-007B

1

* These parts are included in the IDMHDV-130-SP Spare Parts Kit (1

x Diaphragm (IDMHDV-130-114-9539), 1 x Nitrile O-Ring (IDMHDV-

130-VLV-116B), 1 x FFKM O-Ring (IDMHDV-130-VLV-016K), 1x Nitrile

O-Ring (IDMHDV-130-VLV-007B) and 1 x Plastic Luer adapter (IDMHDV-

130-V300-UV)). Contact Intertronics to order.

4

5

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Diagram #IDMHDV-130

Note: Throughout this manual, numbers denoted in brackets refer to the

corresponding parts labelled in Diagram IDMHDV-130

Item

Description

Part Number

Qty

1

Fluid Section, Wand

IDMHDV-130-214-12039

1

2

Diaphragm*

IDMHDV-130-114-9539

1

3

Expansion Insert

IDMHDV-130-95110A112

1

4

Cylinder End Cap

IDMHDV-130-214-11936

1

5

Piston

IDMHDV-130-214-10420

1

6

Air Cylinder

IDMHDV-130-214-11937

1

7

Cylinder Cap

IDMHDV-130-214-11964

1

8

Stroke Adjustment

IDMHDV-130-214-11981

1

9

Lock Nut

IDMHDV-130-214-11996

1

10

Nitrile O-Ring

IDMHDV-130-VLV-007B

1

11

Socket Head Cap Screw

IDMHDV-130-SH5-40x1.625

4

12

Spring

IDMHDV-130-01511

1

13

Nitrile O-Ring*

IDMHDV-130-VLV-116B

1

14

FFKM O-Ring*

IDMHDV-130-VLV-016K

1

15

Nitrile O-Ring*

IDMHDV-130-VLV-007B

1

* These parts are included in the IDMHDV-130-SP Spare Parts Kit (1

x Diaphragm (IDMHDV-130-114-9539), 1 x Nitrile O-Ring (IDMHDV-

130-VLV-116B), 1 x FFKM O-Ring (IDMHDV-130-VLV-016K), 1x Nitrile

O-Ring (IDMHDV-130-VLV-007B) and 1 x Plastic Luer adapter (IDMHDV-

130-V300-UV)). Contact Intertronics to order.

4

5

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Operation

1) Set up the valve as outlined in the Setup procedures (page 3).

2) Regulate the air pressure operating the valve between 50-80psi.

3) Making sure that the valve is not aimed toward anyone, cycle the valve several

times. When the valve is cycling, the piston (5) can be heard hitting the stroke

adjustment bolt (8). If the valve is not cycling properly, refer to the

Troubleshooting section (page 8).

4) When the fluid delivery system is connected to the valve, pressurise the

material to be dispensed.

5) Once again, cycle the valve open to purge. Fluid should begin to dispense from

the tip of the valve. Elevate the valve with the tip pointing up in the air, then

hold a purge cup underneath the tip and cycle the valve to open until all air is

removed.

6) Check fluid connection for leaks. If the valve is leaking or dripping, refer to the

Troubleshooting section (page 8).

7) Adjust the material pressure until the desired fluid flow is achieved.

8) Turn the stroke adjustment bolt (8) until the desired flow rate is achieved.

Turning the adjustment clockwise will decrease the material flow rate and

counter-clockwise will increase the material flow rate. If the stroke is turned all

the way down, it will stop fluid flow entirely.

9) Once the stroke is set, tighten the lock nut (9) against the cylinder cap.

Note: refer to the Troubleshooting section (page 8) for any problems.

Routine Cleaning and Disassembly

Cleaning and rebuilding the valve will be required from time to time. A spare parts kit

(IDMHDV-130-SP) is available with all the normal wear parts included (1 x Diaphragm

(IDMHDV-130-114-9539), 1 x Nitrile O-Ring (IDMHDV-130-VLV-116B), 1 x FFKM O-Ring

(IDMHDV-130-VLV-016K), 1x Nitrile O-Ring (IDMHDV-130-VLV-007B) and 1 x Plastic

Luer adapter (IDMHDV-130-V300-UV)). Contact Intertronics to order.

1) Flush the valve thoroughly with an appropriate solvent before disassembly.

(Refer to SDS of fluid for suggested solvent).

2) Remove fluid pressure from the system, and then remove all fluid delivery

fittings, hoses, etc. from the valve. Remove operating air pressure from the

valve.

3) Using a spanner, unthread and remove the luer adapter (10) from the fluid body

(1).

4) Using a 3/32” Allen® key, evenly remove the four machine screws (11) from

the cylinder cap (7).

5) Pull the fluid body (1) apart from the upper assembly and remove the 016 FFKM

O-ring (14).

Set Up

To actuate the air section the IDMHDV-130 requires a dispensing controller, such as

the FISDC100 Automatic liquid dispenser. Contact Intertronics for more information.

The valve should be operated with clean, dry air between 50-80psi. One #10-32

threaded air port is located on the air section of the valve to open the valve when air

is applied. A spring is then used to return the valve to the closed position. A quick

connect air fitting is typically supplied with the IDMHDV-130 to fit 5/32” tubing.

Fluid is supplied to the IDMHDV-130 through the 1/8” NPT port located on the acetal

fluid section of the valve.

6

3

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Theory of Operation

The IDMHDV-130 is an all-plastic handheld dispense valve that uses a unique rigid

diaphragm design to act as a front closing valve to accurately dispense small dots and

fine beads. This valve is designed for handheld applications, to take the place of

traditional syringe dispensing or other manually applied fluids. The all-plastic

construction allows adhesives such as cyanoacrylates and anaerobic materials to be

dispensed through the valve along with a variety of other low to medium viscosity

fluids. Applications can include potting and the dispensing of dots and beads.

The IDMHDV-130 body comprises:

1) Air section (aluminium top portion)

2) Fluid section (acetal body with PTFE diaphragm and polyethylene luer

adapter)

Air Section

The air section is an aluminium body with a simple piston/cylinder combination using

air to open the valve and a spring to close. A stroke adjustment bolt in the upper air

body controls how far the piston and needle assembly can retract, thus regulating the

rate of fluid flow along with a lock nut to hold it in place.

Note: Upon delivery, the stroke adjustment bolt is fully closed.

Fluid Section

The fluid section is made up of acetal with a rigid PTFE diaphragm connected to the

air piston. Fluid dispenses as the point of the diaphragm is lifted out of the fluid section

orifice then stops as it moves back into place. The stroke adjustment bolt of the air

cylinder regulates the distance that the diaphragm tip can lift out of the fluid section

orifice thus controlling rate of fluid flow. An M3 female thread is available in the fluid

section to hold a grounding wire in place to remove any ESD charge.

Wetted parts on the IDMHDV-130 include:

•Acetal (ESD Safe)

•PTFE

•Polyethylene

Safety

Due to material contents being under pressure, eye protection is recommended for

operators. Refer to the SDS for the material being dispensed for other precautions.

6) Remove the cylinder cap (7) and stroke adjustment assembly (8, 9) from the

air cylinder (6) to remove the spring (12).

7) Insert a flat head screwdriver into the slot of the piston (5) to hold it in place

then spin the diaphragm (2) counter-clockwise to unthread it from the piston.

8) Slide the cylinder end cap (4) off the piston.

9) Push the threaded end of the piston (5) into the air cylinder (6) to slide it

through the back and remove.

10) Remove the 007 Nitrile O-ring (15) from the air cylinder and the 116 Nitrile

O-ring (13) from the piston (5).

11) Clean all of the wetted parts thoroughly with an appropriate solvent.

Replace components with spares provided in the spare parts kit, if necessary.

General Assembly

All O-rings must be lubricated with a small amount of silicone grease.

1) Thread the lock nut (9) onto the stroke adjustment (8) with knurled side first.

2) Thread the stroke adjustment (8) into the cylinder cap (7).

3) Mount the 116 Nitrile O-ring (13) onto the piston (5).

4) Apply a small amount of silicone grease to the inside of the air cylinder (6)

then drop in the piston (5).

5) Mount the 007 Nitrile O-ring onto the end of the piston (5) and slide it down

into the groove of the air cylinder (6).

6) Place the cylinder end cap (4) onto the piston (5), lip side first and slide up

to the air cylinder (6)

7) Using a square head screwdriver, hold the piston (5) in place and thread the

diaphragm (2) on tightly.

8) If the diaphragm (2) does not square up with the air cylinder (6) use the

square head screwdriver to turn the piston until it is aligned.

9) Place the 016 FFKM O-ring (14) into the groove of the fluid body (1).

10) Place the air cap & diaphragm assembly on top of the fluid body (1) and

assemble with four machine screws (11) using a 3/32” Allen key to tighten

them down evenly.

11) Thread the plastic luer adapter (4) into the bottom of the fluid section (3)

and tighten using a spanner.

Note: Be sure not to over-tighten the luer adapter (4).

2

7

IDMHDV-130 Handheld Diaphragm Valve User Manual

IDMHDV-130 Handheld Diaphragm Valve User Manual

Troubleshooting

Problem

Possible Cause

Corrective Action

Valve does

not cycle

•Air pressure to air section is

too low

•Stroke adjustment bolt is

bottomed out

•Material has cured in the

valve

•Valve was assembled w/o

lubricating the O-ring seals

•Increase air pressure to

between 50-80 psi

•Back out stroke adjustment bolt

by turning it counter-clockwise

•Disassemble and clean valve

•Disassemble valve, lubricate

seals and re-assemble

Material

leaks from

valve tip

•Diaphragm is worn

•Air bubble trapped in fluid

body or in dispense needle

•Replace diaphragm

•Flip valve upside down and cycle

until air bubbles are removed

Valve leaks

from mid-

section

•Diaphragm is worn or

damaged

•O-Ring is worn or damaged

•Replace diaphragm

•Replace O-ring

Valve does

not

dispense

anything

•Fluid pressure is too low

•Material has cured in fluid

section

•Stroke adjustment bolt is set

too low

•Increase fluid pressure

•Disassemble and clean valve

•Back out stroke adjustment bolt

by turning it counter-clockwise

Air bubbles

in fluid

•Valve not properly purged

•Problem with fluid delivery

system

•Stroke adjustment set back

too far

•Flip valve upside down and cycle

until air bubbles are removed

•Diagnose and repair

•Turn down stroke adjustment

Dispense

rate too

fast

•Fluid pressure set too high

•Stroke adjust set too high

•Dispense tip gauge too large

•Decrease fluid pressure

•Turn stroke adjust clockwise

•Replace dispense tip with

smaller size

Dispense

rate too

slow

•Fluid pressure set too low

•Stroke adjust set too low

•Dispense tip gauge too small

•Increase fluid pressure

•Turn stroke adjust counter-

clockwise

•Replace dispense tip with larger

size

Table of Contents

Theory of Operation ..................................................................... 2

Air Section............................................................................... 2

Fluid Section............................................................................ 2

Safety......................................................................................... 2

Set Up ........................................................................................ 3

Diagram #IDMHDV-130 ............................................................. 4-5

Operation.................................................................................... 6

Routine Cleaning and Disassembly ................................................. 6

General Assembly ........................................................................ 7

Troubleshooting ........................................................................... 8

Note: Throughout this manual, numbers denoted in brackets refer to the

corresponding parts labelled in Diagram #IDMHDV-130

8

1

For assistance and enquiries, please contact one of our

technical specialists:

01865 842842

sales@intertronics.co.uk

INTERTRONICS

12A Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

England

OX5 1JD

www.intertronics.co.uk

Version 1.1

February 2024

IDMHDV-130

Handheld Diaphragm Valve

User Manual

www.intertronics.co.uk/idmhdv-130

17 Station Field Industrial Estate

Banbury Road, Kidlington

Oxfordshire, England OX5 1JD

t 01865 842842

e sales@intertronics.co.uk

www.intertronics.co.uk

Table of contents

Popular Control Unit manuals by other brands

Eaton

Eaton PKE-COM-RTU Instruction leaflet

Nexta Tech

Nexta Tech PLANO-V5/RGBW quick start guide

RF-Star

RF-Star RF-SM-1312B1 Hardware data sheet

Pepperl+Fuchs

Pepperl+Fuchs KFD2-DWB-Ex1.D instruction manual

Siemens

Siemens SINUMERIK 840Di sl operating manual

StarTech.com

StarTech.com BOX4MODULE quick start guide

Val Controls

Val Controls I 24-AF Series Replacement guide

Velleman

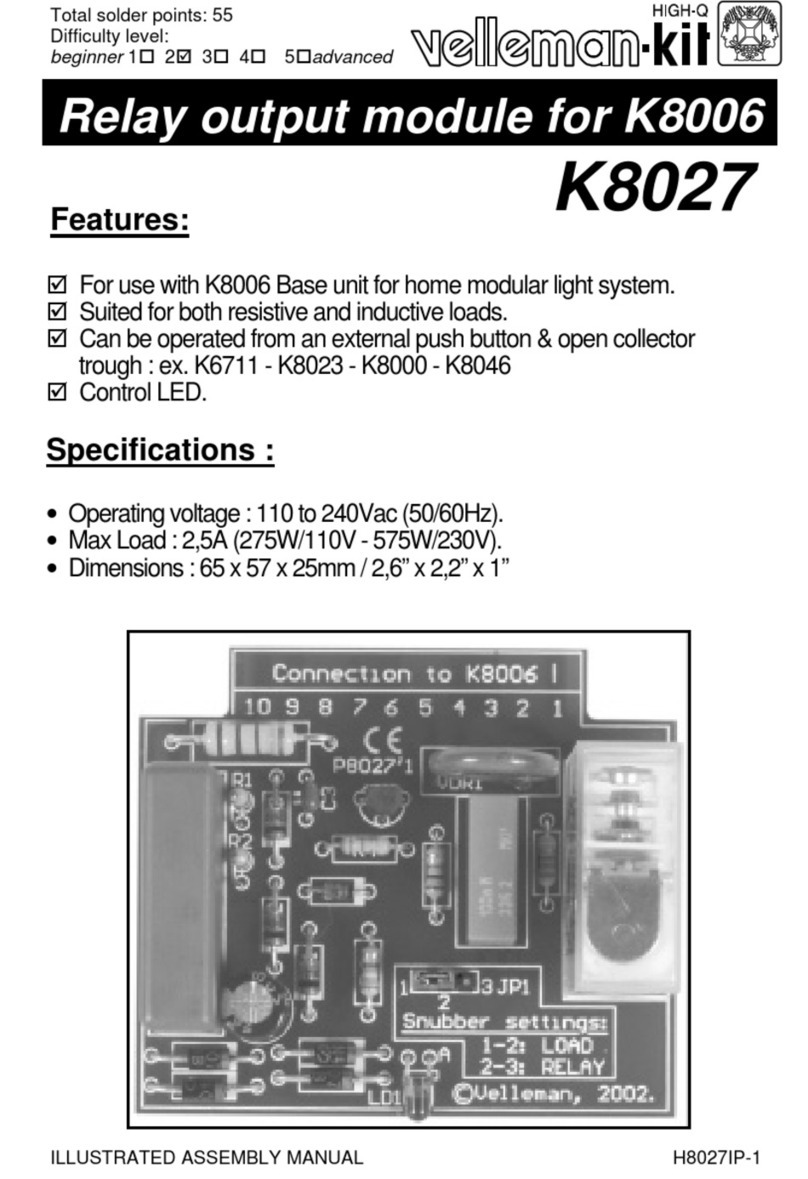

Velleman K8027 Assembly manual

Metso

Metso Jamesbury Wafer-Sphere Series Installation maintenance and operating instructions

Grunbeck

Grunbeck DE200 Operation manual

Graff

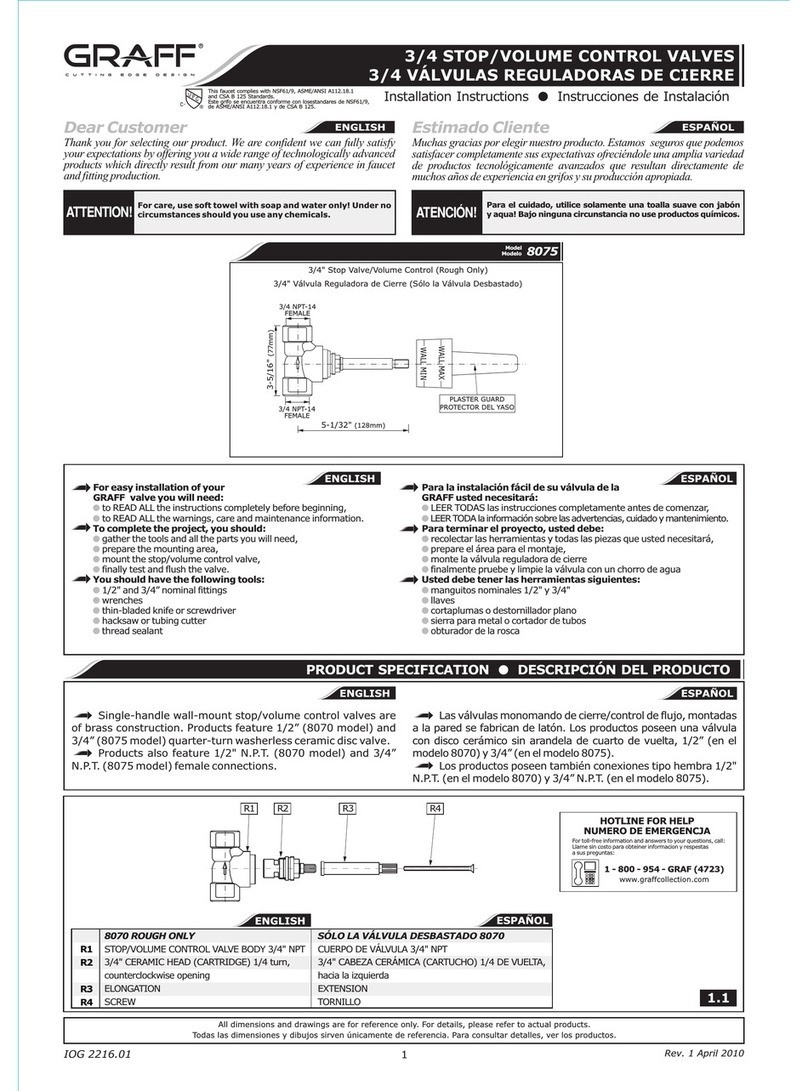

Graff 8075 installation instructions

Interlogix

Interlogix UltraSync UM-W7 Installation sheet