VITO 60 User manual

Seite 1

Contents

1. Product................................................................................................2

1.1 Product descripon.............................................................................2

1.2 Delivery contents................................................................................2

2. Legal informaon.................................................................................2

3. Preface.................................................................................................3

4. General notes.......................................................................................3

5. Safety informaon / symbol explanaon..............................................3

6. VITO® 60 / VITO® 90 usage...................................................................4

6.1 Designated use....................................................................................4

6.2 Non designated use.............................................................................4

7. Preparaon before use.........................................................................4

7.1 Safety guidelines.................................................................................4

7.2 Storage of VITO®.................................................................................4

7.3 Filtraon duraon...............................................................................4

7.4 Checking the factory sengs..............................................................5

7.5 Programming the cycle me...............................................................5

7.6 Acvate / deacvate the beep and set sound level (VITO® 90 only)..5

8. Filtraon process..................................................................................5

8.1 Requirements......................................................................................5

8.2 Operaon notes...................................................................................5

8.3 Starng the ltraon process..............................................................6

8.4 Finishing the ltraon process prematurely........................................6

9. Safety funcons....................................................................................6

9.1 Tilt and vibraon protecon (VITO® 90 only)......................................6

9.2 Acousc signal (VITO® 90 only)...........................................................6

9.3 Temperature control............................................................................6

9.4 Memory...............................................................................................6

10. Care and servicing...............................................................................7

10.1 Notes.................................................................................................7

10.2 Cleaning preparaon.........................................................................7

10.3 Manual cleaning................................................................................7

10.4 Machine cleaning..............................................................................7

11. Polyester lter change.........................................................................7

12. Accessories.........................................................................................8

13. Waste disposal....................................................................................9

13.1 Packaging disposal.............................................................................9

13.2 Filter disposal.....................................................................................9

13.3 Device disposal..................................................................................9

13.4 WEEE (Waste Electrical and Electronic Equipment) Statement.........9

14. Storage recommendaons for polyester lters....................................9

15. Troubleshoong................................................................................10

16. Technical data...................................................................................11

17. Declaraon of conformity.................................................................12

1. Product

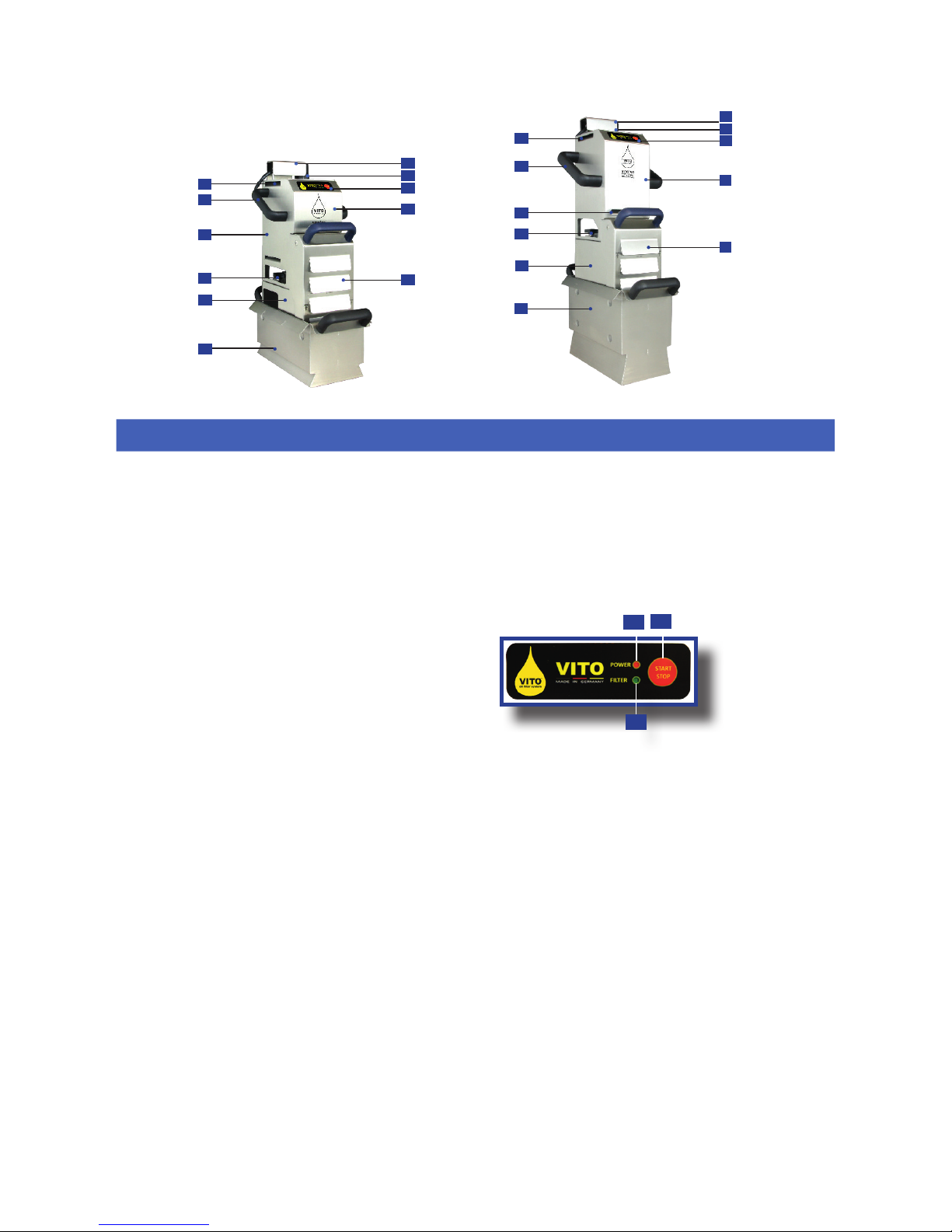

1.1 Product descripon 1.2 Delivery contents

1. Cable protecon

2. Power cord

3. Touch panel

4. Electrical unit

5. Filter box Front vent

6. Drip pan

7. Pump-lter unit

8. Star handles (on both sides )

9. Vent slots

10. Handles

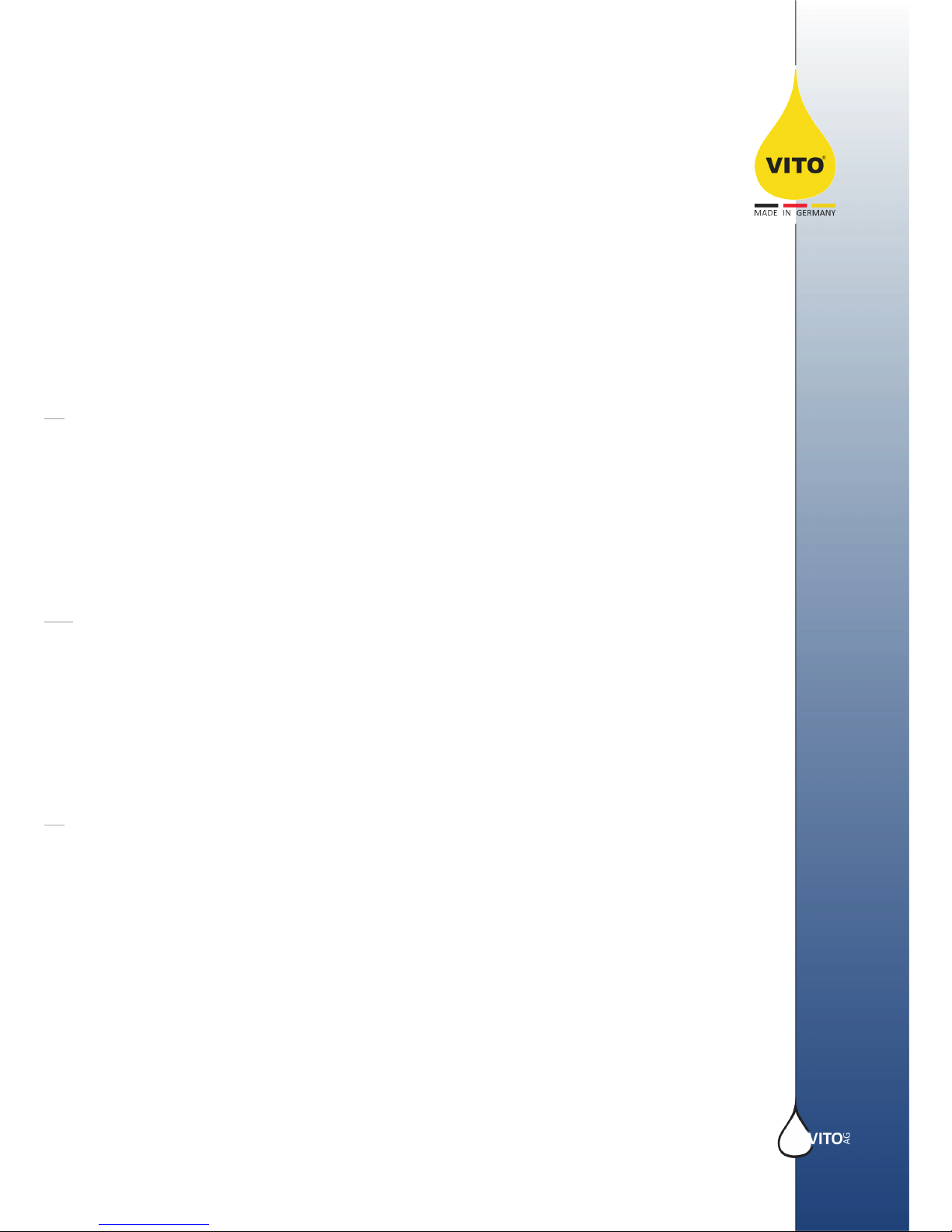

1a Start / Stop buon

2a. Power indicator (red LED)

3a. Filtraon indicator (green LED)

• VITO® Filtraon system system

• User manual

• Warranty card

• Quick guide

• Drip pan

2. Legal informaon

VITO AG

Eltastrasse 6

78532 Tulingen (Germany)

Phone: +49 (0) 7461 / 1508050

Fax: +49 (0) 7461 / 1508051

inf[email protected]om

www.vito-industrail.com

CEO:

Andreas Schmidt (MBA, Dipl.-Wirt.Ing)

Headqarter: Tulingen, Germany

Registry court: Stugart HRB 760227

In cooperaon with:

University Albstadt-Sigmaringen (Germany)

- Industrial engineering with business studies -

Jakobstrasse 1

72458 Albstadt (Germany)

Copyright © VITO AG

All rights reserved

This document is protected by copyright of VITO AG.

Any reproducon, in part or as a whole, without the

wrien permission of VITO AG is prohibited.

VITO® 60 VITO®90

Seite 2

6

8

8

5

5

9

9

7

7

1

1

2

2

3

4

4

10

10

9

9

6

3

3a

1a

2a

Seite 3

3. Preface

Dear VITO® customer,

thank you for choosing this product by VITO AG.

Please read the manual carefully to familiarize yourself with the handling of your VITO® Fil-

traon system for coolant lubricants, oil and watery soluons to ensure proper use. Your local

dealer and the customer service are available to answer your quesons and provide support.

We are grateful for comments and suggesons concerning the VITO® Filtraon system for

coolant lubricants, oil and watery soluons and / or the manual. (Please nd contact infor-

maon contained in this manual.)We hope that you enjoy your VITO® Filtraon system for

coolant lubricants, oil and watery soluons for a long me and increase the eciency in your

establishment. Wit h VITO® you own a high-quality lubricants, oil and watery soluons lter

system from which you can expect a long life and ecient support for your work.

4. General notes

These operaon instrucons contain important informaon about the handling of the VITO®

Filtraon system for coolant lubricants ,oil and watery soluons. Read this informaon

carefully before using your VITO®. Keep this manual available for more informaon.

VITO® is an coolant lubricants ,oils and watery soluons ltraon system, designed for the

cleaning of coolant lubricants ,oil / watery soluons. With VITO®, the coolant lubricants ,oils

and watery soluons can be cleaned directly in the tank. Filtering with VITO® prolongs the

performance of your industrial uids.

The VITO® polyester lter can be used several mes before changing. Once the coolant

lubricant ,oil and watery soluon stops owing through the front vents, replacing the lter.

Used lters should be disposed according to local regulaons.

5. Safety informaon / symbol explanaon

Wrong treatment of the VITO® can lead to dangers and injuries. The following should be

observed. Possible dangers are marked with these signs:

Warning

Danger of injury if this is not

observed

Risk of electric shock

by incorrect use or case

opening

Danger of slipping

if coolant lubricants oil and watery

soluons is spilled to the oor

Cauon

Important security p

Cauon

Hand protechon must be worn

Cauon

Safety goggles must be

worn

Cauon

foot protecon must be worn

Cauon

Protecve clothing must

be worn

Operaon instrucon

Informaon about the handling of

VITO® Filtraon system

6. VITO® 60 / VITO® 90 usage

6.1 Designated use

• VITO® is designed for cleaning and venlaon of industrial basins.

• Follow the safety instrucons! Filtraon is only possible for the coolant lubricants ,oil and watery

soluons.

• VITO® should only be used by suitably trained sta!

• VITO® Filtraon system for coolant lubricants ,oil and watery soluons designed for intermient

duty

6.2 Non designated use

The nonobservance of the contents described in the manual can lead to damage or malfuncon of VITO®

• Do NOT use or store VITO® outside! It will be damaged by rain or humidity!

• VITO® is NOT designed for connuous duty! Risk of overheang/re hazard!

• Do NOT cover vent slots (VITO® 60 / VITO® 90 ) (9)!

• Do NOT touch the power cord (2) with wet hands!

• Do NOT jam or bend the line cord (2)!

• The use of VITO® is strictly prohibited for children!

• VITO® must NOT be operated on a connecon other than protecon class!

No liability will be accepted for improper use!

7. Preparaon before use

7.1 Safety guidelines

• Don’t plug the VITO® machine when you g et it immediately for the rst me wait unl

VITO® can acclimate

• IN SOME CASES BEFORE START WORKING WITH VITO® YOU NEED TO TURN OFF THE MACHINE.

• Clean VITO® before using it the rst me. (See chapter 10 Care and servicing)

• Make sure that the local voltage is conform to the voltage on the type label of VITO®!

• DO NOT MOVE VITO® WHILE FILTRATION IS IN PROGRESS!

• Do NOT get the power cord in contact with coolant lubricants oil and watery soluons! (2)

• The maximum operang temperature is 175°C/357°F!

• Do NOT run the pump-lter unit (9) outside basins or machine tanks!

• To li or transport VITO® only pick it up using the black handles (10)!

7.2 Storage of VITO®

The handles of the drip pan (6) can be fastened oponally at the short or the long side.

• Place VITO® always into the drip pan (6), aer use or for transport

• Store VITO® only in the drip pan (6)

• Allowed ambient / storage temperature: +10 to +35°C (60° to 95°F)

7.3 Filtraon duraon

The factory sengs for one ltraon cycle of VITO® is:

• VITO® 60: 4,5 min (adjustable)

• VITO® 90: 4,5 min (adjustable)

Upon reaching the maximum number of cycles, VITO® must cool down before using for the next ltraon.

Cool down phases

• up to 2 hours:

VITO® 60 and VITO® 90 (if power cord (8) is pulled out)

• approximately 15 min

VITO® 60 and VITO® 90 (if power cord (8) is plugged in)

If the temperature of VITO® is too high, the overheat protecon will acvate.

(VITO® 90 has addional acousc beep signal)

• Power Indicator (red LED) (2a) “Power” is ashing.

• The ltraon process will stop.

Seite 4

Seite 5

7.4 Checking the factory sengs

Pressing the start/stop buon (1a) will be conrmed by one ash of the Power indicator (red

LED) (2a)

1. Press and hold the start/stop buon (1a)

2. Plug VITO® in.

3. Hold the start/stop buon (1a) for 5 seconds. (VITO® 90 will beep)

4. Programmed cycle me is displayed by ashing of the indicators

5. The red LED (2a) indicates 1 minute per ash

The green LED (3a) indicates 30 seconds per ash

e.g. 4x red = 4 min

1x green = 30 seconds

= duraon of lter cycle: 4min 30sec.

7.5 Programming the cycle me

To re-program the cycle me, start with the steps in 7.4 checking the factory sengs, then:

1. Press start/stop buon (1a) instantly aer cycle length was displayed

2. Press start/stop buon (1a) to increase the cycle me by 30 sec.

(Re-program starts at 0 sec!)

(e.g. press 3x for 1,5min etc.)

3. Once the designated cycle me is set, wait for the green LED (3a) to ash

once ( VITO® 90 beeps).

4. Pull out the power cord (8).

The new cycle me is now saved.

7.6 Acvate / deacvate the beep and set sound level (VITO® 90 only)

To set the sound level of the beep, start with the steps in 7.4 checking the factory sengs,

then:

1. Aer the cycle me is displayed wait for the green LED (3a) to ash (VITO® 90

will beep addionally)

2. Set the beeper status using the start/stop buon (1a)

3. The indicators show the selected status:Red

LED (2a) = beeper o

Green LED (3a) = half volume

Red LED + green LED = full volume (2a) + (3a)

Pull out the power cord (2).

The new sengs are now saved.

8. Filtraon process

8.1 Requirements

VITO® 60 / 90

• Insert polyester bre lter into the pump-lter unit (7) (See chapter 11 Polyester lter

change)

• Latch lter-lid

• Put Electrical unit (6) on pump-lter unit (7)

• Tighten the star handles (8).

8.2 Operaon notes

• IN SOME CASES BEFORE START WORKING WITH VITO® YOU NEED TO TURN OFF THE

MACHINE.

• Filtraon cycle can be stopped at any me by pressing Start/Stop buon (1a).

• Do NOT move VITO® while ltraon is in progress!

• Only use VITO® in a straight posion!

• The Power indicator (red LED) (2a) and Filtraon indicator (green LED) (3a) are lit

during ltraon process.

8.3 Starng the ltraon process

1. Take VITO® out of the drip pan (6)

2. Make sure that the polyester lter is in the pump lter unit (7)

3. Put VITO® into the industrial basin or machine tank .

4. Ensure a secure standing (for holding brackets see chapter 12

Accessories)

5. Check the coolant lubricant oil level or watery soluons level

(The coolant lubricant oil level or watery soluons level must be

between the MIN and MAX marking of the pump-lter unit (7)!)

6. Plug in VITO®:

Power indicator (red LED) (2a) is acve

Cooling fan is running (VITO® 60 / VITO® 90)

7. Press start/stop buon (1a)

8. Filtraon indicator (green LED) (3a) is lit during the ltraon.

8.4 Finish the process prematurely

1. Press start/stop buon (1a)

Filtraon indicator (green LED) (3a) is o

2. Keep power cord (2) VITO® 60 / VITO® 90 plugged in!

3. Li VITO®, let the coolant lubricant, oil or watery soluon ow back in

the industrial basin

4. Place VITO® in the drip pan (4)

9. Safety funcons

9.1 Tilt and vibraon protecon (VITO® 90 only)

If VITO® 90 is lted more than 15°, topples over or vibrates too strong because of bad placement or

mechanical defect, the machine will switch o. Both indicators start ashing and a repeang beep will

be heard.

9.2 Acousc signal (VITO® 90 only)

At the end of each cycle VITO® 90 beeps for 5 seconds. VITO® 90 will also beep if any error occurs.

9.3 Temperature control

If the temperature of the electrics is exceeded, VITO® stops the ltraon.

The power indicator (red LED) (2a) starts to ash and VITO® 90 starts to beep connuous.

VITO® must be taken out of the tank to conrm the error by pressing the start/stop buon (1a)

The power indicator (red LED) (2a) will connue to ash unl VITO® is cooled down.

Leave VITO® 60 & VITO® 90 plugged in. VITO® is operaonal again aer approx. 15 min.

It takes up to 2.5 hours if VITO® is unplugged.

If VITO® takes too long to cool down aer a temperature based shutdown. VITO® 90 will connue to beep

every 40 seconds. Take VITO® to a cool place and plug it back in to allow the cooling fan to work.

Do NOT put VITO® into a cold-storage room! Condensaon can destroy the electrics.

9.4 Memory

VITO® records the operang mes and usage values. These values can be readout using the VITO® Data

Reader.

(see chapter 12 Accessories)

Seite 6

Seite 7

10. Care and servicing

10.1 Notes

• Clean pump-lter unit (7) at every polyester lter change

• Clean VITO® only if cooled down

• Do NOT use abrasives

• Do NOT use wire brushes or similar tools

10.2 Cleaning preparaon

1. Make sure VITO® is cooled down

2. Unfasten star handles (8) on both sides

3. Remove electrical unit (4) from pump-lter unit (7)

4. Open pump-lter unit (7)

5. Dispose polyester, cellulose bre lter

6. Manual or machine cleaning

10.3 Manual cleaning

1. Clean electrical unit (4) only with damp cloth!

2. DON’T put VITO® under running water! This can destroy the

electronics!

3. Clean the pump-lter unit (7) with system cleaner or water.

4. Dry VITO® with a towel.

10.4 Machine cleaning

1.Clean electrical unit (4) only with a damp cloth! Do NOT put the electrical unit (4) into

a dishwasher! This will destroy the electrics

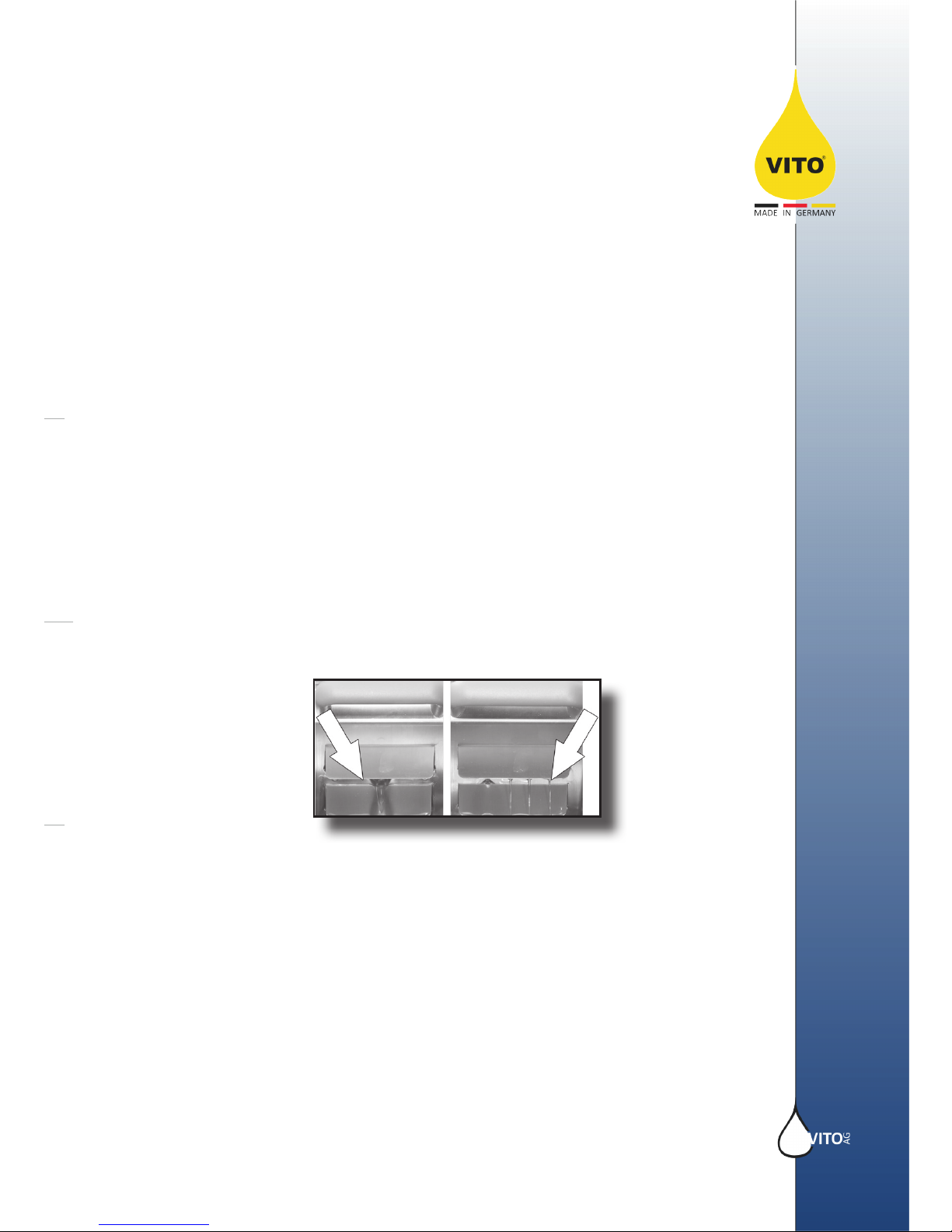

11. Polyester lter change

Change the polyester lter only if necessary. The me of change is based on usage of VITO®

and the

degree of polluon of coolant lubricant, oil or watery soluon.

Pay aenon to the cleaning eciency and the spill of coolant lubricant, oil or watery solu-

on coming out of the pump-lter unit. (9)

Change the polyester bre lter only at a low ltraon performance.

Normal ow Low ow

12. Accessories

Addional accessories for your VITO® are available:

Spare lters for VITO®

bundle size: 1 box (50 pcs.)

lter area: VITO® 60/90: 0.26 m² (2.77 ²)

material: polyester, cellulose bre lter

mesh size: nom.20 µm / e. 5 μm

Holding Brackets

Keep VITO® in secure standing

Customisable for all industrial tank

Reduce vibraon

Clip on Frame

Aach VITO® directly in the tank

Customisable for all industrial tank

Data Reader

Readout the usage informaon of VITO®

Check the use of VITO® according to HACCP

If you need anything else?

Contact us for other soluons. Our customer support will gladly assist you with all quesons.

Do not leave gaps between the lter

and the edges of the pump-lter

(9) unit

Overlap the last fold on both sides

(9) of the pump-lter unit

Seite 8

Seite 9

13. Waste disposal

13.1 Packaging disposal

• The packaging should be recycled

or

• Keep the packaging carefully

13.2 Filter disposal

• Used lters must be disposed in the country-specic way

13.3 Device disposal

If VITO® reaches the end of life it must be disposed accordingly.

This disposal is handled by VITO AG as dened by law.

Send VITO® to:

VITO AG

Eltastrasse 6

78532 Tulingen (Germany)

For further quesons please contact your local dealer or the VITO AG customer support

13.4 WEEE (Waste Electrical and Electronic Equipment) Statement

To protect the global environment and as an environmentalist, VITO AG must remind you that:

Under the

European Union (“EU“) Direcve on Waste Electrical and Electronic Equipment, Direcve

2012/19/EU, which

takes eect on February 14 , 2014, products of “electrical and electronic equipment“ cannot

be discarded as

municipal waste anymore and manufacturers of covered electronic equipment will be obligat-

ed to take back

such products at the end of their useful life. VITO AG will comply with the product take back

requirements at

the end of life of VITO®-branded products that are sold into the EU. You can return these

products to local

collecon points.

14. Storage recommendaons for polyester lters

During storage do not expose the polyester lters to extreme temperature or humidity, for

example near a heat source, air condioning or direct sunlight. Heat and cold have a negave

eect on the properes of the polyester bre lter, especially aer removing or opening the

bag packaging.

The polyester bre lter must not be exposed to frost, as this can cause damage to the micro-

structure of the polyester bre lter, which impairs the funconality of the polyester lter.

• Store dry at 60-65% relave humidity

• Room temperature 24°C ± 5°C (78°F ± 40°F)

• Do NOT put weight on pallets

• Avoid sudden temperature changes

• Store in the cardboard packaging in sealed bag

• Maximum height of the lter stack 185cm (6 )

Under observance of the above condions, the storage period will be

3 years.

15. Troubleshoong

Malfuncon Possible cause Remedial acon

Power indicator (2a)

stays inacve

• Power cord (2) not plugged in

• Connector is defecve

• Plug in VITO®

• Please contact service

VITO® makes loud

noises at

ltraon

• Star handles (8) are too loose

• Rotor scratches on the tank

• Rotor defecve

• Tighten star handles (5)

• Alter posion of VITO® in the

tank

•Please contact service

(1) Power indicator

ashes and/or acousc

indicator is beeping

• overheang protecon is

acvated

• let the device cool down

(1) Power indicator

and ltraon indicator

90 ®ashing (VITO (2)

(beeps addionally

• VITO® is lted more than °15

• Strong vibraons

• defecve turning part

• Check posion of VITO®

• Check posion of VITO®

VITO® cannot be

started

• Electrical unit (6)defecve • Please contact service

Line fuse / Ground

fault circuit interrupter

(GFCI) blowout

• Net protecon or other

electronic components are

blocking

•Rotor defecve

•Circuit overloaded

• Change power outlet, elec.

circuit

• Please contact service

• Change power outlet, elec.

circuit

Low ltraon

performance

• Polyester lter is full

• Pump pipe is blocked

• Motor is defecve

• Change lter

• Empty pump-lter unit (9)

• Please contact service

Coolant lubricant, oil

or watery soluon

splashes at sides / on

top

• Polyester lter blocked

• Too much space between lter

lid and pump lter unit (9)

• Filter is inserted incorrectly

• Change lter / clean unit

• Adjust lter sealing sheet

• Insert lter correctly

• Please contact service

sec. aer 10 LEDs ash

plugging in

• Start/stop buon (3) is

defecve

• Please contact service

Should other issues appear, get in contact with the customer support or your local dealer!

Contact details on page 2 chapter Legal informaon.

Seite 10

Seite 11

16. Technical data

VITO® 60 VITO® 90

Nominal voltage according to

country, see type sign

220 to 240 V ~ %10±

60 to 60Hz

100 to 120 V ~ %10±

60 to 60Hz

220 to 240 V ~ %10±

60 to 60Hz

100 to 120 V ~ %10±

60 to 60Hz

Nominal current

under load

Approx 1,2 A at 230 V

Approx 2,4 A at 115 V

Approx 2,0 A at 230 V

Approx 4,0 A at 115 V

Max.power / Nomial power 300 W / 276 W 500 W / 460 W

Noise level 85db < 85db <

User control (1a) start/stop buon

Temperatures in use Electrical unit (4) up to max. 75°C (167°F)

pump-lter unit (7) up to max. 200°C/392°F (short me)

pump-lter unit (7) up to max. 190°C/356°F (permanent)

(recommended frying temperature max. 175°C/347°F)

Storage temperatures 10°C/60°F to max. 30°C/86°F (At higher temperature less

cycles)

Dimensions (W x H x L)

(without handles) (7)

(with handles) (7)

With drip pan (4)

116 x 400 x 191 mm

4.6 x 15.8 x 7.5 in

195 x 400 x 205 mm

7.7 x 15.8 x 8.1 in

195 x 425 x 325 mm

7.7 x 16.8 x 12.6 in

116 x 485 x 185 mm

4.6 x 19.3 x 7.3 in

210 x 485 x 200 mm

8.3 x 19.3 x 7.8 in

210 x 550 x 324 mm

8.3 x 21.6 x 12.8 in

Weight VITO® : 7,4 kg (16.2 lbs)

Drip pan: 1,3 kg (2 lbs)

VITO® : 9,7 kg (21.4 lbs)

Drip pan: 1,6 kg (3.5 lbs)

Acousc signal no yes

dirt hold capacity 1.4L (3.08 lbs) 2,5 L (5.5 lbs)

Applicaon up to 500L tanks all tanks

Filter ca. folds: 43

Material: polyester

cellulose bre

ca. folds: 43

Material: polyester

cellulose bre

Operaon Intermient operaon

17. Declaraon of conformity

Issued by VITO AG | Eltastrasse 6 78532 Tulingen (Germany) | Phone:+49 (0) 7461 / 1508050

Fax : +49 (0) 7461 / 1508051 | Email: inf[email protected] - www.vitoindustrial.com

for the products VITO®60, VITO®90 EU Patent No. 1326692 U.S. Patent No. US7.052.605.B2

The professional of ltraon equipment is manufactured and tested according to the following

standards:

For the purposes of the EU direcves :

- 2006/42/EG Machinery Direcve

- 2014/30/EU Electromagnec Compability

- 2014/35/EU Low Voltage Direcve

- 2011/65/EU Restricon of use of certain hazardous substances in electrical and electronic equipment

- 2003/10 / EC minimum requirements to protect the safety and health of workers

- 2012/19 EU Waste Electrical and Electronic Equipment

The risks from physical eects of (noise) ,the ltraon devices VITO® 30, VITO® 60, VITO® 90 meet the

relevant community harmonizaon legislaon of the european union.

- EN 61000-6-1: 2007 Immunity

- EN 61000-6-2: 2005 Immunity

- EN 61000-6-3: 2007 + A1: 2011 Emission

- EN 61000-6-4: 2007 + A1: 2011 Emission

with German, European and Internaonal (Non-European) standards

German Standard DIN EN European Standard EN (Internaonal Standard IEC (IEC/CISPR

DIN EN 61000-6-1:2007-10 based on EN 61000-6-1:2007 based on IEC 61000-6-1:2005

DIN EN 61000-6-2:2006-03 based on EN 61000-6-2:2005 based on IEC 61000-6-2:2005

DIN EN 61000-6-3:2011-09 based on EN 61000-6-3:2011-09 based on IEC 61000-6-3:2006 + A1:2010

DIN EN 61000-6-4:2011-09 based on EN 61000-6-4:2011-09 based on IEC 61000-6-4:2006 + A1:2010

DIN EN 61000-3-2:2010-03 based on EN 61000-3-2:2010-03 based on IEC 61000-3-2:2005 + A1:2008 + A2:2009

DIN EN 61000-3-3:2014-03 based on EN 61000-3-3:2014-03 based on IEC 61000-3-2:2005 + A1:2008 + A2:2009

DIN EN 60335-1:2014-11 based on EN 60335-1:2014-11 based on IEC 60335-1:2010

DIN EN 12100:2011-03 based on EN 12100:2011-03 based on ISO 12100:2011-03

DIN EN 60204-1/A1 based on EN 60204-1/A1 based on IEC 60204-1:2005+AMD1:2008 CSV

DIN EN 56014-1:2012-05 based on EN 56014-1:2012-05 based on CISPR 14-1:2005 + A1:2008 + Cor. :2009 + A2:2011

DIN EN 56014-2:2016-01 based on EN 56014-2:2016-01 based on CISPR 14-2:2015

- - EG) Nr. 2023/2006) - -

- - EG) Nr. 1935/2004) - -

Tulingen, December 08, 2014

Andreas Schmidt

CEO

VITO AG

Seite 12

This manual suits for next models

1

Table of contents

Popular Laboratory Equipment manuals by other brands

Radleys

Radleys Reactor-Ready Pilot instructions

Blue-White industries

Blue-White industries C-600P manual

sauter

sauter TVO-S Series instruction manual

Thermo Scientific

Thermo Scientific Compact Digital Rocker user manual

Snow Performance

Snow Performance 20001 installation instructions

Mitutoyo

Mitutoyo MICROPAK-2LA user manual

CORNING

CORNING PC-611 instruction manual

Thermo Electron

Thermo Electron HERAsafe KS Service instructions

Wavelength References

Wavelength References Clarity Series Operator's manual

Huber

Huber Unistat TR Series manual

Buchi

Buchi Kjel Line K-365 Operation manual

THORLABS

THORLABS T-Cube LEDD1B Operation manual