D+H RZN 4503-T User manual

99.823.83 1.1/11/08

© 2008 D+H Mechatronic AG, Ammersbek

Alle Maße in Millimeter. / All sizes in millimetre.

Technische Änderungen vorbehalten. /

Rights to technical modifications reserved.

D+H MechatronicAG • Georg-Sasse-Str. 28-32 • 22949Ammersbek • Tel. 40-605 65 239 • Fax 40-605 65 254 •D- +49 +49 www.dh-partner.com

1/12

smoke ventsmoke vent

Instruction for use

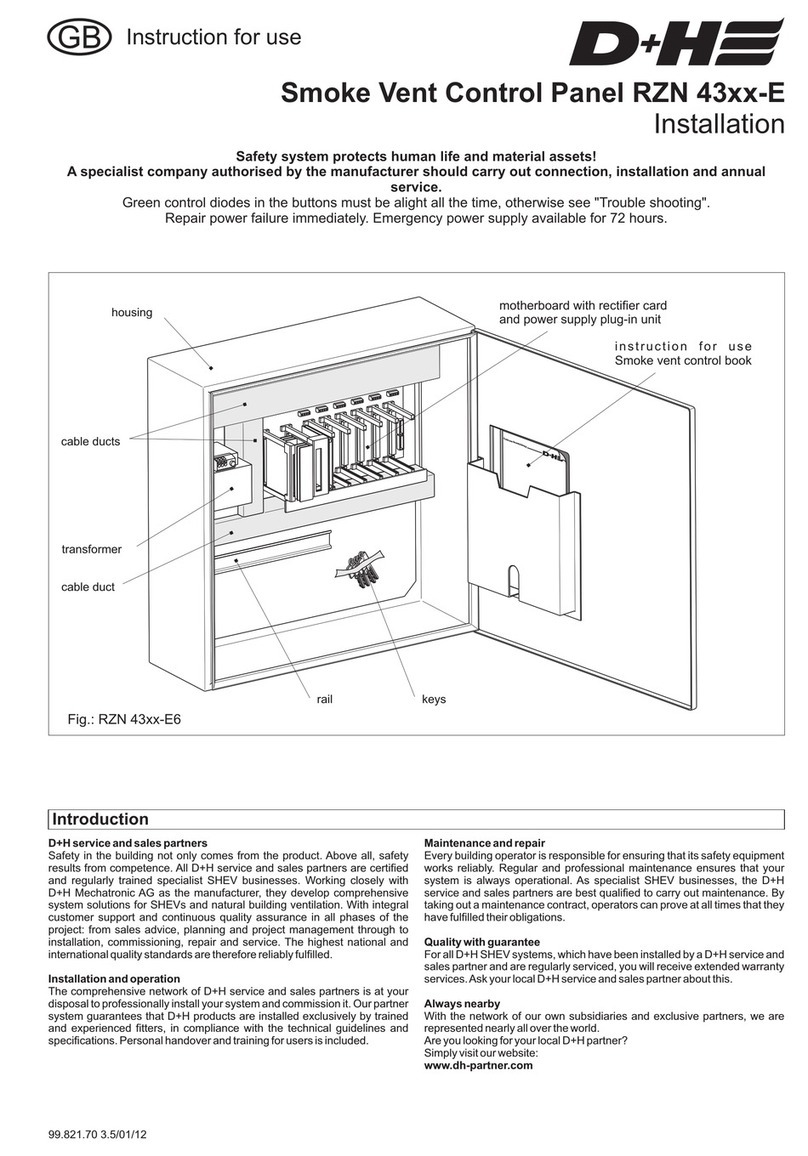

Safety system protects human life and material assets!

Once a year functional testing by a specialist company authorized by the manufacturer.

Connection, mounting and functional testing by a

specialist company authorized by the manufacturer.

Green control diodes in the buttons must constantly be on,

otherwise see "Information for Starting".

Repair power failure at once. Emergency power supply for 72 hours.

Smoke vent button control panel RZN 4503-T

There are guarantee for all D+H products from date of verified handing over of the system

up to maximal 3 years after date of delivery, when mounting and starting has been carried out by a

D+H authorized

D+H guarantee is expired in case of connection of D+H components with external systems or

with mixing of D+H products with parts of other manufacturers.

2 years

distributor.

Guarantee

2/12

99.823.83 Rev.: 1.1

Once a year by a specialist company

authorised by the equipment manufacturer.

Renew test badge. Update logbook.

The respective current D+H maintenance

instructions should be followed.

AD+H authorised company has been specially

trained by D+H for carrying out this

maintenance competently and will be

automatically provided with the latest

maintenance instructions.

Following tests must be carried out during

maintenance:

- External examination and inspection of

system components

- Measuring of insulation resistances

- Checking of all relevant power supply

units.

- Functional testing of connected system

components.

- Logging of competent execution of

maintenance and identification in

accordance with directions.

Information

An overdue maintenance of the system will be

indicated by the control panel after about

14 to 16 months. The yellow diode in the

control panel and in the smoke vent button

RT 43-H will start flashing.

A malfunction in the smoke vent system will be

continually indicated by the extinguished

green control diodes in the smoke vent

buttons.

After the maintenance time is expired (ca. 14 to

16 months), the ventilation function OPEN can

be interrupted depending on the presetting of

the service timer. Reset can be carried out by a

specialist company only who has been

authorized by the appliance manufacturer.

Content

Maintenance

Rated voltage : 230 VAC, 50 Hz

(+10%, -15%)

Rated capacity : 100 VA

Capacity con -

tion standby : < 5 W

Interfering

emission : EN 61000-6-3 (08.02)

Res. to jamming : EN 61000-6-2 (08.02)

Protective

category : I

Fire resistance : -5 to +40 °C

Protective system: IP30

Class of rating

- Monitoring : Continuous duty

- Emergency

state/ ventilation : Short-time duty

Output voltage : 24 VDC / res. ripple <5%

Safe output

- rated current : 3 A (30% power-on time)

Dimensions : 156x83x232 (WxDxH)

D+H Highspeed (HS) drives will be

sump

maximum no. of fire detectors: 14 pcs.

maximum no. of smoke vent buttons: 8 pcs.

Technical Data

1 x pre-assembled control panel

1 x housing

1 x breaking glas

3 x hanger bolt

6 x hexagonal nut M5 DIN 6923-8

1 x mounting tool

1 x sheet "smoke vent" different languages

2 x key

pre-assembled

Scope of delivery

Guarantee

Technical Data, Maintenance, Scope of delivery

..................8

LEDs und functions

..................................................................................................................................1

..........................................................................2

Introduction................................................................................................................................3

Overview operating elements.....................................................................................................4

Operating...............................................................................................................................5-7

Extended functions...................................................................................................

.....................................................................................................................9

Cable und Emergency Supply...................................................................................................10

Starting.....................................................................................................................................11

Examination.............................................................................................................................12

3/12

99.823.83 Rev.: 1.1

Regulations for Hazard Detection Systems VDE 0833, Guidelines for Electrical Systems VdS

2221, VDE 0100, DIN 18232 for Smoke and Heat Ventilation Systems, and the regulations for

mains supply connection from the local fire-authorities and the energy supply company must be

observed.

Important Regulations

Introduction

Smoke and heat ventilation systems (SHEVs) are very important elements of structural

preventive fire protection.

Only regular and professional maintenance guarantees the necessary and permanent

functional safety.

D+H Mechatronic AG

D+H Mechatronic AG

D+H MechatronicAG

D+H Mechatronic AG

D+H MechatronicAG

D+H Mechatronic AG

Smoke and heat ventilation systems are preventive fire protection appliances. They fulfill

important functions in case of fire: safeguarding human life by providing a smoke-free layer which

keeps evacuation routes free for the fire brigade. Consequential damages caused by fire gases

are reduced, and therefore, significant material assets are often protected against destruction.

Precondition for this is that the systems will function absolutely reliably in the case of fire. Only

electrical specialist companies are authorised to install these systems. They have electrical

specialist staff with relevant experiences in installing hazard detection systems or smoke and

heat ventilation systems. Only these can take on the responsibility that the system will function

and can ensure product liability for the whole system (see Product Liability Law BGBL.I S.2198

and BGB (Bodily injury, compensation for damage)).

Therefore, regular maintenance and checking of functional readiness is imperative and must be

ensured. These standard requirements are demanded in accordance with regulations of the DIN,

of the Association of German Insurer against damage of property (VdS) and the respective local

authorities. It is recommended that maintenance work should be carried out by authorised

specialist companies only.

Maintenance and installation of smoke and heat ventilation systems and system components

constructed and distributed by should be carried out by authorised

companies. All partners are qualifyed as authorised companies, which

regularly take part at in-house trainings to ensure their qualification and experience.

Smoke and heat ventilation systems must be reviewed at annual intervals by authorised

companies in accordance with DIN 18232 part 2 paragraph 10.2, and VDE 0833 part 1 paragraph

5.3.4 for hazard detection systems and in accordance with the manufacturer guidelines.

In accordance with DIN VDE 0108 part 1 paragraph 9.1.1, emergency supply accumulator

batteries (lead accumulator batteries) must be checked every six months by a person briefed and

once a year, maintenance must be carried out by an authorised company. Accumulator battery

types which are used for smoke and heat ventilation systems must be VdS

approved and released for use by in Smoke and heat ventilation systems.

In accordance with DIN 18232 part 2 paragraph 10.2 the tests must be logged in an operations

book, which the operator/building owner must present to the building supervision authority on

request. This operations book is available at (part no.: 68.700.13)

Maintenance that has been carried out must be logged in a

maintenance and testing confirmation.

4/12

99.823.83 Rev.: 1.1

OK

M

Po

wer

Po

wer

2

30

VAC

2

30

VAC

B

atte

ry

B

atte

ry

Det

ectorLine

Det

ectorLine

Drive

Drive

Group

Group

Module

Module

Connector

Connector

X2

OFF

Service

X1

Service

X1

0

Reset

/

I

S1

8

1ON

www.dh-partner.com

Service

12 month12 month

www.dh-partner.com

RAUCHABZUG

RAUCHABZUG

RAUCHABZUG

Pictograms

Smoke and heat vent alarm

Control panel O.K.

Fuse actuator

Mains drive

Vent button function "ON"

Vent/ smoke vent function “CLOSE”

Fault

Charging voltage controller

Battery

LED

system O.K.

DIP switch

(factory-set

see p. 9 and 11)

LED mains

LED-alarm

LED group fault

LED-battery

fault LED earthfault

Reset line

LED line fault

LED general fault

LED "not CLOSED"

ventilation button CLOSE

alarm button

alarm reset button

ventilation button OPEN

Overview

smoke ventsmoke vent

www.dh-partner.com

Service

12 month12 month

green control diode

(system O.K.)

yellow (flashing)

(fault)

control diode

red

(alarm)

control diode

Reset button

(masked)

alarm button

ventilation button OPEN

with LED "not CLOSED"

ventilation button CLOSE

5/12

99.823.83 Rev.: 1.1

OK

Po

wer

2

30

VAC

B

atte

ry

Det

ectorLine

Drive

Group

Module

Connector

X2

OFF

Service

X1

0

Reset

/

I

S1

8

1ON

www.dh-partner.com

Service

12 month

www.dh-partner.com

1. 2. 3.

4.

RZN/RT

RAUCHABZUG

RAUCHABZUG

3.

1. 2.

RAUCHABZUG

RAUCHABZUG

RZN/RT

4.

click

1. 2.

4.

RAUCHABZUG

RAUCHABZUG

3. RZN/RT

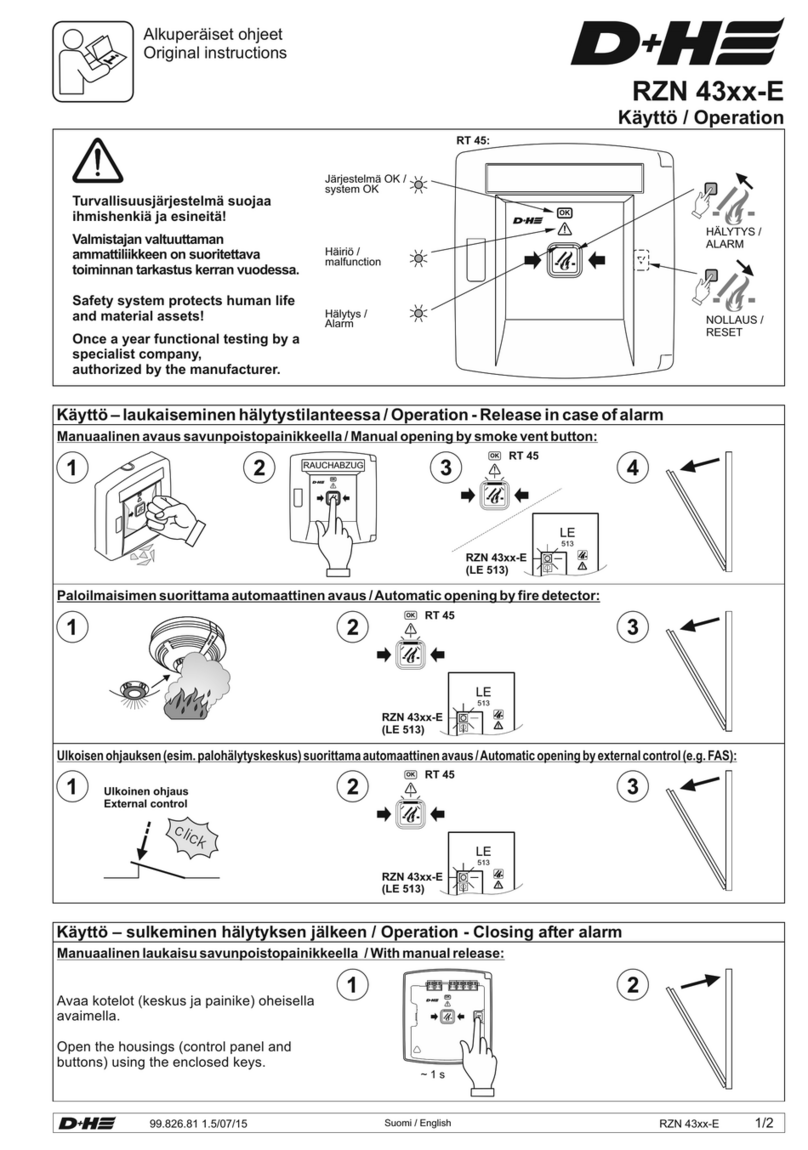

RZN 4503-T Operation

Release in case of alarm

Manual opening by smoke vent button:

Automatic opening by fire detector:

or

and

Automatic opening by external control (e. g. fire alarm control panel (FACP)):

and

smoke vent

www.dh-partner.com

Service

12 month

6/12

99.823.83 Rev.: 1.1

2.

1.

3.

3.

*

RAUCHABZUG

www.dh-partner.com

Service

12 month

RAUCHABZUG

www.dh-partner.com

Service

12 month

RAUCHABZUG

www.dh-partner.com

Service

12 month

Closing after alarm

RZN 4503-T perationO (continuation)

With manual release:

Opening the housing (RZN / RT) with supplied key.

Automatic opening by external control:

see

DIP-switch S1

(page 8)

hold for OFF /

shortly tap for ON

3s

or

or

* function is deactivatable by

D+H PDA service tool

In case of automatic release by external control (e. g. FACP):

or

7/12

99.823.83 Rev.: 1.1

RAUCHABZUG

www.dh-partner.com

Service

12 month12 month

RAUCHABZUG

www.dh-partner.com

Service

12 month12 month

RAUCHABZUG

www.dh-partner.com

Service

12 month12 month

In case of power failure:

Emergency closing

In case of non-resettable alarm:

hold for OFF3s

see

DIP-switch S1

(page 8)

or

Day-to-day ventilation

or

or

or

RZN 4503-T perationO (continuation)

customer

service

8/12

99.823.83 Rev.: 1.1

Extended Functions

The following functions are set by the DIP switch S1 on the PCB at the control panel, or can be set by a

D+H distributor with the D+H PDA service tool:

S1.1 ON =

CLOSE

S1.2 ON =

OPEN

S1.2 OFF= OPEN

Storage operation

S1.1 OFF= Key operation

CLOSE

Storage operation

Key operation

S1.3 ON = activated

S1.3 OFF = deactivated

S1.4 ON = activated

S1.4 OFF = deactivated

S1.5 ON = activated

S1.5 OFF = deactivated

S1.6 ON = activated

S1.6 OFF = deactivated

S1.7 ON = activated

S1.7 OFF = deactivated

S1.8 ON

S1.8 OFF

Programmable by

D+H Distributor with

D+H PDAservicetool

Storage operation

Key operation

Line fault = alarm

Group fault on alarm

OPEN-running time limitation in ventilation operation

Ventilation time limitation

Power failure CLOSED

vent buttons activitated

vent buttons deactivitated

deactivated

deactivated

deactivated

activated

activated

Press ventilating button 1 x shortly. The drives/ NSHEVs will open to

their final position.

The drives/NSHEVs will open only as long as the ventilating button is

pressed.

In case of a line fault the control panel will be switched to alarm and the

smoke vent opens (e.g. at an interrupted button line or missing

terminal resistor).

In case of a group fault the control panel will be switched to alarm and

the smoke vent opens (e.g. in case of an interrupted drive line or

missing terminal module).

If the vent button is actuated in direction OPEN, the drives/ NSHEVs

open for 30 s (factory-set). This running time can be edited by D+H

PDA servicetool. Only possible in conjunction with storage operation

in CLOSE-direction.

The drives/ NSHEVs will automatically close again after the time set

(factory-set 10 min). This time can be edited by the D+H PDA

servicetool. Only possible in conjunction with storage operation in

CLOSE direction!

In case of power failure the drives will close. Only possible in

conjunction with storage operation in CLOSE direction!

Integrated are

Integrated are

OPEN running time retriggering (factory-set: )

Group CLOSE in case of alarm (factory-set: )

Two smoke detectors dependency (factory-set: )

Smoke detector alarm remote reset (factory-set: )

Lamp test

Alarm re-clocking (factory-set: )

Hint: In case of alarm the smoke vent is triggered with an OPEN pulse

every 2 minutes for a duration of 30 minutes according to VdS 2581.

For this, the drive must be protected against blockage according to

VdS 2580 par. 4.7. .All D+H drives meet this precondition.

9/12

99.823.83 Rev.: 1.1

12345678

ON

LEDs und Functions

on off

flashing off

off on

LED line fault LED OK LED general fault

Line fault

Deactivated line

Servicetimer is up

flashing

flashing

flashing

LED Indication

Line switch-off

hold3stoswitch off

line /

tip on to switch on

If the LED line fault flashes, the line is

switched off, e.g. for service reasons. You

cannot activate the control panel in this

status. In case of an actual line error the

LED line fault is permanently on.

DIP switch

factory-set

Programmable by

D+H Distributor with

D+H PDAservicetool

Functions

not changeable

The signalling relay features the following signals:

(factory-set: signalling relais 1="alarm"

signalling relais 2 = "general fault")

Accumulator

Group output

If wind or rain detector is connected.

Do not ventilate via smoke vent button because otherwise there is danger

of damage by wind or water.

optional vent button

LT 43U-W Gap ventilation

is not possible if no vent button LT 43U-W is

available LT 43U-W

pre-alarm, terminated alarm, delayed alarm

general fault, accumulator fault, line fault, group fault, power failure

earth fault, passing on of "central CLOSE", "ResetAlarm" as pulse,

group closed longer = x s

Charge (temperature-guided)

Monitoring: presence, final discharging voltage

Discharge control: In case of power failure and total discharge of accumulator,

the control panel will switch off. In this case, smoke vent is no longer possible.

In this case the LED System O.K. and the LED general fault are not on.

Three minutes after the motor group has been operated in OPEN or CLOSE

direction, the potential between Mot.a and Mot.b is switched to zero potential.

If the respective sensor releases, the group of the control panel will close. Wind

velocities can be adjusted to 4-6 Bft.

If the alarm is released by a smoke and heat vent system, the system will open

regardless of wind and rain.

The weather automatic can be switched-off with an

, if gap ventilation is required in case of bad weather.

in case of bad weather,

. If the weather automatic is switched on via vent button , the

system will automatically close in case of wind or rain. The system will not

automatically open again, if wind or rain has stopped. Opening of the system for

ventilation via vent button.

For further information see information for use VRS 10 REM 42 and WRG 82.

10/12

99.823.83 Rev.: 1.1

Install and feed separately from supply mains.

Mark cable and terminal box red.

Provide for separate electric circuit.

Mark fuses.

Plug covering cap over mains binder on

motherboard of control panel.

Connecting cable: NYM-I3x1.5

Connecting load: 100 VA

Emergency power supply for 72 hours. Use VdS and D+H approved storage batteries only.

1 x min. 12 V / 3.2 Ah (Type 8)

If alarm devices are connected:

Total current of 3 A must not be exceeded. If necessary, reduce drive current. Emergeny

power supply time of 72 hours can be shorter in case of fire alarm. Total standby current must

not exceed 0.25 A.

Weak Current Lines

24 V - Emergency Supply

230 VAC - Supply

The smoke vent control panel is designed for

opening smoke vent devices which operate by

thermal ascending force and by automatic fire

recognition devices (thermal detector, smoke

detector). They release either self-acting or

manual by smoke detectors at an early stage of

a fire, and remain in opened position without

further power consumption. In these cases,

functioning preservation of the electrical line

system is required only at an early stage of fire.

Protected wiring is required with protection

against mechanical damages according to DIN

18232 section 2.5.5 paragraph 4.

Cable from the smoke vent control panel to

connection of drive. Drive lines have a

monitoring wire in which fire recognition

devices (thermal maximal detector e.g. THE)

can be looped-in:

- Safety line with functional conservation

xxx E30*, according to DIN 4102 or standard

guidelines for line systems MLAR.

Control Cable (Group):

Cable for D+H Smoke and Heat Vent Systems

Detector Cables (Line):

Cables through areas not monitored:

The detector cables are monitored for short

circuit and for break.

The opening device is automatically triggered

and opens up in case of fault when DIP

switch 7 is ON.

Smoke vent button cable and cable of

automatic detectors:

- weak current sheathed flexible cable YR

6 x 0.8

or

- house wiring cable IY(ST)Y 4 x 2 x 0.6

An increased time of functioning of the cable

can be required when drive lines are installed

through building parts which are not

monitored.

- Safety line with functional conservation

xxx E90*, according to DIN 4102 or standard

guidelines for line systems MLAR.

(see supplementary sheet 1 to DIN VDE

0108)

* Notice: No type designation is given

for these cables because of a large

variety on the market. Please consult

your D+H distributor about these

11/12

99.823.83 Rev.: 1.1

Information for Starting

Carry out the following sight and performance checks to switch on the smoke and heat vent

control panel.

yes

no

yes

no

yes

yes

yes

yes

yes

yes

no

no

no

no

no

no

All cables

connected?

All necessary moving loads connected?

Smoke vent components are line-monitored.

Factory-set?

(DIP switch)

10 k resistor in

smoke vent button?

Ω

10 k resistor in

fire detector?

Ω

Terminal module

2 x 47 kΩ in branch box?

Connect mains.

Mains control on?

Connect accumulator

lines. Control on?

Performance check alarm/reset and ventilation.

Smoke vent flap

opens and closes?

Partial or incomplete connection of components can

cause malfunction.

Check the following connections: mains 230 V, drives,

smoke vent buttons, if necessary fire detectors and

vent buttons. See wiring and connection plans

Mounting and Installation.

Set DIP switch S1 on

motherboard as follows:

Resistor must be cramped in electric last button on

binding posts 3/ 8 (RT 43-H) or binding posts 3/ 7

(RT 42). See Mounting and Installation.

Resistance must be cramped in last or only fire detector

on binding post 2 and 4 (type FO/FT). Resistance remains

in control panel between binding post RM 1 and 2, when

no fire detector available.

See connection M .ounting and Installation

Cramp terminal module on last or only drive in branch box

on wire 5 yellow orange, 6 black, 7 black.

See M .ounting and Installation

Check line safety fuse in distribution box and fuse mains in

control panel.

Mains still not available or line switch

on "0", see line switch-off page 9, or one of fuses faulty.

Try changing poles in drive.

factory-set:

12345678

ON

12/12

99.823.83 1.1/11/08

Examination

Preparation:

Information

Inspection:

Smoke vent button:

Notify user that the system is out of operation

before starting with inspection.

Notify user about false alarms.

Interrupt or switch off monitored alarm

indication and remote controls.

An overdue maintenance of the system will be

indicated by the control panel after about 16

months. The yellow control diode in the control

panel as well as in the smoke vent button

RT43-H will start flashing.

A malfunction in the smoke vent system will be

continually indicated by the extinguished

green control diodes in the smoke vent

buttons.

After the maintenance time is expired (ca. 14 to

16 months), the ventilation function OPEN can

be interrupted depending on the presetting of

the service timer. Reset can be carried out by a

specialist company only who has been

authorized by the appliance manufacturer.

Check all appliances and cable connections

for outer damage and dirt accumulation.

Fire detectors, smoke vent buttons, smoke

vents and so on must not be impaired in their

function by goods in storage or structural

changings.

Open smoke vent button .

Press red button, red display diode is on in

button and control panel.

Smoke vent must open.

Press masked button (1 s), red display

diode extinguishes in button and control

panel.

Smoke vent must close.

Automatic fire detectors:

Release smoke detector individual by D+H

smoke detector tester, as an alternative by

cigarette smoke (response delay circa 20 s).

Red display diode must be on.

Smoke vent must open.

For closing wait until there is no more smoke in

detector.

Reset line in control panel (switch off/ switch on

line), red display diode

extinguishes in button and control panel.

Press masked button in control panel or in

smoke vent button. Smoke vent must close.

The line can also be directly reset via smoke

vent button, if remote reset is activated. For

this, press masked button in smoke vent

button (for 1 s).

Red display diode extinguishes in button

and in control panel.

In case of severe dirt accumulation visible from

outside, send detector

in for maintenance.

Release external control.

Smoke vent must open.

Open contact in external system for closing, for

example by resetting of fire detector system.

If smoke and heat exhaust do not automatically

close, press masked button in smoke vent

button (1 s). Red display diode

extinguishes in button and control panel.

Smoke vent must close.

Detach fuse MAINS in power distributor.

Green mains indication diode on control

panel must not be on.

Repeat functional testing.

Green control diode in smoke vent buttons

must not be on.

If "power failure-CLOSE" is activated with PDA

servicetool, the group will automatically.

Reconnect fuse MAINS in power distributor

install another one and

close

.

External control (optional):

Emergency supply:

Every six months and after repair by a specialist or staff, who has been introduced to

the task.

Eliminate failings at once. Keep control book.

RZN 4503-T

Montage und Installation

Mounting and Installation

99.823.87

1.1/11/08

D+HMechatronicAG • Georg-Sasse-Str.28-32 • 22949Ammersbek • Tel. 40-60565239 • Fax 40-60565254 •D- +49 +49 www.dh-partner.com 1/2

© 2007 D+H Mechatronic AG,Ammersbek

Alle Maße in Millimeter. / All sizes in millimetre. Technische Änderungen vorbehalten. /

Rights to technical modifications reserved.

RAUCHABZUG

3.

Akku anschliessen / connect accumulator

1.

2.

Montage / Mounting

2

345

Leitungsverlegeplan (Muster) / Wiring plan (example)

Leitungslängen und Querschnitte / Line lengths and cross sections

Die angegebenenAderzahlen und Querschnitte beziehen sich nur auf die benötigten Leitungen.

Bei Verwendung einer Leitung mit Schutzleiter (grün/gelb) wird dieser nicht mitgezählt und darf

nichtbeschaltetwerden./

Number of wires and cross-sections indicated refer to required lines only. In case of using a line

with earthed conductor (green/ yellow), this one will not be counted in and must not be wired.

Gesamtstrom /

total current 0,511,522,53A

3x1,5 mm² 240 120 80 60 48 40 m

3x2,5 mm² 400 200 130 100 80 65 m

*5x2,5mm² 800 400 260 200 160 130 m

1x mind. /

12V / 3,2 Ah (Typ / 8)

1x at least

type

230V 50Hz

nicht abschaltbar /

not possible to

switch off

Brandmelder 24VDC

(z.B. FO 1362 oder FT 1262) /

Fire detector 24VDC

(e.g. FO 1362 or FT 1262)

Lüftungstaster 24VDC

(z.B. LT 43) ca. 1,2 m über OKFF

(bei UP bauseits 55mm UP - Dose) /

Vent button 24VDC

(e.g. LT 43) circa 1,2 m above upper

edge firm flooring (at flush type

at side 55mm flush socket)

JY (St) Y

2x2x0,6

zu weiteren /

to further ones

JY (St) Y

2x2x0,6

siehe Kabelverlegetabelle /

Hauptbedienstelle

Rauchabzugstaster /

Main control

smoke vent button

(RT43-H/N)

Nebenbedienstelle

Rauchabzugstaster /

Secondary control

smoke vent button

(RT43-H/N)

Kontakt Fremdansteuerung

z.B. Brandmeldezentrale /

Contact external control

e.g. fire alarm system

JY (St) Y

4x2x0,6

JY (St) Y

4x2x0,6

JY (St) Y

2x2x0,6

Zentrale RZN Aufputz

(230VAC / 24VDC)

in der Nähe der RWA-Klappe. /

Control panel RZN surface type

(230VAC/ 24VDC) in proximity of

smoke vent flap.

Antrieb(e) 24VDC

an Rauchabzugsklappe(n)

(Leitung in einer UP-Verteilerdose

enden lassen). /

Drive(s) 24VDC

at smoke vent flap(s)

(Lines must end in flush mounted

distribution box.)

1234567

Platinenansicht / Motherboard view

Sicherung ANTRIEBE /

F 2.5 A

fuse DRIVES

Schutzkappe* /

covering cap*

Netzanschluss /

power supply

1234567

Wind- Regenmelder 24VDC

(z.B. WRG 82) /

Wind- rain transmitter 24VDC

(e.g. WRG 82)

JY (St) Y

2x2x0,6

1

3x

1.

2.

Vorher:

Stockschrauben in

Kreuz eindrehen! /

Before:

screw hanger bolt

into tool!

1,36m

ab OKFF /

from top of floor

* ufsetzen/Schutzkappe a

*put on covering cap

3x

Hinweis: Schriftzug bitte aus beiliegendem

Sprachenbogen heraustrennen und einsetzen. /

Hint: Please detach name plate from enclosed

language sheet .and put in

Kabelausbruch /

cable breakout

Linie /

line

Netz /

mains Gruppe /

group

110

183

203

6

Querschnitt /

(mm²)

cross section einfache Kabellänge / (m) x Gesamtstrom /

80

plain cable length total current

=

*2 Adern je Antriebsleitung parallel schalten. /

*Connect in parallel 2 wires for each drive line

zu weiteren /

to further ones

see cable wiring table *

*

Melderelais 1 /

signalling relay 1 Melderelais 2 /

signalling relay 2

-

+

A

K

S

M

Z

B

: notversorgtesPotential-

: notversorgtesPotential+

nichtnotversorgtesPotential+

: Sammelalarm

: Kontrolle

: Sammelstörung

: AnsteuerungHaftmagnete

: Eingang,ZentralfunktionSchließenderGruppe

: BMZ-Eingang

N-

N+

: nichtnotversorgtesPotential-

:

Klemmenbelegung E-Platz / Clamp assignment E-Slot

-

+

N+

A

K

S

M

Z

B

: emergency-supplied electric potential -

: emergency-supplied electric potential +

: electric potential +, without emergency supply

:

: ontrol

: general malfunction

: magnetic clamp

: input, central function, closing of group

: BMZ input

N- : electric potential -, without emergency supply

generalalarm

c

control

99.823.87

1.1/11/08

D+HMechatronicAG • Georg-Sasse-Str.28-32 • 22949Ammersbek • Tel. 40-60565239 • Fax 40-60565254 •D- +49 +49 www.dh-partner.com

2/2

© 2007 D+H Mechatronic AG,Ammersbek

Alle Maße in Millimeter. / All sizes in millimetre. Technische Änderungen vorbehalten. /

Rights to technical modifications reserved.

Anschluss Rauchabzugstaster

Standardanschluss RT 4x-H / -N

Fremd-

ansteuerung /

external excitation Brandmelder /

fire detector

Arbeitskontakt /

operating contact

Alarmwiderstand /

alarm resistor

10k *W

10kW

1kW

out

in

letzter /

last

Rauchabzugstaster /

smoke vent button

RT 43-N (RT 42)

+Alarm / alarm

273164

OK

V

V

wahlweise /

optional

out

in

erster bis

vorletzter /

first to

second

before last

Linie / line

–

–

1210 < wahl-

weise / >optional

ERMRT

345678

-

Kontrolle / control

Alarm / alarm

zu/close

RT 43-H (RT 42-H)

RT 43-N

(RT 42)

10kW

Alarm / alarm

-

Störung / malfunction

27

83164

Alarm /

alarm

zu/close

RD

GN

YE

23164

75

10k *W

Sammelstörung / *general malfunction

* nur bei /

RT 4x-H only at

jeweils erster

bis vorletzter

RWA-Taster /

first to

second before

last smoke vent

button each

jeweils

letzter

RWA-Taster /

every last smoke

vent button

RZN 4503-T

BMZ- / - ResetFACP

12

RM

RT 43-N (RT 42) RT 43-N (RT 42)

-

-

227733116644

12345678

RZN 4503-T

–

–

Alarm / alarm

Sammel-

störung /

*

general

malfunction

RM/RT

RT 43-H (RT 42-H) RT 43-H (RT 42-H)

RT 43-N

(RT 42)

RT 43-N

(RT 42)

10kW

10kW

Alarm / alarm

Alarm / alarm

-

-

Störung / malfunction

22

77

8833116644

Alarm /

alarm

2233116644

77

55

bauseitige

Rangier-

verbindung /

Shunt

connection

by customer

Parallelanschluss RT 4x-H / -N

Anschluss Antriebe und Lüftungstaster / Connection of drives and vent buttons

MOT

Zentrale /

control panel

Mot. b

765

Mot. a

Überw /.

M

M

br

bl

br

bl

Abzweigdose

am Motor /

branch box

on motor

weitere Abzweige

gleichartig schalten /

connect further

branchings alike

Abzweigdose /

branch box

- Versorgungsadern

zweigenparallelab/

- wirddurchalleKabelbis

zumGruppenendedurchgeschleift./

Mot. a und Mot. b

Überwachung

- Supply wires and branch

off parallel

- is looped through

all the cables up to the group end.

Mot. a Mot. b

Monitoring

Anschluss bei Leitungsabzweig / Connection with line branch

Anschluss Brandmelder / Connection of fire detectors

Anschluss eines Brandmelders / Connection of one fire detector

Anschluss mehrerer Brandmelder / Connection of several fire detectors

Anschluss Haftmagneten / Connection of magnetic clamps

* Bei Verwendung von Linienschaltungen mit 2-Melder-Abhängigkeit, darf der Widerstand

nicht eingesetzt werden. /

* The resistor must not be used when line connections with 2-detector dependency

are employed!

-+

-+

- + N- N+ A K S

Unterbrechertaster /

Interrupter button

Haftmagnet /

Magnetic clamp

Haftmagnete / 24V

(max. 200mA* Gesamtstrom /

)

Magnetic clamps

overall power

Ausgang bei

Netzausfall

spannungsfrei! /

Low tension side

in neutral position in

case of power failure!

MZB

*Der maximale

Gesamtstrom darf nicht überschritten werden.

*overall power must not be exceeded

Linie /

line

-

einziger Brandmelder /

180R

1

2

3

4

5

6.

7

*

Endwiderstand /

terminal resistor

10K

single fire detector

Linie /

line

-

erster Brandmelder /

first fire detector zweiter bis vorletzter

Brandmelder / letzter Brandmelder /

last fire detector

180R

1

2

3

4

5

6.

7

*180R

1

2

3

4

5

6.

7

*180R

1

2

3

4

5

6.

7

*

Endwiderstand /

terminal resistor

10K

second to second before

last fire detector

Linie / line

Linie / line

jeweils

letzter

RWA-Taster /

every last smoke

vent button

Rauchabzugstaster /

smoke vent button

Kontrolle / control

zu/close

Linie / line

Linie / line

+Kontrolle / +control

zu/close

Linie / line

Linie / line

* nur bei /

RT 4x-H only at

+Alarm / alarm

+Kontrolle / +control

zu/close

Linie / line

Linie / line

+Alarm / alarm

+Kontrolle / +control

zu/close

Linie / line

Linie / line

Rauchabzugstaster 1. Strang /

smoke vent button 1st Lane Rauchabzugstaster 1. Strang /

smoke vent button 1st Lane

Rauchabzugstaster 1. Strang /

smoke vent button 1st Lane Rauchabzugstaster 1. Strang /

smoke vent button 1st Lane

Kontrolle / control

zu/close

Linie / line

Linie / line

Kontrolle / control

zu/close

Linie / line

Linie / line

RD

GN

RD

GN

zu/close

zu/close

RD

GN

YE

zu/close

RD

GN

YE

zu/close

Störung / malfunction

Kontrolle / control

zu/close

Linie / line

Linie / line

RZN 4503-T

Lüftungstaster /

vent button Antriebe /

drives

LT 43 (-SD)

Querschnitte und Leitungsarten

siehe unten /

cross sections and type of lines,

see below

zu/close

–N

Aufmeldung / OPEN signal

auf / open

erster bis vorletzter /

first to penultimate drive

LT 43

Aufmeldung (wahlweise) /

OPEN signal (optional)

–N

Überwachung /

monitoring

Mot.a

Mot.b

5671234

LT MOT

L

L

P

P

braun /

brown

blau / blue

Branderkennungselement /

thermal detector

THE 4

BK

BK

OR

2x47kW

EM 47K

letzter Antrieb /

last drive

bauseitige Abzweigdose /

branch box by customer

Antriebe mit

HS Funktion /

drives with

HS function

braun / brown

weiss / white

orange (-HS)

zu/close

auf / open

bauseitige Abzweigdose /

branch box by customer

Abzweigdose /

branch box

moni-

toring

Abzweigdose

am Motor /

branch box

on motor

jeweils

letzter

RWA-Taster /

every last smoke

vent button

jeweils

letzter

RWA-Taster /

every last smoke

vent button

V

V

wahlweise /

optional

jeweils erster

bis vorletzter

RWA-Taster /

first to

second before

last smoke vent

button each

Alarm /

alarm Alarm /

alarm

Alarm /

alarm

Other manuals for RZN 4503-T

2

Table of contents

Other D+H Control Panel manuals