Page 4

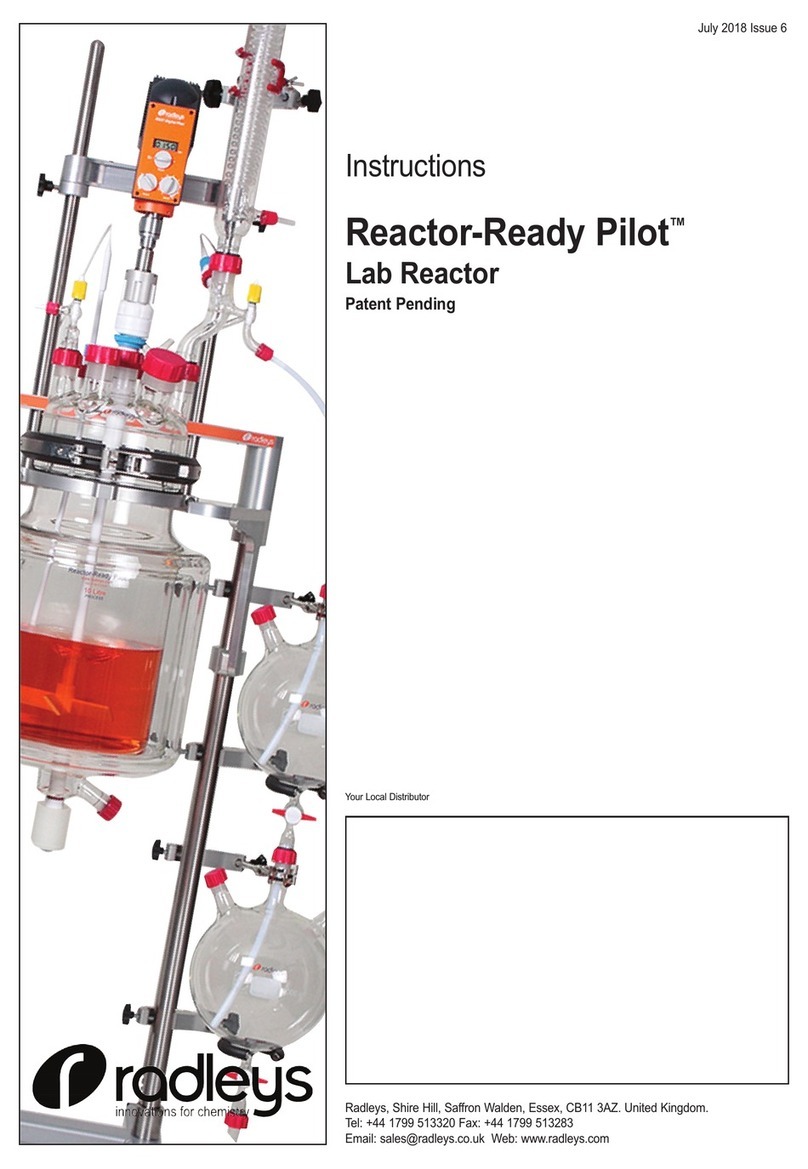

Reactor-Ready Pilot - Lab Reactor

5. Reactor-Ready Pilot and Accessories

How to order Reactor-Ready Pilot

1. Select the Reactor-Ready Pilot Core: RR210000.

2. Choose the lid you require, glass or PTFE.

3. Choose the Vessel Kit or Kits required by selecting the vessel volume and style.

4. Select the Lower Support Plate if using the 30 or 35 litre vessels.

5. Select the overhead stirrer you require.

6. If you need a thermoregulator, hoses, hose adapters, thermofluid or accessory

glassware, then select from the accessory list.

7. If you need automation, add the AVA Lab Control Software and Data Hub.

Reactor-Ready Pilot Core System

RR210000 Reactor-Ready Pilot Core System includes:

• Base frame, support rods, vessel clamp, i-beam

and stirrer support bosses.

• Vessel to manifold insulated hoses with quick-release

connections.

• Lower inlet manifold with drain.

• Upper outlet manifold with vent.

• PTFE Stirrer guide.

• Stainless steel stirrer drive coupling.

• One aluminium vessel support collar.

• FEP flange O-ring and PTFE centring collar.

Important: Hoses to connect the Reactor-Ready Pilot framework to your

thermoregulator are NOT included. You will require hoses with an M30x1.5 female

connection or appropriate adapters. See listing for hoses, adapters and suitable

thermoregulators.

Optional Pilot Core Height Reduction Kits

RR210070 Reactor-Ready Pilot Core - 200mm Height Reduction Kit

RR210072 Reactor-Ready Pilot Core - 300mm Height Reduction Kit

Important: Designed to reduce the overall height of the Pilot Core by 200 or 300mm.

Jacketed and Vacuum Jacketed Reaction Vessel Kits

• Kits include; process vessel, turbine stirrer paddle, PTFE Pt100 temp. probe with

Lemo plug and PTFE temperature probe adapter.

• Custom vessel designs are available on request.

RR220005 5L Single Jacketed Pilot Process Vessel Kit

RR220010 5L Vacuum Jacketed Pilot Process Vessel Kit

RR220015 10L Single Jacketed Pilot Process Vessel Kit

RR220020 10L Vacuum Jacketed Pilot Process Vessel Kit

RR220025 15L Single Jacketed Pilot Process Vessel Kit

RR220035 20L Single Jacketed Pilot Process Vessel Kit

RR220045 30L Single Jacketed Pilot Vessel Kit (must also purchase RR210002)

RR220050 35L Single Jacketed Pilot Vessel Kit (must also purchase RR210002)

Jacketed and Vacuum Jacketed Reaction Vessel Only

RR235050 5L Single Jacketed Pilot Vessel

RR235052 5L Vacuum Jacketed Pilot Vessel

RR235100 10L Single Jacketed Pilot Vessel

RR235102 10L Vacuum Jacketed Pilot Vessel

RR235150 15L Single Jacketed Pilot Vessel

RR235200 20L Single Jacketed Pilot Vessel

RR235300 30L Single Jacketed Pilot Vessel (must also purchase RR210002)

RR235350 35L Single Jacketed Pilot Vessel (must also purchase RR210002)

30L and 35L Vessel Lower Support Plate

RR210002 Reactor-Ready Pilot Lower Support Plate with Silicone Ring

RR210085 Optional - PTFE Support Ring for Lower Support Plate

RR210086 Replacement - Silicone Support Ring for Lower Support Plate

Reaction Vessel Support Collar

RR210018 Pilot Vessel Support Collar

Important: One support collar is supplied with each Reactor-Ready Pilot Core.

We recommend one support collar per vessel.

Glass DN200 Lids

• Choice of 6 or 7 Rodaviss glass joints.

• Custom lid designs are available on request.

RR236000 6 Neck Lid DN200 - 1xB19, 1xB24, 1xB29, 2xB34, 1xB45

RR236002 7 Neck Lid DN200 - 1xB19, 1xB24, 1xB29, 3xB34, 1xB45

PTFE DN200 Lids

RR136200 8 Neck PTFE Lid DN200 - with sockets

1 x B19, 1 x B24, 2 x B29, 3 x B34, 1 x B45

RR136210 8 Neck PTFE Lid DN200 - with 8 Threaded Ports

2 x ¾” NPT, 1 x 1” NPT, 5 x 1½” NPT

PTFE Sockets, Compression Fittings

& Blanking Plugs for DN200 PTFE Lids

RR136300 Rodaviss B19 Socket Adapter (¾” NPT)

RR136301 Rodaviss B24 Socket Adapter (¾” NPT)

RR136302 Rodaviss B29 Socket Adapter (¾” NPT)

RR136303 Rodaviss B34 Socket Adapter (¾” NPT)

RR136304 Rodaviss B45 Socket Adapter (¾” NPT)

RR136305 Rodaviss B24 Socket Adapter (1” NPT)

RR136306 Rodaviss B29 Socket Adapter (1” NPT)

RR136307 Rodaviss B34 Socket Adapter (1” NPT)

RR136308 Rodaviss B45 Socket Adapter (1” NPT)

RR136309 Rodaviss B24 Socket Adapter (1½” NPT)

RR136310 Rodaviss B29 Socket Adapter (1½” NPT)

RR136311 Rodaviss B34 Socket Adapter (1½” NPT)

RR136313 Rodaviss B45 Socket Adapter (1½” NPT)

RR136312 Reactor-Ready Pilot Central B34 Socket Adapter (1½” NPT)

RR136316 8mm Bore Compression Fitting ¾” NPT

RR136317 12mm Bore Compression Fitting ¾” NPT

RR136318 14mm Bore Compression Fitting ¾” NPT

RR136319 16mm Bore Compression Fitting ¾” NPT

RR136320 19mm Bore Compression Fitting ¾” NPT

RR136321 8mm Bore Compression Fitting 1” NPT

RR136322 12mm Bore Compression Fitting 1” NPT

RR136323 14mm Bore Compression Fitting 1” NPT

RR136324 16mm Bore Compression Fitting 1” NPT

RR136325 19mm Bore Compression Fitting 1” NPT

RR136326 25mm Bore Compression Fitting 1” NPT

RR136327 PTFE Blanking Plug ¼” NPT

RR136328 PTFE Blanking Plug ¾” NPT

RR136329 PTFE Blanking Plug 1” NPT

RR136330 PTFE Blanking Plug 1½” NPT

PTFE Pt100 Temperature Probes and Adapters

RR145000 Pt100 PTFE Temp. Probe 9mm + Lemo Plug - 5L to 10L Vessels

RR146000 Pt100 PTFE Temp. Probe 9mm + Lemo Plug - 15L to 35L Vessels

RR140015 PTFE Temperature Probe Adapter - 9mm

PTFE Baffles + PTFE Probe Baffles

RR257000 PTFE Baffle, 16mm OD Shaft, 35mm x 600mm long

RR257002 PTFE Baffle, 16mm OD Shaft, 35mm x 700mm long

RR257004 Pt100 PTFE Baffle Probe + Lemo, 16mm OD Shaft,

35mm x 600mm long

RR257006 Pt100 PTFE Baffle Probe + Lemo, 16mm OD Shaft,

35mm x 700mm long

RR257008 B24 to 16mm PTFE Compression Fitting

RR257010 B29 to 16mm PTFE Compression Fitting

RR257012 B34 to 16mm PTFE Compression Fitting Overhead Stirrers