Vitasalus Inline Chlorinator Product manual

Installation and Maintenance Guide

Inline ChlorinatorTM

Vitasalus, Inc. 1-877-284-5042 ∙ 248-585-8815

1409-H Allen Drive. Troy, Michigan 48083 USA

www.vitasalus.com

Vitasalus™ is a trademark owned by Vitasalus, Inc.

Vitasalus Technical Support

1-877-284-5042

- 2 -

Revision 030613

Table of Contents

System Capabilities

Effective Operating Conditions.............................................................................3

Performance/Specifications Data..........................................................................3

Equipment Installation

Included Installation Components........................................................................4

General Warning and Safety Precautions ..............................................................5

Installing Inline Chlorinator .................................................................................6

Filling Inline Chlorinator ......................................................................................7

Setting Inline Chlorinator.....................................................................................7

Maintenance

Refilling Procedure..............................................................................................8

Replacement Parts Description.............................................................................9

Manufacturers Guarantee, Warranty and Return Policy

Warranty Policy and Limitations......................................................................... 10

Return Policy.................................................................................................... 10

Re-Ordering, Replacement Parts & Accessories

Company Information ....................................................................................... 11

Troubleshooting................................................................................................. 12

Blending Water Bypass Option........................................................................... 13

Example Installation Diagrams

Well Water System Package #1 ......................................................................... 14

Well Water System Package #3 ......................................................................... 14

Well Water System Package #4 ......................................................................... 15

Well Water System with Retention Tank ............................................................. 15

Vitasalus Technical Support

1-877-284-5042

- 3 -

Revision 030613

System Capabilities

The Inline Chlorinator™ is a chlorine feeder system designed for ease of use, to help disinfect and/or control iron,

iron bacteria, sulfur, hydrogen sulfide, and rotten-egg odor, within well and other source water. As the source

water passes through the Inline Chlorinator, the chlorine pellets are dissolved based on the simple pre-set feed

rate, allowing for disinfection, oxidization and precipitation to take place.

The Inline Chlorinator is primarily used in combination with our other water treatment systems and is rarely used

as a standalone system. Below is a list of some of the Vitasalus water treatment systems the Inline Chlorinator is

most popularly used with (all not listed): For examples, go to pages 14 & 15.

Well Water Packages (#1, #2, #3, #4)

Lake Water System Packages (#2 and #3)

Retention Tank

Note: The Inline Chlorinator must be used with a *Retention Tank or Inline Ultraviolet (UV) System for the

treatment of bacteria, ie. E. Coli, Fecal Coliform, etc., this does not apply for iron bacteria in most cases.

*The purpose of the retention tank or contact tank is to provide ample amount of contact time so the chlorine can

disinfect properly.

If you feel your application may require additional treatment or equipment, please contact Vitasalus

Technical Support for more information, 877-284-5042

Vitasalus Technical Support

1-877-284-5042

- 4 -

Revision 030613

Congratulations on your purchase of the Inline ChlorinatorTM Water Treatment and Disinfection System, an

effective easy to use chorine feeder system available through Vitasalus, Inc. The Inline ChlorinatorTM System is

capable of oxidizing iron, manganese, sulfur/ hydrogen sulfide (Rotten-egg odor) and disinfecting against

bacteria* as well as iron and sulfur reducing bacteria.

The Inline Chlorinator often compliments many water treatment systems exclusively through Vitasalus, Inc

including the MetalMasterTM, Lake Water Systems, Well Water Systems and Retention Tanks

Included Installation Components

(1) Complete Inline Chlorinator with Black Lid

(2) 1.5” PVC Tube Adapters

(2) 1” PVC Tube Adapters

(2) Black Tube Adapter Gaskets

(2) Adapter Nuts

(1) Blue Wrench

(1) 2.2 Bag of Chlorine

Vitasalus Technical Support

1-877-284-5042

- 5 -

Revision 030613

Equipment Installation

General Warning and Safety Precautions

Unit must be installed after pressure tank

Install PVC check valve after pressure tank and before feeder inlet.

It is recommend installing a shut off and draining valve as illustrated below for ease of servicing chemical feeder

DANGER: DO NOT MIX DIFFERENT TYPES OR BRANDS OF CHLORINE AN EXPLOSION CAN OCCUR!

USE CAUTION WHEN HANDLING CHLORINE:

Chlorine can bleach clothes and may burn eyes and skin. See manufacturer details for proper handling.

REMOVE CHEMICAL FROM "FEEDER" WHEN NOT BEING USED

Please check the inside center tube (image 1) is screwed in tightly to the base of the chlorinator. It

may become loose in shipping, resulting in chlorine to feed into the water supply in higher doses

Image 1

Vitasalus Technical Support

1-877-284-5042

- 6 -

Revision 030613

Equipment Installation

Installing Inline Chlorinator

1. Insert the black tube adapter gasket to the inlet/outlet of the Inline Chlorinator (image 1)

2. Glue 1” PVC tube adapter fitting into the

1.5” tube adapter fitting (image 2)

3. Thread the PVC tube adapter nut to the chlorinator, hand tighten only, repeat on outlet side (image 3-4)

Black Tube Adapter Gasket

Image 1

Image 2

Image 3

Image 4

Vitasalus Technical Support

1-877-284-5042

- 7 -

Revision 030613

Equipment Installation

Filling Inline Chlorinator

Fill the Inline Chlorinator with the 2.2lb of chlorine pellets (provided with purchase) around the center stem.

Note: Do not fill the center tube with pellets

DANGER: DO NOT MIX DIFFERENT TYPES OR BRANDS OF CHLORINE AN EXPLOSION CAN OCCUR!

Setting Inline Chlorinator

For most applications, the outside dial should be set to the first bold notch,

unless otherwise specified from a Vitasalus technician. (see image 5) Also, if the

user wants to add even more control over dosing, see page 13 of this

document.

Image 5

Set dial to first bold notch

Vitasalus Technical Support

1-877-284-5042

- 8 -

Revision 030613

Maintenance

Refilling Procedure

1. Shut off water supply

2. Open drain valve after feeder to relieve line pressure.

3. Unscrew top with included wrench and remove center tube to drain unit. To clean the removed tube, soak

in a mixture of Muriatic Acid. One part Muriatic Acid to 5 parts water. Always pour the acid into the water.

ADHERE TO THE WARNINGS FOR HANDLING AND USE OF MURIATIC ACID. Tube can also be cleaned by

soaking in white vinegar. If tube requires additional cleaning, soak in vinegar over-night or longer.

4. Unit Housing needs cleaning when center hole has built-up. Unscrew unions, remove housing and soak in

same mixture of Muriatic Acid as tube until clean. Be sure flow arrow is in the same direction when

reinstalling housing.

5. Make sure unit is completely “bone-dry” and there are no residual used chlorine pellets before adding new

pellets

6. Fill with chlorine pellets (2.2lbs)

7. Thread the top back onto the chlorinator and use wrench to secure and close drain valve

8. Turn on water supply

Vitasalus Technical Support

1-877-284-5042

- 9 -

Revision 030613

Maintenance

Replacement Parts Description

Part# Description

1. Cover Cap

2. Cap Screw

3. Lid

4. Spacer

5. Inner Lid

6. Lid O-Ring

7. Lock Clip

8. R.O.F O-Ring

9. Rate of Feed Valve

10. Flow Tube

11. Union Nut (2)

12. 1.5” Socket Adaptor (2)

13. Union O-Ring (2)

14. 1” Socket Fitting (2)

15. Lid Wrench

Vitasalus Technical Support

1-877-284-5042

- 10 -

Revision 030613

Manufacturers Guarantee, Warranty and Return Policy

Warranty Policy and Limitations:

All Water Filtration products are warranted to be free from defects in materials and workmanship for a period of

one (1) year. There are no forms or warranty cards necessary from our customers as warranty registration is

automatic and begins on the day our customers receive their product.

We cannot, and will not, be responsible for a recommended solution that falls short resulting from lack of

information/disclosure by the customer. Our representatives base all product recommendations on information

provided by our customers; if other conditions (i.e. water, installation space, power, water pressure, etc.) exist

which were not previously disclosed, then additional/other products may be required to make the overall solution

successful. However, as always, we are committed to positively working with the customer to help remedy any

troubled solution by providing the customer with the most effective and affordable options available.

Under no circumstances will Vitasalus/Equinox Products financially cover, or be responsible for, any service, 100%

satisfaction guarantee, or warranties, that have resulted from improper application, poor handling, neglectful

damage, set-up, installation, start-up procedure, and/or lack of thorough follow through of installation procedures

found on or with the unit, and in any service guides, product manuals, and/or related website pages.

Return Policy:

For the return of any product you must first call to get a Return Merchandise Authorization (RMA) number. This

RMA number must be written on the outside of the shipping box, or the receiving department will refuse the

shipment. The RMA number is only valid for 30 days.

For returns that do not qualify for our 100% satisfaction guarantee due to improper installation, improper use,

neglectful damage, unused product, and/or problems that are not due to performance issues, a restocking

fee/charge of 15% will be assessed within 30 days, 30% within 60 days, and no refund/credit after 60 days unless

stated otherwise for water filtration units, otherwise, NO EXCEPTIONS. After a RMA has been issued by a

Vitasalus, Inc. Customer Service Representative, product must be returned freight pre-paid, in original packaging.

Vitasalus Technical Support

1-877-284-5042

- 11 -

Revision 030613

Re-Ordering, Replacement Parts & Accessories

Company Information

Vitasalus, Inc.

1409-H Allen Drive,

Troy, Michigan 48083 USA

(Toll-Free) 1-877-284-5042

(Int’l) 248-585-8815

(Fax) 248-583-6950

(Email) [email protected]

www.vitasalus.com

Vitasalus Technical Support

1-877-284-5042

- 12 -

Revision 030613

Troubleshooting

CHEMICAL FEEDER –TROUBLE SHOOTER

SYMPTOMS

REMEDIES

White Paste/Glue Build Up

1. Chlorinator service requires dry basin for adding pellets and center

tube replacement/cleaning

2. Never expose wet chlorine to air

3. Do not remove cap during operation or until pellets are gone

4. Air entering unit during operation

5. Isolate chlorinator with shut off valves and drain port

NOTE: To isolate the Inline Feeder for maintenance, install a shut off valve

before and after the inline feeder. Install a drain-port after the inline feeder

and before the second shut off valve to allow the unit to drain properly

before adding pellets. This is not necessary but strongly recommended.

Lid is hard or impossible to remove

(No.4).

1. Line pressure has not been relieved

2. Unit was not previously cleaned when re-filled and inside tube is

plugged. (No.8). The unit is under pressure. Be extremely careful when

removing a lid under pressure. It can blow off with extreme force

Low pressure or low water flow after

carbon tank

1. Carbon fouled and needs back washing or replaced

Tube appears warped or melted.

1. Do not mix different types or brands of chlorine. Make sure no oil or

petroleum products mix with the chlorine

Chlorine smell after carbon and/or

Unit appears to be using chemical

fast.

1. No carbon or carbon tank is internally bypassing or carbon fouled with

oxidized iron

2. Pressure tank is water logged or pressure is low or high in the air bag.

3. Improper chemical feeder adjustment or adjustment holes are plugged

and needs cleaning. (Tube No.*)

4. Improper pressure switch adjustments. There should be a minimum

differential pressure of 20PSI

5. the chart for chlorine output is for a 42 gal. pressure tank. If using a

smaller tank such as a 20 gal. tank, cut the chlorine output by one half.

The chemical feeder will output the same amount of chemical for each

pump cycle and a smaller tank is delivering less water on each pump

cycle increasing the chemical concentration.

High Odor and/or Unit appears not to

be dispensing the proper amount of

chlorine.

1. Unit needs chlorine or it is over filled. (Max. ¾ full

2. Wrong chlorine. Only calcium hypochlorite tablets will dispense high

amounts of chlorine. Stabilized chlorine is not approved by the FDA for

potable water.

3. Pressure was released from the unit and fluid was not removed from the

unit before re-pressurizing the unit.

4. Carbon tank internally bypassing.

5. Pellets placed in center tube instead of basin

Odor only in hot water

1. Magnesium anode rod in hot water tank. Remove the rod. Clean,

replace and/or remove

Vitasalus Technical Support

1-877-284-5042

- 13 -

Revision 030613

Troubleshooting

Inline Chlorinator – Blending Water Option

In some applications where the chlorine feed needs to be adjusted more accurately, in addition to the control dial, a method

commonly used is a blending technique that allows the user to further adjust the amount of chlorine being fed into the water

supply. The diagram below illustrates how the plumbing would be installed to achieve this.

When the installation done correctly, the user can open or close Shut Off Valve #1 and Shut Off Valve #2 to certain

percentages to maintain full pressure but control how much or how little chlorine they want to go into the feeder.

This is not required for all installations but is recommended to install just in case the blending water bypass needs to be

utilize. Also, you get the advantage of bypassing the unit completely in the event servicing needs to be completed with the

chlorinator off line.

Shut Off

Valve #1

Check Valve

(Backflow Preventer) Drain Valve

BFP

From Pump &

Pressure Tank

Inline Chlorinator

Shut Off

Valve #2

Outgoing

FLOW

DIRECTION

Open Valve #1 to 50%

Open Valve #2 to 50% Open Valve #1 to 70%

Open Valve #2 to 30% Open Valve #1 to 80%

Open Valve #2 to 20%

Examples:

Open Valve #1 to 20%

Open Valve #2 to 80%

Vitasalus Technical Support

1-877-284-5042

- 14 -

Revision 030613

Example Installation Diagrams

Vitasalus Technical Support

1-877-284-5042

- 15 -

Revision 030613

Example Installation Diagrams

Vitasalus™ is a trademark owned by Vitasalus, Inc.

5 Micron

Pre-Filter

MetalMaster

Drain Line

To House

20" Carbon Filter

Shut Off

Valve

BFP

Shut Off

Valve

From Pump &

Pressure Tank

Inline Chlorinator

Check Valve Drain Valve

Table of contents

Popular Lighting Equipment manuals by other brands

HAMPTON BAY

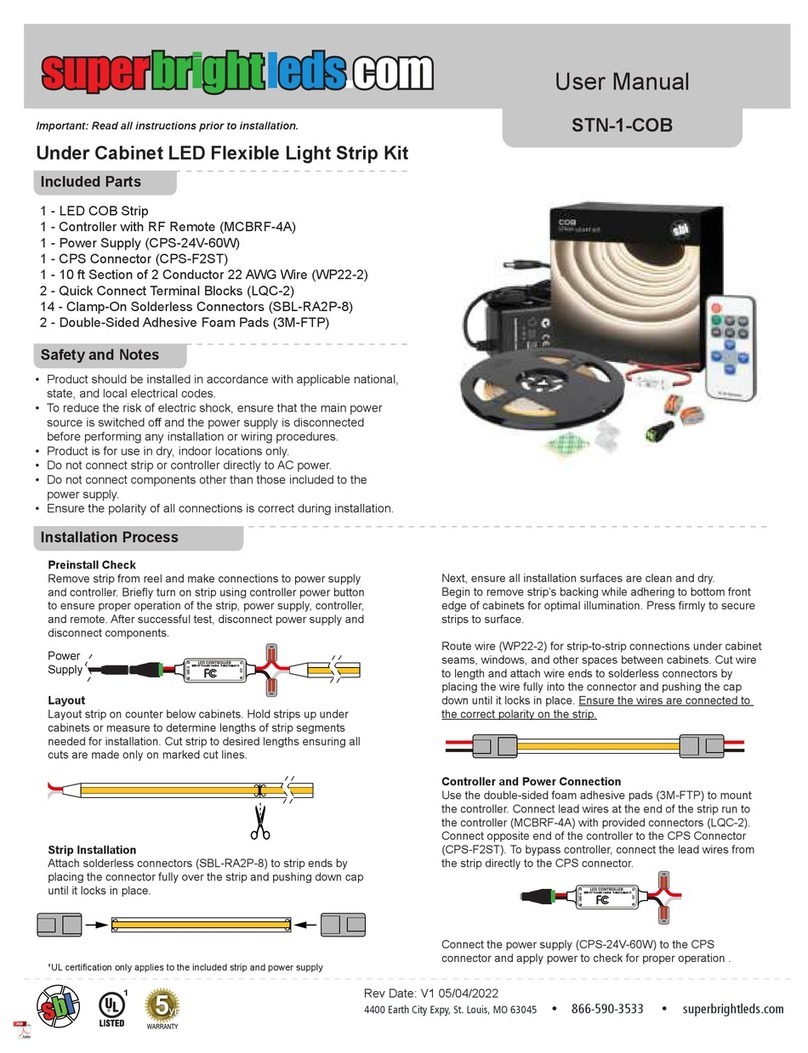

HAMPTON BAY Home Depot instruction manual

HAMPTON BAY

HAMPTON BAY Towne Heights 335-975 instruction manual

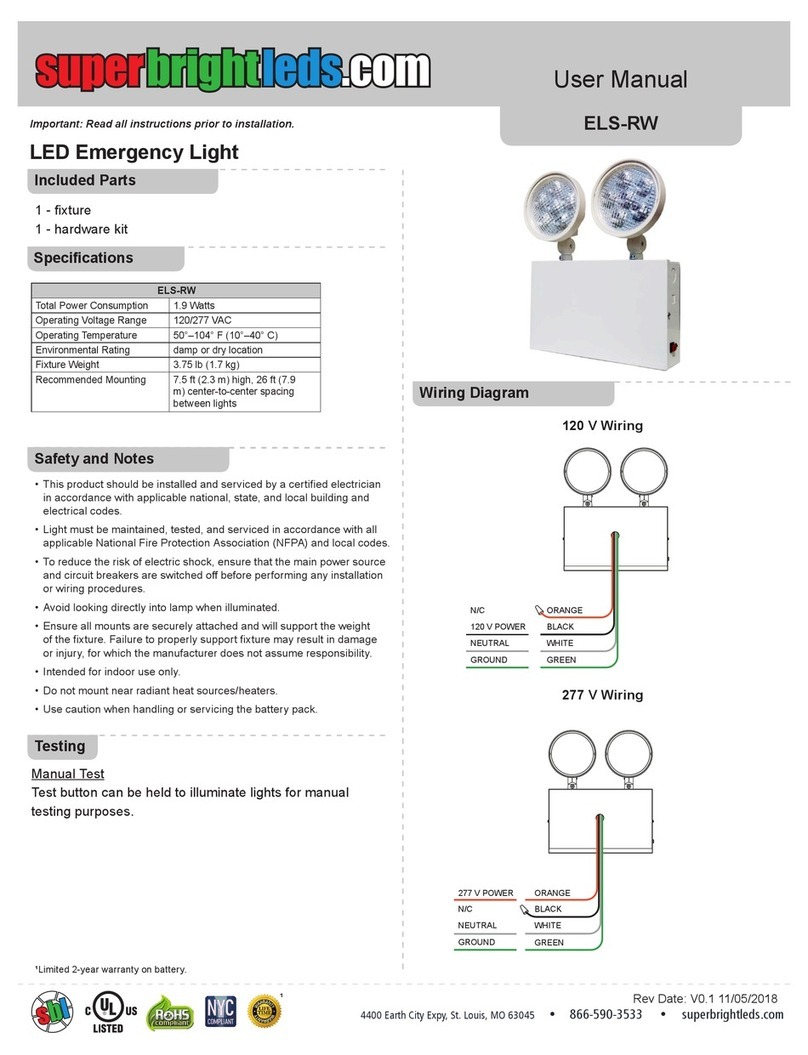

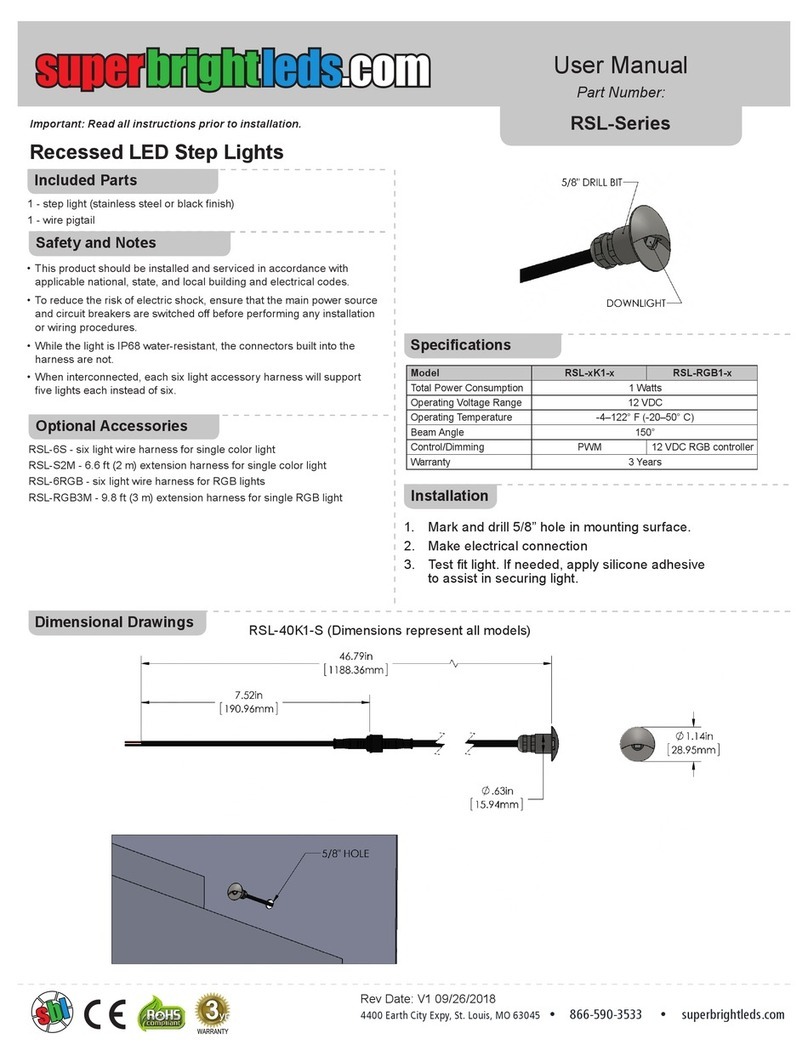

superbrightleds

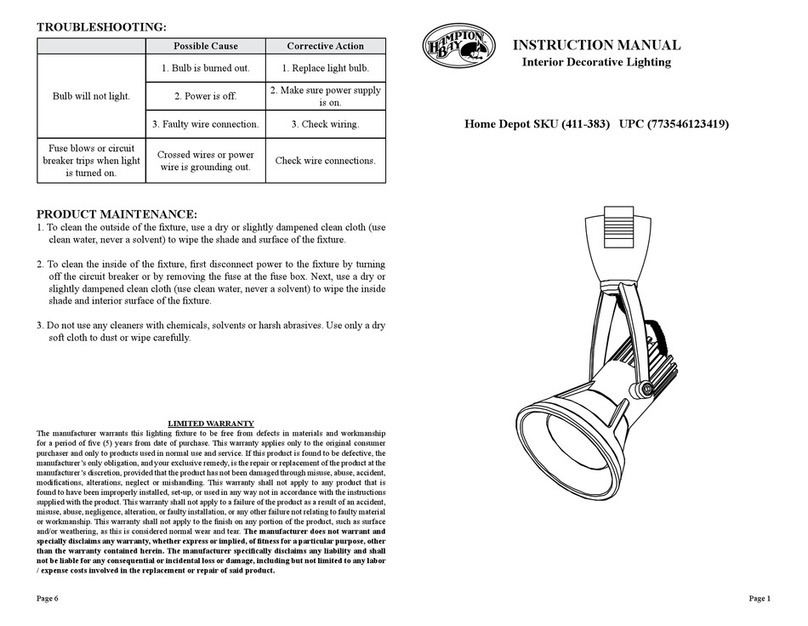

superbrightleds ELS-RW user manual

Heath Zenith

Heath Zenith LED Lighted Push Button with Keyfinder Light... owner's manual

superbrightleds

superbrightleds RSL Series user manual

ecoStage

ecoStage ED MATRIX BEAM 14 user manual