Vivo Link VL120018 User manual

VL120018

Programmable Control Panel

User Manual

Programmable Control Panel

Preface

Read this user manual carefully before using this product. Pictures shown in this

manual is for reference only, different model and specifications are subject to real

product.

This manual is only for operation instruction only, not for any maintenance usage.

Trademarks

Mentioned product model and logo are trademarks. Any other trademarks mentioned in

this manual are acknowledged as the properties of the trademark owner. No part of this

publication may be copied or reproduced without prior written consent.

FCC Statement

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. It has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a commercial

installation.

Operation of this equipment in a residential area is likely to cause interference, in which

case the user at their own expense will be required to take whatever measures may be

necessary to correct the interference

Any changes or modifications not expressly approved by the manufacture would void

the user’s authority to operate the equipment.

Programmable Control Panel

SAFETY PRECAUTIONS

To insure the best from the product, please read all instructions carefully before using

the device. Save this manual for further reference.

Unpack the equipment carefully and save the original box and packing material for

possible future shipment

Follow basic safety precautions to reduce the risk of fire, electrical shock and injury

to persons.

Do not dismantle the housing or modify the module. It may result in electrical shock

or burn.

Using supplies or parts not meeting the products’ specifications may cause

damage, deterioration or malfunction.

Refer all servicing to qualified service personnel.

To prevent fire or shock hazard, do not expose the unit to rain, moisture or install

this product near water.

Do not put any heavy items on the extension cable in case of extrusion.

Do not remove the housing of the device as opening or removing housing may

expose you to dangerous voltage or other hazards.

Install the device in a place with fine ventilation to avoid damage caused by

overheat.

Keep the module away from liquids.

Spillage into the housing may result in fire, electrical shock, or equipment damage.

If an object or liquid falls or spills on to the housing, unplug the module immediately.

Do not twist or pull by force ends of the optical cable. It can cause malfunction.

Do not use liquid or aerosol cleaners to clean this unit. Always unplug the power to

the device before cleaning.

Unplug the power cord when left unused for a long period of time.

Information on disposal for scrapped devices: do not burn or mix with general

household waste, please treat them as normal electrical wastes.

Programmable Control Panel

Table of Contents

1. Introduction..............................................................................................2

1.1 Introduction to the VL120018.........................................................2

1.2 Features.........................................................................................2

1.3 Package List................................................................................... 2

1.4 Installation...................................................................................... 2

2. Panel Descriptions .................................................................................. 3

2.1 Front Panel..................................................................................... 3

2.2 Side Panel......................................................................................4

2.3 Rear Panel..................................................................................... 5

3. Connections ............................................................................................6

3.1 System Diagram.............................................................................6

3.2 Connection of Programming and Looping......................................6

4. System Operations.................................................................................. 8

4.1 USB Driver Installation...................................................................8

4.2 Software Programming...................................................................8

4.2.1 Main Menu ...........................................................................9

Panel/Key setting.........................................................................11

Action list..................................................................................... 13

Event setting............................................................................... 14

Event List.................................................................................... 21

5. Specification.......................................................................................... 23

6. Panel Drawing....................................................................................... 23

7. Troubleshooting & Maintenance............................................................ 24

8. After-sales Service ................................................................................ 25

Programmable Control Panel

2

1. Introduction

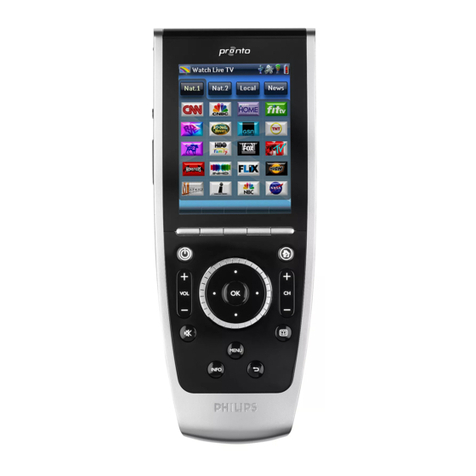

1.1 Introduction to the VL120018

VL120018 panel is a Wall Control Panel. Every button is programmable and works

either individually or together. VL120018 is built in the programmable 3 RS232, 1

RS485, 3 Infrared & 2 Relay, and 1 mini USB for programming.

Please notice, RS232 (1) and IR2 share the same port, cannot be used at the same

time. Also, RS232 (2) and IR3 share the same port, cannot be used at the same time.

It can fully control our product, as well as third party devices such as projectors,

screens etc. It is an easy-to-use control device for presentation show rooms,

classrooms and boardrooms.

1.2 Features

Every button can be programmed to send the bi-direction RS232 and RS485

commands simultaneously to control third party devices.

Every button can be programmed to send the infrared code, control the relay, to let

them work simultaneously to control the third party devices.

Every button is built in the infrared code and RS232 code learning function, and

baud-rate setting.

ID looping function. 99pcs programmable control panels can be looped and

controlled together, by ID identifying.

Programmed by USB or RS232, working with the PC software (PS-WP).

Crystal and backlit buttons with easy user-friendly customizable changeable labels.

The backlit brightness is controllable.

Dimension: 11.4cm long and 7cm wide.

1.3 Package List

1 x VL120018

1 x Power adapter (DC 12V)

4 x Captive screw connector

3 x IR emit probe

1 x Button labels

1 x User Manual

Notes:Please confirm if the product and the accessories are all included, if not,

please contact with the dealers.

1.4 Installation

Follow the steps to install the device:

Programmable Control Panel

3

Firstly, dig a hole on the desk to the size marked on the aperture paper (shown in

Figure 1-1).

Secondly, put the device into the hole and adjust it to flush with the table (shown in

Figure 1-2).

Then, plug a set screw into the fixing mounting and screw the nuts tightly.

Figure 1- 1 Aperture paper

Figure 1- 2 Installation Guide

2. Panel Descriptions

2.1 Front Panel

Crystal and luminescent, programmable buttons:

Every button can be programmable with the software PS-WP.

Connect the PC via USB or RS232.

And every label inside the button can be changeable. You can choose the label you

need and change it very easily like below:

(For the specific transparent paper table, please contact the local distributor or reseller

Programmable Control Panel

4

for it)

2.2 Side Panel

Note: When use this USB port to program the control panel’s buttons, the

available COM port number should not be more than 10.

Mini USB Connector:

1.

Communicate with PC

which uses PS-WP to

program the buttons.

2. Transmit the infrared

data when learning IR

(Optional).

Infrared sensor port:

receive and learn the IR

code, to build the IR

database.

Programmable Control Panel

5

2.3 Rear Panel

VL120018 has various ports in the rear panel, including Lopping port, RS232 port,

RS485 port, IR port, Relay port and Power port. Below is the introduction:

①Power connector: 12VDC. Be sure that the “+” and “-” never be mixed or

wrong connection.

②Low-Voltage relay ports: set the relay on/off by software PS-WP.

③This port includes: RS232 (1)/IR2, IR1 and RS485.

a) RS232 (1)/IR2: share the same port, the detailed use depends on the setting of

PS-WP. When be used as RS232, it is unidirectional transmission, transmit data

but without receive.

b) IR1: for control other devices, it can be programmable by the PS-WP.

c) RS485: the RS485 can be programmed as different commands and control the

device with RS485 port. The command of RS485 is the same as RS232 (1).

④This port includes two parts:

One part is RS232 (2)/IR3, it can be used for control other devices or looping output.

RS232 (2) and IR3 share the same port, the detailed use depends on the setting of

PS-WP.

Other part is RS232 (3), it can be used for control other devices or looping output,

or connect with PC.

These two parts share the same grounding.

①

④

③

②

Programmable Control Panel

6

3. Connections

3.1 System Diagram

VL120018 can active different ports at one time. It means every button can send the

RS232 and RS485 commands, IR code and control the relay at the same time. The

demo system diagram as below:

3.2 Connection of Programming and Looping

VL120018 can be connected to the computer for programming, to default the functions

of every button. It can be connected by USB or RS232, working with the PS-WP

software. It is shown as below:

Programmable Control Panel

7

Programming Connection

Several pieces programmable control panels can be also looped to be a system, for

control more devices. It is looped by the inter RS232 setting. Please check the demo

picture as below:

Several programmable control panels Looping connecting

After connect the programmable control panels as above, and then we should set the

ID of each programmable control panel by PS-WP. The ID number is from 01 to 99, and

it also is the class of VL120018 in the loop, different programmable control panels

should set to different ID. After connections finish, we can set the control modes by PS-

WP. For detailed connecting, please check the picture below:

Programmable Control Panel

8

Detailed looping connecting

Note: Up to 99 programmable control panels can be looped within one system.

However, to achieve normal interaction, loop less programmable control panels (10

tops) in the system.

4. System Operations

4.1 USB Driver Installation

There are USB driver file and PS-WP software in the disk. The PS-WP can run directly

without installation.

But when connect VL120018 with PC by USB, it may need to install the USB driver.

Use the driver file to install the driver of USB, we can use USB to program the

programmable control panel.

4.2 Software Programming

You can use this software PS-WP to easily set every button of the programmable

control panel.

After connect VL120018 with PC by USB or RS232, we can open the PS-WP to

program the buttons for controlling.

The main window of PS-WP has five parts: main menu, panel (button) setting, event

setting, action list and event list. In this manual we will take programmable control

panels-V for example, to show the uses of all functions.

The main window of PS-WP is as below:

First class

Second class

Last class …

Programmable Control Panel

9

We will introduce all the configurations one by one.

4.2.1 Main Menu

The main menu includes file management, system model, connection type and help.

1) File management: Open/Save/Save as a configuration. After program, user can

save the configuration to a file, so that you can use the same configuration next

time.

2) System model: includes programmable control panels-H, programmable control

panels-V, WP19R etc, and the buttons interface view are different with different

models. The pictures below show the differences between programmable control

panels-V and programmable control panels-H.

Programmable Control Panel

10

NOTICE: When select the model, it will pop up “Output Port Selection” dialog, user can

select different RS and IR types, depend on the uses of the two shared ports. The

dialog is as the picture below:

The output port set in PS-WP and the port used in VL120018 is corresponding.And

there are four output types. They are showed as below form (“√” means port is

available):

Output port of

the Panel

Output mode

of PS-WP

IR1

RS232(1)

IR2

RS232(2)

IR3

RS232(3)

RS485

RS232(1)(2)

√

√

√

√

√

RS232(2),IR2

√

√

√

√

RS232(1),IR3

√

√

√

√

√

IR2,3

√

√

√

√

Programmable Control Panel

11

3) Connection type: the instructions are in the picture below:

The functions of the programmable control panel’s buttons will be available only

after the programmed data is uploading successfully.

4) Help: Show the information of PS-WP.

Panel/Key setting

There are three different colors of keys in the panel set of PS-WP. Add a key action to

action list, then add events to this action, make this action will execute the events. Here

take programmable control panels-V for example, to introduce the uses of different

buttons:

1. White keys: keys 1-8, correspond to the buttons on the programmable control panel.

Click the key, it will pop up dialog as below:

1:Com, connect by serial port.

2:USB, connect by mini USB.

3:Disconnect, disconnect the

connection.

4:Upload: upload the

programmed data to the

programmable control panel. It

will clear all the old data in the

programmable control panel.

5:Clear, clear the data in the

programmable control panel.

Programmable Control Panel

12

When select the type “Toggle”, the setting interface is as below:

The toggle class is the action loop class, depends on the numbers of looped

actions. When the class is 2, there are two actions in the toggle. And so on.

2. Blue Keys: Keys 9-32, all are virtual keys, used in the loop function. When use the

loop function, the ID must be set, the ID can be 1 to 99. Press “add”will add the

Key Action Type:

1. Press: Execute events

when press button.

2. Release: Execute events

when release button.

3. Page: Built-in most 4

actions, actions need to

be switched by other

buttons, press to execute.

4. Toggle: Built-in most 4

actions, actions will loop

run when press. Actions

can also be switched by

other buttons, press to

execute.

Programmable Control Panel

13

button to action list.

3. Yellow Keys: Keys 33-36, all are virtual keys. Key 33 and 34 are for I/O control, which

is not supported with VL120018. Key 36 is a start action, if add events to this action,

when VL120018 is power on, it will execute the events in this action. Key 35 is delay

button, there are three time slots can be set. See in the picture below:

The time is counted from VL120018 start. When come to time1, VL120018 will execute

the events in time1. Then recount from time2, and then time3.

Example: Set time1 to 5 minutes, and time2 to 3 minutes, add event1 to time1 and

event2 to time2. When the unit starts, it will execute event1 after 5 minutes, and then

execute event2 after 8 minutes.

Action list

Action list shows all the set actions. An available action must be added to the list. The

action list is as the picture below:

Delete a

selected action.

Refresh, delete all the

actions that with no event.

Delete all actions.

Programmable Control Panel

14

Event setting

Event setting includes RS232, IR, I/O, Relay, Delay, Compare, LED, Page, Loop and

Toggle setting. Before set events, an action must be added first. The following

introduction will show you the setting of each event:

RS232 Setting

This item is used for setting the parameters of the programmable control panel’s serial

ports. Click “RS232”, it will show as below:

1) The data of RS232 can be directly entered or selected from library. Click “Change Lib”

to select a library file and open it. Click “Edit Lib”to create or edit a library file as

below:

Notice: When editing finish, remember to save the editing, and then press “OK”.

Send

Type

Send

Port

Enter the serial command for device control.

Create/delete the function

name of the command

Create/open a library

Programmable Control Panel

15

2) There are two send types: send once and send more times. When select “more times”,

the send times and the delay between times can be set. See in picture below:

3) The send port must be selected as the same as model setting, otherwise the event

cannot be added.

4) User can set the event name. It is optional function, not necessary.

IR Setting

This item is used for setting the parameters of the programmable control panel’s IR

ports. Click “IR”, it will show as below:

1) The data of IR need to be selected from library. Click “Change Lib”to select a

library file and open it. Click “Edit Lib”to create or edit a library file as below:

Create/delete/rename the

function name of the IR

Create/open a library

Programmable Control Panel

16

Notice: When editing finish, remember to save the editing, and then press “OK”.

2) There are two send types: send once and send more times. When select “more

times”, the send times and the delay between times can be set. See in picture

below:

3) The send port must be selected as the same as model setting, otherwise the

event cannot be added.

4) The IR can set the carrier on/off, to turn on/turn off the IR sending.

I/O Setting

There is no I/O port in the programmable control panel, so the setting is not

introduced in this manual.

Programmable Control Panel

17

Relay Setting

This item is for the replay ports setting. The setting is as the picture below:

Delay setting

This item is to set a delay time, user can add a delay between two events; so when one

event is finished, it will delay a certain time then start another event. The delay setting

is as picture below:

Compare Setting

This item is used for compare the feedback of RS232 commands. When VL120018

send a RS232 command to the controlled device, the device will send back a feedback.

If we add the correct feedback in the data, VL120018 will compare it with the feedback

received from controlled device, to verify the command is work or not. The compare

setting is as the picture below:

Send

Type

Port Action: “On”for

connected, “Off”for

disconnected.

Table of contents