5

C

CO

ON

NT

TE

EN

NT

TS

S

1. THE SYSTEM WINPRO®......................................................................7

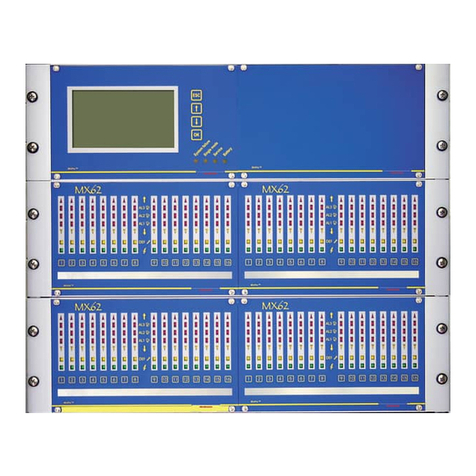

1.1. THE MX62 SYSTEM BRIEFLY ................................................................................8

1.2. THE MX62 SYSTEM SYNOPSE ...............................................................................9

1.3. MX62 SYSTEM : FUNCTIONAL DRAWING........................................................10

2. CONFIGURATION ...............................................................................11

2.1. DESCRIPTION OF MODULES................................................................................12

2.1.1. Controller Module (CM) ..............................................................................12

2.1.2. Analog Input Module (AEM).......................................................................13

2.1.3. LED Module.................................................................................................14

2.1.4. Basic Relay Module (RBM) and Extension Relay Module (REM).............15

2.1.5. Analog Output Module (AAM)....................................................................17

2.1.6. LCD Module.................................................................................................18

2.1.7. Logo Module................................................................................................18

2.1.8. Adapter module (numeric loop)...................................................................19

2.2. DESCRIPTION OF REDUNDANCY.......................................................................20

2.3. DESCRIPTION OF CONTROL PANEL..................................................................20

3. OPERATION OF THE SYSTEM WINPRO®.....................................21

3.1. CHANNEL AND SYSTEM INFORMATION .........................................................21

3.2. CONNECTING STATUS ..........................................................................................23

3.3. NORMAL OPERATION...........................................................................................23

3.3.1. Normal Status ...............................................................................................23

3.3.2. Channel Malfunction....................................................................................23

3.3.3. Insufficient Signal ........................................................................................24

3.3.4. Alarms ..........................................................................................................24

3.3.5. Excess of Measuring Range .........................................................................24

3.3.6. Resetting of Alarm Signals...........................................................................24

3.4. MAINTENANCE MODE..........................................................................................25

3.4.1. Forcing of the alarm relays into "out of alarm" position...........................26

3.4.2. Operational Test...........................................................................................27

3.4.3. Calibration....................................................................................................27

3.4.4. Channel On/Off ............................................................................................27

3.4.5. PC Communication ......................................................................................28

3.5. SINGLE MODE.........................................................................................................28

3.6. SYSTEM FAILURE ..................................................................................................28

3.7. MEASURES AGAINST FAULTS............................................................................29

4. OPERATING OF LCD MODULE........................................................30

4.1. DISPLAY OF CHANNELS.......................................................................................30

4.2. MENU........................................................................................................................31

4.2.1 Functions of the four LCD Key Buttons ......................................................31