Vitrum Clima User manual

1

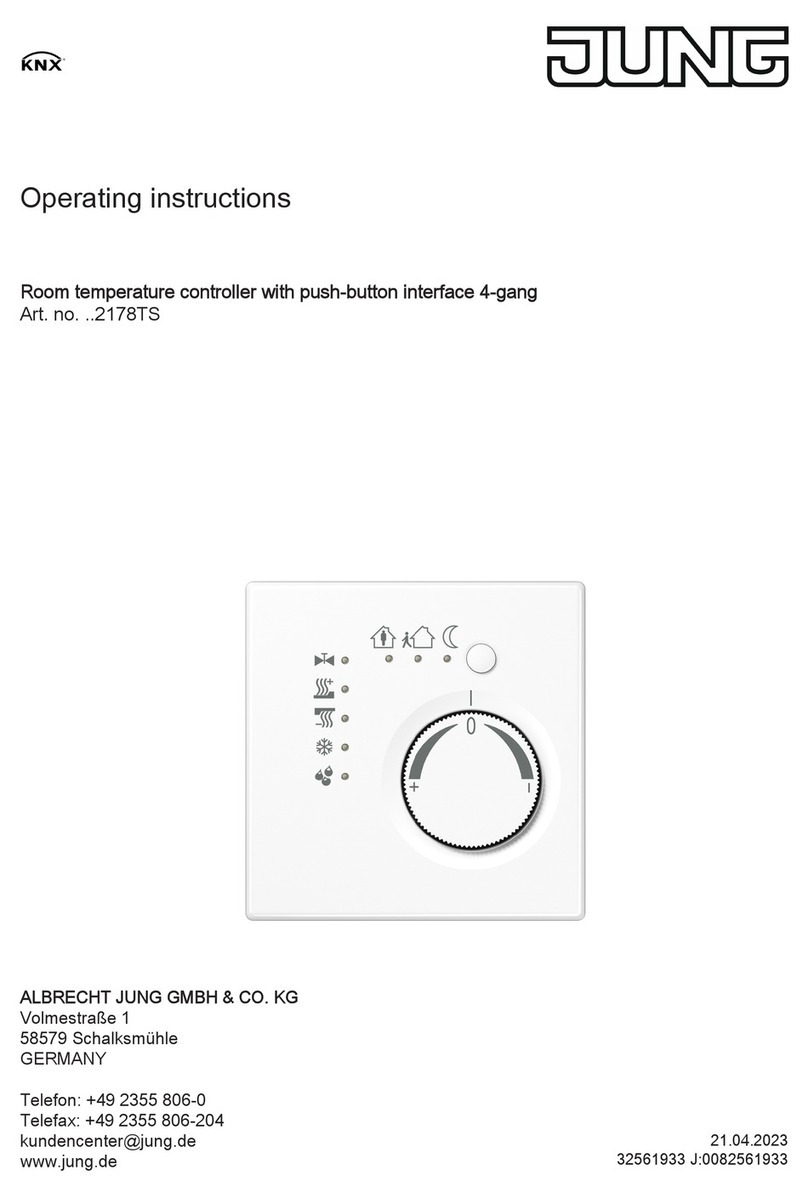

Clima controller

Temperature Controller

Clima Control in style.

Product Handbook.

SIMPLY INIMITABLE.

2

SUMMARY

4

8

General Introduction

Input: Shutter and Blind

4

8

Product and functional overview

Input: Scene Management

5

9

13

General Parameter conguration

Commands in Sequence

3.

11.

2.

10.

1.

9.

6

10

14

Right Button conguration

Temperature sensor function

Fan coil on-o

4.

12.

17.

6

10

15

Central/Left button

Thermostat function

Fan coil Control % ( or genric continuous control)

5.

13.

18.

6

10

15

Activation on press/edge

Target Setpoint Settings

Temperature probe failure /out of range measurement

6.

14.

19.

7

12

17

Actiovation short/long press

Two Points on-o

Behavior of Thermostat on voltage failure, recovery and

commissioning

7.

15.

20.

8

17

Input: Dimming

On-o with PMW control

Control Panel

8.

16.

21.

SIMPLY INIMITABLE. 3

Any information inside this manual can be changed without advice.

Exclusion of liability:

Despite checking that the contents of this document match the hardware and software,

deviations cannot be completely excluded. We therefore cannot accept any liability for this.

Any necessary corrections will be incorporated into newer versions of this manual.

Symbol for relevant information

Symbol for warning

4

SIMPLY INIMITABLE.

1. General Introduction

This manual is intended to be used by installers

and describes functions and parameters of the

device VM_IPxxAxxKNX and how is possible to

change settings and congurations using ETS

software tool.

This manual is intended to be used by installers

and describes functions and parameters of the

device VM_IPxxAxxKNX and how is possible to

change settings and congurations using ETS

software tool.

2. Product and functional overview

VM_IPxxAxxKNX module is designed to be

installed in Home and Building installations (i.e.

oces, hotels, private houses, etc...).

The module includes ve capacitive touch

buttons.

The capacitive buttons can be used to on/o

commands, dimming, shutter control, scene

recall and control, sequences of 3 objects.

The VM_IPxxAxxKNX can manage one zone

thermoregulation with its temperature probe

and/or with one KNX temperature probe (with

On/O threshold) or one thermostats to control

heating and cooling equipments, valves, 2 and 4

pipes fan coils; etc..

The VM_IPxxAxxKNX can be also used as

Control Panel.

Capacitive buttons main functions:

• 1 bit commands: load activation /

deactivation commands (ON/OFF/TOGGLE) with

short press or with dierentiation of long and

short press

• 1 byte commands (unsigned 0-255 or HVAC commands or

value % commands).

• Sending of long action telegrams on the same address of

short action or on a dierent group address

• Cyclic sending

• Sequences (3 commands mixing 1bit/1byte objects) with

dierent group addresses

• Edges for 1 bit / 1 Byte / sequences

• Dimmer management (with single or double push-button)

• Blind / Roller Shutter management (with single or double

push-button)

• Scene management

• Thermostat management

Device congured as Temperature sensor - main functions:

• 2 dierent temperature thresholds to trigger 1 bit telegrams

alarm/warning

• Enable / disable of alarm / warnings via 1 bit object

Congured as Thermostat - main functions:

• Dierent control algorithms: 2 point on/o; PWM;

Continuous Control / Fan Coil Control

• Dierent setting modes: via HVAC automatic / via HVAC

Manual / via Setpoint

• Window contact function

• Additional external temperature sensors (optional)

Congured as Control Panel Main function

• Display the actual temperature or actual setpoint

• Permit to control a remote KNX thermostat

• Additional external temperature sensors (optional)

SIMPLY INIMITABLE.

5

KNX PARAMETER KNX PARAMETERSETTINGS SETTINGS

Delay on Power-up Value associated with

backlight ON mode

[0..100%]

Value associated with

backlight OFF mode

[0..100%]

Probe Function

Proximity function

Standby Mode

Acoustic signal on press

5 ÷ 15 seconds 0-100%

0-100%

Through this parameter is possible to set the delay of tran-

smission of telegrams after a power on by selecting the time

by which the device is allowed to send telegrams.

In large systems after a power failure or shutdown this delay

avoids to generate excessive trac on the bus, causing slow

performance or a transmission block.

If there are dierent devices requiring sending telegrams on

the bus after a reset, these delays must be programmed to

prevent trac congestion during the initialization phase.

The input detection and the values of objects are updated at

the end of the transmission delay time

At the end of ETS programming the device behaves like after

a power on.

Temperature Sensor”: measures and sends temperature on

the bus. See par. 6

“Thermostat”: controls dierent types of actuators regulating

heating and cooling. See par. 7

“Control Panel”: permit to control a remote KNX thermostat.

See Par. 21

With this parameter, during the ETS conguration, you can

set the brightness of backlight of the button when value is

OFF

With this parameter, during the ETS conguration, you can

set the brightness of backlight of the button when value is

ON

This parameter permit to enable or disable the proximity

funzion of the glass panel

This parameter permit di disable or enable the stanby mode

of the glass panel

This parameter permit di disable or enable the Acoustic

signal on press the glass panel.

When this parameter is enabled an acoustic signal notify that

one button is pressed

Temperature sensor

Thermostat

Control Panel

Disable

Enable

Disable

Enable

Disable

Enable

3. General Parameter Conguration

SIMPLY INIMITABLE.

6

Number of byte values

Function

Value <x> [1..9]

4. Right button conguration

5. Central / Left button

6. Activation on press / edge

The right button of the glass room temperature

controller can be congured to perform the “fun-

ction mode” or “nothing”

For each of the two button, present on the device, the se-

lections are made through a conguration page.

Every single button can be congured to perform one of the

following functions:

• Nothing

• Activation on press

• Activation on short and long press

• Dimming

• Shutter and blinds

• Scene

• Command in sequence (on short and long press)

• Command in sequence (toggle mode)

The “Activation on edge “ allows you to congure

the sending of telegrams when the button is pres-

sed or released

You can set to send a telegram with dierent va-

lues associated with dierent edges, or decide to

send commands only one of the two edges

With the“Activation of the press”selection device

can also be congured to send periodic messages

with repetition period.

KNX PARAMETER

KNX PARAMETER

SETTINGS

SETTINGS

Function

Minimum time long

press input

nothing

function

mode

0,3 sec

0,5 sec

0,8 sec

1,0 sec

2,0 sec

3,0 sec

5,0 sec

10 sec

2-9

Nothing

Activation on press

Activation on short and

long press

Dimming

Shutter and blinds

Scene

Command in sequence

(short/long press)

Command in sequence

(toggle mode)

0-255

Select the number of byte values used in the “fun-

ction mode” function.

Select the corresponding value to be assigned to

the value <x>

If function mode is selected,“number of byte values”

parameter is displayed.

When “function mode” is enable each press sends

the next byte of the sequence set

Determines how long must be a press to be consi-

dered long; if shorter than the selected value the

press will be considered short.

Nothing

When the capacitive button is pressed no

action are made

Activation on press

see par. 5.1- Activation on press

Activation on short and long press

see par. 5.2-Activation short/ long press

Dimming

see par. 5.3- Dimming

Shutter and Blind

see par. 5.4- Shutter and Blind

Scene

see par. 5.5 - Scene Management

Command in sequence

see par. 5.6 - Command in sequence

KNX PARAMETER SETTINGS

Telegram Associated 1 byte

1 bit

It is possible to send 1 bit or 1 byte objects

SIMPLY INIMITABLE. 7

• On

• O

• Toggle

Congurations for 1 bit object in events of pressing or

releasing the button:

• Value 0-255 (generic signed int)

• Value o-100% (scaling value in steps of 5%0)

• HVAC Mode value (according to DPT_HVAC-

Mode 20.102)

o AUTO

o COMFORT

o STANDBY

o ECONOMY

o BUILDING PROTECTION

Feedback object

Send Telegram on

power up

KNX PARAMETER SETTINGS

Function On press / release

On press / release

, cyclic if press

On press / release

, cyclic if release

On press / release

and always cyclic

Enabled

Disable

Enabled

Disable

Can be used when button is set as“1 bit – Toggle” in

order to have always the status of actuator updated.

With this parameter it is enabled the sending of

the status of the button without having to wait for

a change of front; a telegram is sent accordingly to

the press/release state of the button.

Note 1:

When periodical sending is enabled for one only

of the two edges, switching in the state where “no

telegram”is associated causes the periodic sending

stop.

Note 2:

If you want to handle both instant sending and

periodic sending on only one of two fronts without

performing an action on the other, for this you must

select the option “no telegram”.

Note 1:

If you enable the sending of the telegram for button

where you have already set the cyclic sending ; then

the cyclic sending will start automatically at power

on; at the end of the rst period.

Note 2:

If the command selected is “TOGGLE”, the rst

value sent is always 1 because the CO value on

power on is 0.

7. Activation short/ long press

The dierence duration between short and long

press is dened by the generic parameter“Mini-

mum time for long press button central / left”. You

can set to send a telegrams with dierent values

on short and long press or decide to send com-

mands only on one of this events.

The parameters and mode of transmission of

telegrams can be managed through “activation

on long and short press” are the same set with the

conguration“Activation of press “ to the exclu-

sion of the function of cyclic sending that is not

provided here.

SIMPLY INIMITABLE. 8

8. Input: Dimming

9. Input: Shutter and Blind

10. Input: Scene Management

Through the dimming function it’s possible to

control a light dimmer using short & long press

of a button. Each button uses 2 communication

objects:

• 1 bit dimension for ON /OFF command

associated to short press operation

• 4 bit dimension for brightness regulation

associated to long press operation

Through the Shutter and Blind function it’s possi-

ble to control Roller Shutters or Blinds using short

& long press of a button.

Each button uses 2 communication objects:

• 1 bit dimension for STEP /STOP command

associated to short press operation

• 1 bit dimension for UP / DOWN command

associated to long press operation

In this conguration page it’s possible to set the

button for scene management: learn and recall

scene commands.

These dierent behavior (recall and learn) are per-

formed through two dierent actions (short and

long press) of butto.

Learn scene on long press action is enabled by a

parameter.

Store scene on long

press

Enable learn scene

object

KNX PARAMETER SETTINGS

Scene Number Number of the

scene:

0 ÷ 63

Disable

Enable

Disable

Enable

If disable, long press action is ignored and no

telegram is sent to the bus; if enable on long press

action a learn scene telegram is sent to the bus.

If this parameter is enabled you have a communica-

tion object (size = 1 bit). When this object receives

a telegram“1” then the function associated to the

long press of the button (send the telegram storage

scenario) is enabled, when it receives a telegram“0”

the command associated with the long press is not

sent.

This parameter sets the value of the scene you

intend to learn / recall (one per button).

Remember that output devices (i.e. actuators, etc.)

generally can manage several scenes, each identi-

ed by a value (that varies from 0 to 63); therefore

is important to set this parameter correctly and

matching the number set on the actuators.

SIMPLY INIMITABLE.

9

11. Commands in sequence

The function allows you to associate to short and

long press, sequences of dierent commands on

the bus.

For inputs this function is available for short and

long press or for toggle evaluation.

The sequence consists of 2 or 3 commands which

can each be sized as 1 bit or 1 byte.

Once dened the number of elements in the

sequence (2 or 3) and their size (1-bit / 1 byte),

you can associate dierent commands to each

element of the sequence or decide to send com-

mands only on one of the two events.

The waiting time between a command and the

next is xed in 1 second.

Each object communication can be connected to

a dierent group address.

For example it is possible to dene a sequence:

Com. Dim.

Command on

short press

(edge)

Command on

short press

(edge)

A1 bit ON

( to actuators)

100%

(to a dimmer)

COMFORT

(to a

thermostat)

ECONOMY

(to a

thermostat)

0%

(to a dimmer)

OFF

( to actuators)

1 byte

1 byte

B

C

SIMPLY INIMITABLE.

10

12. Temperature sensor Function

The temperature probe allows a reading of the tem-

perature within its range with resolution 0.1 ° C.

KNX PARAMETER

KNX PARAMETER

SETTINGS

SETTINGS

Temperature sensor

calibration

Enable threshold T1

(low)

Temperature sensor

calibration

Enable threshold T2

(high)

Initial value enable

object

Sending interval

Value threshold T1

Value threshold T2

Telegram to send whenT< T1

Telegram to send whenT< T2

Object enable for Trigger

1 and 2

-5,0°C ÷ +5,0°C with

resolution, 0,1°C

0

1

It’s ‘possible to add an oset to the temperature value

measured by the probe before it is sent on the bus or made

available for reading.

You can also enable two thresholds for temperature and, for

each thresholds, send a telegram of attention (of size 1 bit)

whenever the measured temperature exceeds or falls below

the threshold.

For each threshold can be set whether to send the tele-

gram “1” when the measured temperature “T” exceeds the

threshold temperature “Tx” and then send the telegram “0”

when the measured temperature “T” becomes less than the

threshold temperature “Tx“or vice versa.

It’s ‘possible to enable the periodic sending of measured

temperature value, if this option is disabled, reading can be

done only on read-request.

See description of “Enable threshold T1 (low)”.

Allows to initialize enable object as active (1) or inactive (0)

after power on, reset or download.

It’s ‘possible to enable/disable the remote temperature

sensor with a communication object. When this object is

enabled and receives a telegram “1” the temperature probe

is active and sends trigger telegrams according to thresholds

T1 and T2 values; otherwise only temperature value is

periodically sent.

If you enable the periodic sending the sending interval is set

by this parameter.

Disable

Enable

Disable

Enable

Disable

Enable

1 min 30 min

5 min 1 h

10 min 4 h

15 min 12 h

45 min 24 h

-15°C ÷ +55°C

-15°C ÷ +55°C

Telegram “0”

Telegram “1”

Telegram “0”

Telegram “1”

Hide

Show

13. Thermostat Function

14. Target Setpoint Settings

The temperature sensor can be congured as a

thermostat to control the temperature of a room

or area by driving heating or cooling equipment

/ air conditioning fan coils / valves or through

commands on / o to heating /cooling elements

such as radiators, heat pumps, split, etc. ..

• The thermostat operates temperature in

a range from -50 ° C to + 100 ° C with 0.1 ° resolu-

tion.

• Setpoint values sent to the device on the

bus are accepted in a range from 10°C to 50°C

• Setpoint accepted in SETPOINT MODE are

in a range from 10°C to 50 °C

The temperature sensor can be congured as a

thermostat to control the temperature of a room

or area by driving heating or cooling equipment

/ air conditioning fan coils / valves or through

commands on / o to heating /cooling elements

such as radiators, heat pumps, split, etc. ..

• The thermostat operates temperature in

a range from -50 ° C to + 100 ° C with 0.1 ° resolu-

tion.

• Setpoint values sent to the device on the

bus are accepted in a range from 10°C to 50°C

• Setpoint accepted in SETPOINT MODE are

in a range from 10°C to 50 °C

SETPOINT MODE object

When “Thermostat control mode” parameter is

selected with the value SETPOINT MODE, object

HVAC Mode is no longer visible.

Each time the thermostat receives a value on

object SETPOINT MODE ( 2 byte size), it is used as

setpoint for temperature control.

HVAC MODE object (switched heat / cool)

SIMPLY INIMITABLE.

Using the object HVAC MODE (1 byte size), you can set

the thermostat in one of the following modes: OFF;

ECONOMY; STANDBY; COMFORT; each mode is asso-

ciated with a setpoint set by a ETS parameter.

OFF mode is associate to setpoint antifreeze in

heating mode and high temperature protection in

cooling mode.

HVAC MODE object (automatic heat / cool)

Behaviour for this value of parameter “Thermostat

control mode” is the same as above described but

the switching from heating to cooling mode and vice

versa is automatic. With this setting it is necessary to

set an insensitive zone as in parameter “Dead zone”.

Whenever temperature becomes greater than :

Setpoint comfort heating + (Dead Band / 2) active

control is cooling; when temperature becomes less

than: Setpoint comfort cooling - (Dead Band / 2) acti-

ve control is heating. COMFORT object

COMFORT object (1 bit size) is visible only when “Ther-

mostat control mode” parameter is selected with the

value HVAC MODE.

When a telegram“1” is received thermostat goes

in COMFORT mode (it applies for both heating and

cooling)

On receipt of a telegram “0”, thermostat returns to the

mode set by HVAC MODE object.

COMFORT mode can be set also with timing: after

a time set by a parameter thermostat returns in the

previous mode.

WINDOW CONTACT object

This object, if enabled, has higher priority than HVAC MODE,

SETPOINT MODE, COMFORT objects.

When a telegram is received (“0”or “1”) on the communication

object WINDOW CONTACT thermostat enters a power saving

mode:

• BUILDING PROTECTION (if running in HVAC MODE)

• Setpoint antifreeze / high temperature protection (if

running in SETPOINT MODE)

SETPOINT COMFORT object

SETPOINT STANDBY object

SETPOINT ECONOMY object

These 2 byte objects are used to set the setpoint va-

lues for COMFORT, STAND-BY, ECONOMY mode.

Whenever change, the setpoint are in saved in me-

mory.

After download these setpoint are reset to values ac-

cording to ETS parameter; on power up these object

are set according to last values before power down.

• Use these communication objects to change

current setpoint for every HVAC Mode according to

the current active control (heating or cooling)

SETPOINT OBJECTS

Telegram received on:

Comfort Object

Comfort Overwrite Time

Setpoint changed:

Time limited

Time unlimited

1.. 255 (minutes)

COMFORT ( OBJ # 25)

STANDBY ( OBJ # 24)

ECONOMY ( OBJ # 23)

COMFORT ( OBJ # 28)

STANDBY ( OBJ # 27)

ECONOMY ( OBJ # 26)

Setpoint comfort heating

Setpoint comfort heating

Setpoint economy heating

Setpoint comfort cooling

Setpoint standby cooling

Setpoint economy cooling

KNX PARAMETER SETTINGS

11

SIMPLY INIMITABLE.

If the telegram received indicates that the window is

opened thermostat change its mode or setpoint after

1 minute from the reception of the telegram.

When it receive a telegram corresponding to state

“window closed” it restores the previous mode, always

with a delay of 1 minute . The value of SETPOINT

ADJUSTMENT (if enabled) is always restored.

SETPOINT ADJUSTMENT object

The object SETPOINT ADJUSTMENT allows you to

temporarily change the setpoint value used by the

thermostat applying an oset to the current value.

If the thermostat is operating in “HVAC MODE” the

oset value is applied from the time of receipt of a

valid telegram on object SETPOINT ADJUSTMENT until

this value does not change, even in case of change

of the active mode (Comfort and Standby only); this

does not happen with regard to Economy mode and

Building Protection: in this modes the value of object

SETPOINT ADJUSTMENT is forced to 0.

Similarly, if the thermostat is operating in SETPOINT

MODE the oset value is applied also when the

setpoint value received on this object changes.

ADDITIONAL TEMPERATURE object

It is possible to enable the reading of a second exter-

nal probe which sends the measurement data to the

thermostat via the communication object ADDITIO-

NAL TEMPERATURE of size 2 bytes.

KNX PARAMETER SETTINGS

Ratio between internal

and additional sensor

90 % internal–10 %

external

80 % internal–20 %

external

70 % internal–30 %

external

60 % internal–40 %

external

50 % internal–50 %

external

40 % internal–60 %

external

30 % internal–70 %

external

20 % internal–80 %

external

10 % internal–90 %

external

Additional sensor only

This parameter set the“weight” to assign to internal and

additional temperature;

Surveillance time for

additional sensor

10..255 (min)

Whenever the thermostat receive a valid data from additio-

nal temperature sensor it consider this value in the calcula-

tion of the measured temperature and reset the internal time

(monitoring time), if the surveillance time expires without

receiving any valid data thermostat start considering only

the internal probe (at 100%) until it receives a new valid data.

(see paragraph 10“Temperature probe failure / out of range

measurement “)

• If external probe is enabled the monitoring

time is used to check if the additional temperature

sensor periodically sends valid data to the thermostat.

This mechanism avoids to consider as valid some data

which can be old hours or days, for example if the

additional sensor should fail or the thermostat could

not receive data for long time.

• It is strongly recommended to set a value for

surveillance time of the additional sensor more than

twice of the period set for the cyclical sending of the

additional sensor.

• If the external probe is weighted at 100%

(Parameter Ratio between internal and external =

external sensor only) then when the monitoring time

expires the thermostat switch o all controlled loads

until the reception of a valid telegram

ACTUAL SETPOINT object

The ACTUAL SETPOINT object send the setpoint in use

and is sent every time:

• The value of HVAC mode object changes

• The value BASE SETPOINT changes

• The value of SETPOINT ADJUSTMENT object

changes

• After download

• One minute after power on

Control algorithm“2 points on / o” is used to control

heating or cooling elements that can be controlled by

switching on and o of the same elements, radiators,

underoor heating with on-o valves, boilers, etc. ..

When the thermostat switches to“winter mode”

(heat mode) sends a o command on object ON/OFF

COOLING and operates the control only through the

object ON/OFF HEATING (the object ON/OFF COO-

LING is therefore not updated anymore until it returns

in “cooling mode”).

Therefore in the transition from“ winter” to “summer”

mode sends a o command on ON/OFF HEATING

commands and activates the control through the

object ON/OFF COOLING.

15. Two points on/o

12

SIMPLY INIMITABLE. 13

13

on/o control in heating mode:

On/o with PWM control is an algorithm that reduces

the eects of hysteresis around the set point value

by adjusting the controls on the values ranging from

0% to 100% where 0% means“control o”and 100%

means “maximum control action”.

Once a cycle time is dened the thermostat sets the

actuator to ON for a fraction of the cycle time and OFF

for the remaining part. Driving the actuator with the

control value of 80% means that it is active (i.e., ON)

for 80% of cycle time and OFF for the remaining 20%.

16. On/o with PWM control

KNX PARAMETER SETTINGS

Cycle time (TCp)

Proportional band (Bp)

10, 20, 30, 60 min

It denes the time interval.

The proportional band BP is a range of temperatures

between “Setpoint” and “Setpoint-Bp” in heating mode and

between “Setpoint” and “Setpoint+Bp” in cooling mode, wi-

thin this interval thermostat controls the temperature using

the proportional algorithm; outside It drives actuator always

in ON or OFF.

When temperature is inside this range device wait the end of

the cycle time before calculating the duty cycle of the next

cycle.

When temperature is outside of this range : below “Setpoint-

Bp”in heating mode or above “Setpoint+Bp”in cooling mode

it starts a new cycle as soon as temperature enters the Bp

0.8, 1.2, 1.6, 2.0 °C

SIMPLY INIMITABLE. 14

14

PWM control in heating mode: Control logic for a 3 speed fan coil in heating:

When temperature increasing

Fan coil is a device that controls the ow of cooling /

heating liquid driving a valve (2-pipe fan coil) or two

valves (4-pipe fan coil).

Liquid exchanges heat/cool with the environment

through a ventilation system controlled by a fan. The

fan is driven by an engine that typically has 3 windin-

gs that can be enabled at 3 distinct speeds.

Where:

Tsp : Target setpoint temperature

Tdrv1 : regulation dierential in heating for V1 Speed

Tdrv2 : regulation dierential in heating for V2 Speed

Tm : Actual measured temperature

17. Fan coil on/o

SIMPLY INIMITABLE. 15

15

Control logic for a 3 speed fan coil in cooling:

When temperature decreasing

Where:

Tsp : Target setpoint temperature

Tdcv1 : regulation dierential in cooling for V1 Speed

Tdcv2 : regulation dierential in cooling for V2 Speed

Tm : Actual measured temperature

18. Fan coil control %

(or generic continuous control)

19. Temperature probe failure / out of

range measurement

Logic and parameters are the same used in On/o

with PWM control mode; the dierence is that now

the proportional value is sent to the bus via a 1 byte

object format as a % value from 0% to 100%.

This mode is useful to control fan coils (selecting 2

or 4 pipes) or generic proportional actuators as valve

drivers only linking the 1 byte communication object

and avoiding to link the valve objects.

CONTINUOUS CONTROL object

This 1 Byte object send % control value to actuator.

SET MAN/AUTO MODE object

SET MAN/AUTO MODE Objects is a CO for changing

the calculation mode for CONTINUOUS CONTROL

object; in AUTO Mode the calculation is carried out

via a proportional algorithm (Δ temperature between

actual temp. and Setpoint Temp) and a integral cor-

rection (Cycle Time ); in MAN mode the output value

control is set by the value send to the object FORCE

VALUE IN MANUAL MODE object.

• If the temperature probe is disconnected or

in short circuit the control action is interrupted and

the controlled actuators are switched o.

• The value of temperature sent on the bus in

case of probe disconnection or short circuit or for out

of range measured value is 0 °C (according to KNX

DPT_Value_Temp 9.001)

TEMPERATURE SENSOR ALARM object

In event of temperature probe failure / out of range

measurement a telegram from 1 bit communication

object - obj #33: “Temperature sensor alarm” - is sent

on the bus with value 1. As soon the temperature sen-

sor works good again a value “0” is transmitted.

To correctly manage the use of internal and/or addi-

tional refers to the following possible conguration

modes:

• If the temperature probe is disconnected or

• The value of temperature sent on the bus in

SIMPLY INIMITABLE.

CONFIGURATION MODE 1 CONFIGURATION MODE 3

CONFIGURATION MODE 2

Internal probe Internal probe

Internal probe

Additional probe Additional probe

Additional probe

Ratio between probes Ratio between probes

Ratio between probes

Used Not used

Used

Disabled Connected or by bus

Received by bus

NA. (100% internal) 100% external

10 % to 90%

Measure of temperature is performed every 60 seconds; if

the temperature probe is disconnected or in short circuit the

control action is interrupted and the controlled actuators are

switched o.

probe disconnection / short circuit / out of range measure-

ment:

Obj #15 “Actual temperature”transmits 0 °C

Obj #33 “Temperature sensor alarm transmits “1”

If the additional temperature is out of range or the surveil-

lance time expires without any message received, thermostat

stops the control action and the controlled actuators are

switched o.

If internal probe is anyway connected (but not used until ad-

ditional probe is working good) then in event of failure of the

additional probe the internal probe is used (see behaviour of

conguration mode 1).

When additional probe begin to measure a “in-range”value

thermostat start again its control action and return to consi-

der the additional probe.

Measure of internal temperature is performed every 60 se-

conds; the additional temperature is read every 60 conside-

ring last value received on Obj #16“Additional temperature”.

The value of temperature sent on the bus is the pounded

average between internal and additional probes value.

If the additional temperature is out of range or the surveil-

lance time expires without any message received, thermostat

start considering only the internal probe until it receives a

new valid value from the additional probe; in this case the

additional value is taken in count again.

Anyway, if the internal temperature is out of range or probe

is disconnected / short circuit then the control action is inter-

rupted and the controlled actuators are switched o:

Obj #15 “Actual temperature”transmits 0 °C regardless the

value received from additional sensor.

Obj #33 “Temperature sensor alarm transmits “1”

When internal probe starts again to measure a“in-range”

value thermostat start again its control action.

16

SIMPLY INIMITABLE.

20. Behavior of Thermostat on voltage failure,

recovery and commissioning.

21. Control Panel

Behavior on bus voltage failure

On failure of bus voltage no actions are executed by

the device; behavior of controlled actuators must be

set using their own parameters.

Behavior on bus voltage recovery

On bus voltage recovery all the communication

objects are set to 0 except for objects for which a

parameter is dened for the initial value.

Thermostat keeps these values in memory and restore

them after recovery:

• Heat / Cool mode (if enabled)

• HVAC Mode (if enabled)

• Base Setpoint (if enabled)

• Force value in manual mode (if enabled)

Control values (i.e. commands to actuators) are cal-

culated on the base of actual setpoint and measured

temperature.

• After power on device recalculates the com-

mands to actuators and switch them on, if necessary,

otherwise does not carry out any action; you are

recommended to set the behavior of actuator in order

to switch the heating / cooling equipment o after

bus power on.

Behaviour on commissioning (ETS Download)

After download it is possible to set initial value of:

• Heat / Cool mode (if enabled)

• HVAC Mode (if enabled)

For other communications objects the behavior is

identical to bus voltage recovery.

Wrong application download

If the wrong ETS application is downloaded then KNX/

EIB led starts blinking and device is not operative on

the bus. A power reset must be done and the correct

ETS application must be downloaded.

The operator panel mode is used when the device

behaves as a user interface while the temperature

control function is delegated to another device or to

a subsystem that communicates with the operator

panel via the KNX bus

Communication object what can be written on the

KNX bus (can be used all or some):

• Temperature Alarm

• Actual Temperature

• Actual Setpoint

In this Mode the three capacitive buttons continue to

work normally. [1]

[1]: functions freely congurable can be used to

manage the type HVAC controls, the speed of the fan

coil, or various commands such as ECO; DND, MUR,

OFF; etc ..

Communication object what can be read on the KNX

bus (can be used all or some):

• Actual Temperature (from another KNX devi-

ce)

• Setpoint Adjustment (1 bit or 1 byte object

that permits the adjustment “-“/”+” of the sepoint)

• After power on device recalculates the com-

17

follow Vitrum

THINK SIMPLE S.r.l.

SEDE AMMINISTRATIVA E OPERATIVA

Viale Lino Zanussi, 3

33170 Pordenone IT

T+39 0434 516216

F+39 0434 516230

SEDE LEGALE E COMMERCIALE

Corso Garibaldi, 86

20121 Milano IT

T+39 02 65560029

F+39 02 45498295

info@thinksimple.it

vitrum.com

vitrumsense.com

Table of contents

Popular Temperature Controllers manuals by other brands

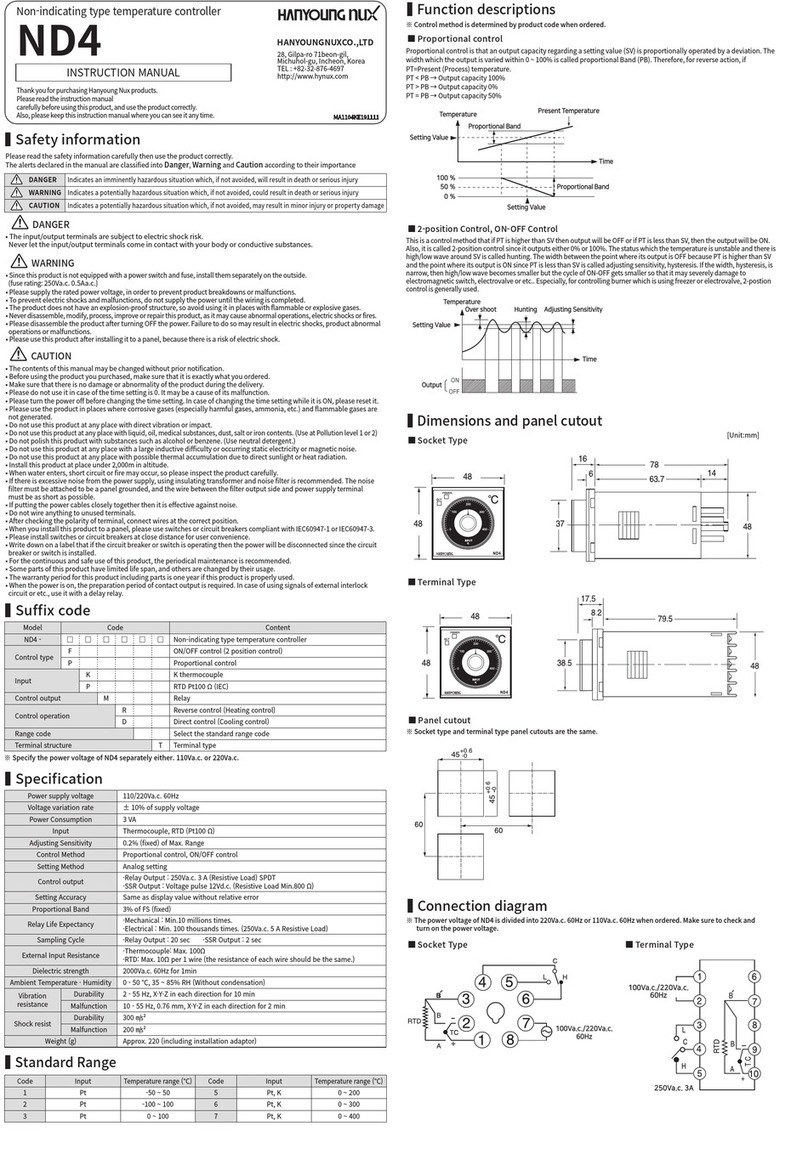

HANYOUNG NUX

HANYOUNG NUX ND4 instruction manual

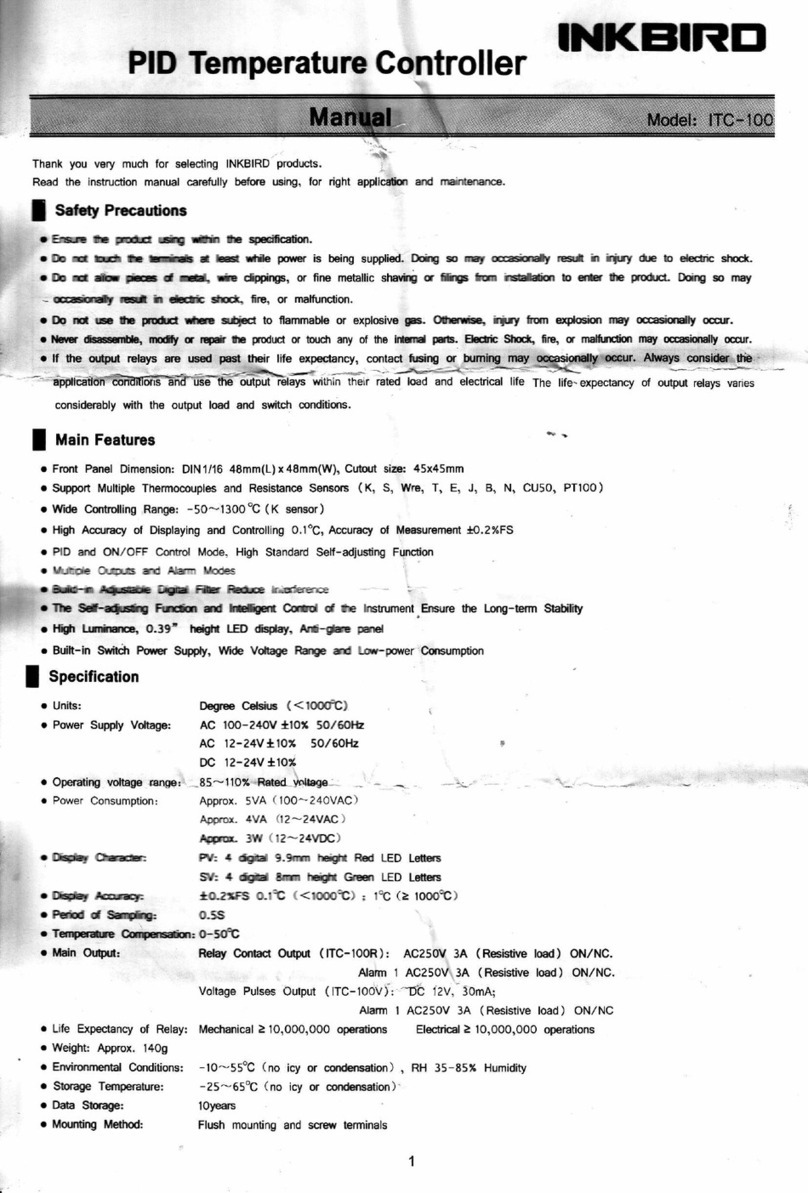

Ink Bird

Ink Bird ITC-100 manual

thermastor

thermastor Ultra Aire DEH 3000 Installer's and owner's manual

Delta

Delta DTE10T Series instruction sheet

elsner elektronik

elsner elektronik KNX T-AP Installation and adjustment

Delta

Delta DTE Series instruction sheet