5

Fläkt Woods 9191 GB 2015.09.24 Specifications are subject to alteration without notice

Installation and maintenance instructions

Fläkt Woods PM-Motor

With suPPlied FC 102 FrequenCy Converter

[Status]

indicates the status of the frequency converter and/or the motor.

3 different readouts can be chosen by pressing the [Status] key:

5 line readouts, 4 line readouts or Smart Logic Control.

Use [Status] for selecting the mode of display or for changing

back to Display mode from either the Quick Menu mode, the Main

Menu mode or Alarm mode. Also use the [Status] key to toggle

single or double read-out mode.

[Quick Menu]

allows quick set-up of the frequency converter. The most com-

mon VLT HVAC Drive functions can be programmed here.

The [Quick Menu] consists of:

• My Personal Menu

• Quick Set-up

• Function Set-up

• Changes Made

• Loggings

The Function set-up provides quick and easy access to all

parameters required for the majority of VLT HVAC Amongst

other features it also includes parameters for selecting which

variables to display on the LCP, digital preset speeds, scaling

of analog references, closed loop single zone and multizone

applications and specific functions related to Fans, etc.

The Quick Menu parameters can be accessed immediately

unless a password has been created via par. 0-60 Main Menu

Password, par. 0-61 Access to Main Menu w/o Password,

par. 0-65 Personal Menu Password or par. 0-66 Access to

Personal Menu w/o Password.

It is possible to switch directly between Quick Menu mode

and Main Menu mode.

[Main Menu]

is used for programming all parameters. The Main Menu para-

meters can be accessed immediately unless a password has

been created via par. 0-60 Main Menu Password, par. 0-61

Access to Main Menu w/o Password, par. 0-65 Personal Menu

assword or par. 0-66 Access to Personal Menu w/o Password.

For the majority of VLT HVAC Drive applications it is not neces-

sary to access the Main Menu parameters but instead the Quick

Menu, Quick Set-up and Function Set-up provides the simplest

and quickest access to the typical required parameters. It is

possible to switch directly between Main Menu mode

and Quick Menu mode.

Parameter shortcut can be carried out by pressing down

the [Main Menu] key for 3 seconds. The parameter shortcut

allows direct access to any parameter.

[Alarm Log]

displays an Alarm list of the ten latest alarms (numbered

A1-A10). To obtain additional details about an alarm, use the

arrow keys to manoeuvre to the alarm number and press [OK].

Information is displayed about the condition of the frequency

converter before it enters the alarm mode.

The Alarm log button on the LCP allows access to both

Alarm log and Maintenance log.

[Back]

reverts to the previous step or layer in the navigation structure.

[Cancel]

last change or command will be cancelled as long as the

display has not been changed.

[Info]

displays information about a command, parameter, or function

in any display window. [Info] provides detailed information

when needed.

Exit Info mode by pressing either [Info],[Back], or [Cancel].

Navigation Keys

The four navigation arrows are used to navigate between the

different choices available in [Quick Menu], [Main Menu] and

[Alarm Log].

Use the keys to move the cursor.

[OK] is used for choosing a parameter marked by the cursor

and for enabling the change of a parameter.

Operation Keys for local control are found at the bottom

of the control panel.

• Yellow LED/Warn.: Indicates a warning.

• Flashing Red LED/Alarm: Indicates an alarm.

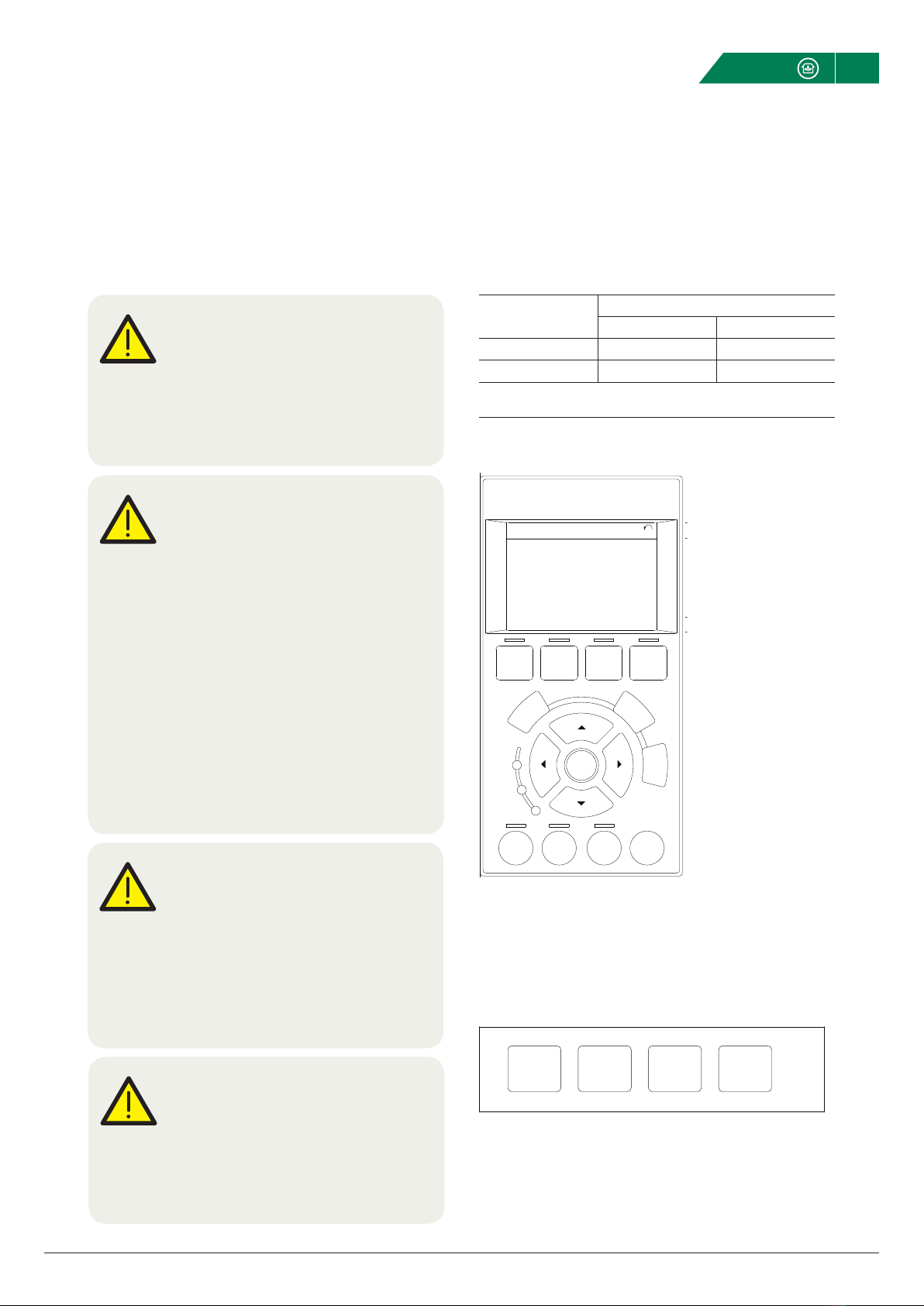

Menu keys

The menu keys are divided into functions. The keys below the display

and indicator lamps are used for parameter set-up, including choice of

display indication during normal operation.

130BP045.10

Status Quick

Menu

Main

Menu

Alarm

Log

[Status]

indicates the status of the frequency converter and/or the motor. 3 dif-

ferent readouts can be chosen by pressing the [Status] key:

5 line readouts, 4 line readouts or Smart Logic Control.

Use [Status] for selecting the mode of display or for changing back to

Display mode from either the Quick Menu mode, the Main Menu mode

or Alarm mode. Also use the [Status] key to toggle single or double

read-out mode.

[Quick Menu]

allows quick set-up of the frequency converter. The most common

VLT HVAC Drive functions can be programmed here.

The [Quick Menu] consists of:

- My Personal Menu

- Quick Set-up

- Function Set-up

- Changes Made

- Loggings

The Function set-up provides quick and easy access to all parameters

required for the majority of VLT HVAC Drive applications including most

VAV and CAV supply and return fans, cooling tower fans, Primary, Sec-

ondary and Condenser Water Pumps and other pump, fan and com-

pressor applications. Amongst other features it also includes parame-

ters for selecting which variables to display on the LCP, digital preset

speeds, scaling of analog references, closed loop single zone and multi-

zone applications and specific functions related to Fans, Pumps and

Compressors.

The Quick Menu parameters can be accessed immediately unless a

password has been created via par. 0-60

Main Menu Password

,

par. 0-61

Access to Main Menu w/o Password

, par. 0-65

Personal Menu

Password

or par. 0-66

Access to Personal Menu w/o Password

.

It is possible to switch directly between Quick Menu mode and Main

Menu mode.

[Main Menu]

is used for programming all parameters. The Main Menu parameters

can be accessed immediately unless a password has been created via

par. 0-60

Main Menu Password

, par. 0-61

Access to Main Menu w/o

Password

, par. 0-65

Personal Menu Password

or par. 0-66

Access to

Personal Menu w/o Password

. For the majority of VLT HVAC Drive ap-

plications it is not necessary to access the Main Menu parameters but

instead the Quick Menu, Quick Set-up and Function Set-up provides the

simplest and quickest access to the typical required parameters.

It is possible to switch directly between Main Menu mode and Quick

Menu mode.

Parameter shortcut can be carried out by pressing down the [Main

Menu] key for 3 seconds. The parameter shortcut allows direct access

to any parameter.

[Alarm Log]

displays an Alarm list of the ten latest alarms (numbered A1-A10). To

obtain additional details about an alarm, use the arrow keys to ma-

noeuvre to the alarm number and press [OK]. Information is displayed

about the condition of the frequency converter before it enters the

alarm mode.

The Alarm log button on the LCP allows access to both Alarm log and

Maintenance log.

[Back]

reverts to the previous step or layer in the navigation structure.

[Cancel]

last change or command will be cancelled as long as the display has

not been changed.

[Info]

displays information about a command, parameter, or function in any

display window. [Info] provides detailed information when needed.

Exit Info mode by pressing either [Info], [Back], or [Cancel].

B

a

c

k

C

a

n

c

e

l

I

n

f

o

Navigation Keys

The four navigation arrows are used to navigate between the different

choices available in [Quick Menu], [Main Menu] and [Alarm Log].

Use the keys to move the cursor.

[OK] is used for choosing a parameter marked by the cursor and for

enabling the change of a parameter.

VLT HVAC Drive High Power Operating In-

structions 5 How to Operate the Frequency Converter

MG.11.F3.02 - VLT® is a registered Danfoss trademark 85

5

OK

Back

ofnI

Warm

Alarm

On

Cancel

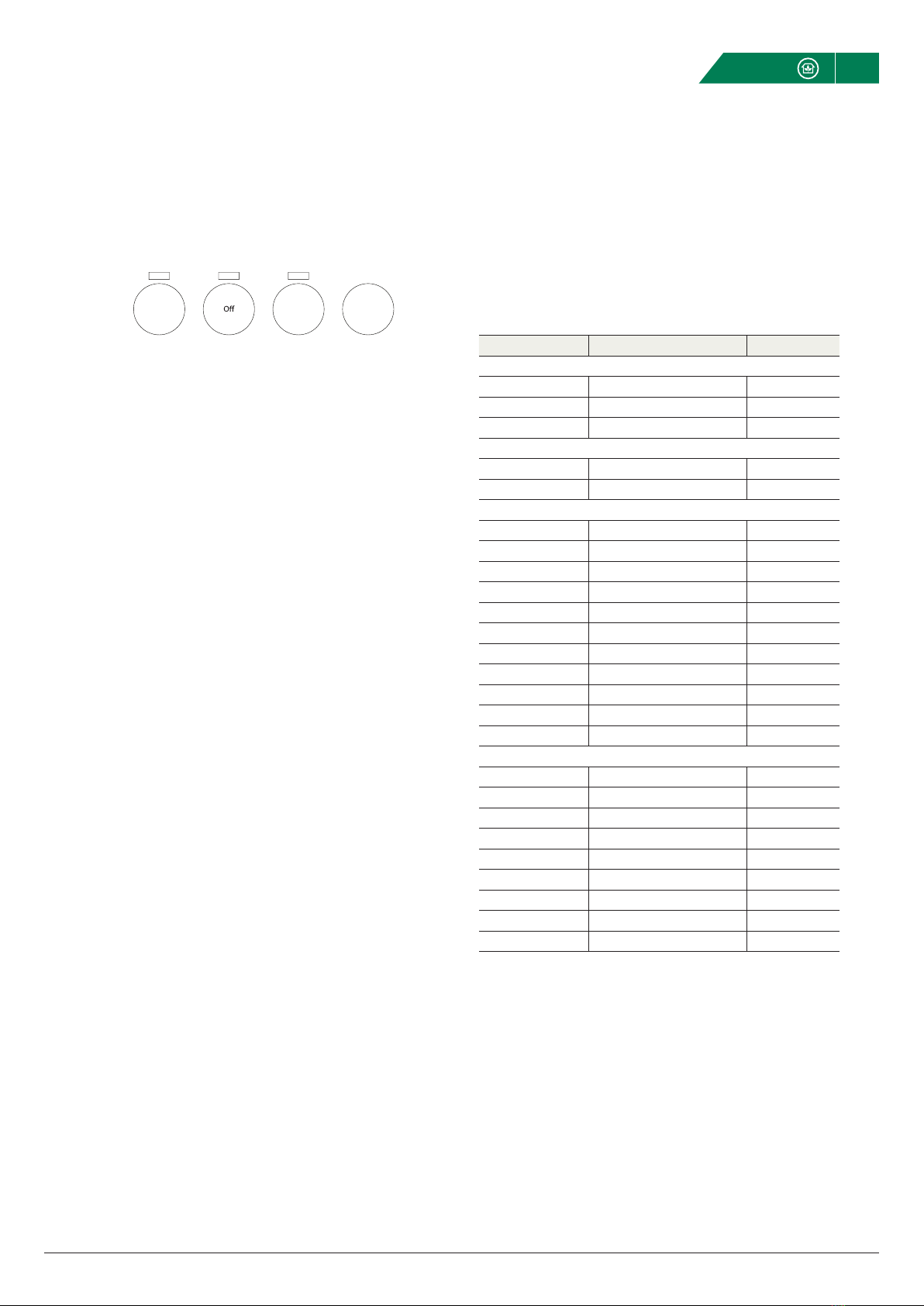

Operation Keys for local control are found at the bottom of the con-

trol panel.

Hand

on

Auto

on Reset

[Hand On]

enables control of the frequency converter via the GLCP. [Hand On] al-

so starts the motor, and it is now possible to enter the motor speed da-

ta by means of the arrow keys. The key can be selected as

Enable

[1]

or

Disable

[0] via par. 0-40

[Hand on] Key on LCP

.

The following control signals will still be active when [Hand On] is acti-

vated:

•[Hand on] - [Off] - [Auto on]

•Reset

•Coasting stop inverse

•Reversing

•Set-up select lsb - Set-up select msb

•Stop command from serial communication

•Quick stop

•DC brake

NB!

External stop signals activated by means of control

signals or a serial bus will override a “start” com-

mand via the LCP.

[Off]

stops the connected motor. The key can be selected as Enabled [1] or

Disabled [0] via par. 0-41

[Off] Key on LCP

. If no external stop function

is selected and the [Off] key is inactive the motor can only be stopped

by disconnecting the mains supply.

[Auto on]

enables the frequency converter to be controlled via the control termi-

nals and/or serial communication. When a start signal is applied on the

control terminals and/or the bus, the frequency converter will start. The

key can be selected as Enabled [1] or Disabled [0] via par. 0-42

[Auto

on] Key on LCP

.

NB!

An active HAND-OFF-AUTO signal via the digital in-

puts has higher priority than the control keys [Hand

on] – [Auto on].

[Reset]

is used for resetting the frequency converter after an alarm (trip). It

can be selected as

Enable

[1] or

Disable

[0] via par. 0-43

[Reset] Key

on LCP

.

The parameter shortcut can be carried out by holding down the [Main

Menu] key for 3 seconds. The parameter shortcut allows direct access

to any parameter.

5.1.3 RS-485 Bus Connection

One or more frequency converters can be connected to a controller (or

master) using the RS-485 standard interface. Terminal 68 is connected

to the P signal (TX+, RX+), while terminal 69 is connected to the N sig-

nal (TX-,RX-).

If more than one frequency converter is connected to a master, use

parallel connections.

130BA060.11

68 69 68 69 68 69

RS 485

RS 232

USB

+

-

Illustration 5.1: Connection example.

5 How to Operate the Frequency Converter

VLT HVAC Drive High Power Operating In-

structions

86 MG.11.F3.02 - VLT®is a registered Danfoss trademark