Vitotherm VCD2 User manual

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

1

Introduction

The following operating and maintenance instructions have been compiled to

guarantee a maximum life span for the Vitotherm CO detector.

In accordance with the warranty conditions, the warranty will be invalidated if

the operating and maintenance instructions are not adhered to.

All deviating operating situations will be assessed on their permissibility on a per

event basis.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

2

Table of contents

1. General Assembly Instructions. ................................................................3

1.2 Electrical Connection (referring to NEN 1010)........................................3

1.3 Mechanical Connections ......................................................................3

2. VCD2....................................................................................................4

3. Crouzet Millenium 3 PLC..........................................................................4

3.1 Millennium display..............................................................................4

4. Testo Citycell CO Sensor. ........................................................................5

5. The functioning of the CO detector. ..........................................................6

5.1 The reaction of the CO detector to CO is as follows: ...............................6

5.2 In the case of a cable breakage and sensor malfunction. ........................6

5.3 Resetting the device...........................................................................6

5.4 Last fault ..........................................................................................6

5.5 Three-way valve ................................................................................6

5.6 Timer function ...................................................................................6

5.7 Pressure switch .................................................................................6

5.8 Monitoring the closed position of the chimney valve. ..............................7

6. Commissioning the VCD2 ........................................................................7

6.1. Inspecting the VCD2 .........................................................................7

6.2 Testing after leaving the factory ..........................................................7

7. Maintenance VCD2 .................................................................................7

8. Diagram on how to connect the CO detector to the chimney. .......................8

9. APPENDIX .............................................................................................9

9.1 Calibration of the VCD2 ......................................................................9

9.2 Technical instruction manual service technicians .................................. 10

All rights reserved. No part of this publication may be reproduced and/or published by means of

printing, photocopying, micro film or in any other way, without the prior written permission of

Vitotherm BV. This also applies to the accompanying drawings and diagrams.

Vitotherm BV reserves the right to change parts of this manual at any time without prior or direct

notice to the customer. The content of this instruction manual can also be changed without prior

warning.

This instruction manual applies to the VitoTherm CO detector. Consequently, Vitotherm BV cannot

be held liable for any damage resulting from the improper use of the CO detector. Improper use

means using the device for purposes other than those stated in this instruction manual. The

removal or alteration of parts of the CO detector also falls under the concept of improper use.

Please contact the Vitotherm BV Service Department for information regarding settings,

maintenance activities or repairs, as this is not provided in this instruction manual.

Although great care was taken in the compilation of this instruction manual, Vitotherm BV cannot

accept any responsibility in respect of possible errors in this instruction manual or any results

thereof.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

3

1. General Assembly Instructions.

For the proper functioning of the CO detector, inspection and maintenance play

an important role. The operating staff needs to carefully read these instructions

which are to be kept in the switch box of the device so they can be consulted in

the event of a possible fault.

When the fault cannot be solved on the basis of these instructions, you can

contact our Service Department. They can be reached at all times at telephone

number +31(0)15-3694757.

1.2 Electrical Connection (referring to NEN 1010)

(also see technical information for an electrical connection).

Connecting the device to the mains requires a power cord with a 230V isolation

switch. The power cord must consist of 3 wires, namely phase + neutral + earth.

This power cord needs to reach well into the switch box. The CO detector

operates on 230V and 100V alternating current and neutral.

When connecting to the mains, the relevant standards (NEN 1010), any relevant

local standards and the connection conditions for electric power must be taken

into account at all times.

1.3 Mechanical Connections

The CO detector's measuring connection must be fitted above the condenser.

This connection must consist of a ø12 mm copper pipe which must be connected

as described in the diagram on page 9.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

4

2. VCD2

The VCD uses a priming pump. The flue gasses are measured directly from the

boiler to the chimney after which the CO2 sets can be exhausted ensuring a safe

operation.

3. Crouzet Millenium 3 PLC

The heart of the CO detector is the Crouzet Millenium which operates via a

programme developed by Vitotherm.

3.1 Millennium display

This is a 4 line display in which the status and possible fault lines of the device

are indicated. The ESC function, next to the display, offers the option to view the

inputs and outputs. In addition, there are a number of buttons next to the

display that do not have a function. These are A, B, - and +.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

5

4. Testo Citycell CO Sensor.

This sensor comes with a push button for calibration. The initial calibration is

carried out in our factory. A possible re-calibration and the annual inspection can

be carried out by our qualified staff on location.

See also the Calibration Appendix of the VCD2.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

6

5. The functioning of the CO detector.

In the case of a CO2demand, the pump will be activated and will blow clean air

over the sensor for 2 minutes. The display will indicate 'flush'. After 2 minutes

the device will start measuring the flue gasses which will be released via the

connected CO2 fan or chimney valve. The display will indicate the word

'measurement'. There will always be some CO release at the start. The 2 minute

waiting time decreases the chance of a fault and immediate shutdown, and

leakage of these harmful compounds into the CO2 installation will be prevented.

5.1 The reaction of the CO detector to CO is as follows:

When measuring a CO concentration higher than 30 ppm.

With a CO concentration of more than 30ppm the release will cease after 1

minute and the device will be locked. The pump will flush the sensor with clean

air which will ensure that the measured level drops to 0 ppm. Pressing and

holding the OK button will display the last recorded fault in the memory showing

the last measured CO level.

Any CO fault will activate a red light and the device can be reset by pressing the

OK button.

5.2 In the case of a cable breakage and sensor malfunction.

The CO detector is safeguarded against a sensor malfunction. This works as

follows; if the input signal of the CO sensor is measured and it becomes too low,

the CO detector will go into fault mode after 1 minute. Subsequently, the fault

light comes on and the display will show 'sensor defective'.

5.3 Resetting the device

You can reset the device by pressing the OK/reset button.

When the fault keeps reoccurring, you will have to contact our Service

Department to solve this issue.

5.4 Last fault

The last device fault can be displayed by pressing and holding the OK/reset

button.

5.5 Three-way valve

The three-way valve ensures a long sensor life-span and is used to flush the

sensor with clean air.

5.6 Timer function

The device contains various timers with set times. Although they are suitable for

most applications a customer-specific adaptation is possible.

5.7 Pressure switch

The pressure switch monitors the flow over the sensor. An insufficient flow will

result in a fault and immediate shutdown. The device will be locked and the

display will read 'pump malfunction'.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

7

5.8 Monitoring the closed position of the chimney valve.

Optionally, it is possible to connect a ES6 limit-switch to the device. The ES6 will

monitor the closed position of the chimney valve for 5 minutes after there is no

demand for CO2. This is required for the burner to stop drawing in any unwanted

flue gasses. There is a contact in the device, part of the safety chain, that needs

to be connected to the burner for deactivating/switching off the burner in the

case of a fault.

6. Commissioning the VCD2

6.1. Inspecting the VCD2

Inspect the VCD2 for the following:

Whether the steam trap is connected at the right height

Whether the connection diagram relates to the actual situation

(see Chapter 8 for the connection diagram)

Whether the VCD2 is connected to the correct voltage supply

Whether the steam trap holds one centimetre of water

6.2 Testing after leaving the factory

The VCD2 is tested extensively in our factory. When commissioning the device,

all that needs to be checked is whether the electrical and mechanical connections

are correct.

7. Maintenance VCD2

Maintenance of the VCD2 needs to be carried out on an annual basis and by

qualified staff.

During this maintenance the CO sensor needs to be checked/calibrated using

calibration gas.

The pump needs to be checked for pressure and switch value of the pressure

switch.

You can have the maintenance performed by our qualified staff. To discuss the

options, please contact our Service Department.

Telephone number: +31 (0)15-3694757.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

8

8. Diagram on how to connect the CO detector to the chimney.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

9

9. APPENDIX

9.1 Calibration of the VCD2

EasyCal 4-20 mA Transmitter (Toxic CiTiceLs)

Instruction manual

Vitotherm B.V.

Tel: +31 (0) 15 –369 47 57

Overgauwseweg 8

Fax: +31 (0) 15 –369 77 42

2641 NE, Pijnacker

Internet: www.vitotherm.nl

Table of contents

Introduction 2

Available Options 3

Electrostatic Discharge Guidelines 4

Connection and Wiring 4

Power supply and Total Loop Resistance 5

Calibration Guidelines 6

Calibrating to Cross Sensitive Gases 6

Recommended Gas Flow Rates 6

User Calibration Procedures 7-8

Standard - Span Gas = 20mA Signal 7

Non-Standard - Span Gas within ±5% of Full Range 7

Non-Standard - Span Gas not within ±5% of Full Range 8

Important Notes 9

Transmitter Error Condition 10

Reset to Factory Calibration 10

Handling and Storage 10

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

2

Introduction

In many applications it may be more cost effective to replace a sensing head

with one precalibrated at a testing station or laboratory, so reducing disruption

of the measuring system. To enable this, some CiTiceLs are available as 4-20 mA

Transmitters, comprising a three electrode Toxic Gas CiTiceL and a circular

Surface Mount Design (SMD) printed circuit board (PCB). The prime features of

these units are ease of use, compactness, and the ability to replace both CiTiceL

and electronics very quickly.

The EasyCal PCB has an amplifier circuit to convert the microamp level output

signal of the sensor to the industry standard 4-20 mA output for two-wire,

remote monitoring systems. The circuit employed imposes no constraints on the

sensor, so the performance characteristics of the sensor are unaltered by the

addition of the circuit board. The microprocessor board removes the need for

potentiometers used on the standard boards, and only requires a single button

press when gas is applied for calibration. This makes the calibration process

quick and simple to perform.

All transmitters are fitted with a diffusion mounting assembly (the Mounting

Nose) for convenient mounting and fast replacement in a wide range of

weatherproof housings. It requires a 25 mm diameter hole in the outside wall of

the housing to allow installation, and also features a

calibration plug for easy zeroing and exposure to

calibration gas. A bonded membrane and mesh is

included to prevent the ingress of dirt and dust

particles into the sensor.

Besides periodic recalibration, transmitters are

maintenance-free, and should give faultless service

throughout the working life of the sensor. It is a

matter of customer choice whether the unit is

replaced automatically after this time or when the

sensor fails to calibrate.

Toxic Gas CiTiceL 4-20 mA EasyCal Transmitter

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

3

Available Options

Every transmitter is supplied precalibrated to a customer specified range. The

table in the next section gives an indication of the ranges available for each

particular sensor. Any option can be recalibrated to an intermediate range, using

the calibration procedure detailed later in this document.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

4

Electrostatic Discharge Guidelines

This component is susceptible to ESD (Electrostatic Discharge) when being

installed or adjusted. To prevent ESD related damage during installation, follow

the following guidelines.

- Ensure all power supplies are turned off.

- If possible, wear an ESD strap connected to ground. If this is not possible,

discharge yourself by touching a metal part of the equipment into which

the transmitter is being installed.

- Ensure that any tools are discharged by contacting them against a metal

part of the equipment into which the conditioning electronics is being

installed.

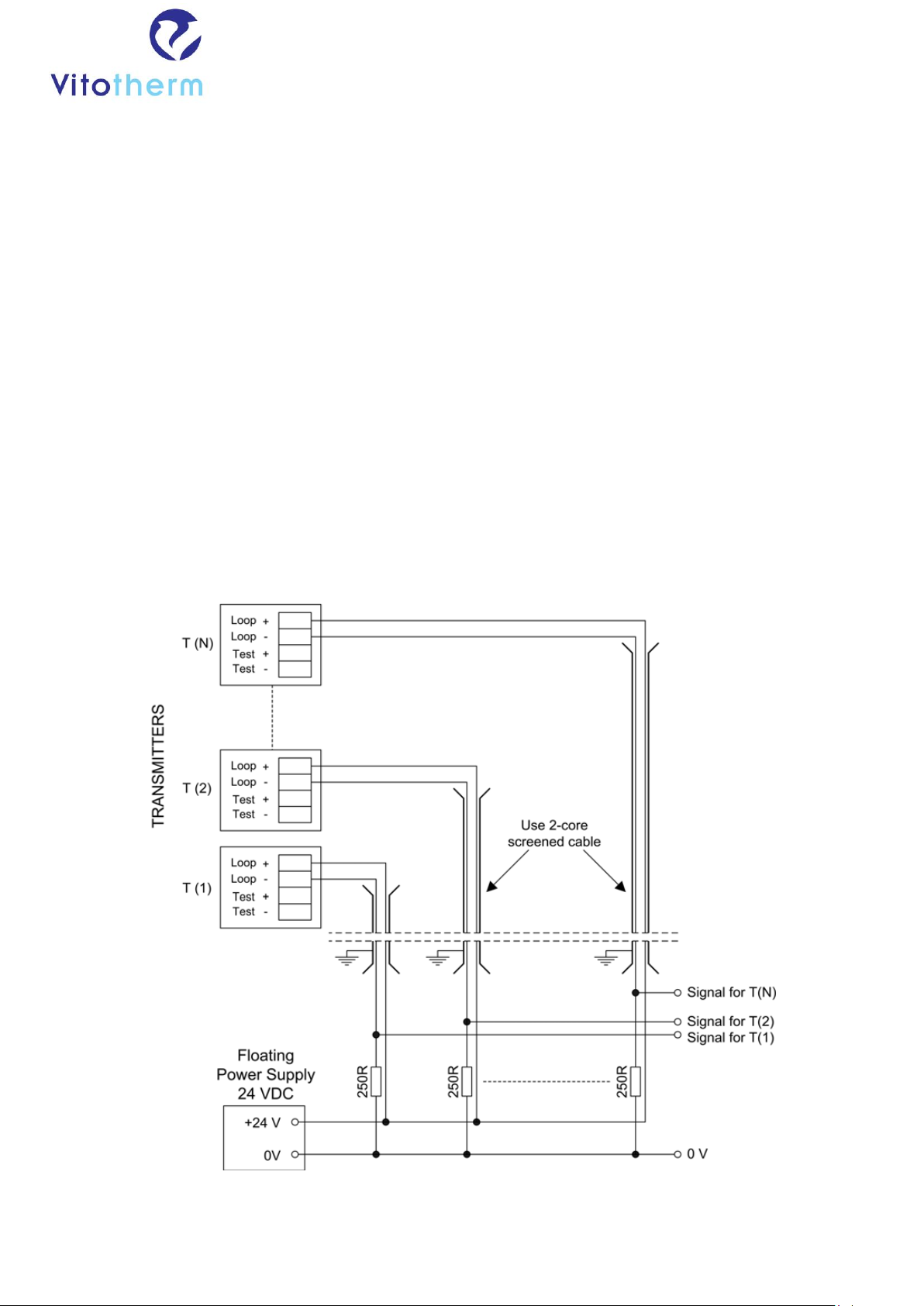

Connection and Wiring

Transmitters are designed for standard two-wire operation where the output is

supplied via the same wire pair as the power supply. The external circuit loop is

connected to the transmitter PCB via a screw terminal connector. Schematic

Wiring Diagram for 4-20 mA Transmitters

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

5

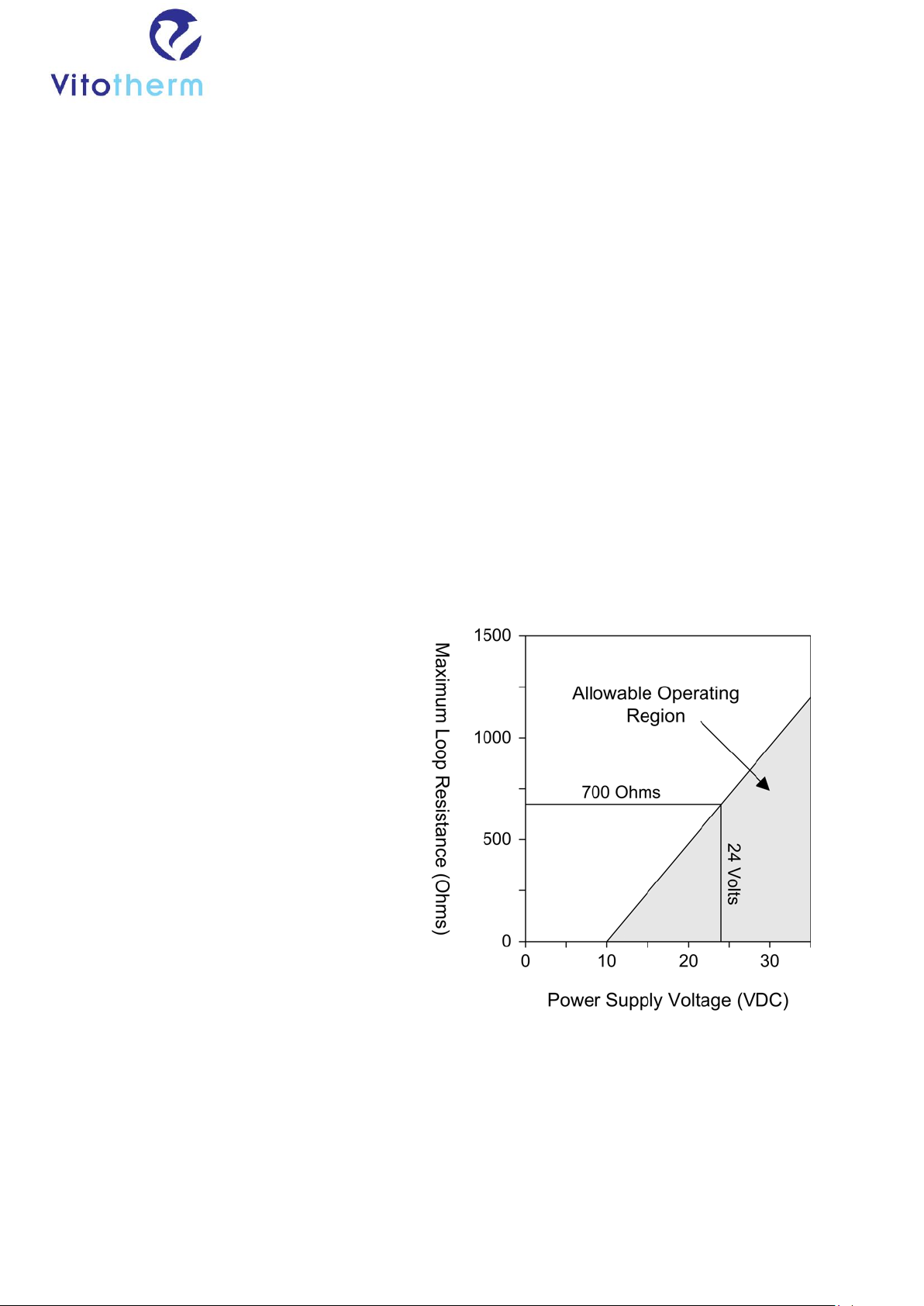

Power Supply and Total Loop Resistance

Transmitters can be operated with any single-sided power supply within the

range 10 - 35 VDC. However the power supply used will impose constraints on

the total loop resistance in the external circuit, and this must be taken into

account when choosing the supply voltage. This includes the measuring resistor

at the remote receiver and any meters for calibration etc. The example below

illustrates the relationship between the two considerations.

So that the sensor only requires a few seconds to settle after start-up, the

transmitter circuit has an FET powered shorting link between the sensing and

reference electrodes of the CiTiceL when left unpowered. However, due to the

different operating nature of biased sensors (which include nitric oxide and

hydrogen chloride sensors), this link is omitted with these transmitters. They

therefore require a longer start-up time when first powered, and must remain

powered continuously in the actual application.

IMPORTANT : The transmitter is designed for power supplies within the range

10 - 35 VDC only. Connection to mains electricity will result in transmitter failure.

Relationship Between Power Supply Voltage and Total Loop Resistance

Example : Using a transmitter with a standard 24 VDC power supply, the total

allowable resistance is as follows:

The minimum voltage required at

the transmitter for operation is 10

Volts. Therefore, the maximum

drop allowed due to loop resistance

is 14 Volts.

Full scale deflection current

requirement : 20 mA

Therefore, the maximum loop

resistance allowable

(using Ohm's law):

R = V / I

R = (14 x 1000) / 20

R = 700 Ohms

In this case, a measuring resistor of 250 Ohms is appropriate, giving a scale of 1

V to 5 V.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

6

Calibration Guidelines

CiTiceL transmitters are supplied precalibrated, and

the sensitivity of the device should not drift by more

than 2% of full signal per month. The circuit board

has a single push button which can be used to

calibrate the transmitter should this be required.

The standard mounting system allows easy aspiration

using the calibration plug provided. With the plug in

place and sealing caps fitted, the CiTiceL is

completely isolated from the atmosphere. With sealing caps removed, calibration

gas can be supplied through one inlet and exhausted through the other.

Calibrating to Cross Sensitive Gases

Electrochemical CiTiceLs are cross sensitive to certain non-target gases.

Information regarding cross sensitivities for particular sensors can be found on

the product datasheets. It is important to remember however, that cross

sensitivity data is only very approximate and cross sensitivities will vary between

sensors and sensor batches. Therefore, it is not advisable to calibrate sensors or

transmitters to non-target gas as this will result in a degree of measurement

error.

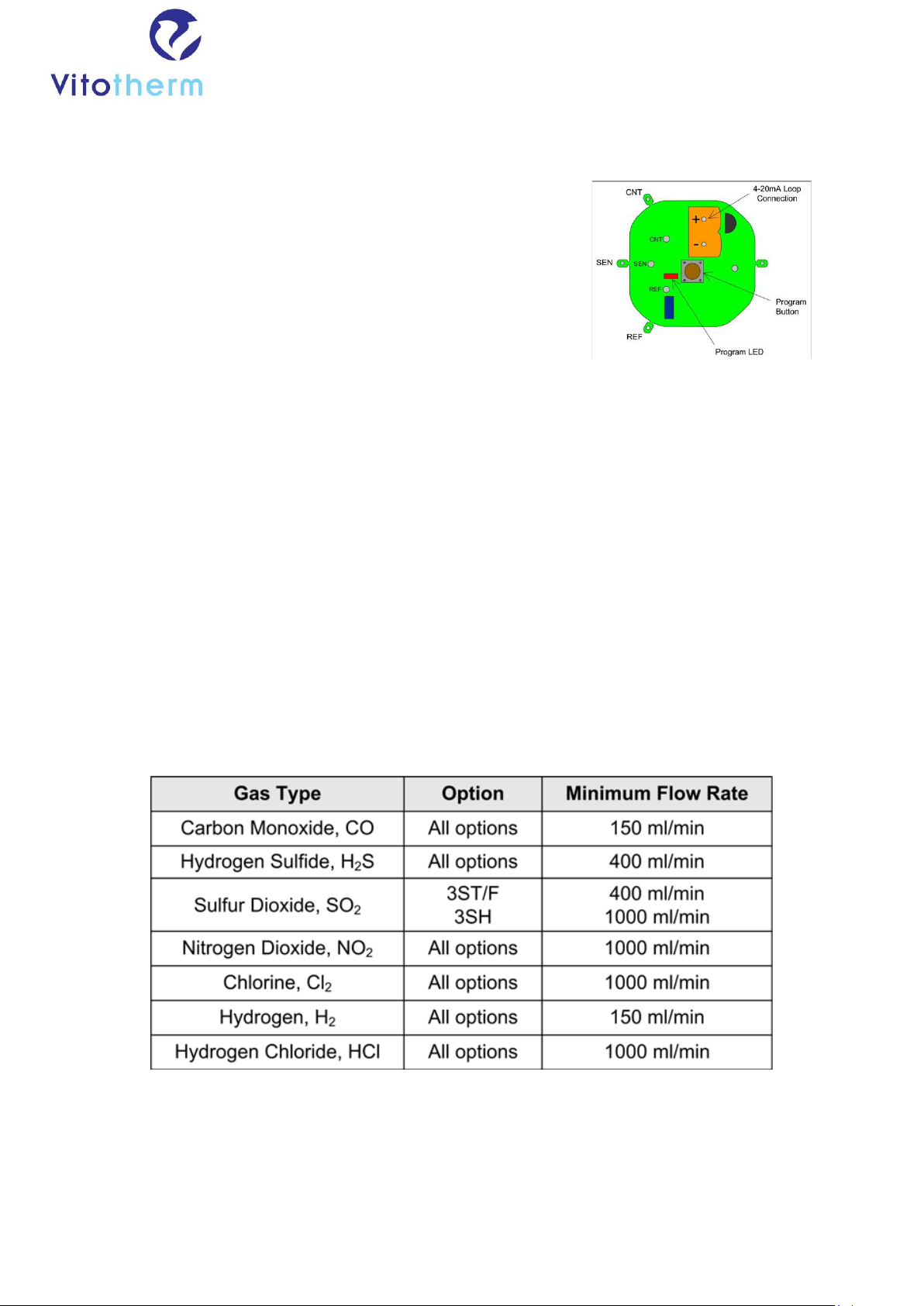

Recommended Gas Flow Rates

A minimum flow rate is required to ensure accurate calibration - it also means

that the response from a CiTiceL is equivalent in configurations where gas is

flowing over the sensor and those where the sample is allowed to diffuse into the

sensor. The minimum flow rate which is required will be different depending on

the CiTiceL type –these are shown in the table below.

These flow rates are based on gas delivery apparatus used at City Technology

Ltd. Other designs of gas delivery may have an influence on the flow rates

required. EasyCal Circuit Board Layout

Standard User Calibration Method (Span Gas = 20 mA Signal)

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

7

1. Connect loop power to the transmitter.

2. Apply clean air or an inert gas to the transmitter for 2 minutes.

3. Hold down the program button until the LED flashes at approximately 1 Hz.

The 4 mA level is now set.

4. Apply the required span gas to the transmitter for 2 to 5 minutes.

5. Press and release the program button. The 20 mA level is now set to

represent the concentration of the calibration gas used.

6. The LED will flash at approximately 8 Hz for 8 Seconds. This is the timeout

period.

7. Calibration is complete. The LED will clear and the transmitter will return to

normal mode.

Non-Standard Span Gas Calibration Methods

Span Gas Within ±5% of Full Range

1. Calculate the mA signal expected for span gas. The output range available

is 19.2 mA to 20.8 mA.

Example

Required 4-20 mA range is 0-500 ppm

Available span gas is 480 ppm

Dynamic Range is 16 mA

Therefore, 1 mA = 31.25 ppm

Expected signal at 480 ppm = (15.36 mA + 4 mA) = 19.36

mA

2. Connect loop power to the transmitter.

3. Apply clean air or an inert gas to the transmitter for 2 minutes.

4. Hold down the program button until the LED flashes at approximately 1 Hz.

The 4 mA level is now set.

5. Apply the required span gas to the transmitter for 2 to 5 minutes.

6. Press and hold the program button to set the 20 mA level.

7. The LED will flash at approximately 8 Hz for 8 Seconds. Continued momentary

pressing of the program button during this timeout period will increase the

output by 40 μΑ per press. When the output reaches 20.8 mA, the next button

press will take the output to 19.2 mA. Further button presses will again increase

the output by 40 μΑ When the required output is reached, allow the transmitter

to time out.

8. Calibration is complete. The LED will clear and the transmitter will return to

normal mode.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

8

Span Gas not within ±5% of Full Range

Note : A current source is required for this procedure.

1. Apply a gas of known concentration to the sensor for 2 to 5 minutes.

2. Measure the current from the sensor. This can then be used to calculate

the sensitivity (in μΑ/ppm) for the specific sensor being calibrated (see

step 3).

3. Calculate the expected current when the sensor is exposed to the full

scale of target gas.

Example

Required 4-20 mA range is 0-500 ppm

Available span gas is 300 ppm

Current from sensor when exposed to span gas = 33 μΑ (from step 2)

Therefore, sensitivity = (33 μΑ/ 300 ppm) = 0.11 μΑ/ppm

Expected signal at 500 ppm = (0.11 μΑ/ppm x 500 ppm) = 55 μΑ

4. Connect the current loop power to the transmitter

5. Connect the current source to the transmitter.

or Oxidising Sensors (CO, H2S, SO2, NO ...) Connect the negative to 'SEN'

and the positive to 'CNT'. Connect 'CNT' and 'REF' together. For Reducing

Sensors (CL2, NO2 ...). Connect the negative to 'CNT' and the positive to

'SEN'. Connect 'CNT' and 'REF' together.

6. Set the current source to zero.

7. Hold down the program button until the LED flashes at approx. 1 Hz (4 mA

level now set in RAM).

8. Set the current source to the value calculated for the full scale of target

gas (from step 3).

9. Press and release the program button (20 mA level now set in RAM).

10.The LED will flash at approximately 8 Hz for 8 Seconds. This is the timeout

period.

11.Calibration is complete. The LED will clear and the transmitter will return

to normal mode.

Important Notes

Recalibration is only possible if the output of the sensor at full scale is greater

than 50% of the original factory calibration. Failure can occur if:

1. Attempt is made to recalibrate to a range less than 50% of the original

calibrated range.

2. The output of the sensor has fallen by more than 50%. In this case, the

sensor must be replaced.

3. Incorrect span gas is used.

4. Insufficient time is allowed for the output to settle after exposing the sensor

to span gas. Span gas should be applied for 2-5 minutes before setting the 40

mA level.

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

9

Transmitter Error Condition

Any time the error condition is set, the output will be forced to 21 mA and the

LED will be held on. Carry out the Reset function to reset the sensor.

Reset to Factory Calibration

1. Remove loop power from transmitter.

2. Hold down the program button and connect loop power to transmitter.

3. The LED will blink as soon as power is applied (approx. 2 Hz). The

transmitter output is now set to 21 mA.

4. Releasing the program button will start an 8 second timeout period.

5. After 8 seconds, the factory calibration will overwrite the user calibration.

6. The LED will clear and the transmitter will return to normal mode.

Handling and Storage

Electrochemical sensors are relatively insensitive to mishandling. Following the

simple guidelines given below should ensure correct operation.

Sensors may be stored for up to six months. They should be kept sealed in the

containers in which they were supplied in clean dry air at 0 - 20°C.

Sensors should not be stored in areas containing solvent vapours. All

electrochemical sensors are unsuitable for use in applications where organic

solvent vapours are present as exposure may inhibit performance.

Sensors must not be subjected to any pressure when handling or clamping.

MSDS’s can be provided for all City Technology products, detailing their

hazardous content. The hazardous waste disposal regulations depend on

geographic location, and local regulations should be checked before discarding

the sensors.

WARNING: By the nature of the technology used, any electrochemical or

catalytic bead sensor can potentially fail to meet specification without warning.

Although City Technology makes every effort to ensure the reliability of our

products of this type, where life safety is a performance requirement of the

product, and where practical we recommend that all sensors and instruments

using these sensors are checked for response to gas before use

Instruction and operating guideline CO-detector

Type:

VCD2 CO-Detector

10

Every effort has been made to ensure the accuracy of this document at the time of printing. In accordance

with the company’s policy of continued product improvement City Technology Limited reserves the right to

make product changes without notice. No liability is accepted for any consequential losses, injury or damage

resulting from the use of this document or from any omissions or errors herein. The data is given for guidance

only. It does not constitute a specification or an offer for sale. The products are always subject to a

programme of improvement and testing which may result in some changes in the characteristics quoted. As

the products may be used by the client in circumstances beyond the knowledge and control of City Technology

Limited, we cannot give any warranty as to the relevance of these particulars to an application. It is the

clients’ responsibility to carry out the necessary tests to determine the usefulness of the products and to

ensure their safety of operation in a particular application.

Performance characteristics on this data sheet outline the performance of newly supplied sensors. Output

signal can drift below the lower limit over time.

9.2 Technical instruction manual service technicians

Clip numbers Crouzet M3:

Input: output:

+ 24 VDC 01 three-way valve measurement flue gas

- 24 VDC 02 output alarm red light

I1 enable controls 03 safety circuit burner ok

I2 start CO2 demand 04 pump activated

I3 pump pressure present 05 chimney valve open (make

contact in centre)

I4 selection text CO2 vent activated instead of

RGK activated 06 chimney valve closed (when desired

with CO2 vent activated)

I5 ES6 chimney valve not closed 07 alarm potential-free (make contact

in centre)

I6 not in use 08 no alarm potential-free

IB 0-10V input CO sensor

IC not in use

ID reset

IE not in use

Description VCD2 Programme:

After enabling the controls and start of CO2 demand at input l1 and l2, the pump

will be activated. The pressure switch will get a 10 second window to build up

pressure. After a delay-time the three-way valve will activate and flue gasses will

be measured. When U5 increases, the fan or chimney valve will be activated.

After losing the demand for CO2, l1 and l2, U5 (chimney valve) and U1 (3-way

valve) will switch over and after the flush time U4 (pump) will switch off. After

the delay of the chimney valve, approx. 5 minutes, l5 should be present. When

l5 is not present, l4 will switch off (safety circuit burner ok) and so will the MY2

relay. The contacts of the MY2 relay are connected to 3 terminals as a potential

free contact which can, subsequently, be connected to the safety circuit of the

burner.

In the following situations a fault and immediate shutdown will take place:

1. Pump pressure not present; U5/6 and U7/8 and U2 will switch over. The

three-way valve is activated for 2 min. (flushing).

2. CO too high after a delay-time of 1 minute, the display will show 'CO too

high'. U5/6 and U7/8 and U2 will switch over. The three-way valve is activated

for 2 min. (flushing).

3. Sensor signal not present (4 mA not present)

Table of contents

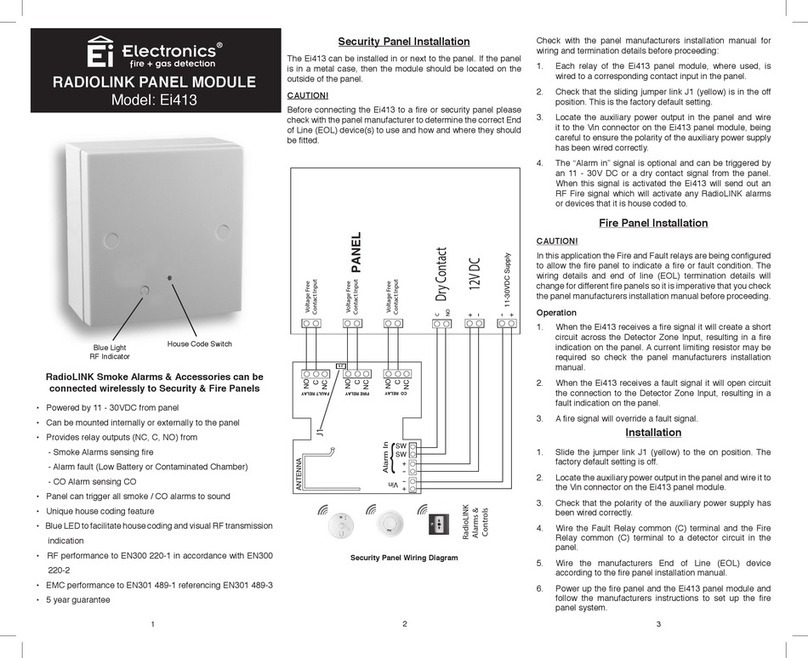

Popular Gas Detector manuals by other brands

BEINAT

BEINAT BXI32 Installation and user guide

ATI Technologies

ATI Technologies PortaSens III D16 O & M Manual

Electronics

Electronics Ei413 quick start guide

Blackline Safety

Blackline Safety G7 BRIDGE Technical user's manual

Tecnocontrol

Tecnocontrol TS282E Series user manual

seeed studio

seeed studio Grove MQ3 manual