307456 7

Service

NOTE: Repair Kit 214584 is available. For best results,

use all the new parts in the kit, even if the old parts

look good. Parts included in the kit are marked with a

dagger, for example (6†), in the text and illustrations.

Air Piston and Lower Spring Service

WARNING

To reduce the risk of injury from trapped air pres-

sure when servicing the air motor, always remove

air cap (7) from air cylinder (8) before removing air

cylinder from base (22).

1. Unscrew the cylinder cap (7) from the cylinder (8).

To remove the spring (5), pry gently under the coils

in the direction of the helix.

2. Unscrew the cylinder (8) from the base (22) and lift

the cylinder off the air piston (11). Using a pliers

(B) on the air exhaust plate (16) and a wrench (C)

on the piston shaft (23), unscrew the piston from

the shaft. See Fig. 2.

CAUTION

Ketone fumes may damage the piston o-rings. When

pumping ketones (such as acetone, MEK, etc.), use

Conversion Kit 221038. This kit replaces the stan-

dard fluoroelastomer o-rings with EPDM o-rings

which are resistant to ketones.

3. Disassemble the piston and wash all parts in

compatible solvent. Refer to the parts list on

page 9. Blow parts dry and inspect for wear or

damage. If any of the valve plate spacers (13) are

damaged, replace all three to maintain proper

clearance between the valve plates and the seats.

4. Remove and inspect the lower spring (20). Re-

place if necessary, and reinstall.

5. A decrease in performance accompanied by a

slower than normal cycle rate is commonly caused

by icing. It is recommended that the pump is shut

down, and the ice is allowed to thaw.

6. Reassemble the air piston (11), using new parts as

needed. Apply a good grade of thread sealant to

the threads of the screws (12). and torque evenly

to 1.1–1.6 NSm (10–14 in-lb). With the washer (4)

in place, apply thread sealant to the threads of the

piston. Carefully screw the piston (11) onto the

shaft (23) by hand so it is securely fastened. Do

not use pliers on the air exhaust plate while tight-

ening. When installed, there should be 0.8 mm

(0.032 in.) minimum clearance between the wash-

er (4) and the piston shaft shoulder. See Fig. 2.

Packing Replacement

1. Unscrew the cylinder cap (7) from the cylinder (8).

To remove the spring (5), pry gently under the coils

in the direction of the helix.

2. Unscrew the cylinder (8) from the base (22) and lift

the cylinder off the air piston (11). Disconnect the

piston shaft (23) from the pump connecting rod

and pull the shaft up out of the air motor base.

Remove and inspect the packing (9†), being

careful not to mar the inner lip. See Fig. 2.

NOTE: Fluoroelastomer packing 111383 is available as

an accessory, for use with solvents not compatible with

the standard nitrile rubber packing.

3. Replace the packing and reassemble the air motor

in the reverse order of disassembly.

Upper Spring Replacement

Unscrew the cylinder cap (7) from the cylinder (8). To

remove the spring (5), pry gently under the coils in the

direction of the helix.

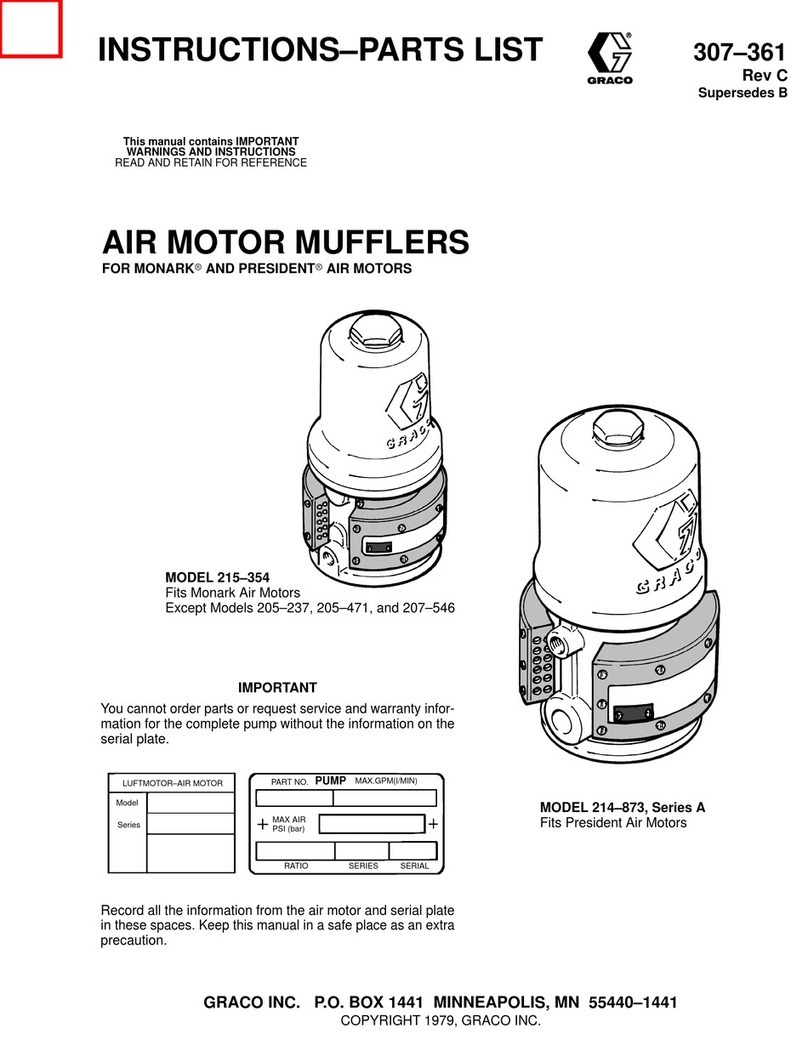

Cleaning the Muffler

To clean the muffler (26), remove it from the unit and

soak it in mineral spirits, then blow dry with air to

remove excess solvent.