Page 2

Technical features

Main features

Optional cabinet for BXI32, composition:

a) Rail DIN Omega for insertion BXI32,

b) Switching Power Supply 110/230 VAC 35W 12 VDC

c) Control unit cable and power supply,

d) Battery holder bracket

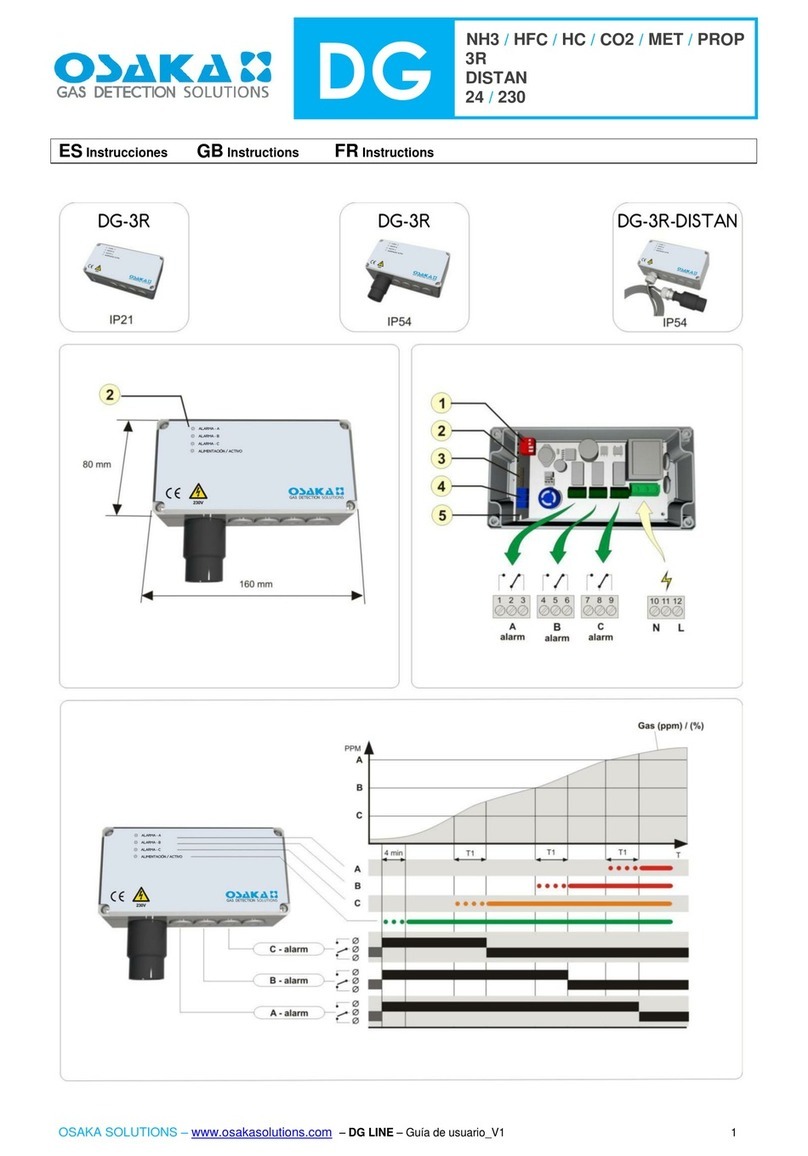

Dimensions: 340x280x160

Degree of protection: IP65

Control unit power supply : 15 VDC ± 10%

Probe power supply Separately from the control unit: 15 VDC ± 10%

Set: Date and time

Select: The number of sensors, and their disablement

Select: The Operating range of the sensors, from 0 to 20%, or 0-100 of L.E.L.

Select: The type of gas that the sensor must detect “Toxic or Explosive”

Choice of ALARM Thresholds

Prealarm: The Pre-Alarm level, for every sensor from 3% to 16%

1st Alarm: The Alarm level, from 10 to 20%. of the LEL, Step 1% (Default 20% of the LEL)

2nd Alarm: The Alarm level, from 10 to 50%. of the LEL, Step 5% (Default 20% of the LEL)

With password entry

Select: The operation of the relay “ pulsed or continuous”

Select: The function of Positive Safety

Select: The function of saving the alarm triggered

Select: The exclusion or insertion of “external siren”

Select: The exclusion or insertion of “internal buzzer” if an alarm is triggered

Data logger: Alarm and events resulting from self-diagnosis: faults, transmissions, malfunctions, etc.

Connection: a) Of a portable printer, b) relay expansion card

LCD display

Display: the Brand, the serial number, Date and Time

Display: automatic Explosive Gas and Operating range L.E.L. or Toxic Gas ppm

Display: the chart of the amount of gas detected

Display: Warm up on Display appears the “count-down” time

Front Panel

Push-buttons for navigation and confirmation of data set

Test push-buttons for total control of the BXI32 checking the efficiency of the unit and the connected sensors.

Reset button used to reset alarm and faults memories

LED that displays the silenced external siren. This operation can be performed by entering the Password

All operation and alarm LEDs: read page 3 to find out their functions

LED that displays the charge status of Buffer battery

Main Power Supply

............................

..........................................................................15 VDC ± 10%

Power demand .................................................. ................from 1.2W min. to a max. of 3W Max 15 DC

Secondary power supply via battery Max 2,2 Ah (not supplied) ...................................... 12,7 V ± 10%

Battery Charger Max 2,2 Ah ...................................................................................................... controlled

Relay Contact Range ..................................................................................................... 10A 250V resistive

ALARMS

Pre-Alarm ..... adjustable ......for each sensor from 2% (450ppm) to 15% (240ppm) of the LEL with Step

1st Final alarm adjustable for each sensor from 10% to 20% - with Step of 1% from factory to 20% of the LEL

With password entry

2nd final alarm adjustable for each sensor from 10% to 50% - with Step of 5% from factory to 20% of the LEL

ALARMS Oxygen ................. <Oxygen deficiency and > Oxygen excess ................ See thresholds page 3

INDICATIONS

Signaling the % of the monitored gas ............................................................................. visible on display

Indication of mains power supplied

, alarms, battery state, sensor and battery over load, faults

Manual alarm

indication

............................................................................................................ built-in

Siren ON

indication

.................................................................................................................. built-in

Duration of pre-heating phase via count-down ......................................................................... 90 seconds

Manual test ........................................................................................................................... built-in

External siren and internal Buzzer silencing ............................................................... via software operation

ALARM ZONE AND ADDRESSABLE SENSORS

Number of connectable sensors ........................................................................................................ 32

Sensor connection/disconnection .............................................................................. via software operation

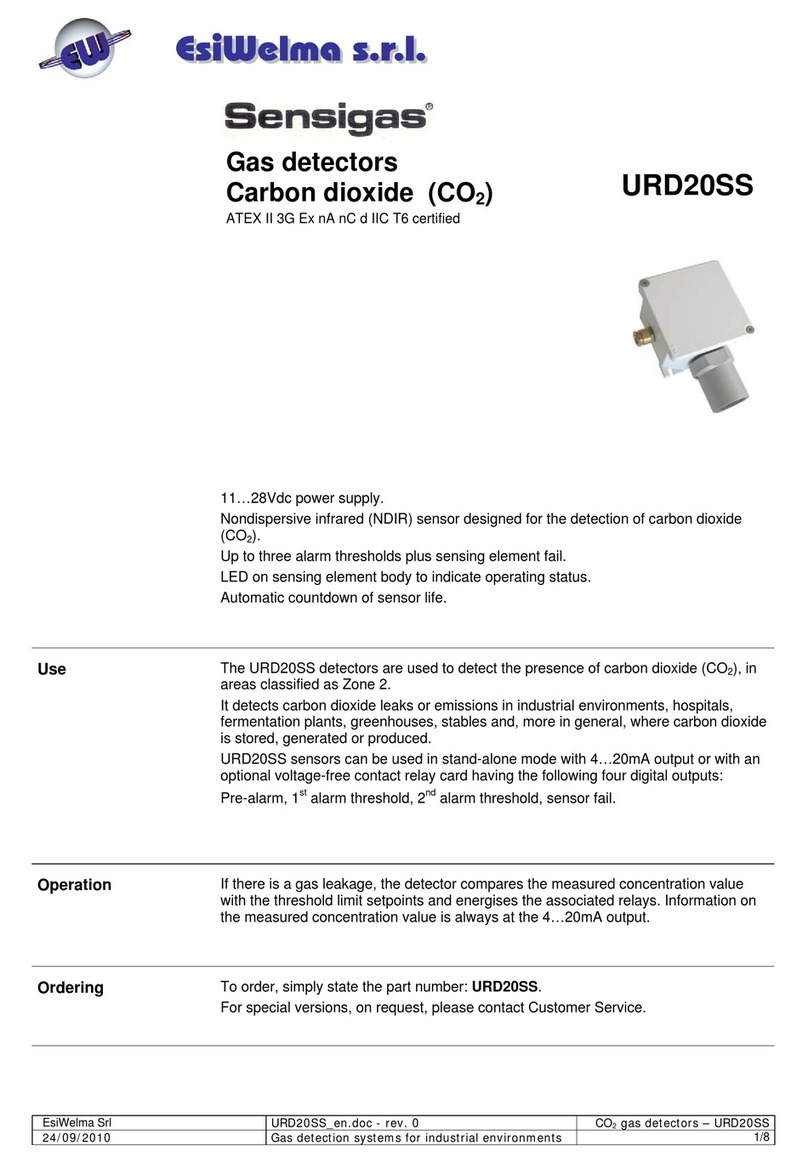

Connectable sensors ....................... Semi-conductor, Catalytic, Electrochemical cell, Pellistore, Infrared Red

Faults detected by fault circuit .............................................................. Interruption , short circuit or fault

Addressed data line ............................................................................... RS485 prot. ModBus RTU

Operating Range .......................................................................................... 0-20% or 0-100% of L.E.L.

Equipment precision ................................................................................................................. 1% FS

Response time ........................................................................................................................... < 2"”

Maximum distance between sensors and control unit .....................................................................1000 m

Cable diameter for connecting sensors ..............................................................0,25 mm2 Twisted

CONNECTIONS

Printer ..................................................................................................... through dedicated USB port

CARD-TX4R Relay expansion card ....................................................................... each card has 4 relays

Operating temperature ..................................................................................................... -10°C + 60°C

DIN rail omega dimensions DIN EN 50092 9 modules ........................................................ 158x90x58 mm

Degree of Protection ........................................................................................................... in air IP20

GENERAL INFORMATION

Attention !! The sensors must be powered by a source of energy external to the panel keeping in mind that each sensor has

an absorption of 200 mA